Driving device of electromagnetic relay

A technology for electromagnetic relays and driving devices, applied in electromagnetic relays, detailed information of electromagnetic relays, relays, etc., can solve the problems of large size, large magnetic interference, and short stroke traction of ordinary electromagnetic relays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

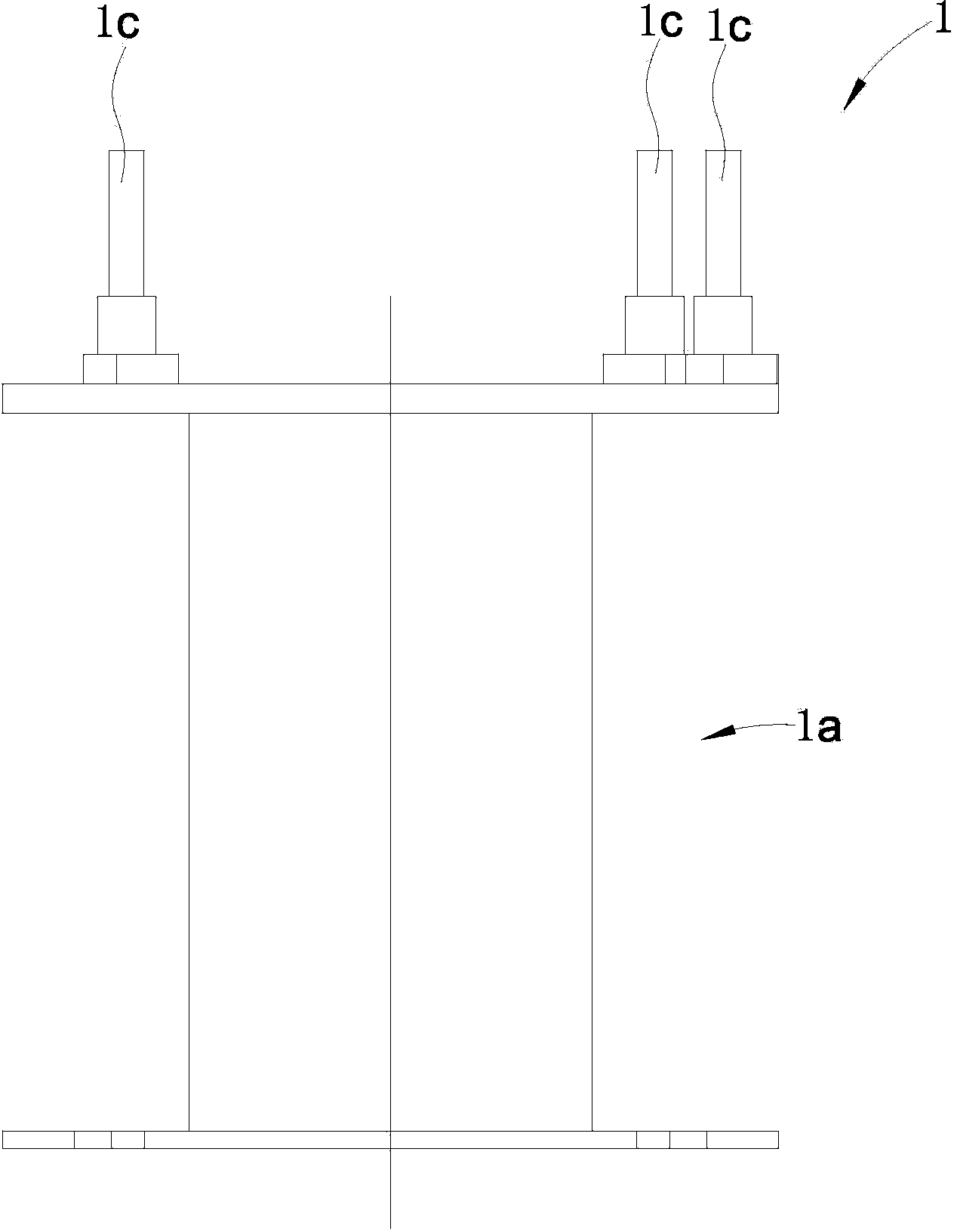

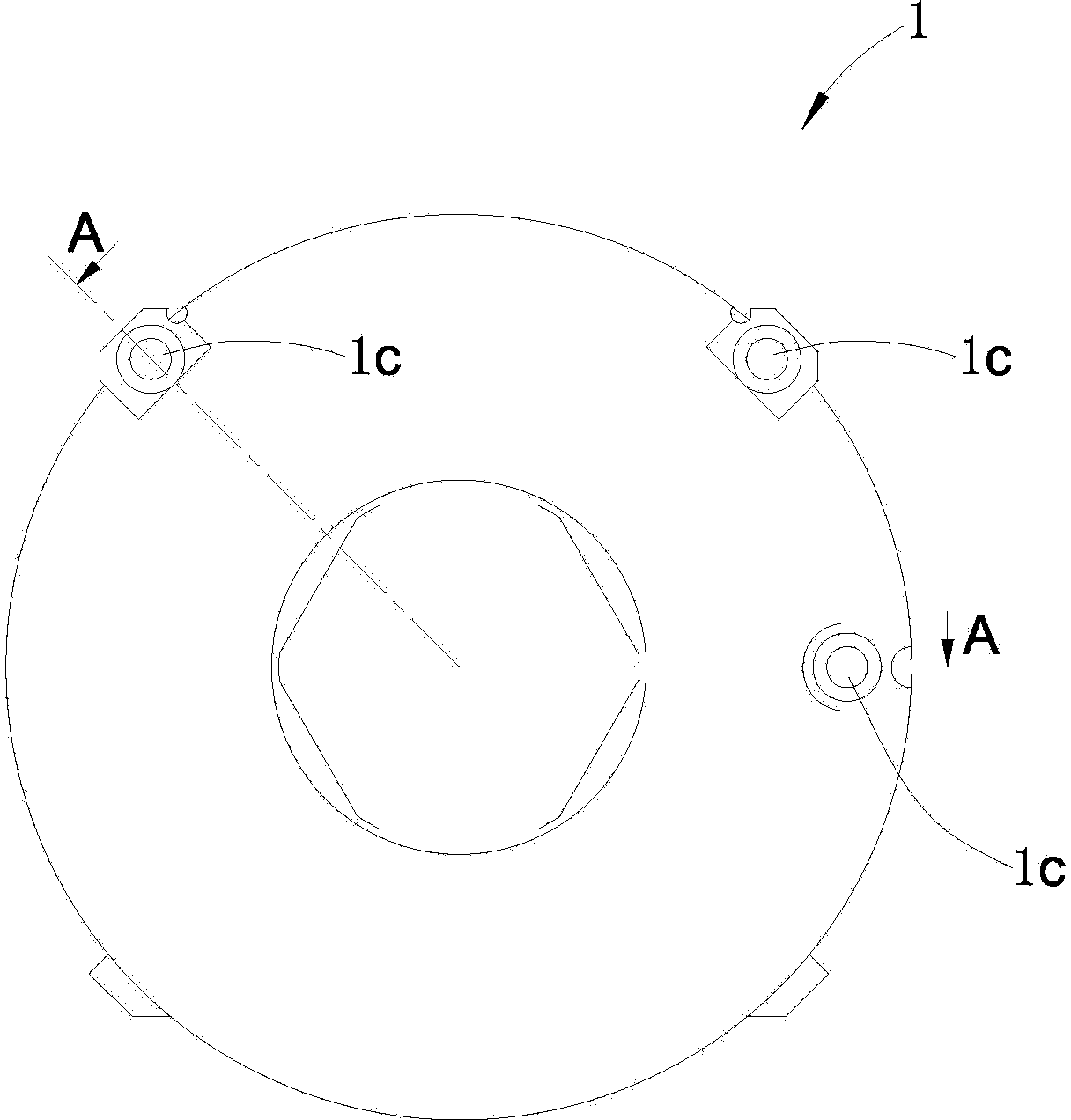

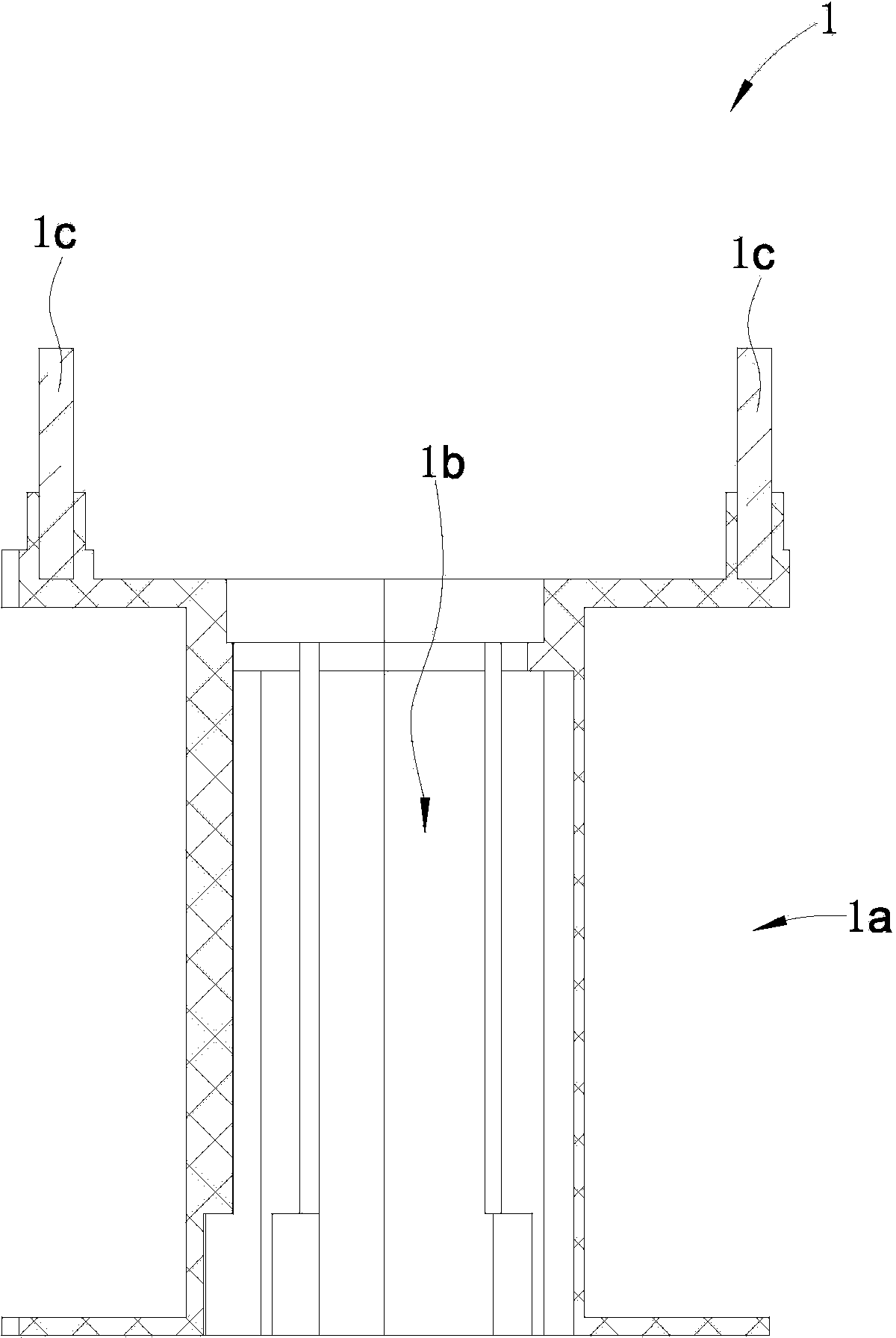

[0020] like Figures 1 to 4 shown

[0021] The bobbin 1 is in the shape of a hollow shaft. There is a coil groove 1a on the outer wall of the bobbin 1. The direction of the coil groove 1a is consistent with the axial direction of the bobbin 1. There are six permanent magnet grooves 1b on the inner wall of the bobbin 1. , six permanent magnet grooves 1b are uniformly distributed on the inner wall of the coil bobbin 1, and three terminal posts 1c are welded on the upper end of the coil bobbin 1.

[0022] like Figures 5 to 6 shown

[0023] There is a coil 2 in the coil groove 1a on the outer wall of the coil bobbin 1. The coil 2 includes two strands of enameled wire wound to form a first winding and a second winding respectively. One end of the first winding and the second winding are connected in parallel to form a common terminal, so that the entire The coil 2 has two windings and three terminals, and the three terminals of the coil 2 are respectively fixed on the three ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com