Molding die for ceramic fiber filtering pipe

A technology of ceramic fiber and forming mold, which is used in ceramic forming machine, mold, dispersed particle filtration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

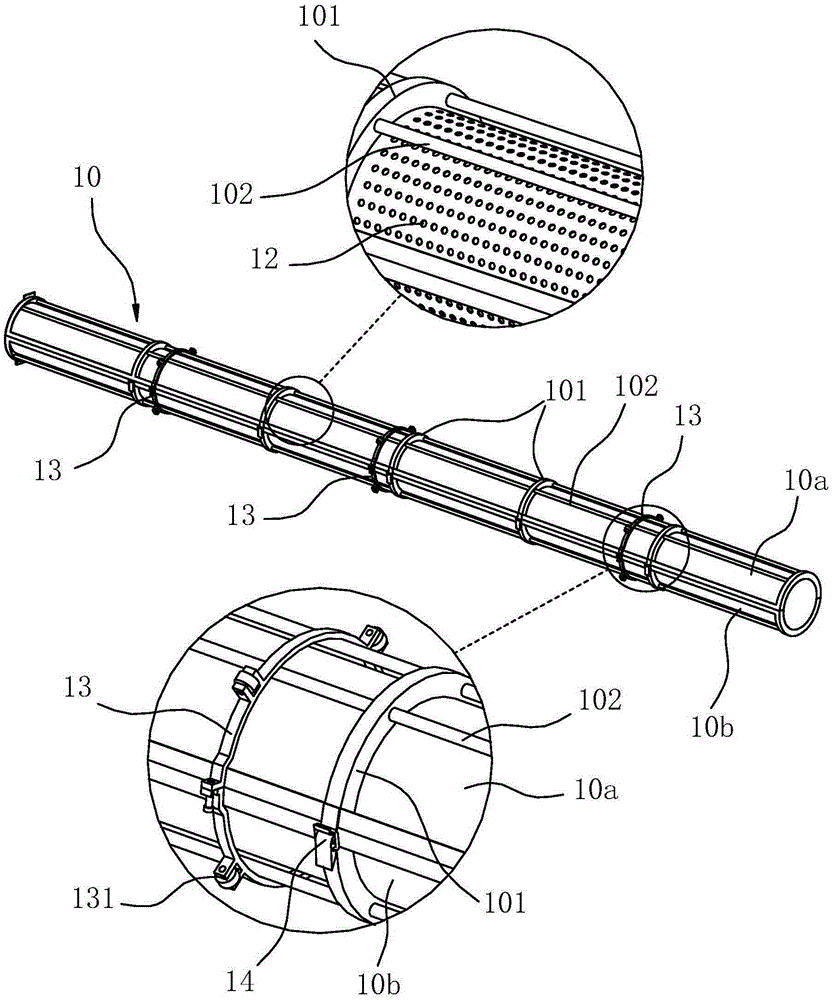

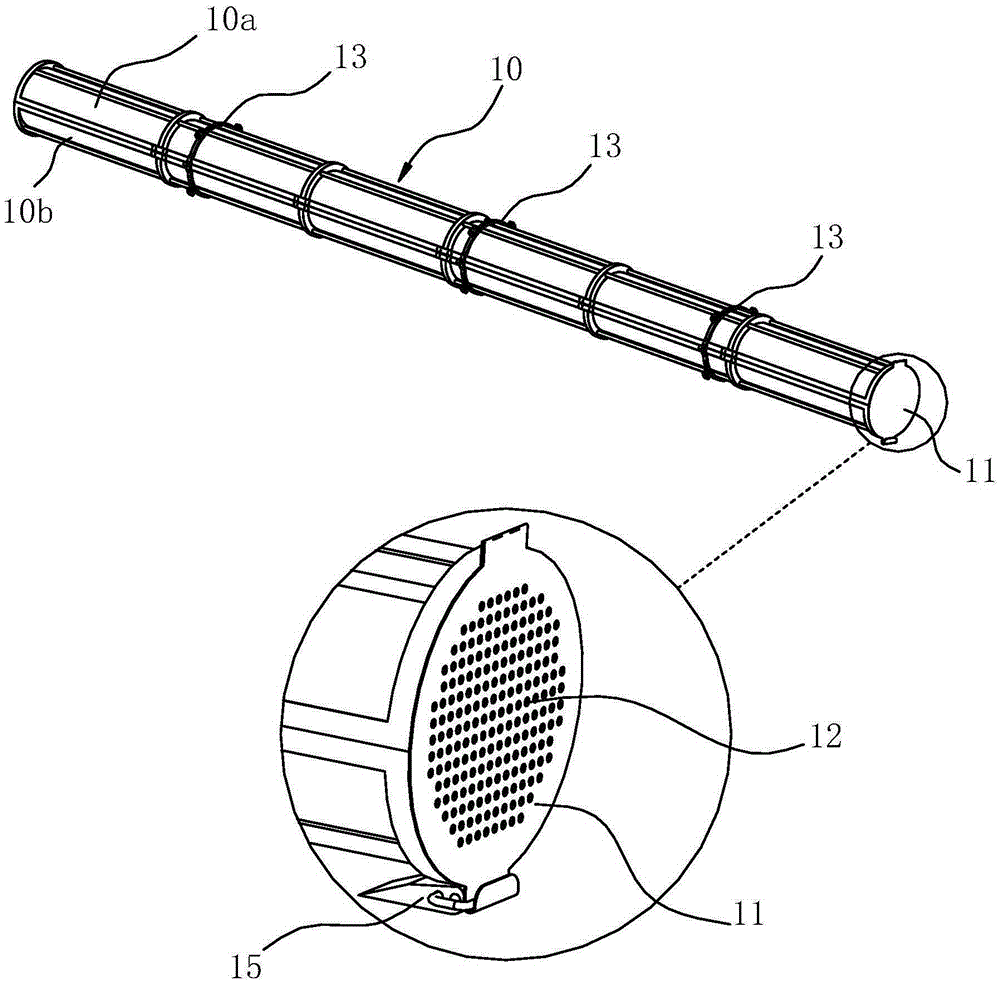

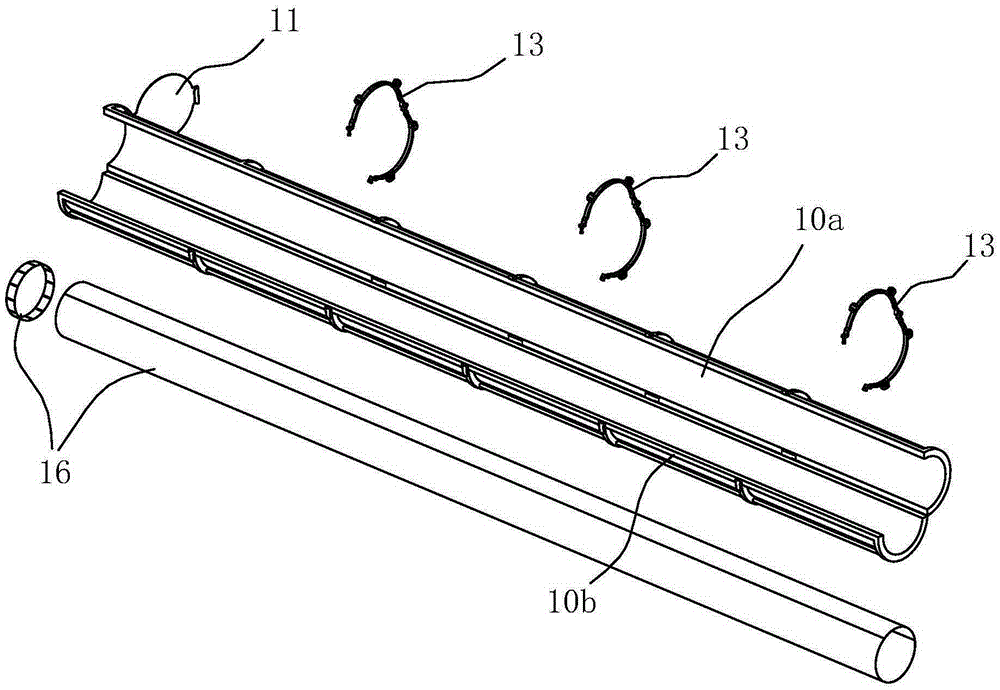

[0009] Such as figure 1 , 2 , 3, a molding die for a ceramic fiber filter tube, including a tubular body 10 formed by fastening two half-pipes 10a, 10b, one end of the tubular body 10 is provided with an end cap 11; The two half-pipes 10a, 10b and the end cap 11 are detachably locked locking units; the two half-pipes 10a, 10b and the end cap 11 are evenly distributed with suction filter holes 12, and the tubular body 10 and the end cap The inner wall of 11 is laid with filter cloth 16. When the mold is filled with slurry containing ceramic fibers and placed in a negative pressure environment, uniform suction is generated on the tubular body 10 and end cap 11, the slurry in the mold is sucked out, and the ceramic fibers in the slurry will adhere to the mold On the laid filter cloth 16, the slurry containing ceramic fibers of different specifications is poured into the mold several times for suction filtration to form a pipe wall with gradually changing pores.

[0010] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com