Chip suction device and chip suction method thereof

A suction device and chip technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as particle residue, achieve uniform suction, reduce production costs, and reduce complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the prior art, it is usually necessary to grasp the packaged chip, but particles are often easily retained on the surface of the chip, resulting in damage to the chip.

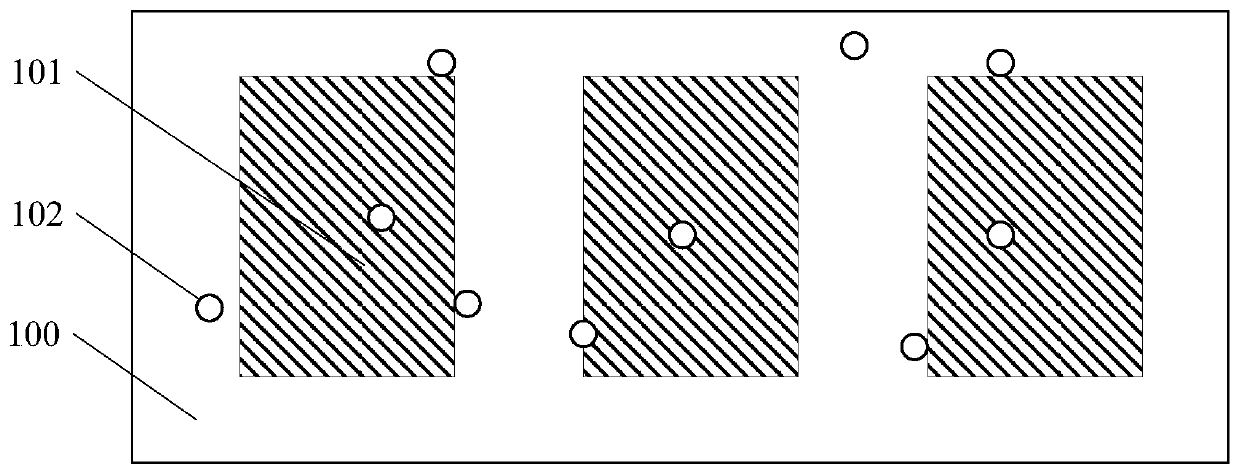

[0027] refer to figure 1 , figure 1 It is a top view of a chip to be sucked in the prior art.

[0028] Specifically, the diced individual chips 101 are usually placed on the surface of the blue film 100 , and particles 102 are formed due to the dicing process.

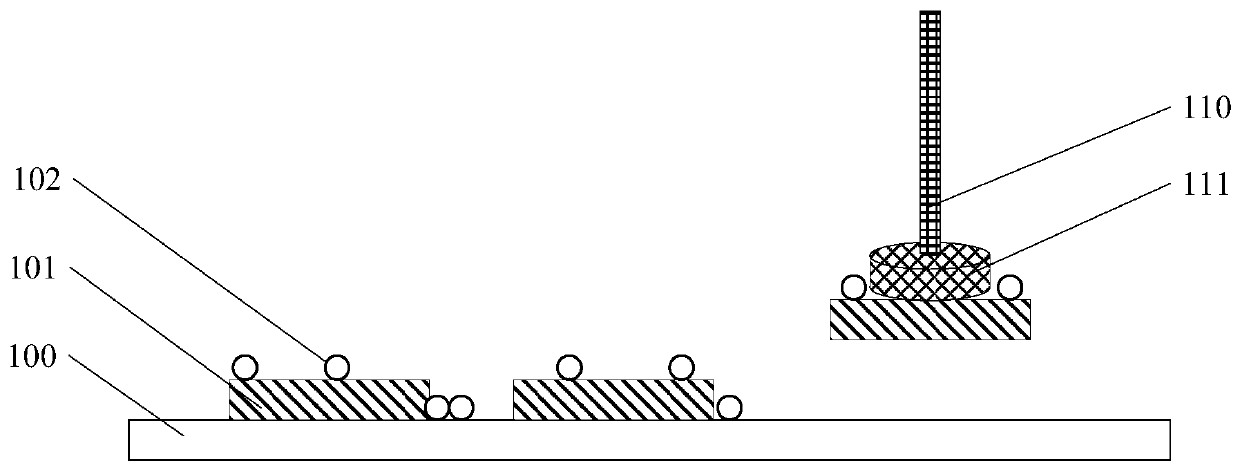

[0029] refer to figure 2 , figure 2 It is a schematic diagram of a working scene of a chip picking device in the prior art.

[0030] The chip suction device generally includes a chip suction pipe 110 , a suction cup 111 is provided at the top of the first end of the chip suction pipe 110 , and the suction cup 111 can be used to suck the top surface of the chip 101 .

[0031] The inventors of the present invention have found through research that particles (such as debris produced during cutting) remain around the chip 101 and in the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com