Cylindrical vacuum charger

A cylindrical barrel and feeder technology, which is applied in the fields of tobacco, food science, and tobacco preparation, can solve the problems of unreliable uniformity, loss of aroma, and inability to enter the cell wall of tobacco sheets, and achieve the effect of improving chemical properties and improving taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

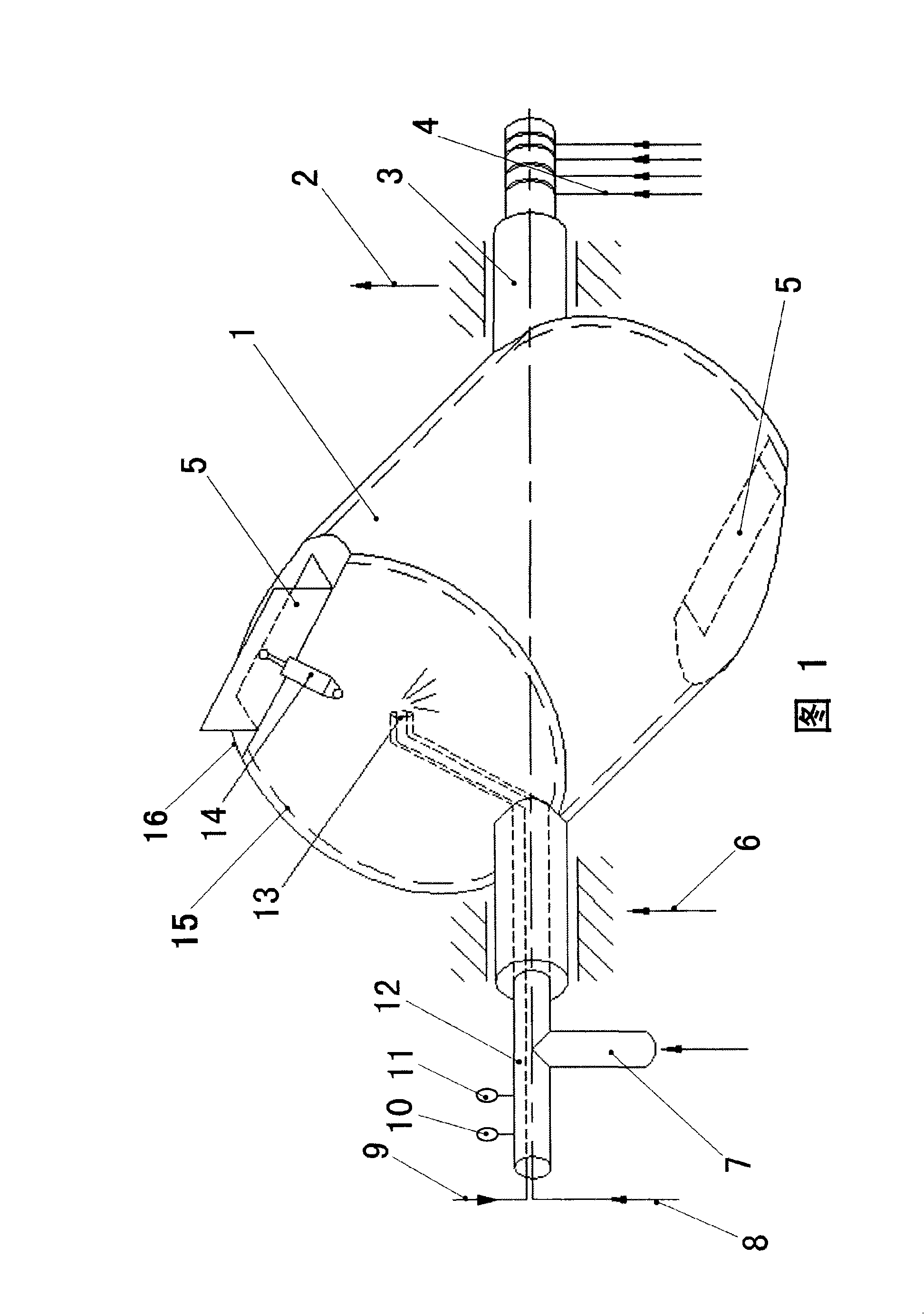

[0016] Referring to Figure 1, the feeding barrel is a double-layer positive cylindrical barrel body 1 that can rotate around the diagonal direction, and the inner barrel 15 is a stainless steel right cylindrical barrel of Φ2500×2500, with a wall thickness of 6mm and a volume of the inner barrel of 12m 3 , if each feed accounts for 55% of the volume, if the specific gravity of flakes is 120kg / m 3 In total, each feed can reach 800kg. Outer barrel 16 is common carbon steel, wall thickness is 5mm, interlayer is hot water layer, and interlayer thickness is 40mm, and inner and outer layer is welded by discontinuous 40mm wide longitudinal bar, can not block the flow of hot water. The outer wall of outer barrel 16 is covered with thermal insulation layer, so that certain ambient temperature is kept in the inner barrel. The diagonal direction of the rotation axis is the horizontal direction, and the other diagonal direction vertically intersects with it, that is, the vertical directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com