Suction nozzle assembly and cleaning robot

A technology for components and dust collection chambers, applied in the field of cleaning robots, can solve the problems of uneven suction of the nozzle, low cleaning efficiency, and side leakage of dust particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the purpose, structure and function of the present invention, a suction nozzle assembly and a cleaning robot of the present invention will be further described in detail below in conjunction with the accompanying drawings.

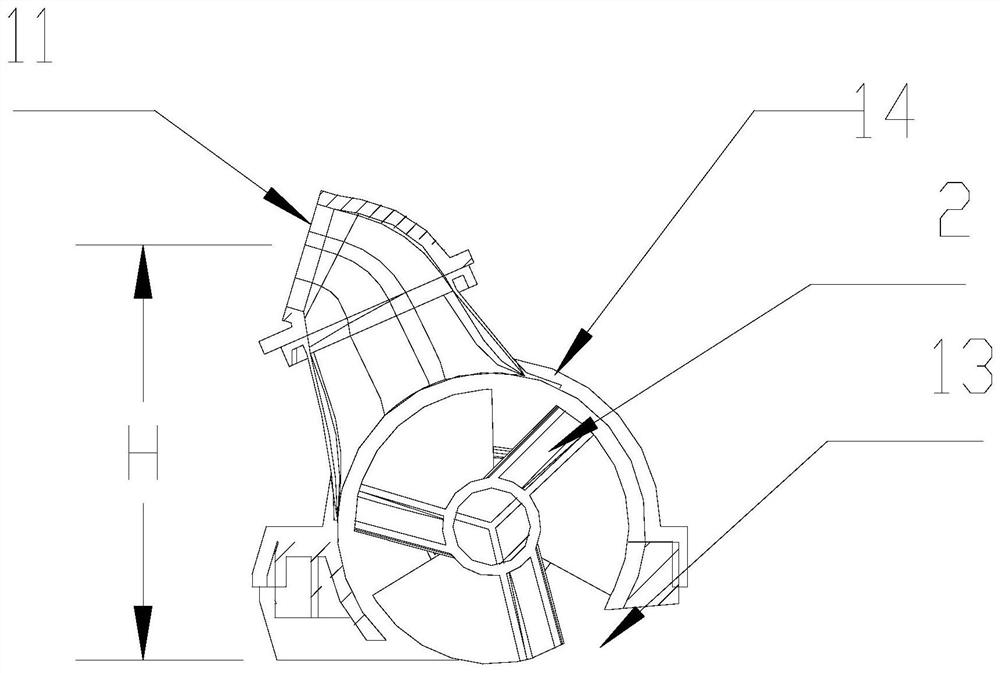

[0029] like figure 1 As shown, the nozzle assembly in the prior art includes a nozzle body 1, usually increasing the air outlet 11 of the nozzle body 1 to the height of the ground and the dust suction chamber 12 so that the average wind speed in the cavity is low, especially near the ground The wind speed is low, the suction to the ground is weak, and the dust particles continue to accumulate under the suction pipe, and it is too late to be lifted, which is prone to leakage.

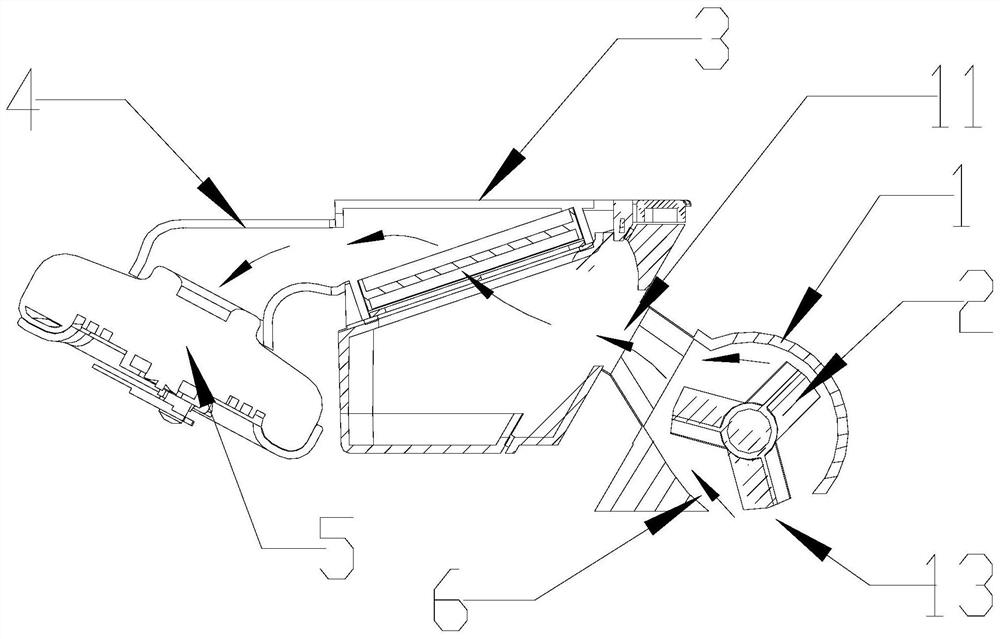

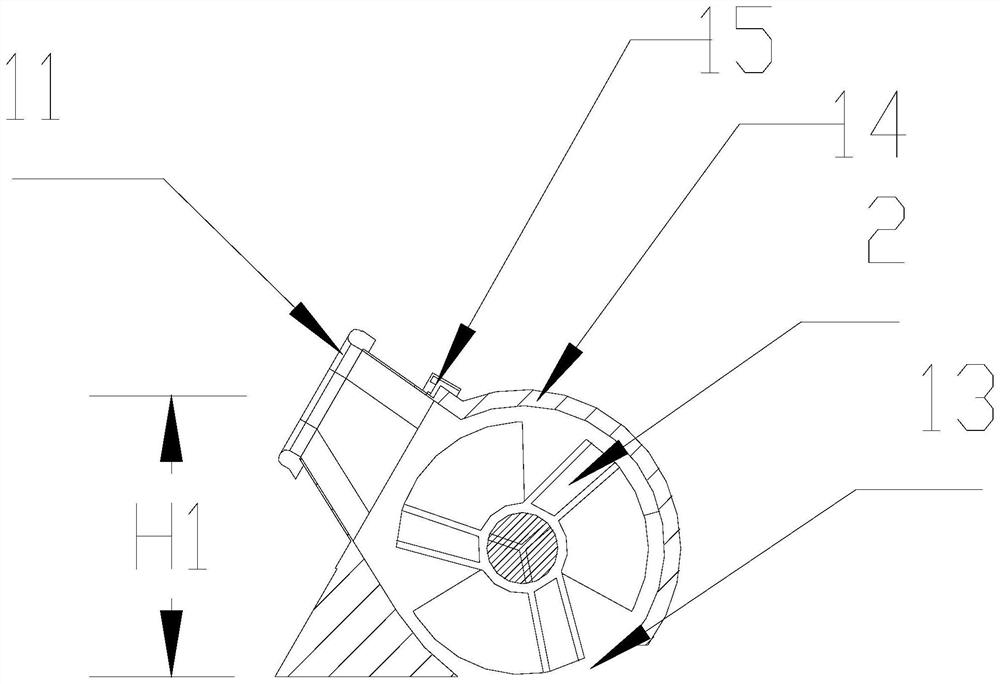

[0030] like figure 2 As shown, the present invention provides a nozzle assembly, including a nozzle body 1, a housing 15 is provided on the nozzle body 1, an inclined side wall is provided on the housing 15, and a suction nozzle body 1 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com