Method for manufacturing cold-drawing formed sealing pad

A manufacturing method and technology for sealing gaskets, applied in the manufacturing field, can solve the problems of reduced work efficiency, poor dimensional stability, low consistency, etc., and achieve the effects of improved part qualification rate, good deformation consistency, and good dimensional consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for manufacturing a cold-drawn sealing gasket, comprising the following steps:

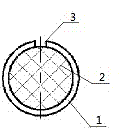

[0020] Step 1, making strips: Curl one end of the steel strip 1, cut the braided rope 2 according to the length of the steel strip 1 and put it into the curled steel strip to wrap tightly;

[0021] Step 2, fixing the drawing die: fixing the drawing die on the lathe;

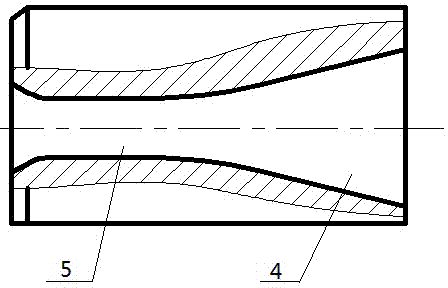

[0022] Step 3, drawing die forming: the strip material is in contact with the drawing die part, and the strip material and the center line of the drawing die form an angle of 7°, and then the lathe adopts the automatic cutting method to make the strip material pass through the drawing die at a uniform speed to make parts;

[0023] Step 4, straightening: machining the straightening parts by clamping.

[0024]

Embodiment 2

[0026] A method for manufacturing a cold-drawn sealing gasket, comprising the following steps:

[0027] Step 1, making strips: Curl one end of the steel strip 1, cut the braided rope 2 according to the length of the steel strip 1 and put it into the curled steel strip to wrap tightly;

[0028] Step 2, fixing the drawing die: fixing the drawing die on the lathe;

[0029] Step 3, drawing die forming: the strip material is in contact with the drawing die part, and the strip material and the center line of the drawing die form an angle of 10°, and then the lathe adopts the automatic cutting method, so that the strip material passes through the drawing die at a uniform speed, and the strip material is first drawn The cross-section is circular, and then the strip is drawn into parts of the desired shape;

[0030] Step 4, straightening: machining the straightening parts by clamping.

[0031]

Embodiment 3

[0033] A method for manufacturing a cold-drawn sealing gasket, comprising the following steps:

[0034] Step 1, making strips: Curl one end of the steel strip 1, cut the braided rope 2 according to the length of the steel strip 1 and put it into the curled steel strip to wrap tightly;

[0035] Step 2, fixing the drawing die: fixing the drawing die on the lathe;

[0036] Step 3, drawing die forming: the strip material is in contact with the drawing die part, and the strip material and the center line of the drawing die form an angle of 15°, and then the lathe adopts the automatic cutting method, so that the strip material passes through the drawing die at a uniform speed, and the strip material is first drawn The cross-section is circular, and then the strip is drawn into parts of the desired shape;

[0037] Step 4, straightening: machining the straightening parts by clamping.

[0038] In addition, the shape of the die is simple, and different shapes of the die can be made ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com