Anti-stretch solid wood floor and manufacturing method thereof

A technology of solid wood flooring and manufacturing methods, which is applied in the direction of floors, buildings, building structures, etc., and can solve the problems of geothermal systems that are more difficult and difficult to withstand the test of cold and heat expansion and contraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention the purpose of the invention, the technical means and effects adopted, the following will be described in detail in conjunction with the accompanying drawings and preferred embodiments.

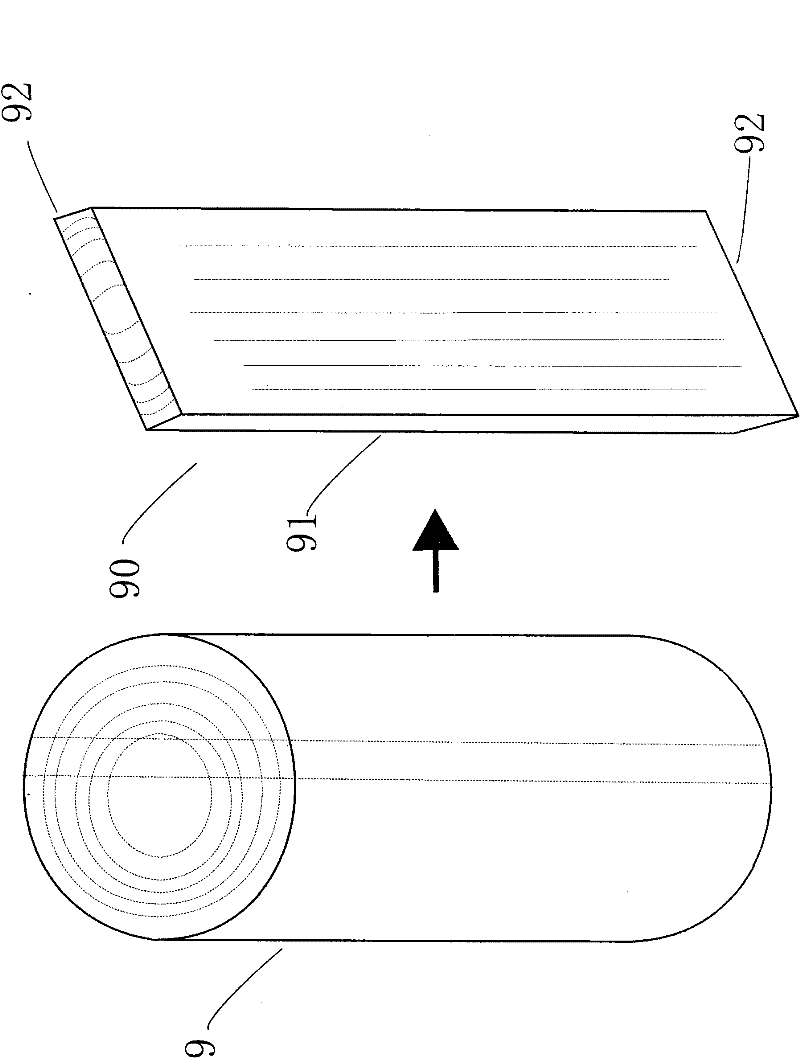

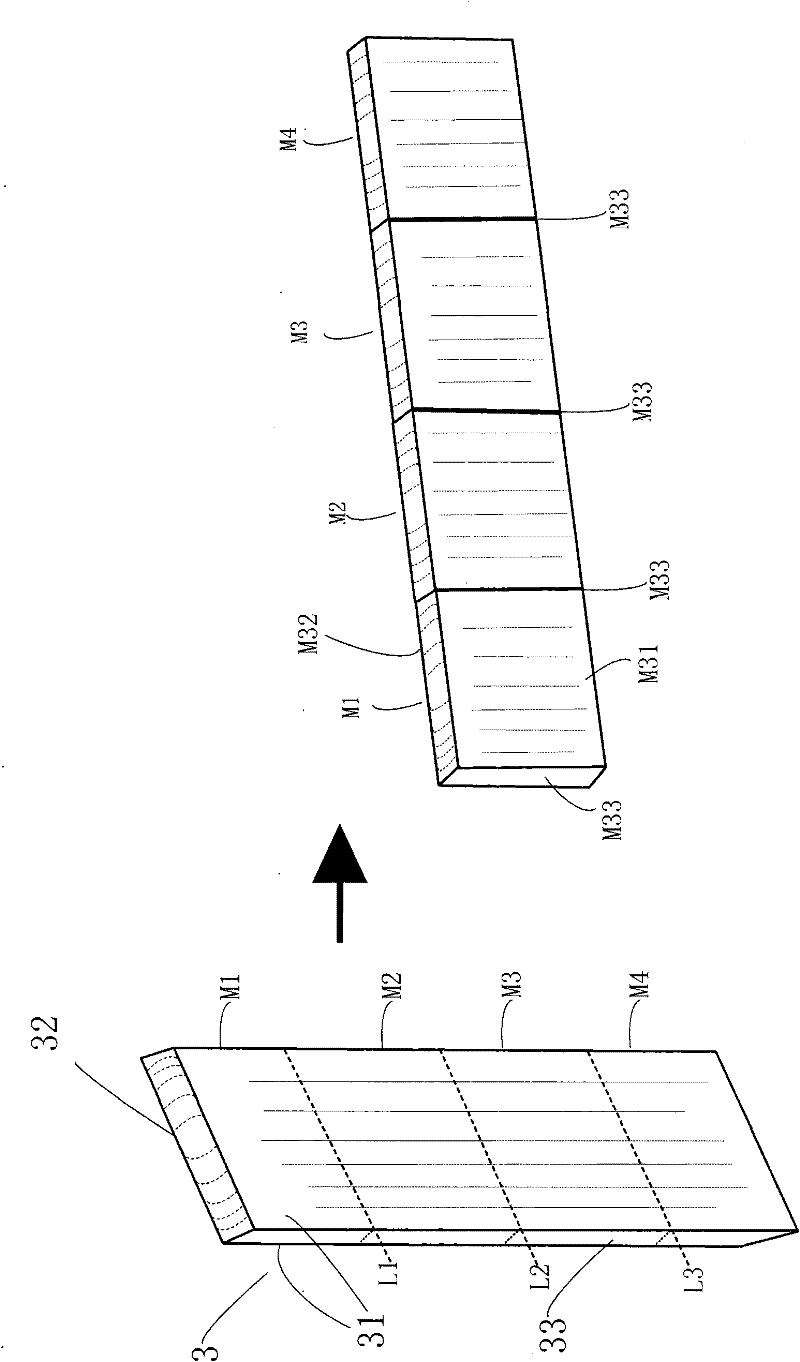

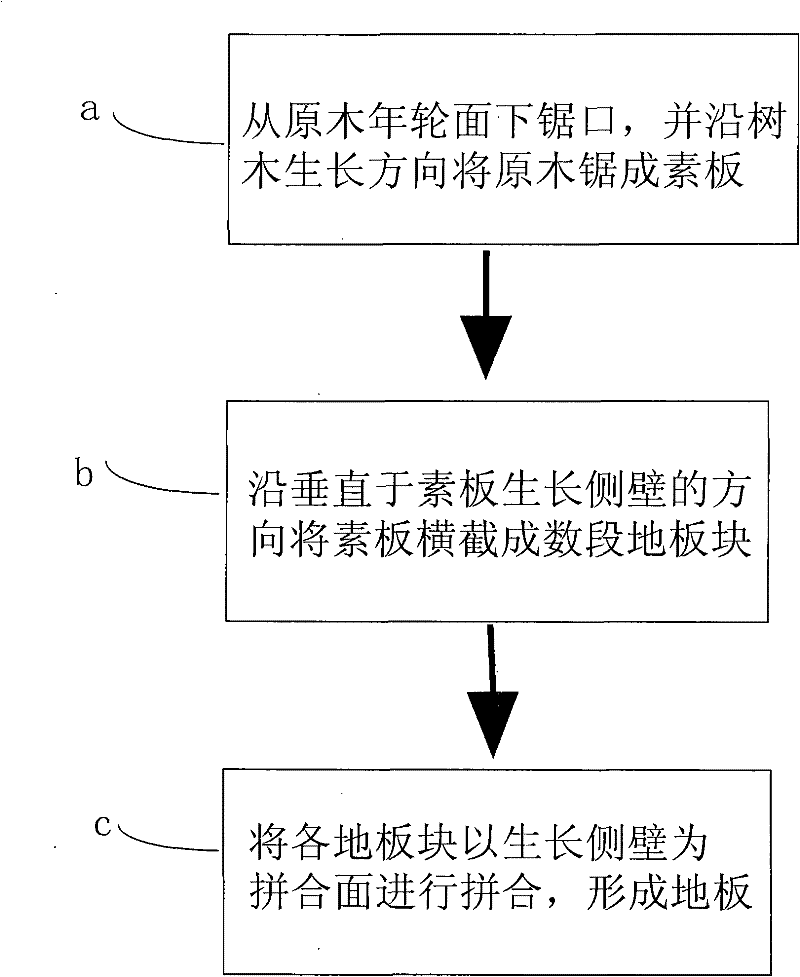

[0025] Tree cells are elongated cells along the growth direction. The deformation and expansion of trees is mainly along the vertical direction of the cells. The vertical direction of cells refers to the direction of the tree rings. Due to the one-way expansion and contraction characteristics of wood, the idea of the present invention is to convert the expansion and contraction in the width direction of the existing wooden floor to the expansion and contraction along the length direction of the wooden floor by using the method of rotating the setting direction, so that the expansion and contraction is limited to the floor Internally, by means of internal expansion slots and expansion joints, the expansion allowance in the length direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com