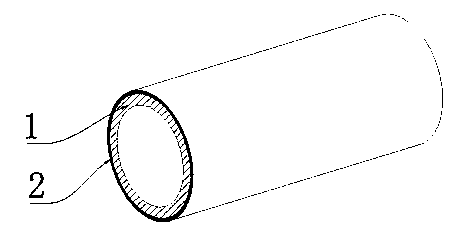

Sun-proof anti-aging polyethylene pipe

A polyethylene pipe, anti-aging technology, applied in pipeline protection, chemical instruments and methods, pipeline damage/wear prevention, etc., can solve the performance of pipes used above the ground or exposed to sunlight, limit the application scope of polyethylene pipes, The performance of polyethylene pipes is reduced and other problems, so as to expand the application range and safety factor, improve the performance of light fastness, thermal oxygen resistance and photoaging, and improve light fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The outer layer raw material composition of the present embodiment is by weight:

[0041] mLLDPE60 parts,

[0042] 40 copies of EPDM,

[0043] 3 parts of chain extender dihydroxymethyl-formaldehyde resin,

[0044] 0.5 parts of chain extender 2,5-2 methyl-2,5-bis(tert-butyl peroxy)hexane,

[0045] Catalyst SnCl 2 2H 2 O 0.4 parts,

[0046] 7 parts of carbon black,

[0047] 2 parts of titanium dioxide,

[0048] 0.5 parts of anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer,

[0049] Anti-aging agent thiourea derivative 0.5 part,

[0050] 1.3 parts of calcium stearate.

[0051] The above-mentioned components are mixed by a high-speed mixer, and then added to a single-screw extruder with an aspect ratio of not less than 36 to extrude the outer sun-resistant and anti-aging protective layer 2 of the pipe at an extrusion temperature of 160-190°C. The HDPE compound with a carbon black content of more than 2% and a carbon black dispersion of less than grade...

Embodiment 2

[0053] The outer layer raw material composition of the present embodiment is by weight:

[0054] mLLDPE60 parts,

[0055] 40 copies of EPDM,

[0056] 1.5 parts of chain extender 2,5-2 methyl-2,5-bis(tert-butyl peroxy)hexane,

[0057] Catalyst SnCl 2 2H 2 O 0.4 parts,

[0058] 7 parts of carbon black,

[0059] 2 parts of titanium dioxide,

[0060] 0.5 parts of anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer,

[0061] Anti-aging agent thiourea derivative 0.5 part,

[0062] 1.3 parts of calcium stearate.

[0063] The above-mentioned components are formed into pipes according to the method of Example 1. The performance test index of the pipe is shown in Table 1.

Embodiment 3

[0065] The outer layer raw material composition of the present embodiment is by weight:

[0066] mLLDPE60 parts,

[0067] 40 copies of EPDM,

[0068] 3 parts of chain extender dihydroxymethyl-formaldehyde resin,

[0069] 0.5 parts of chain extender 2,5-2 methyl-2,5-bis(tert-butyl peroxy)hexane,

[0070] Catalyst SnCl 2 2H 2 O 0.4 parts,

[0071] 7 parts of carbon black,

[0072] 2 parts of titanium dioxide,

[0073] 1 part of anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer,

[0074] 1.3 parts of calcium stearate.

[0075] The above-mentioned components are formed into pipes according to the method of Example 1. The performance test index of the pipe is shown in Table 1.

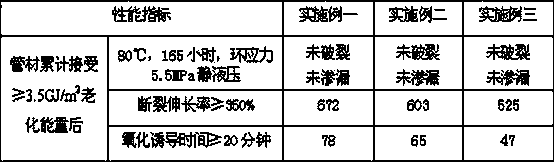

[0076] Table 1 Anti-aging properties of light-resistant and anti-aging polyethylene pipes

[0077]

[0078] It can be seen from Table 1 that the light-resistant and anti-aging polyethylene pipe prepared in Example 1 has the best anti-aging performance, and the compounding of chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com