A kind of food and drug conveyor belt and preparation method thereof

A technology for conveyor belts and pharmaceuticals, applied in conveyors, chemical instruments and methods, layered products, etc., can solve the problem of unsatisfactory creep resistance and service life of conveyor belts, poor adhesion of surface silica gel, and attack sensitivity, etc. problems, to achieve excellent cleaning and sanitation performance, excellent resistance to ozone aging, and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

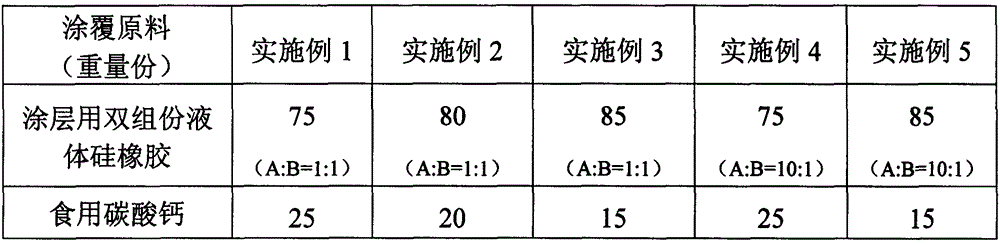

Embodiment 1~3

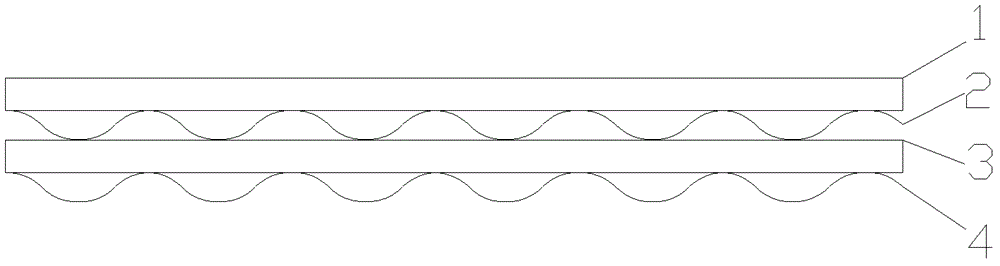

[0030] Such as figure 1 As shown, a food and drug conveyor belt is a four-layer structure conveyor belt composed of food-grade silicone coating 1, mesh fabric middle layer 2, PVC soft material layer 3 and dense fabric bottom layer 4, which are arranged in sequence from top to bottom. .

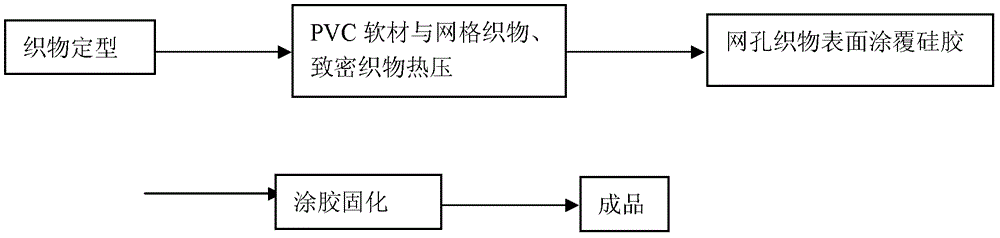

[0031] Such as figure 2 As shown, the food and drug conveyor belt is made by hot pressing and coating process. The production process is as follows: mesh fabric and dense fabric shaping, compounding with PVC hot pressing, coating the surface with food-grade silica gel, and finished product. The specific steps are:

[0032] The first step: the mesh fabric made of nylon (Taizhou Liancheng Fabric Co., Ltd., the mesh size is 0.01mm×0.01mm, and the weight is 120g / m 2 ) and dense fabrics (Taizhou Liancheng Fabric Co., Ltd., 1000D) are stretched and heat-set by the knitting tenter setting machine under the process conditions of the drying room at a working temperature of 160°C and a speed of 40m / ...

Embodiment 4

[0050] A preparation method of a food and drug conveyor belt, the steps of the method are as follows:

[0051] 1) The mesh fabric and the dense fabric are tenter-shaped by a knitting tenter setting machine respectively, wherein: the mesh fabric and the dense fabric are made of nylon with a thickness of 0.1 mm, and the mesh fabric is provided with fine and dense Mesh, mesh size is 0.05mm×0.05mm, weight 100 / m 2 , the dense fabric is the skeleton layer of 1200D.

[0052] 2) Lay the front side of the PVC soft material with the mesh fabric and the reverse side with the dense fabric, and then heat-compress and compound the PVC soft material through a flat vulcanizer. Lead-free PVC soft sheet, thickness 4mm.

[0053] 3) Coat a layer of food-grade silica gel on the upper surface of the mesh fabric, then coat a layer of food-grade silica gel on the side of the obtained product, and then send it to an oven for curing and molding. The temperature of curing and molding is 110°C, and the...

Embodiment 5

[0056] A preparation method of a food and drug conveyor belt, the steps of the method are as follows:

[0057] 1) The mesh fabric and the dense fabric are tenter-shaped by a knitting tenter setting machine respectively, wherein: the mesh fabric and the dense fabric are made of nylon with a thickness of 0.3 mm, and the mesh fabric is provided with fine and dense Mesh, mesh size is 0.02mm×0.02mm, weight 150g / m 2 , the dense fabric is the skeleton layer of 900D.

[0058] 2) Lay the front side of the PVC soft material with the mesh fabric and the reverse side with the dense fabric, and then heat-compress and compound the PVC soft material through a flat vulcanizer. Lead-free PVC soft sheet, thickness 2mm.

[0059] 3) Coat a layer of food-grade silica gel on the upper surface of the mesh fabric, then coat a layer of food-grade silica gel on the side of the obtained product, and then send it to an oven for curing and molding. The temperature of curing and molding is 140 ° C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com