Patents

Literature

33results about How to "Excellent resistance to ozone aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-density ethylene propylene diene monomer extruded sponge material and preparation method thereof

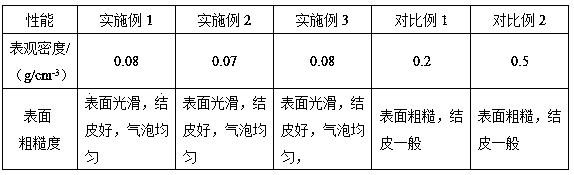

The invention relates to a low-density ethylene propylene diene monomer extruded sponge material and a preparation method thereof. The sponge material disclosed by the invention is prepared from the following components in parts by weight: 100 parts of raw rubber matrix, 20-50 parts of carbon black; 50-100 parts of a plasticizer, 100-200 parts of an inorganic filler, 1-3 parts of a vulcanizing agent, 15-30 parts of a blowing agent, 5-10 parts of a vulcanization accelerator, 5-10 parts of an activator, 5-10 parts of calcium oxide; wherein the raw rubber matrix is ethylene propylene diene monomer rubber, the ethylene content of the raw rubber matrix is 40-55%, the Mooney viscosity (ML(1 + 4)125 DEG C) of the raw rubber matrix is 40-80, and the content of a third monomer ENB of the raw rubbermatrix is 7-10%. The low-density ethylene propylene diene monomer extruded sponge material has the advantages of light density, smooth surface, excellent weather resistance, ozone resistance and coldresistance, the preparation method is simple and convenient to operate and low in cost, and the sponge material can be applied to the fields of pipeline or building insulation, fitness products and the like.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

Height adjustment support and technique for utilizing height adjustment support to adjust height

InactiveCN101538829AGood wear resistanceGood mechanical propertiesBridge structural detailsBridge erection/assemblyEngineeringCheck valve

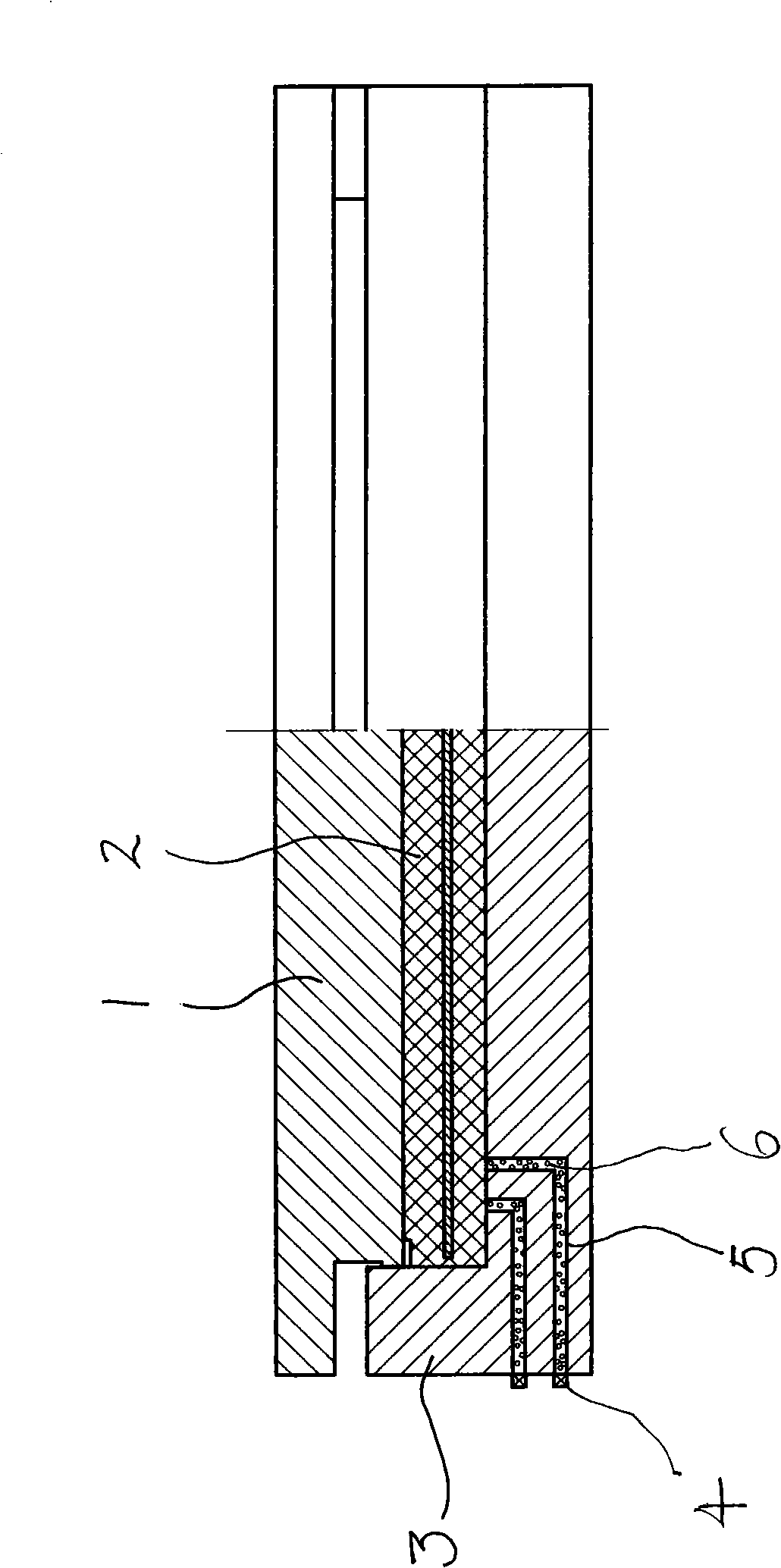

The invention belongs to the technical field of bridge supports and discloses a height adjustment support and a technique for utilizing the height adjustment support to adjust height. The invention has the main technical characteristics that the height adjustment support comprises an upper seat plate, a rubber bearing plate and a base basin; the base basin is provided with injection agent pipelines with a valve; the injection agent pipelines are connected with an injection-moulding machine by a check valve, a throttle and a flow divider; the injection agent pipelines are internally poured with bicomponent polyurethane rubber are two or more than two; and the injection-moulding machine is connected with a hydraulic sensor. The height adjustment support can lead the height of the girder to reach conformity or meet design requirements by adjusting the height, can adjust height in a stepless and multiple times manner, can measure load force, has simple and convenient construction in the processes of leveling, measuring force and adjusting height, does not need large machines and other jacking equipment and can adjust height with dynamic load.

Owner:HEBEI BAOLI ENG EQUIP GRP CO LTD

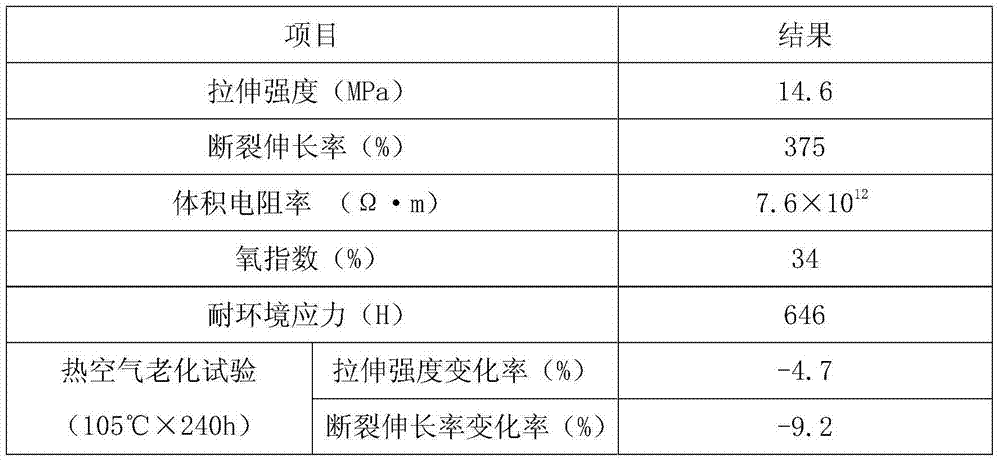

Environmental stress crack-resistant polyethylene sheath material for power wire and preparation method thereof

InactiveCN103540008AGood environmental stress cracking resistanceGood high and low temperature resistancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethyleneLead phosphate

The invention discloses an environmental stress crack-resistant polyethylene sheath material for a power wire and a preparation method thereof. The environmental stress crack-resistant polyethylene sheath material is prepared from the following substances in parts by weight: 80-100 parts of linear low-density polyethylene, 15-20 parts of polystyrene resin, 10-15 parts of polyphthalamide, 4-8 parts of dimethyl silicon oil, 2-3 parts of dibasic lead phosphate, 1-2 parts of calcium stearate, 1-2 parts of zinc stearate, 0.5-1 part of antioxidant 1010, 1-2 parts of antioxidant 168, 2-4 parts of ethylene distearate amide, 4-6 parts of chlorinated paraffin and 3-5 parts of pine tar. The sheath material has the advantages of excellent environmental stress crack resistance, high-low temperature resistance, acid-base resistance, salt mist resistance, ozone aging resistance, ultraviolet radiation resistance, abrasive resistance and tensile strength, is capable of working normally in a working environment at a temperature ranging from 60 DEG C below zero to 105 DEG C, is non-deformable and non-cracking in long-time use, is safe and reliable and is applicable to internal and external sheathes of overhead power wires in the outdoor.

Owner:天长市富达电子科技股份有限公司

Rubber composition and preparation method thereof

The invention discloses a runner composition. The rubber composition is characterized by being prepared from the following materials in parts by weight: 100-110 parts of ethylene-propylene-diene rubber, 30-40 parts of nitrile rubber, 0.5-1.5 parts of stearic acid, 0.02-2 parts of paraffins, 2-4 parts of anti-ageing agent MB, 5-10 parts of titanate coupling agent, 15-20 parts of calcium carbonate, 0-1.5 parts of antioxidant and 5-10 parts of butyl acetate. The rubber composition, which is prepared by utilizing ethylene-propylene-diene rubber and nitrile rubber, disclosed by the invention has the advantages of being excellent in oil resistance, wear resistance, ozone ageing resistance, low temperature resistance and the like.

Owner:WUJIANG DEZUO DAILY CHEM PROD

Heat-resisting conveyor belt designed according to temperature distribution and preparing method of heat-resisting conveyor belt

The invention relates to a heat-resisting conveyor belt designed according to the temperature distribution and a preparing method of the heat-resisting conveyor belt. The conveyor belt is composed of a laminated structure of a framework layer, a transition layer, upper covering glue and lower covering glue. According to the using requirement, the parameters of the conveyor belt in the running process are known before design and manufacture are carried out, the temperature distribution of a belt body of the conveyor belt in the running process is tested or worked out, a reasonable belt body structure is designed, any one of EP canvas, nylon canvas and cotton canvas which are small in shrinking amount under the high temperature condition and insensitive in strength to the temperature is selected as the framework layer, the framework layer, the transition layer, the upper covering glue and the lower covering glue are laminated to form a complete belt billet, the belt billet is vulcanized through a vulcanizing machine, and then the heat-resisting conveyor belt can be obtained through cooling and forming after vulcanizing. The heat-resisting conveyor belt is reasonable in structure, the overall using performance of the conveyor belt is greatly improved, the production cost and energy consumption are effectively reduced, and the heat-resisting conveyor belt can be widely applied to coal, mines, ports, metallurgy, electric power, casting, cement, chemical engineering and other industries and places needing materials to be conveyed at a high speed.

Owner:刘山根

Seamless conveying belt and manufacture method thereof

InactiveCN101638171AImprove photoagingImprove thermal stabilityConveyorsTextiles and paperEngineeringSilica gel

The invention relates to a seamless conveying belt. The conveying belt forms a closed hybrid layer by a joint-free closed base belt and rubber, an outer rubber layer is designed on the outer surface of the closed hybrid layer, and an outer silica gel layer is designed on the outer surface of the outer rubber layer. The manufacture method of the conveying belt comprises the following steps: (1) selecting a plane annular woolen blanket as the joint-free closed base belt; (2) mounting the joint-free closed base belt on a rubber spreading machine; (3) starting the rubber spreading machine, pouringliquid rubber on the joint-free closed base belt and spreading the liquid rubber by a scraper; (4) spraying liquid silica gel on the outer surface of the outer rubber layer; (5) after the outer silica gel layer is solidified, abrading the outer surface of the outer silica gel layer by an abrading machine; (6) taking the product out of the machine and putting into a warehouse. The seamless conveying belt produced by the method has seamless integration and high strength and quality without sticking a conveying object and meets the requirement of a super wide and / or a super long product by a user. The invention has simple manufacture method, high production efficiency and less equipment investment.

Owner:周炳光

Seamless silica gel conveying belt and manufacture method thereof

InactiveCN101638170AThere will be no phenomenon of sticking to the conveyed objectImprove thermal stabilityConveyorsTextiles and paperLiquid stateEngineering

The invention relates to a seamless silica gel conveying belt. The conveying belt forms a closed hybrid layer by a joint-free closed base belt and silica gel, an outer silica gel layer is designed onthe outer surface of the closed hybrid layer, and the closed hybrid layer and the outer silica gel layer are integrally molded into a whole in such a way that liquid silica gel is poured and spread onthe joint-free closed base belt. The manufacture method of the conveying belt comprises the following steps: (1) connecting the head and the tail of a plane strip base belt to be woven into the joint-free closed base belt; (2) mounting the joint-free closed base belt on a gel spreading machine; (3) starting the gel spreading machine, pouring the liquid silica gel on the joint-free closed base belt and spreading the liquid silica gel by a scraper on the gel spreading machine; (4) after the silica gel is solidified, abrading the outer surface of the outer silica gel layer by an abrading machine; (5) taking the product out of the machine and putting into a warehouse. The seamless silica gel conveying belt produced by the method has seamless integration and high strength and quality without sticking a conveying object and meets the requirement of a super wide and / or a super long product by a user. The manufacture method has simpler working procedures.

Owner:周炳光

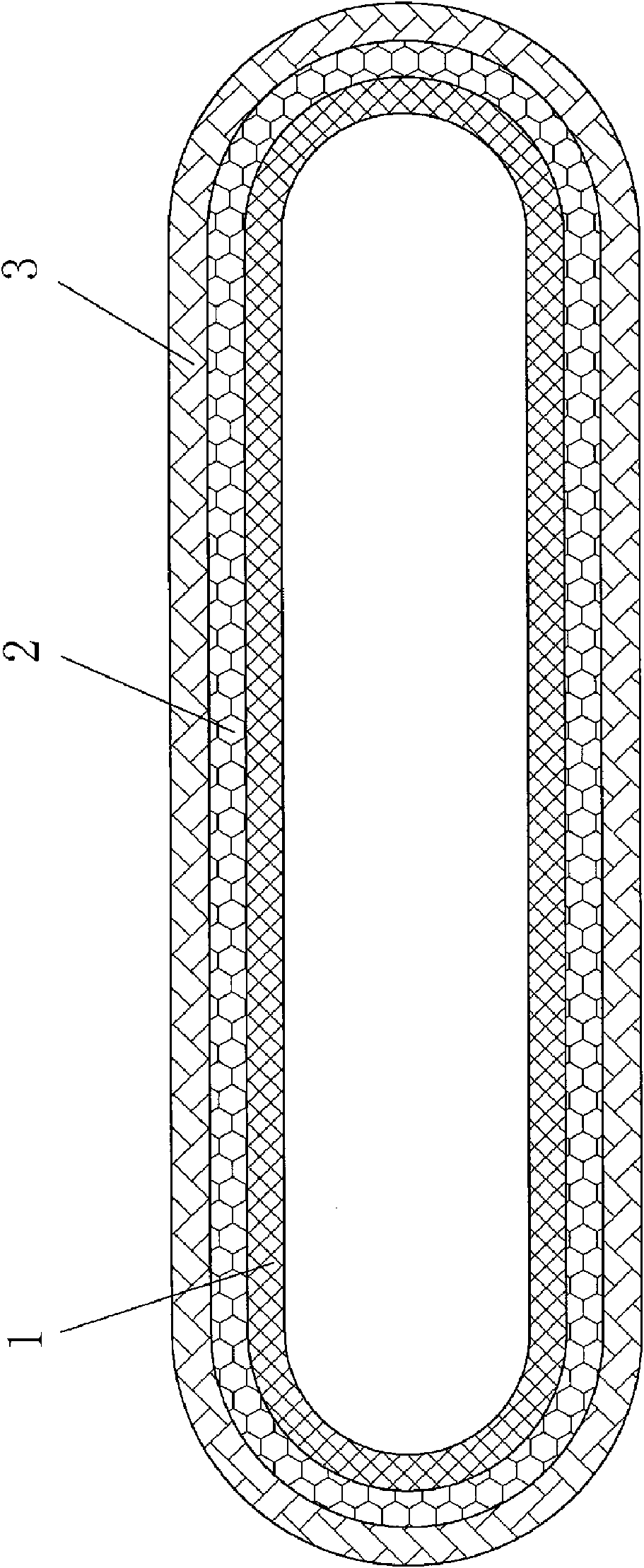

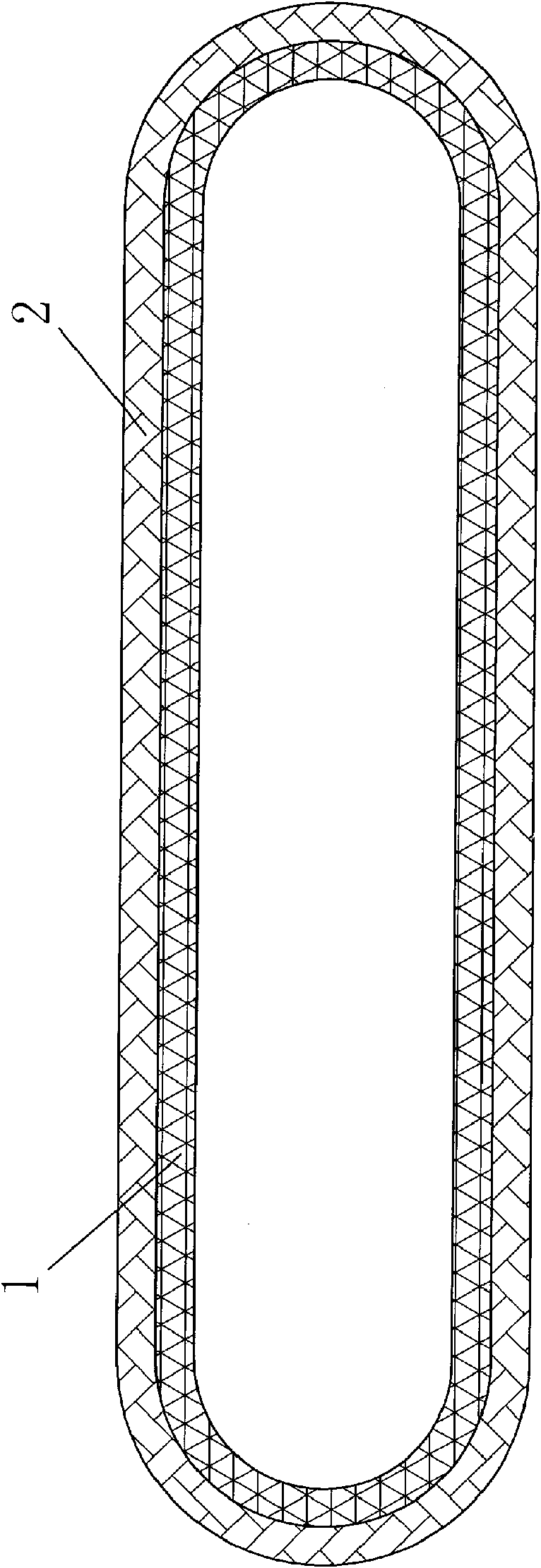

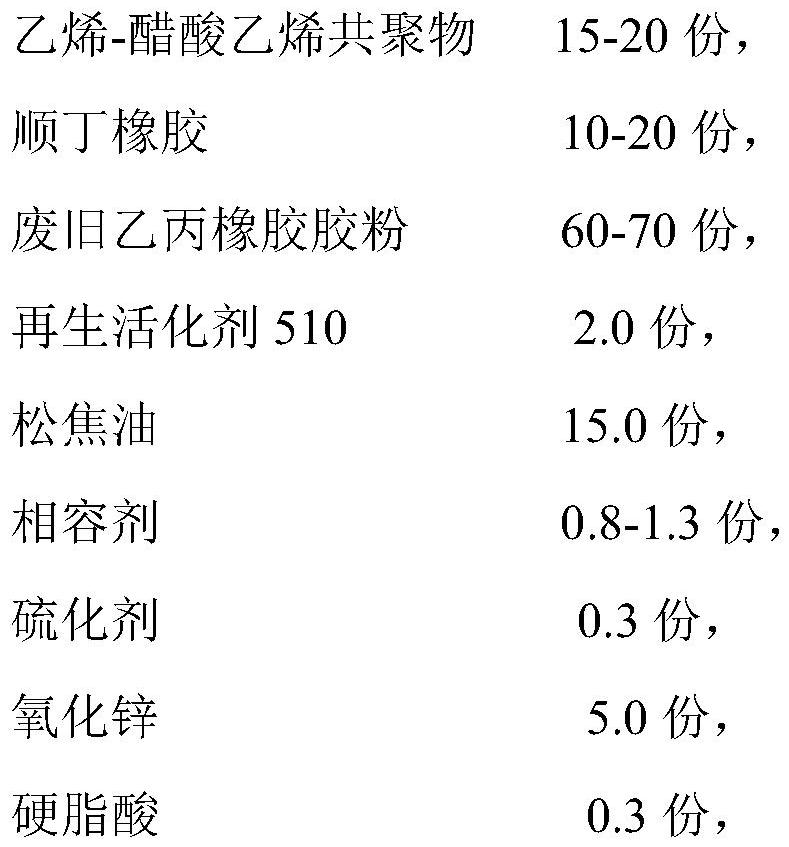

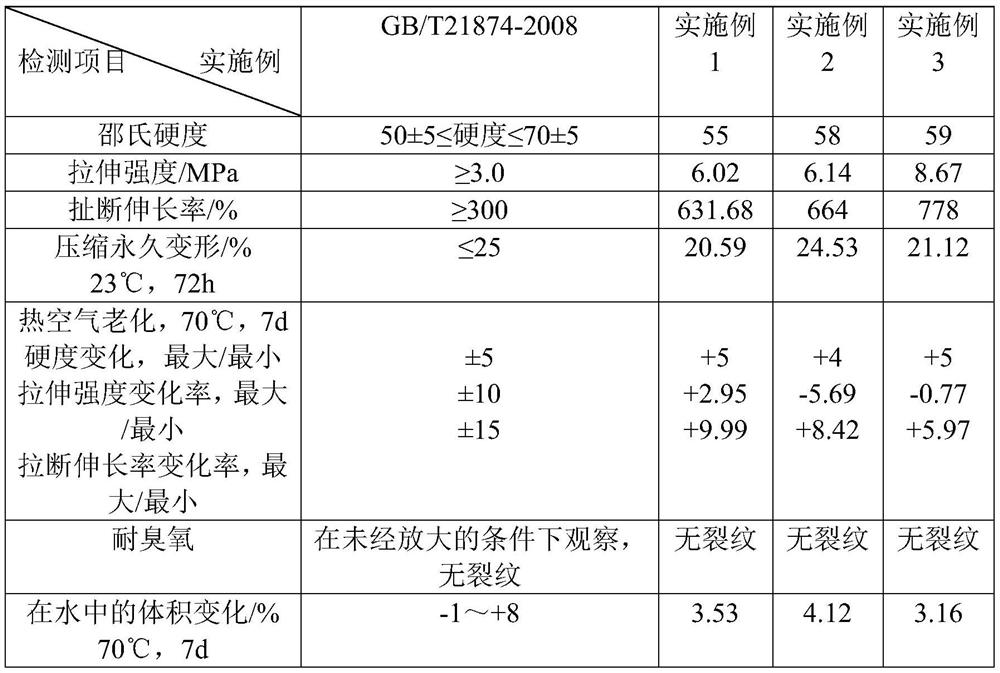

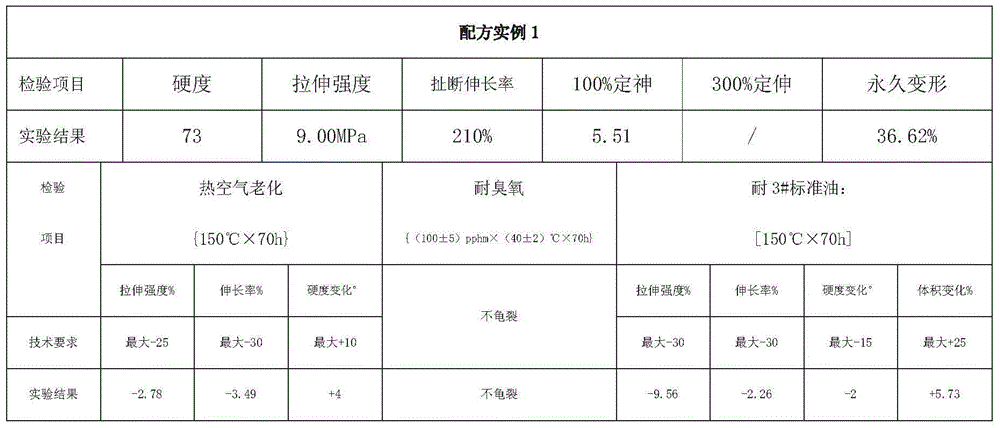

Preparation method of anti-aging ethylene-propylene rubber powder-based EVA thermoplastic elastomer sealing element

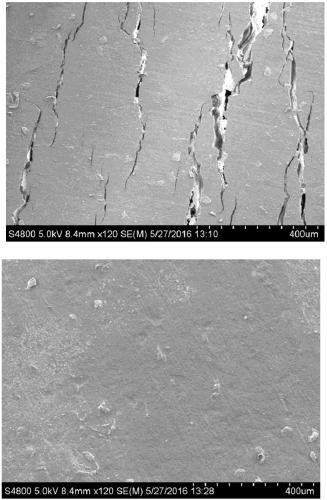

InactiveCN113549280AExcellent resistance to ozone agingNo crackCoatingsBuilding insulationsElastomerPolymer science

The invention discloses a preparation method of an anti-aging ethylene-propylene rubber powder-based EVA thermoplastic elastomer sealing element. The preparation method comprises the steps: activating waste ethylene propylene rubber powder at the temperature of 200 DEG C for 30 minutes; plasticizing butadiene rubber for 5 min at normal temperature, uniformly dispersing the activated ethylene propylene rubber fine rubber powder and the transparent ethylene-vinyl acetate copolymer in a kneading machine, adding the mixture into butadiene rubber plasticated rubber at the temperature of 160+ / -5 DEG C, and uniformly mixing to obtain mixed plastic; and adding a vulcanizing agent, a compatilizer, zinc oxide, stearic acid and an antioxidant 1010 into mixed plastic in a double-screw extruder at the temperature of 180 DEG C, uniformly dispersing, and carrying out a cross-linking reaction on rubber powder, EVA resin and various compounding ingredients to obtain an thermoplastic elastomer for the ethylene-propylene rubber powder-based EVA water pipe sealing element, and carrying out mold pressing into sheets.

Owner:XUZHOU COLLEGE OF INDAL TECH

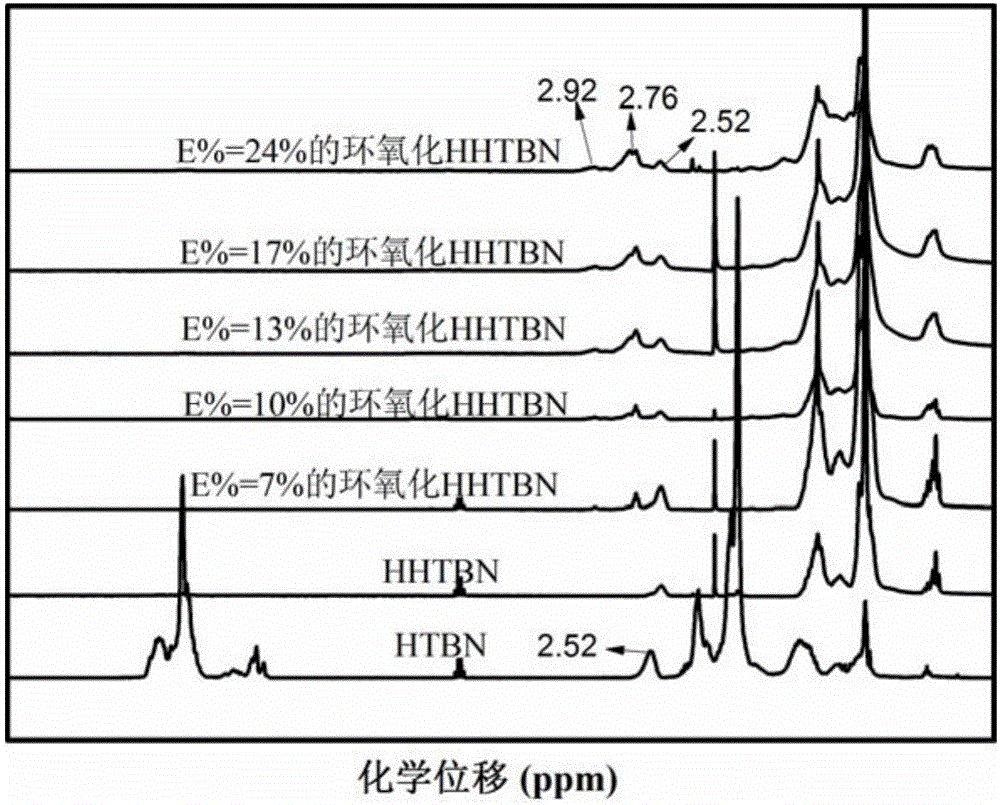

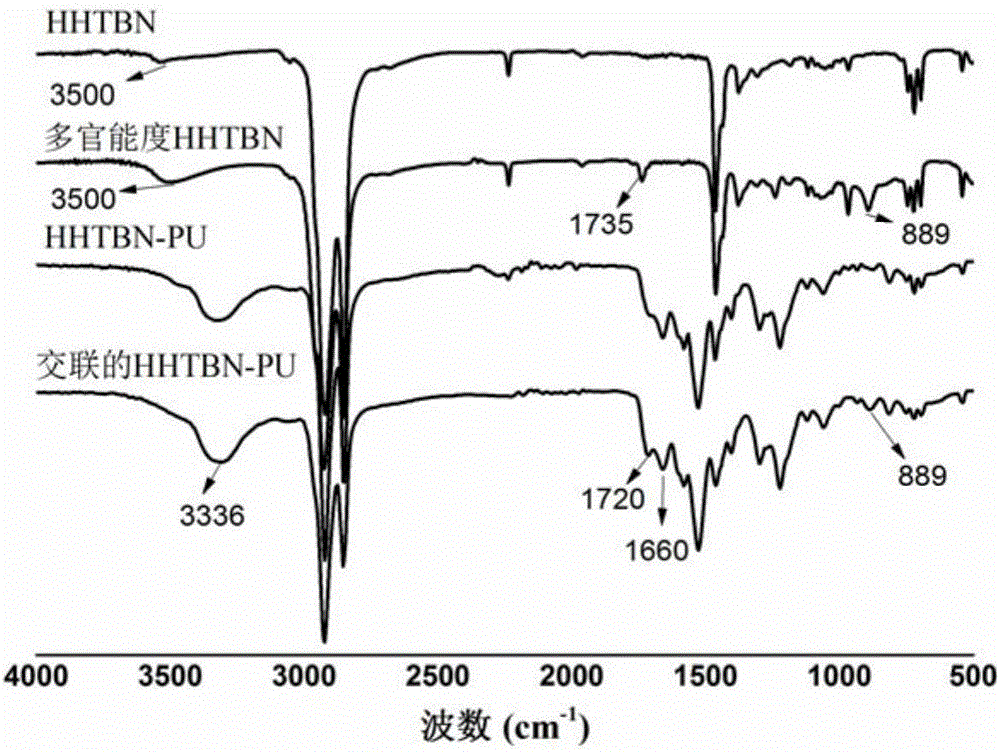

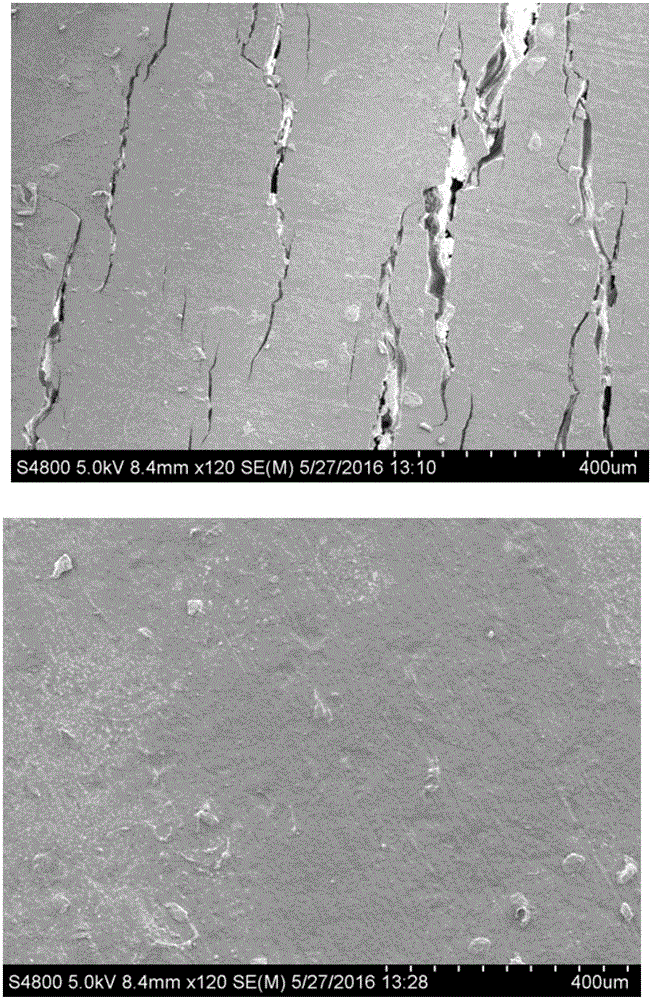

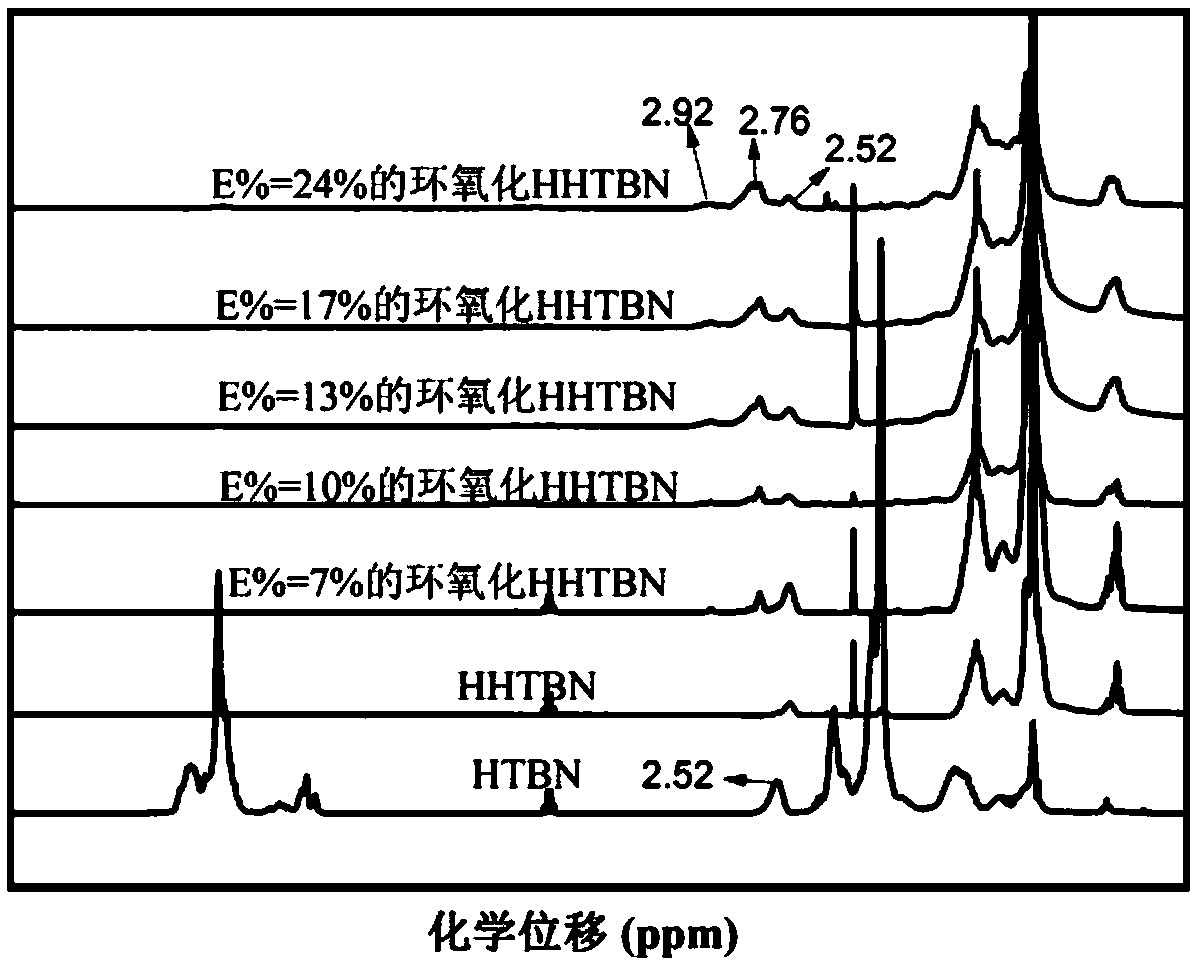

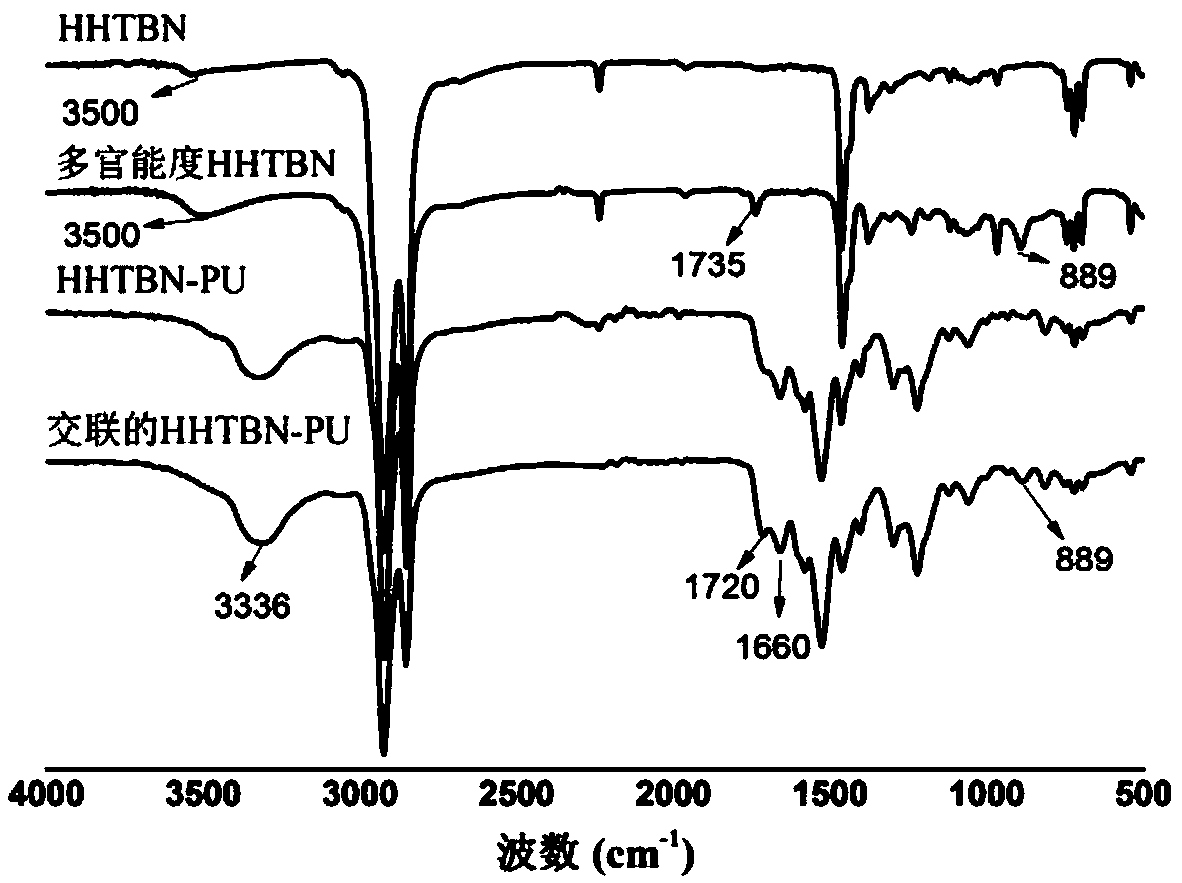

Cross-linked hydrogenated butyronitrile type polyurethane

The invention provides cross-linked hydrogenated butyronitrile type polyurethane. The cross-linked hydrogenated butyronitrile type polyurethane is formed by cross-linking multifunctional hydrogenated terminal hydroxyl liquid nitrile rubber and isocyanato; and the multifunctional hydrogenated terminal hydroxyl liquid nitrile rubber is obtained by introducing an epoxy group in terminal hydroxyl liquid hydrogenated nitrile rubber and then introducing hydroxyl in part of the epoxy group in a ring opening manner by carboxylic acid. The invention further provides a preparation method of the cross-linked hydrogenated butyronitrile type polyurethane. By the novel cross-linked hydrogenated butyronitrile type polyurethane provided by the invention, the shortcoming that butyronitrile type polyurethane is poor in ageing resistance and not high in mechanical strength is overcome. Measurement of swelling ratio and gel fraction proves that chemical crosslink bonds are introduced in the polyurethane, and owing to introduction of the chemical crosslink bonds, the shortcoming that the mechanical property of the polyurethane is poor at high temperature due to the fact that the polyurethane is lack of the chemical crosslink bonds is also overcome.

Owner:BEIJING UNIV OF CHEM TECH

Membrane for electromagnetic control valve of water supply and irrigation system and processing method

InactiveCN107011583AImprove impact resistanceGood physical and mechanical propertiesRubber membraneVulcanization

The invention discloses a membrane for an electromagnetic control valve of a water supply and irrigation system. The membrane is prepared from the following components in parts by weight: 60-70 parts of an ethylene propylene terpolymer, 20-30 parts of nitrile rubber, 22-26 parts of chlorinated polyethylene, 4-8 parts of an activator, 2-4 parts of an anti-ager, 20-30 parts of carbon black, 6-8 parts of a vulcanizing agent, 4-6 parts of a plasticizer, 6-10 parts of a vulcanization accelerator, 2-4 parts of a coupling agent, 12-16 parts of carbon microspheres, 6-10 parts of a urea formaldehyde polymer, 5-8 parts of hexamethylenetetramine, 2-5 parts of octadecanol and 6-10 parts of talcum powder. The ethylene propylene terpolymer is taken as a main body and matched with the nitrile rubber and the chlorinated polyethylene, so that the rubber membrane has good high temperature resistance, ozone aging resistance, chemical resistance, oil resistance, corrosion resistance and wear-resisting property under the premise of ensuring the tensile strength and the tearing strength. The membrane has good shock resistance, good dynamic property, good oil resistance, wear-resisting property and long service life.

Owner:NINGGUO XINGYUAN RUBBER PROD

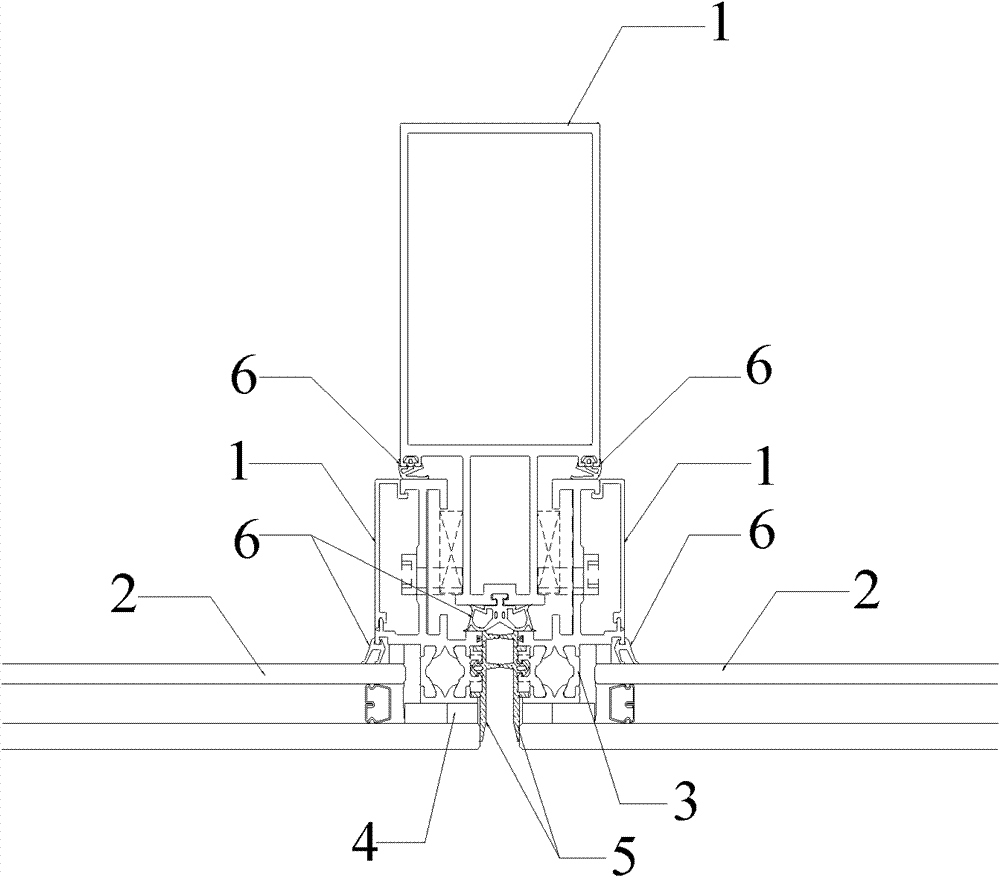

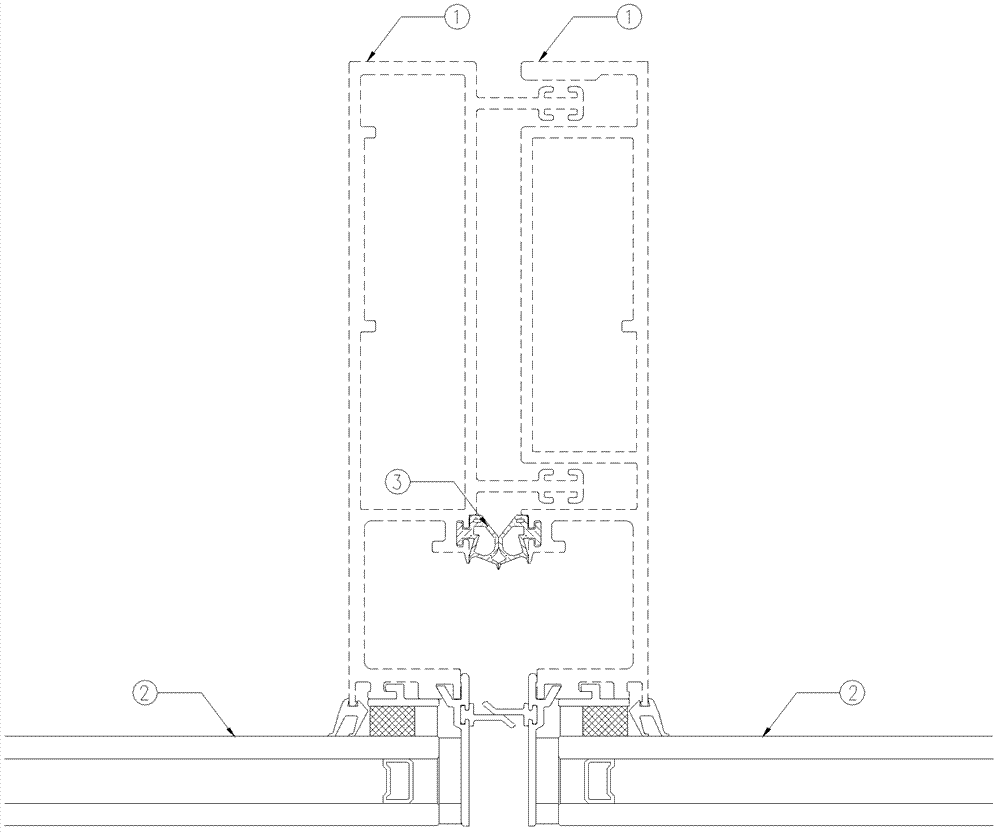

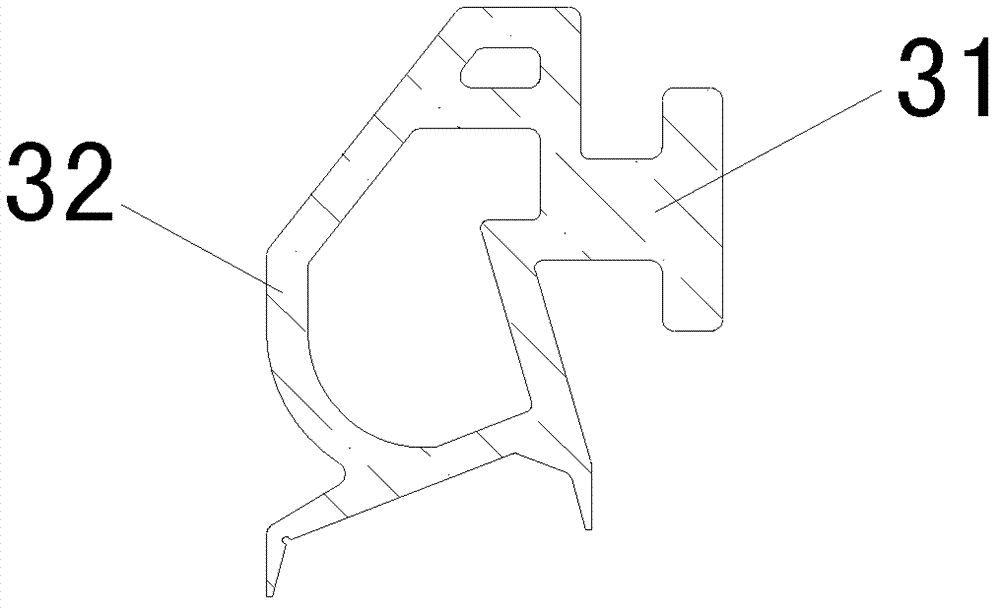

Combined insertion sealing rubber strip

InactiveCN102953434AExcellent resistance to ozone agingGood weather resistanceWallsEngineeringMechanical engineering

The invention relates to a combined insertion sealing rubber strip which is arranged in a unit curtain wall and is of a branched structure. Horizontal protruding branches are arranged on two sides of the upper portion of the combined insertion sealing rubber strip. The combined insertion sealing rubber strip is arranged in a first waterproof interface in a vertical direction of an aluminum alloy section of the unit curtain wall. Compared with the prior art, the combined insertion sealing rubber strip is capable of improving watertightness and airtightness of the unit curtain wall by combination of the sealing rubber strips of different shapes, and has the advantages of convenience in construction, high-speed installation and the like.

Owner:SHANGHAI MEITE CURTAIN WALL

Polymer pre-paved waterproof coiled material

InactiveCN112708359AExcellent resistance to ozone agingExcellent oxygen aging resistanceFilm/foil adhesivesRadiation-absorbing paintsAdhesive cementPolymer science

The invention discloses a polymer pre-laid waterproof coiled material, and relates to the technical field of waterproof coiled materials. The polymer pre-laid waterproof coiled material comprises a polymer sheet and a polymer adhesive layer, and the polymer adhesive layer is formed on the polymer sheet. By adopting a water-based protective layer, on one hand, the main chain of an organic silicon rubber emulsion molecule is a -Si-O- bond, the organic silicon rubber emulsion molecule is a linear polymer taking a mono-valent organic group as a side group, and the organic silicon rubber has the widest use temperature range in all rubbers and has excellent ozone aging resistance, oxygen aging resistance, light aging resistance and weather aging resistance; on the other hand, the added fumed silica has extremely strong ultraviolet absorption and infrared light reflection characteristics, the aging resistance of a coating can be improved when fumed silica is added into the coating, in addition, silicon-alcohol bonds on the surface and calcium ions in concrete carry out a chemical reaction, the bonding between the pre-laid coiled material and the concrete is enhanced, and a synergistic bonding effect is achieved.

Owner:苏州鲲腾龙盈新材料科技有限公司

Low-permeability and high-adhesion conductive automobile fuel pipe and preparation method thereof

ActiveCN111204080AImprove peeling resistanceLow costSynthetic resin layered productsFuel supplyAutomotive engineeringElectrically conductive

The invention discloses a low-permeability and high-adhesion conductive automobile fuel pipe and a preparation method thereof, and belongs to the technical field of fuel pipes. The fuel pipe comprisesan NBR rubber layer, a THV fluoroplastic layer, an NBR rubber layer, an aramid fiber reinforcing layer and an NBR / PVC alloy layer from inside to outside to achieve the effect of improving the bondingstrength among all the layers of the fuel pipe.

Owner:ZHEJIANG JUNHE RUBBER TECH

Oil and high temperature resistant acrylate rubber tube

InactiveCN104945810AMeet the requirements of high temperature resistant oilExcellent heat and oxygen aging resistanceFlexible pipesPolymer scienceStearic acid

The invention relates to an oil and high temperature resistant acrylate rubber tube. The rubber tube comprises or contains the following components in parts by weight: 100 parts of acrylate rubber, 1-10 parts of light magnesium oxide, 1-5 parts of stearic acid, 1-5 parts of anti-aging agent TR-101, 1-5 parts of pentaerythritol ester, 5-15 parts of precipitated hard charcoal, 15-60 parts of natural gas semi-reinforced carbon black, 15-60 parts of fast extruding furnace black N550, 15-60 parts of heavy carbonic acid, 1-10 parts of plasticizer TP-95, 0.5-2 parts of sulfur, 0.5-5 parts of 1# accelerant, 0.5-5 parts of 2# accelerant and 0.5-5 parts of 3# accelerant. The rubber tube has the best physical and mechanical properties. Through tests, the hardness of the rubber tube is 70+ / -5 degrees, the tensile strength is more than 8MPa, the elongation at break is more than 200%, the rubber tube can be used for a long term in a 150 DEG C high-temperature oil medium environment, and the 3# oil weight change resistance is lower than 25%.

Owner:柳州日高汽车减振技术有限责任公司

A special cable for public facilities

ActiveCN106782803BNovel structureImprove cold resistanceInsulated cablesCable/conductor manufacturePolyesterCopper wire

Owner:ANHUI TIANYUAN CABLE

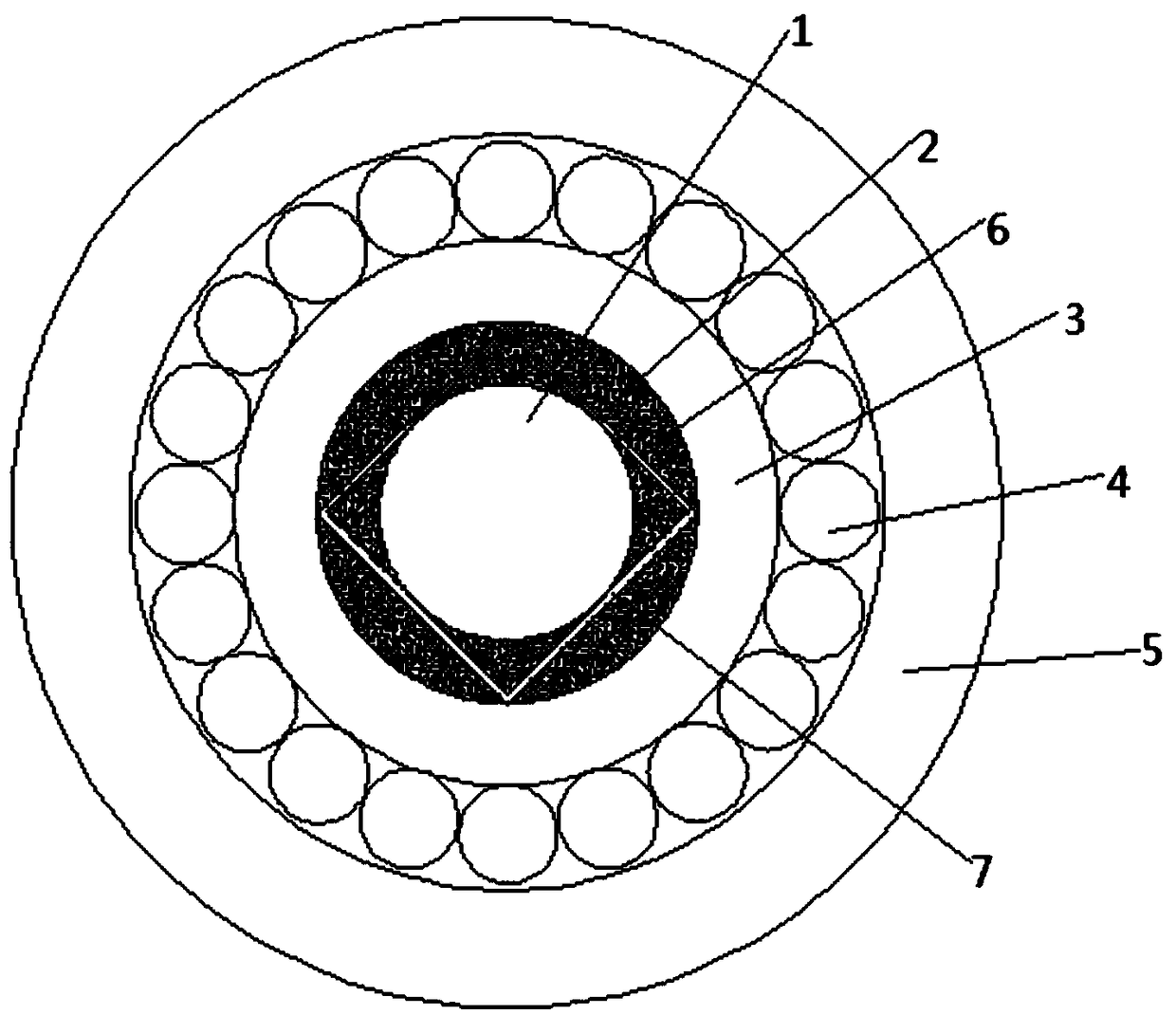

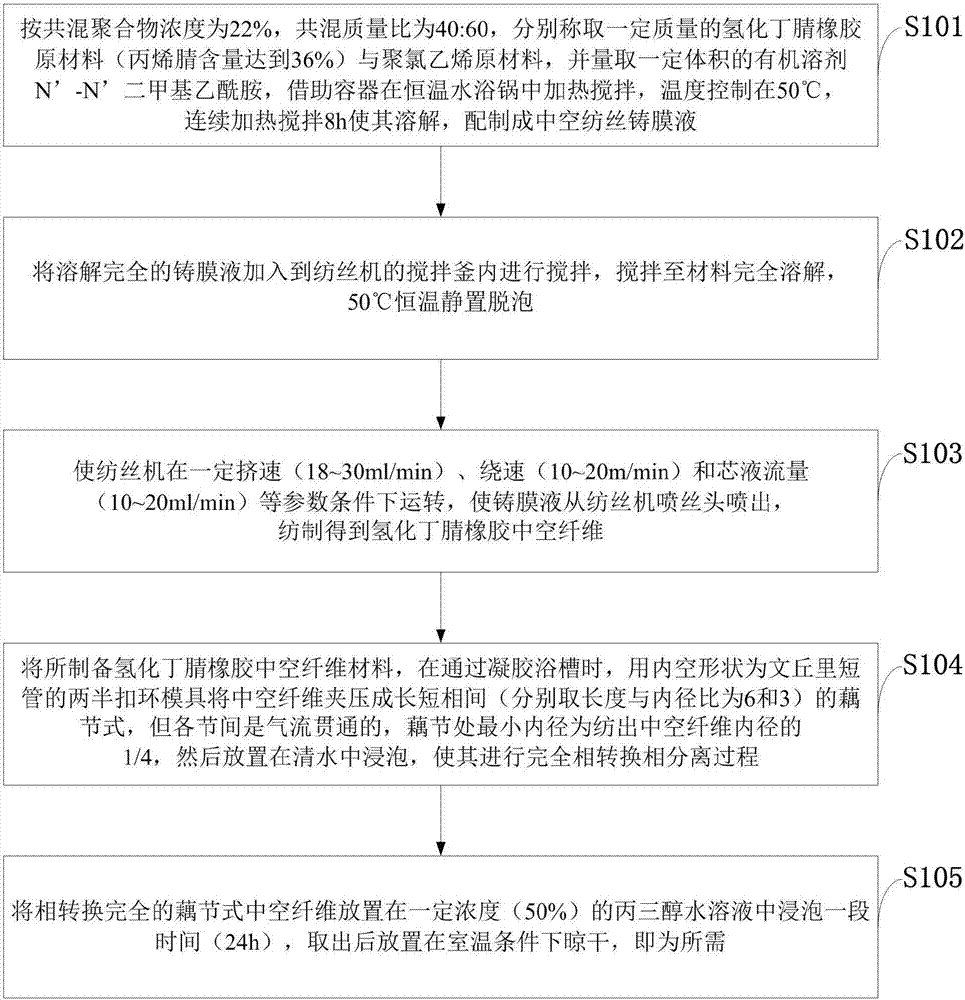

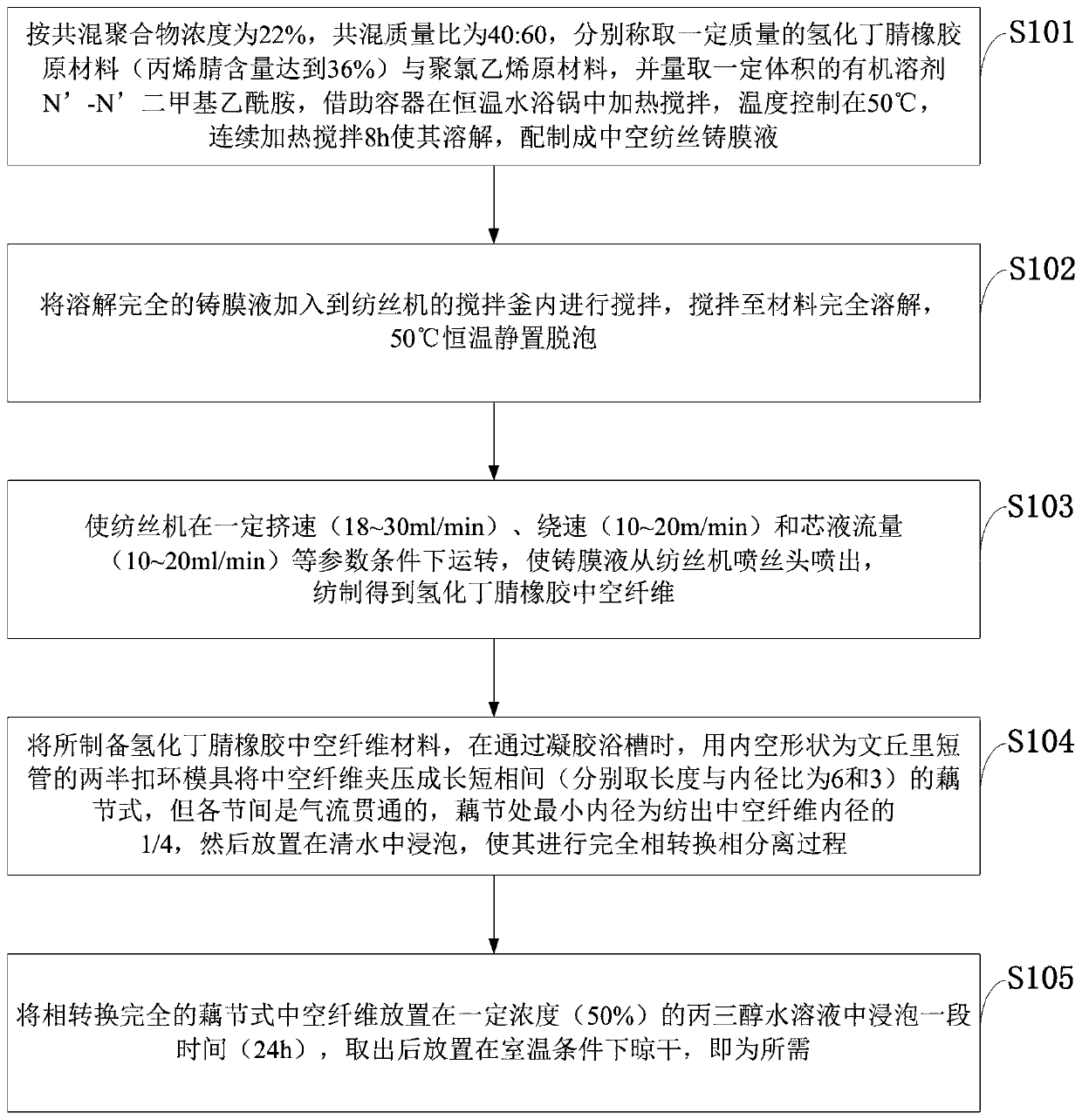

Preparation method of hollow fiber damping material with lotus root section type air bag adjustment

ActiveCN107119344ALow temperature resistantWith wear resistanceFilament/thread formingConjugated synthetic polymer artificial filamentsFiberAcrylonitrile

The invention belongs to the technical field of hollow fiber damping materials, and discloses a preparation method of a hollow fiber damping material with lotus root section type air bag adjustment. The preparation method comprises the following steps: preparing a hollow spinning film casting solution; adding the completely dissolved film casting solution into a stirring kettle of a spinning machine for stirring; spraying the film casting solution from a spinning jet of the spinning machine, thus spinning hydrogenated butadiene-acrylonitrile rubber hollow fiber; when the hollow fiber passes through a gel bath tank, clamping and pressing the hollow fiber into long and short lotus root sections through two half retaining ring dies with Venturi short tube-shaped inner cavities, and placing the lotus root sections in clean water for soaking, conversion and phase separation; standing the phase conversion-completed lotus root section type hollow fiber, taking out the hollow fiber, and drying the hollow fiber under a room temperature condition, thus obtaining the hollow fiber damping material. An adjustment method which improves the air bag damping of the hollow fiber damping material has important application value, and the problem that an air bag of the hollow fiber, of which the size is not changed along the axial direction, on the section of the hollow fiber damping material is too simple is solved.

Owner:NANCHANG HANGKONG UNIVERSITY

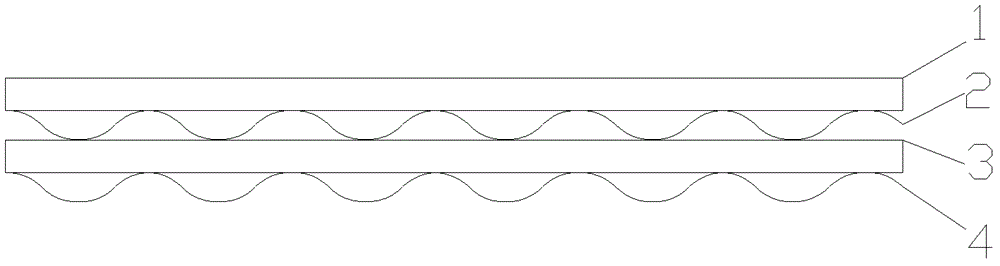

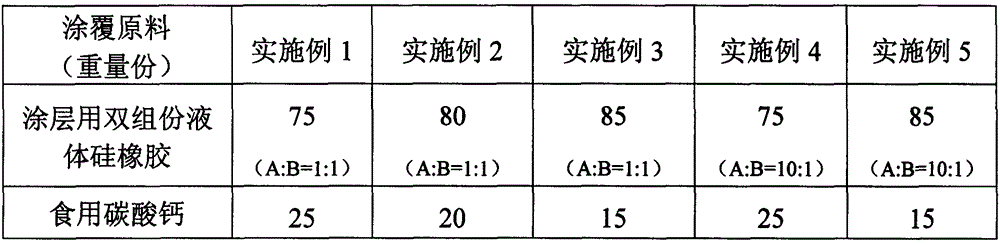

A kind of food and drug conveyor belt and preparation method thereof

ActiveCN103192560BImprove hydrolysis resistanceReduce contentConveyorsSynthetic resin layered productsCompound aFood grade

The invention relates to a food and medicine conveyor belt and a making method thereof. The conveyor belt is a four-layer structure conveyor belt formed by compounding a food grade silica gel coat, a mesh fabric interlayer, a soft PVC layer and a compact fabric substrate which are sequentially arrayed from top to bottom. The food and medicine conveyor belt is made through a hot pressing and coating technology. The preparation method comprises the following steps: setting the mesh fabric and the compact fabric, carrying out hot pressing compounding of the set mesh fabric and compact fabric and PVC, and coating the surface by a food grade silica gel to form a finished product. Compared with conveyor belts in the prior art, the conveyor belt provided by the invention has the advantages of long service life, low cost, reaching of food and medicine contact standards, and suitableness for the food and medicine fields.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Rubber material

InactiveCN109135069AImprove high temperature resistanceImprove low temperature resistanceFiberRubber material

The invention discloses a rubber material. The rubber material is prepared from, by weight, 42-70 parts of ethylene propylene rubber, 65-82 parts of aluminum oxide, 55-90 parts of titanium dioxide, 35-67 parts of graphite, 50-65 parts of carbon fibers, 1-3 parts of vegetable oil and 3-5 parts of resin. The rubber material has remarkable high-temperature resistance, low-temperature resistance, high-voltage resistance, ozone aging resistance, radiation resistance, high gas permeability and solvent resistance.

Owner:HAIMEN BIWEI INTPROP SERVICE CO LTD

Ultraviolet-resistant and weather-resistant nylon material for mudguards of automobiles and method for manufacturing ultraviolet-resistant and weather-resistant nylon material

InactiveCN105086441AHigh mechanical strengthGood weather resistanceETHYLHEXYL HYDROXYSTEARATEGlycidyl methacrylate

The invention discloses an ultraviolet-resistant and weather-resistant nylon material for mudguards of automobiles and a method for manufacturing the ultraviolet-resistant and weather-resistant nylon material. The ultraviolet-resistant and weather-resistant nylon material comprises, by weight, 38-49 parts of nylon 66, 24-38 parts of polybutylene terephthalate, 16-32 parts of polydiallylphthalate, 5-10 parts of ethylhexyl hydroxystearate, 12-16 parts of flax fibers, 11-16 parts of dicapryl phthalate, 14-22 parts of pigment soot carbon, 18-34 parts of acrylic powder, 5-10 parts of glycidyl methacrylate, 4-6 parts of phenyl salicylate, 15-25 parts of rutile powder, 4-7 parts of ricinoleamide mea, 3-5 parts of lead fumarate and 5-8 parts of auxiliaries. The ultraviolet-resistant and weather-resistant nylon material and the method have the advantages that the ultraviolet-resistant and weather-resistant nylon material manufactured by the aid of the method is high in mechanical strength and excellent in weather resistance, ozone aging resistance and impact resistance, and service requirements of the mudguards of the automobiles can be completely met.

Owner:ANHUI ANLAN MOLD

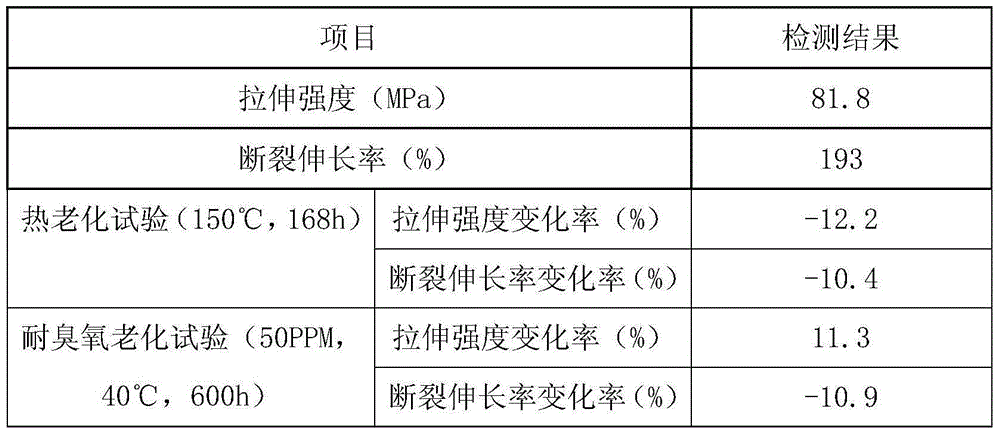

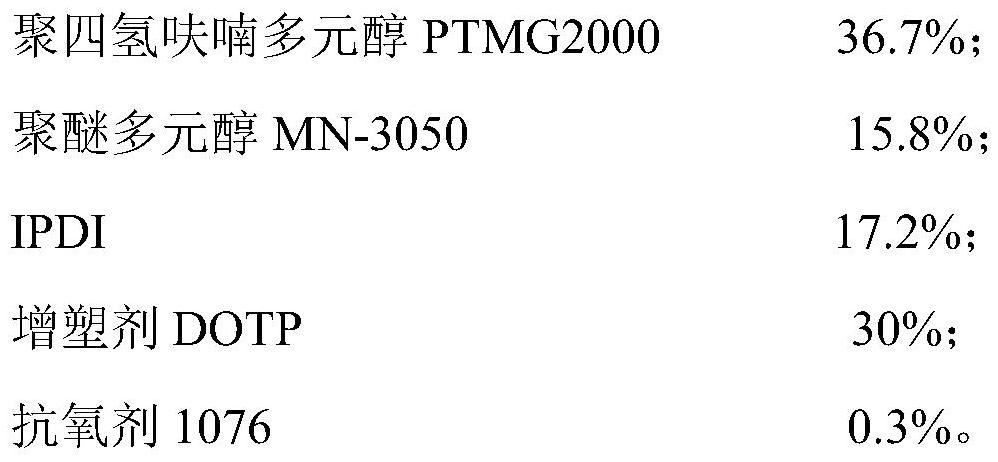

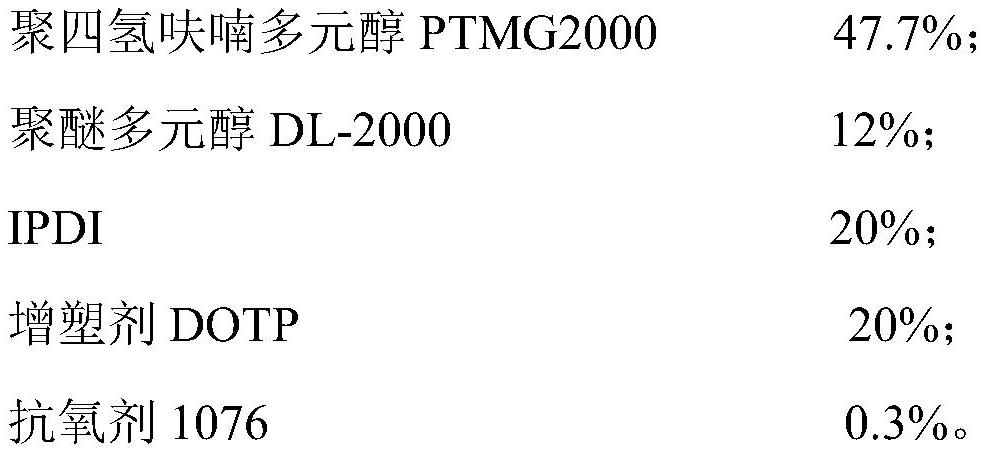

Polyurethane elastomer for fluorocarbon paint and preparation method thereof

ActiveCN109679418BAchieve room temperature curingImprove wear resistanceAntifouling/underwater paintsPaints with biocidesPolyurethane elastomerPolymer science

Owner:SHANDONG INOV POLYURETHANE

A kind of lithium battery explosion-proof gasket material and preparation method thereof

The invention discloses a lithium battery explosion-proof gasket material, which is characterized in that it is made of the following raw materials in parts by weight: 10-15 parts of fluorinated phosphazene rubber, 5-10 parts of polydiphenylsilaboroxane, ethylene 80-100 parts of base-terminated fluorosilicone rubber, 1-3 parts of initiator, 0.5-1.5 parts of phosphorus pentoxide, 10-20 parts of vinyl modified thermally conductive filler, 2-5 parts of coupling agent, 2-(2 ‑[(3‑Ethyl‑5‑methyl‑2(3H)‑benzothiazolyl)methyl]‑1‑butenyl)‑1‑(3‑sulfonic acid)naphtho[1,2‑ d] 3-6 parts of azole hydroxide inner salt, 1-3 parts of 1,3-adamantanediol monoacrylate, 1-allyl-2-(trifluoromethyl)-1H-benzo[D] 1‑3 parts of imidazole. The invention also discloses a preparation method of the lithium battery explosion-proof gasket material. The lithium battery explosion-proof gasket material disclosed by the invention has good comprehensive performance and thermal conductivity, good flame retardant insulation effect, excellent mechanical properties such as tensile strength and tear resistance, high performance stability, and long service life.

Owner:深圳市增长点科技有限公司

A preparation method of hollow fiber damping material with coupling airbag adjustment

ActiveCN107119344BWith wear resistanceMeet performance requirementsFilament/thread formingConjugated synthetic polymer artificial filamentsPhase conversionFiber

Owner:NANCHANG HANGKONG UNIVERSITY

Positive and negative pressure resistant sealing rubber strip for unit curtain wall

InactiveCN102953458AExcellent resistance to ozone agingGood weather resistanceWallsEngineeringToughened glass

The invention relates to a positive and negative pressure resistant sealing rubber strip for a unit curtain wall. The sealing rubber strip is used on the unit curtain wall which comprises a unit curtain wall aluminum alloy vertical frame and toughened glass. The unit curtain wall aluminum alloy vertical frame is fixed on the toughened glass and provided with two waterproof structures including an external waterproof structure and an internal waterproof structure. The sealing rubber strip is mounted on the inner side of the internal waterproof structure. Compared with the prior art, the positive and negative pressure resistant sealing rubber strip has the advantages of quick mounting, good water tightness and air tightness and the like.

Owner:SHANGHAI MEITE CURTAIN WALL

Explosion-proof gasket material for lithium battery and preparation method thereof

Owner:深圳市增长点科技有限公司

A low-permeability and high-adhesion conductive automobile fuel pipe and its preparation method

ActiveCN111204080BHigh bonding strengthEnhanced resistance to peelingSynthetic resin layered productsFuel supplyMechanical engineeringAramid

The invention discloses a low-permeability and high-adhesion conductive automobile fuel pipe and a preparation method thereof, which belong to the technical field of fuel pipes. Rubber layer, aramid reinforced layer, and NBR / PVC alloy layer can achieve the effect of improving the bonding strength between the layers of the fuel pipe.

Owner:ZHEJIANG JUNHE RUBBER TECH

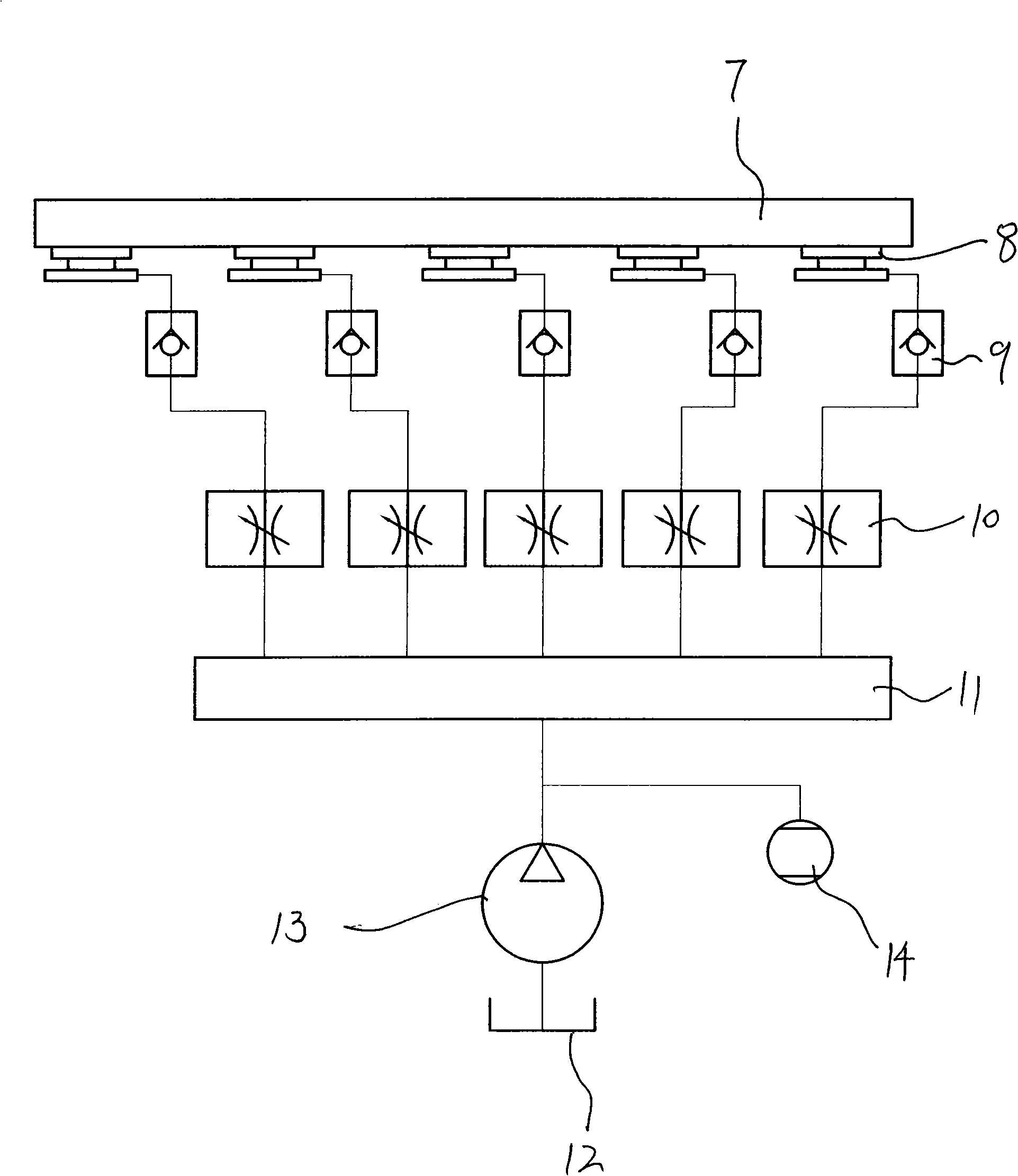

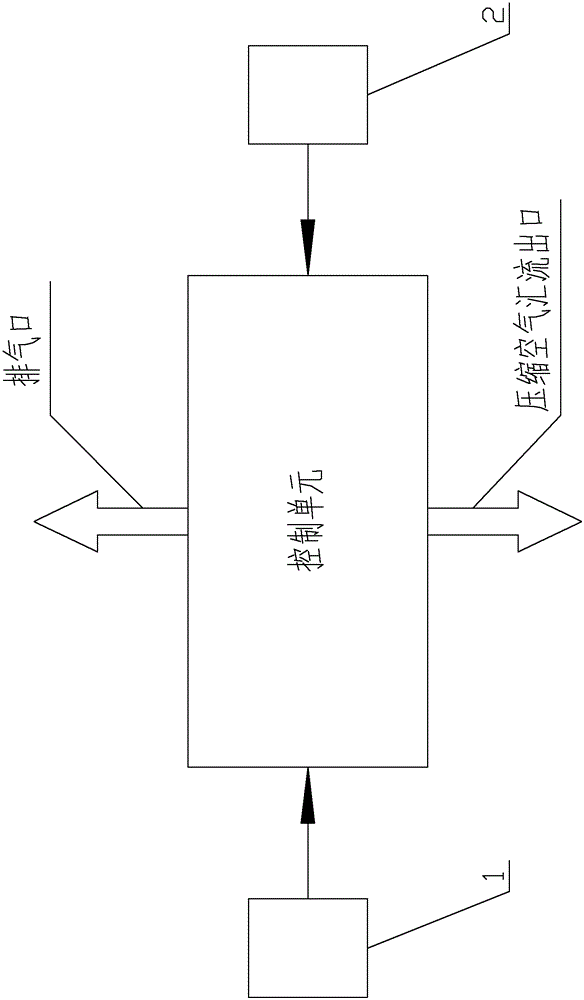

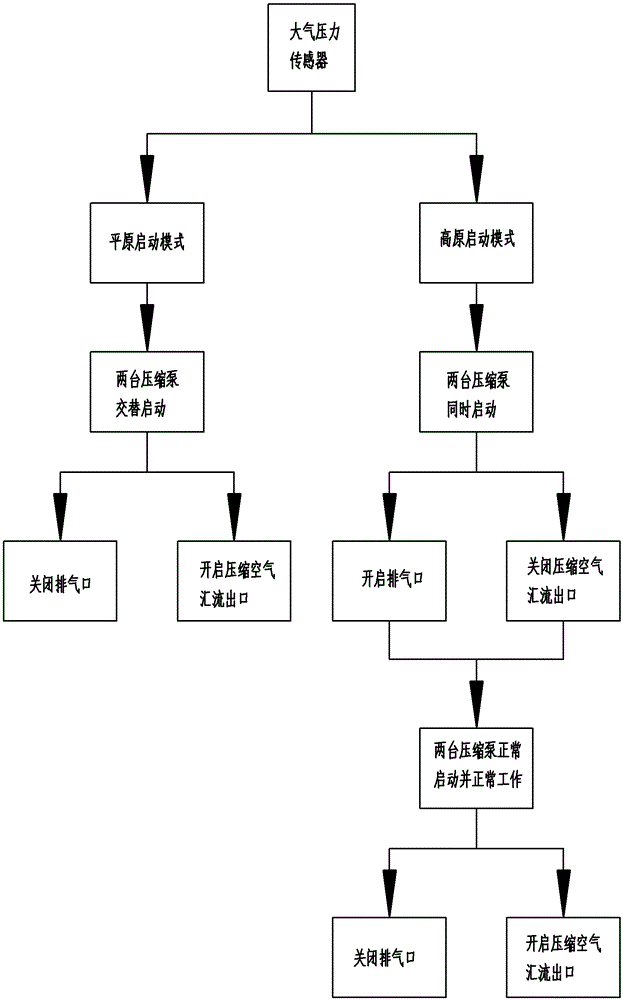

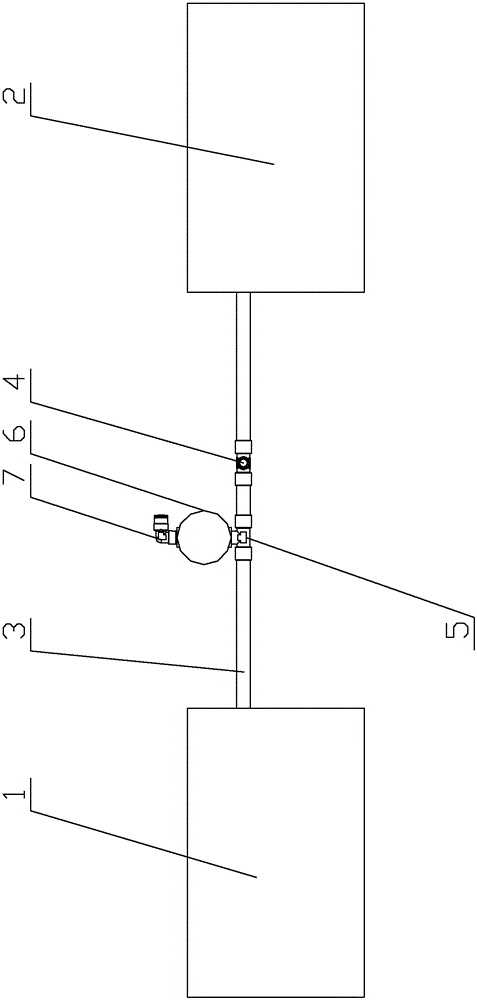

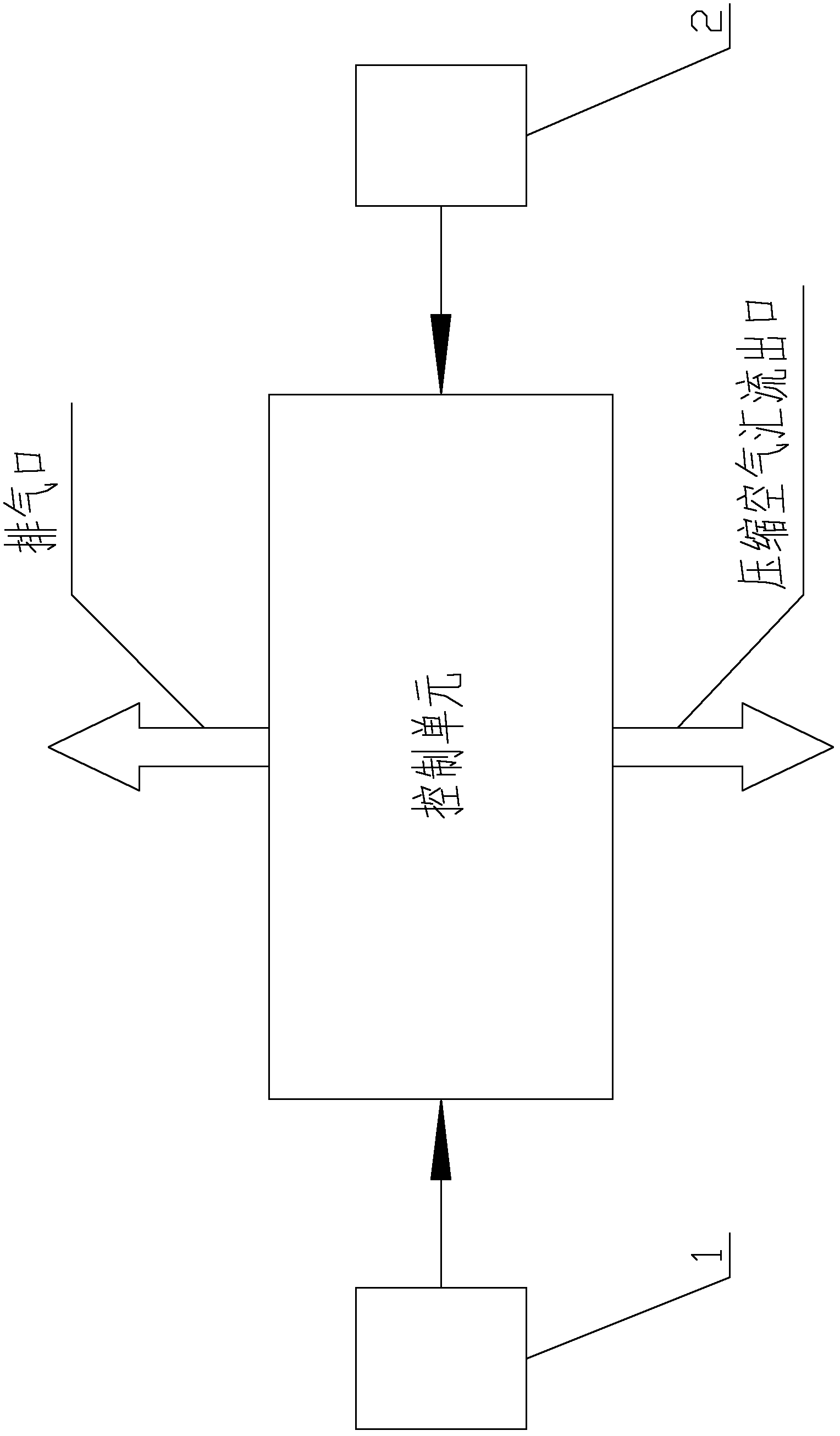

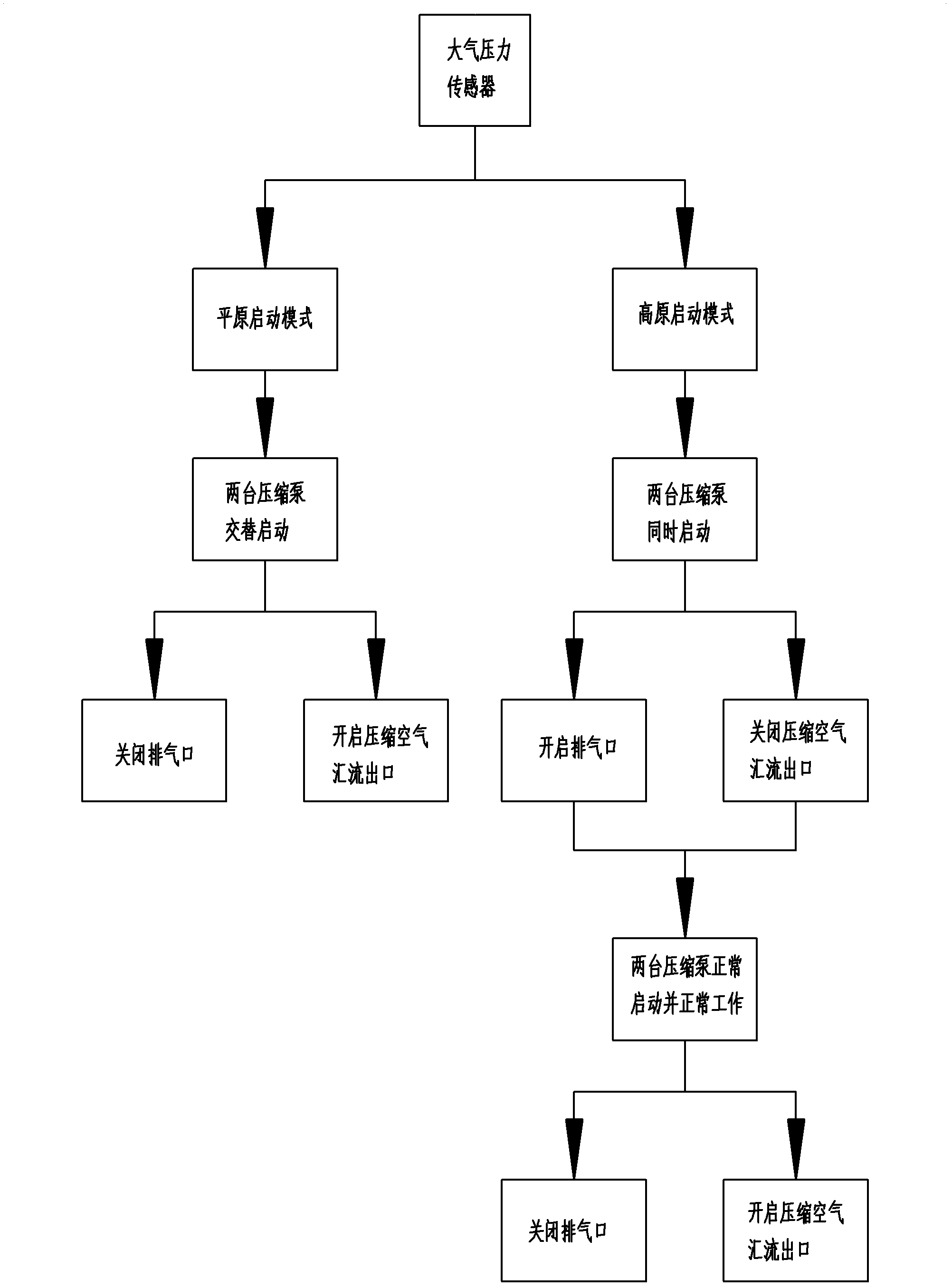

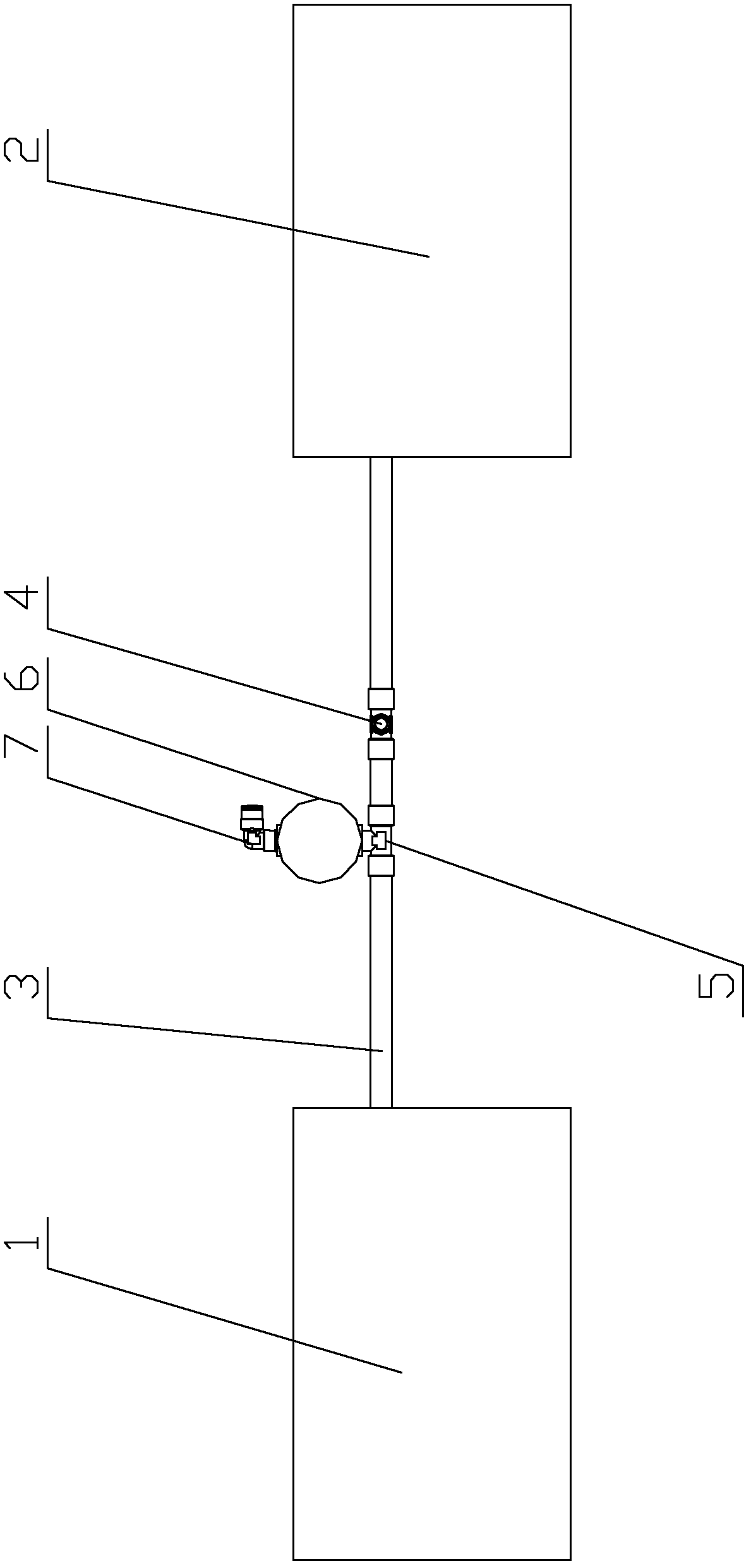

Compression pump control system for oxygen generator and its control method

ActiveCN103185001BImprove the problem of life mismatchExtended service lifePump controlPositive-displacement liquid enginesControl systemCompression Pump

The invention discloses a control system and a control method of a compression pump for an oxygenerator. Output ends of two same compression pumps are connected through a pipeline; a compressed air confluence outlet is formed in the pipeline; an air discharge opening which can be closed is formed in any one side of the pipeline; the two compression pumps are controlled by a control unit to be alternatively started or simultaneously started and the air discharge opening and the compressed air confluence outlet are controlled to be opened or closed, so that the oxygenerator is normally used in plateau and plain, and moreover the problem that one of the two compression pumps cannot be normally started as the starting speeds do not match or an air path has pressure when the two compression pumps are simultaneously started is solved, and a whole air path system can be normally and safely operated and switched.

Owner:HEYER CARE CO LTD

A kind of cross-linked hydrogenated nitrile polyurethane

ActiveCN106478924BOvercome the disadvantages of poor mechanical propertiesExcellent resistance to ozone agingCross-linkEpoxy

The invention provides cross-linked hydrogenated butyronitrile type polyurethane. The cross-linked hydrogenated butyronitrile type polyurethane is formed by cross-linking multifunctional hydrogenated terminal hydroxyl liquid nitrile rubber and isocyanato; and the multifunctional hydrogenated terminal hydroxyl liquid nitrile rubber is obtained by introducing an epoxy group in terminal hydroxyl liquid hydrogenated nitrile rubber and then introducing hydroxyl in part of the epoxy group in a ring opening manner by carboxylic acid. The invention further provides a preparation method of the cross-linked hydrogenated butyronitrile type polyurethane. By the novel cross-linked hydrogenated butyronitrile type polyurethane provided by the invention, the shortcoming that butyronitrile type polyurethane is poor in ageing resistance and not high in mechanical strength is overcome. Measurement of swelling ratio and gel fraction proves that chemical crosslink bonds are introduced in the polyurethane, and owing to introduction of the chemical crosslink bonds, the shortcoming that the mechanical property of the polyurethane is poor at high temperature due to the fact that the polyurethane is lack of the chemical crosslink bonds is also overcome.

Owner:BEIJING UNIV OF CHEM TECH

Control system and control method of compression pump for oxygenerator

ActiveCN103185001AImprove the problem of life mismatchExtended service lifePump controlPositive-displacement liquid enginesCompression PumpControl system

The invention discloses a control system and a control method of a compression pump for an oxygenerator. Output ends of two same compression pumps are connected through a pipeline; a compressed air confluence outlet is formed in the pipeline; an air discharge opening which can be closed is formed in any one side of the pipeline; the two compression pumps are controlled by a control unit to be alternatively started or simultaneously started and the air discharge opening and the compressed air confluence outlet are controlled to be opened or closed, so that the oxygenerator is normally used in plateau and plain, and moreover the problem that one of the two compression pumps cannot be normally started as the starting speeds do not match or an air path has pressure when the two compression pumps are simultaneously started is solved, and a whole air path system can be normally and safely operated and switched.

Owner:BEIJING AEONMED

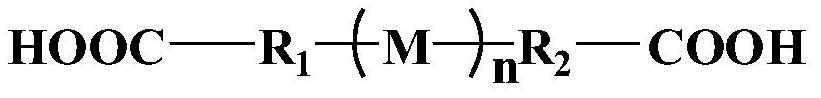

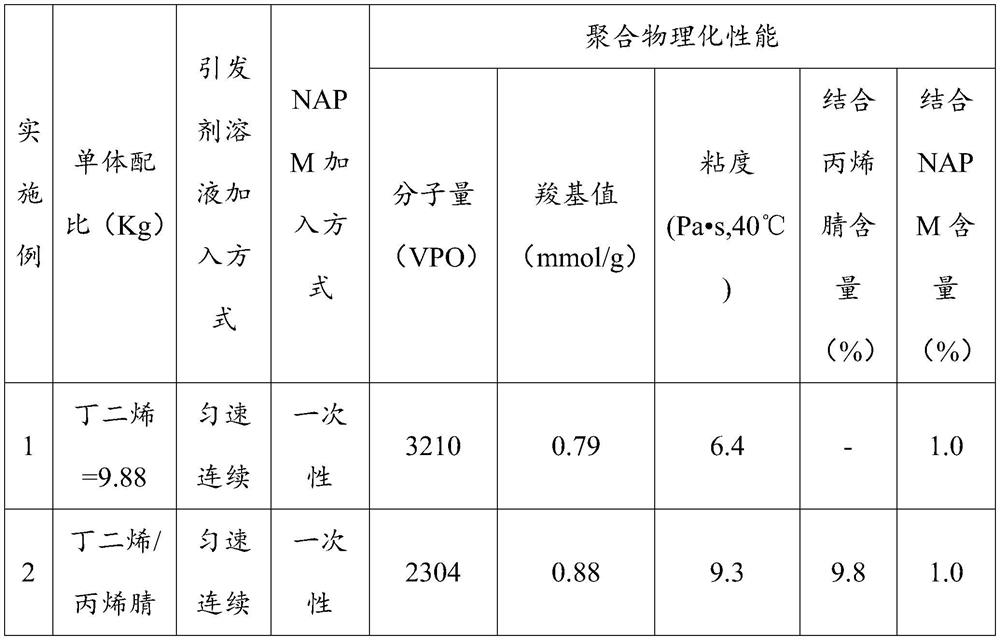

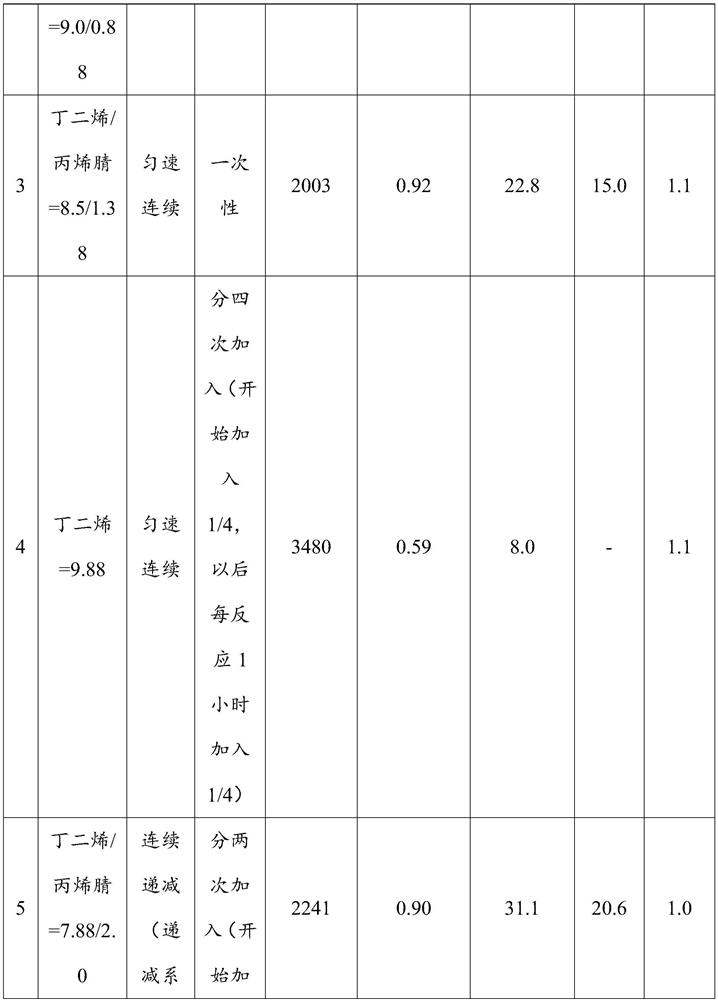

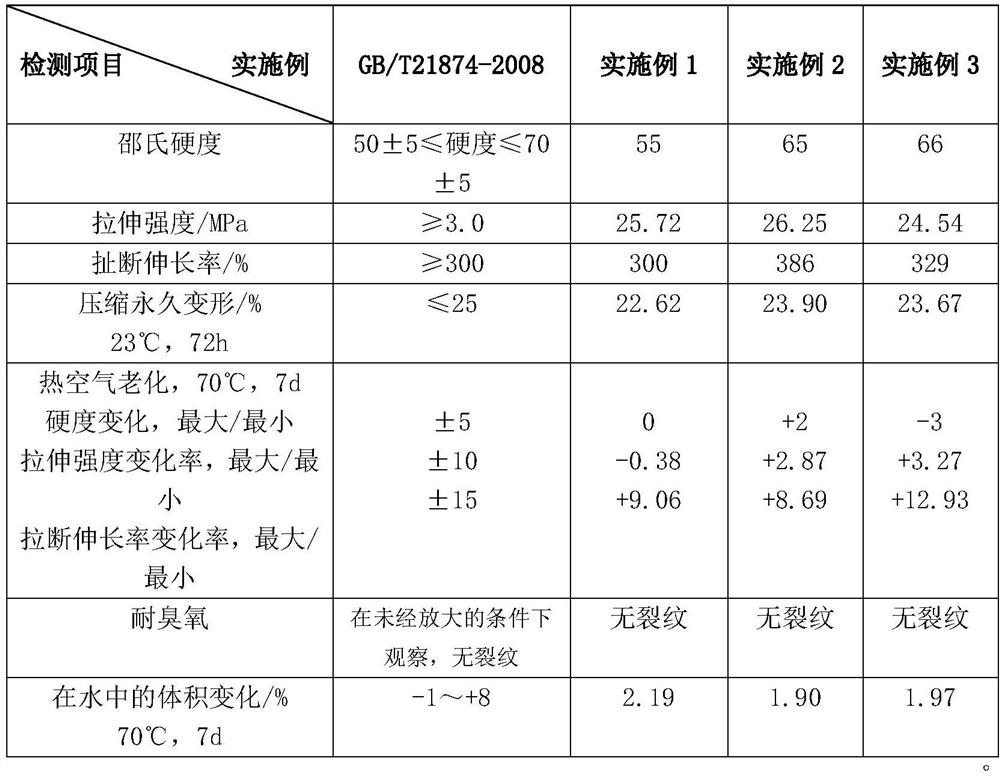

Ozone aging resistant carboxyl-terminated telechelic liquid rubber preparation method

The invention discloses an ozone aging resistant carboxyl-terminated telechelic liquid rubber preparation method, which is characterized by comprising the steps of adding a diacid peroxide or diacid azodiisobutyronitrile and a polar solvent into a preparation tank according to a mass ratio of 1: (5-10) to prepare an initiator, and stirring until the diacid peroxide or the diacid azodiisobutyronitrile is completely dissolved, adding a polymerization monomer, a reaction type anti-aging agent and the initiator into a reactor according to a mass ratio of (9.99-9.6): (0.01-0.4): (7-16), removing anupper-layer solvent from a polymerization solution through sedimentation and layering, washing with water, and drying to obtain a carboxyl-terminated telechelic oligomer. The polymerization monomer is butadiene, or the polymerization monomer is formed by mixing butadiene and acrylonitrile. Compared with CTPB and CTBN added with an anti-aging agent in a traditional physical blending manner, the CTPB and CTBN of which the molecular chains are combined with the reaction type anti-aging agent have the advantages that the ozone aging resistance is improved, the self-storage and high-temperature aging resistance are improved, and meanwhile, the aging resistance and the mechanical property of the modified epoxy resin are also improved.

Owner:天元(杭州)新材料科技有限公司

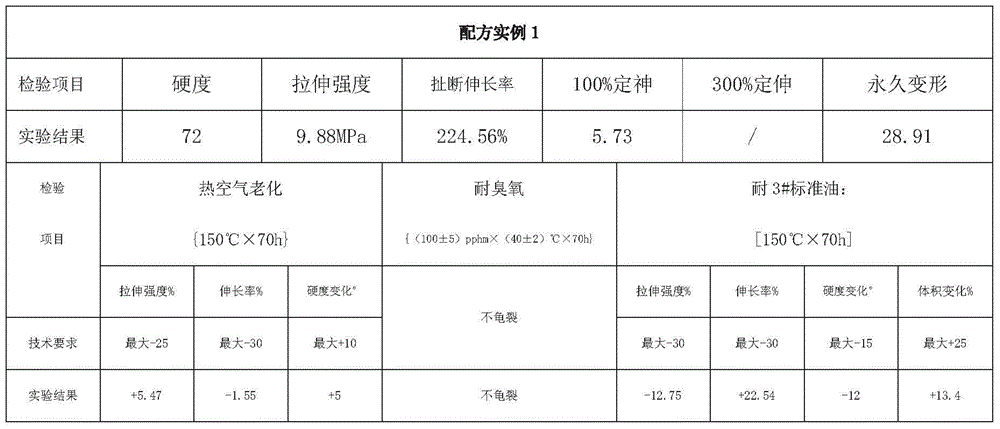

Preparation method of anti-aging tire rubber powder-based PP thermoplastic elastomer automobile part

InactiveCN113583319AExcellent resistance to ozone agingImprove performanceBuilding insulationsElastomerKneader reactor

The invention discloses a preparation method of an anti-aging tire rubber powder-based PP thermoplastic elastomer automobile part. The method comprises the steps: selecting tire rubber powder of 60 meshes or below, PP, EPDM, BR, different compatilizer systems and stearic acid SA; uniformly dispersing the tire rubber powder and powdery PP in a kneading machine, adding the mixture into EPDM / BR plasticated rubber at 160 + 5 DEG C, and uniformly mixing to obtain the mixed plastic; and adding various compounding agents into the mixed plastic, and carrying out cross-linking reaction by virtue of a dynamic cross-linking system and strong mechanical shear stress to obtain the anti-aging tire rubber powder-based PP thermoplastic elastomer automobile part. Then performance detection is carried out to obtain the tensile strength, the elongation at break, the compression set, the water resistance, the thermo-oxidative aging hardness change, the tensile strength change rate and the elongation at break change rate; and when the samples are tested and free of cracks under the ozone aging resistance condition, it is shown that the ozone aging resistance is excellent.

Owner:XUZHOU COLLEGE OF INDAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com