Polyurethane elastomer for fluorocarbon paint and preparation method thereof

A polyurethane elastomer and fluorocarbon paint technology, which is applied in the field of polyurethane elastomer, can solve the problems of poor aging resistance, poor gloss and color retention, and difficulty in controlling the construction ratio of fluorocarbon paint coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

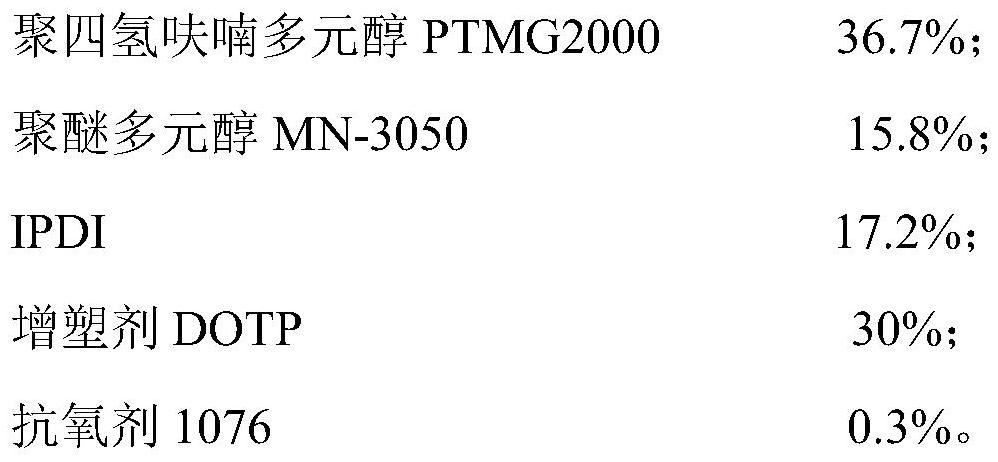

[0033] Raw materials and their mass percentages are as follows:

[0034] A component:

[0035] Fluorocarbon resin CF-803 99.5%;

[0036] Bismuth catalyst CX-18 0.5%;

[0037] B component:

[0038]

[0039] (1) Mix fluorocarbon resin CF-803 and bismuth catalyst CX-18 evenly to obtain component A;

[0040] (2) Mix polytetrahydrofuran polyol PTMG2000, polyether polyol MN-3050, and plasticizer DOTP, heat up to 100°C, vacuum dehydrate to moisture content <0.05%; cool down to 60°C, add IPDI, antioxidant in turn 1076, react at 90°C for 5 hours, vacuum defoaming, and obtain a prepolymer with an isocyanate content of 4.3%, which is the B component;

[0041] (3) Mix component A and component B according to the mass ratio A:B=100:100 to obtain polyurethane elastomer for fluorocarbon paint.

Embodiment 2

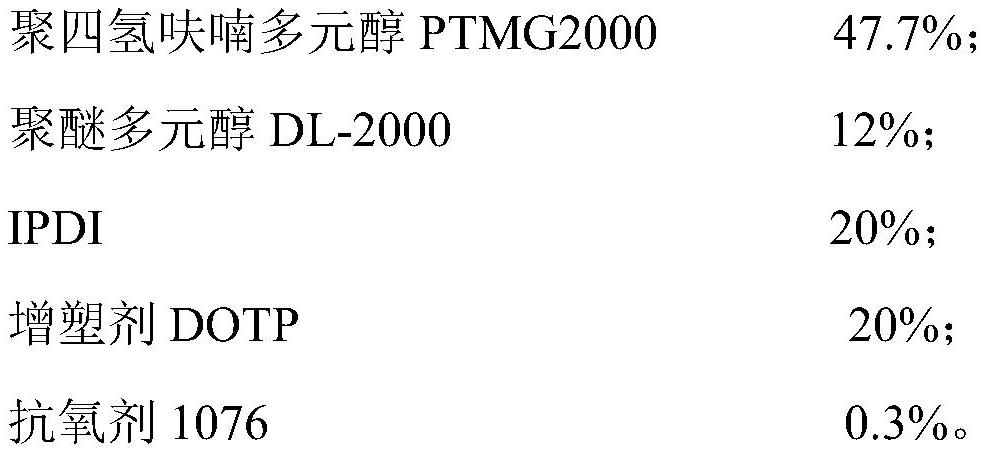

[0043] Raw materials and their mass percentages are as follows:

[0044] A component:

[0045] Fluorocarbon resin CF-803 99.7%;

[0046] Tin catalyst T-9 0.3%;

[0047] B component:

[0048]

[0049] (1) Mix fluorocarbon resin CF-803 and tin catalyst T-9 evenly to obtain component A;

[0050] (2) Mix polytetrahydrofuran polyol PTMG2000, polyether polyol DL-2000, and plasticizer DOTP, heat up to 120°C, vacuum dehydrate to moisture content <0.05%; cool down to 40°C, add IPDI, antioxidant in turn 1076, reacted at 80°C for 4 hours, degassed in vacuum to obtain a prepolymer with an isocyanate content of 5.0%, which is the B component;

[0051] (3) Mix component A and component B according to the mass ratio A:B=120:100 to obtain polyurethane elastomer for fluorocarbon paint.

Embodiment 3

[0053] Raw materials and their mass percentages are as follows:

[0054] A component:

[0055] Fluorocarbon resin CF-803 99.7%;

[0056] Tin catalyst T-9 0.3%;

[0057] B component:

[0058]

[0059] (1) Mix fluorocarbon resin CF-803 and tin catalyst T-9 evenly to obtain component A;

[0060] (2) Mix polytetrahydrofuran polyol PTMG2000 and plasticizer DOP, heat up to 100°C, vacuum dehydrate to moisture content 12 MDI and antioxidant PDP were reacted at 90°C for 4 hours, and vacuum degassed to obtain a prepolymer with an isocyanate content of 6.5%, which was component B;

[0061] (3) Mix component A and component B according to the mass ratio A:B=150:100 to obtain polyurethane elastomer for fluorocarbon paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com