A kind of halogen-free flame-retardant hand lay-up epoxy resin composition and preparation method thereof

An epoxy resin, hand lay-up molding technology, applied in the field of halogen-free flame retardant epoxy resin composition and its preparation, halogen-free flame retardant hand lay-up molding epoxy resin composition and its preparation field, can solve the problem of unenvironmental raw materials, Low impact toughness, fast gel time of epoxy resin composition, etc., to achieve high flame retardant and toughening effect, improve flame retardant performance, high impact toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of a halogen-free flame-retardant hand lay-up epoxy resin composition, the operation is as follows:

[0043] (1) Preparation of component A

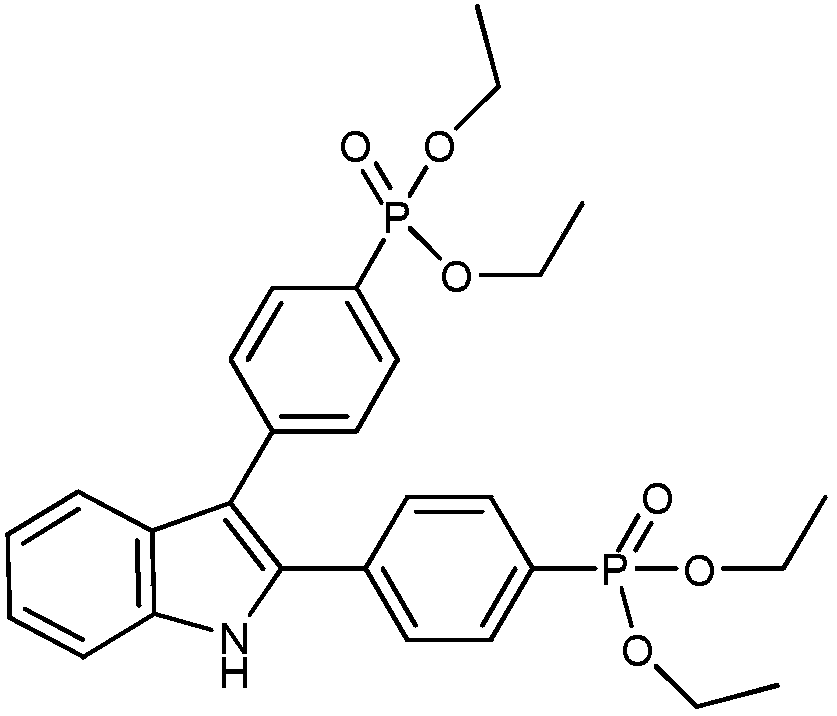

[0044] Put 55 parts by weight of bisphenol A type epoxy resin, 25 parts by weight of aluminum hydroxide, and 20 parts by weight of the new indole phosphonate flame retardant into the stirring tank, and put the resin into the first packaging barrel after stirring;

[0045] (2) Preparation of component B

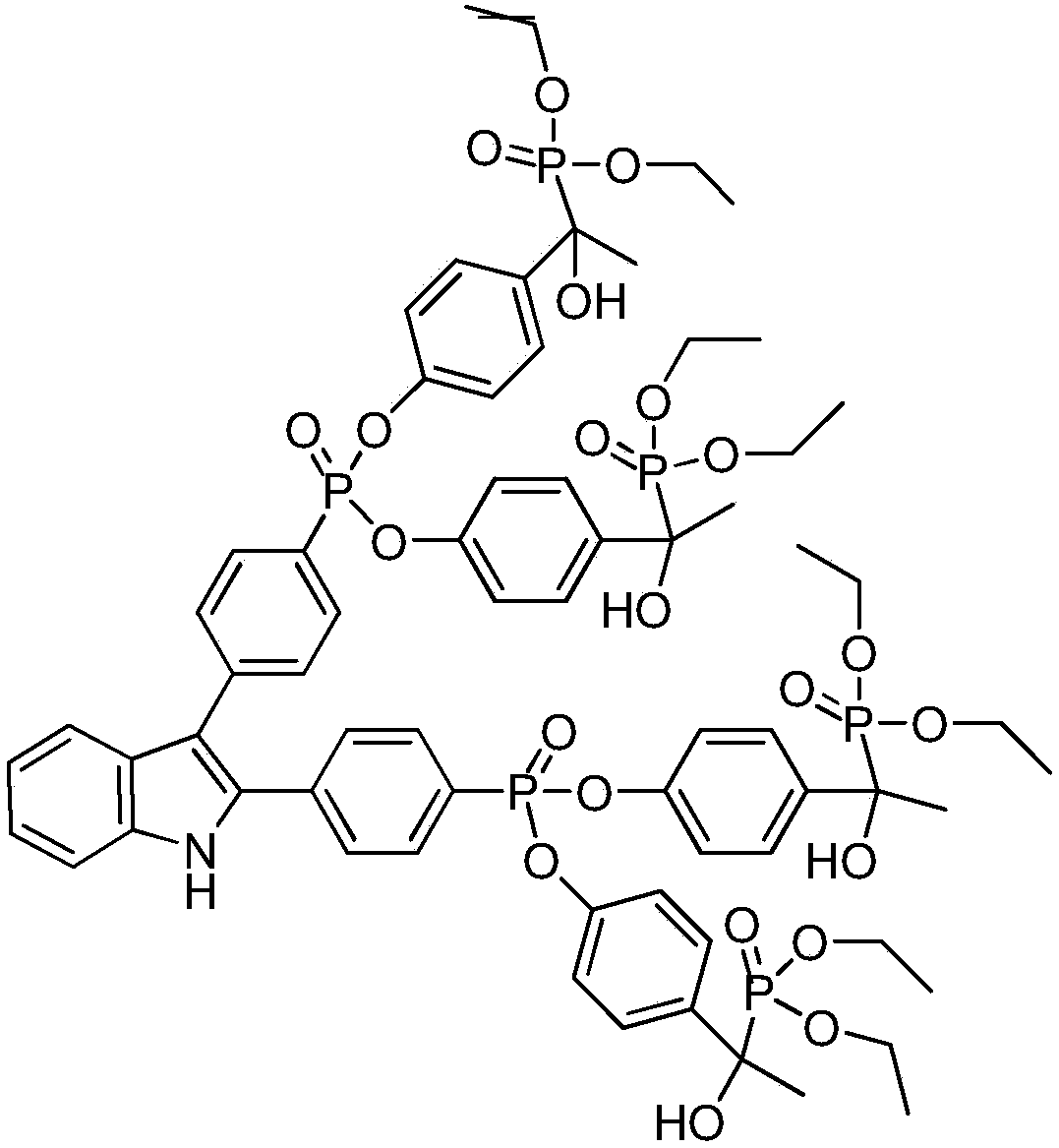

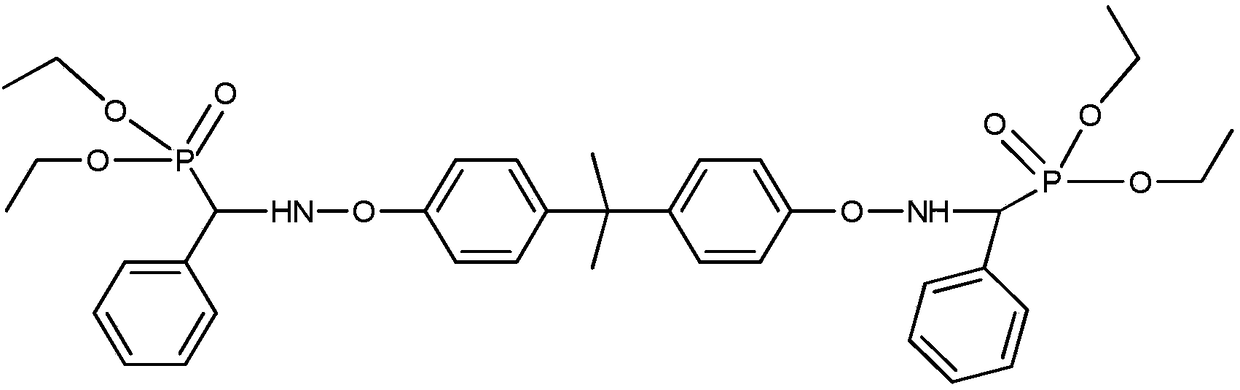

[0046] Put 20.9 parts by weight of α-aminophosphonate and 15 parts by weight of bisphenol A into the reactor, raise the temperature to 50°C, react for 0.5h, cool down to room temperature, then add 9 parts by weight of isophorone diamine, m-phthalylene 40 parts by weight of amine, 15 parts by weight of indole phosphonate flame retardant of novel quaternary carbon α-hydroxyl and 0.1 part of anilinomethyltriethoxysilane, stirred at room temperature for 2.5h at a stirring speed of 50r / min, pumped After 5 minutes o...

Embodiment 2

[0049] A preparation method of a halogen-free flame-retardant hand lay-up epoxy resin composition, the operation is as follows:

[0050] (1) Preparation of component A

[0051] Put 60 parts by weight of bisphenol A type epoxy resin, 24 parts by weight of aluminum hydroxide, and 16 parts by weight of a new type of indole phosphonate flame retardant into a stirring tank, and put the resin into packaging barrel 1 after stirring;

[0052] (2) Preparation of component B

[0053] Put 25 parts by weight of α-aminophosphonate and 8 parts by weight of bisphenol A into the reactor, raise the temperature to 60°C, react for 1 hour, cool down to room temperature, then add 10 parts by weight of isophoronediamine, m-xylylenediamine 40 parts by weight, 16 parts by weight of indole phosphonate flame retardant of novel quaternary carbon α-hydroxyl and 0.5 parts by weight of anilinomethyltrimethoxysilane, 0.5 part by weight of γ-aminopropyltrimethoxysilane, at room temperature Stir at a stirri...

Embodiment 3

[0056] A preparation method of a halogen-free flame-retardant hand lay-up epoxy resin composition, the operation is as follows:

[0057] (1) Preparation of component A

[0058] Put 58 parts by weight of epoxy resin, 23 parts by weight of aluminum hydroxide; 19 parts by weight of the new indole phosphonate flame retardant into the stirring tank, and put the resin into the first packaging barrel after stirring;

[0059] (2) Preparation of component B

[0060] Put 20 parts by weight of α-aminophosphonate and 12 parts by weight of bisphenol A into the reaction kettle, raise the temperature to 65°C, react for 0.8h, cool down to room temperature, then add 12 parts by weight of isophorone diamine, m-phthalamide 40 parts by weight of methylamine, 15 parts by weight of a novel quaternary carbon α-hydroxyl indole phosphonate flame retardant and 1 part by weight of γ-aminopropyl triethoxysilane, stirred at a stirring speed of 60 r / min for 2 hours at room temperature , stop stirring aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com