A phosphate-based anti-corrosion coating for steel bars

An anti-corrosion coating, phosphate technology, applied in the coating, metal material coating process and other directions, can solve the problems of easy damage, loss of steel protection effect, etc., to achieve good bonding performance, dense structure, good coating performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

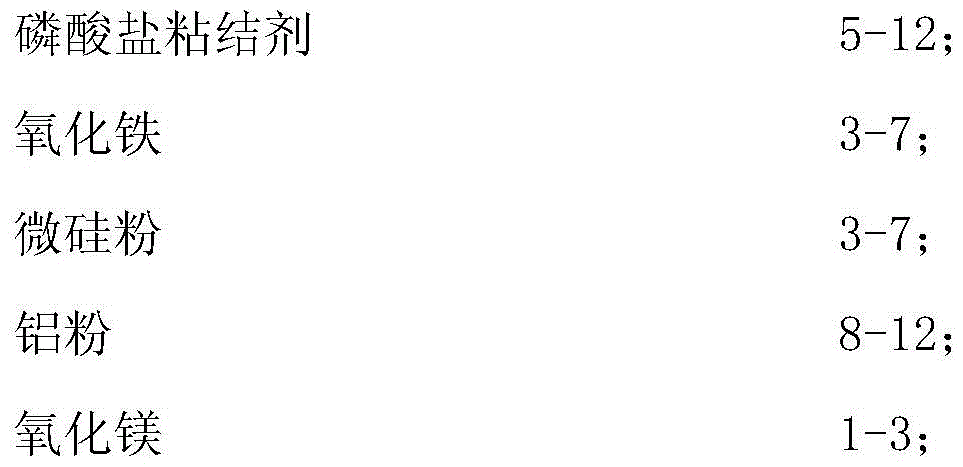

[0024] A phosphate-based steel anticorrosion coating is prepared from phosphate binder, iron oxide, micro-silica fume, aluminum powder, magnesium oxide, and aldehyde-based resin modifier raw materials, and the parts by weight of each raw material are listed in the table 1.

[0025] Table 1 raw material ratio

[0026]

[0027]

[0028] Prepared as follows:

[0029] 1) Add aluminum hydroxide to phosphoric acid, heat and keep it at 70-90°C for 3-5h to obtain a phosphate binder;

[0030] 2) taking the phosphate binder as the base liquid, adding an aldehyde-based resin modifier, iron oxide, micro-silica fume, aluminum powder and magnesium oxide, grinding and stirring evenly to obtain a phosphate coating;

[0031] Iron oxide is used as pigment and filler, which also has anti-corrosion effect.

[0032] Microsilica fume is a filler for phosphate coatings, improving the viscosity and compactness of coatings.

[0033] Magnesium oxide is used as a curing agent to achieve room t...

Embodiment A-F

[0040] For the anti-corrosion phosphate-based coating material, the parts by weight of each raw material are shown in the table below. The preparation process is the same as above.

[0041] The parts by weight of each raw material in table 3

[0042]

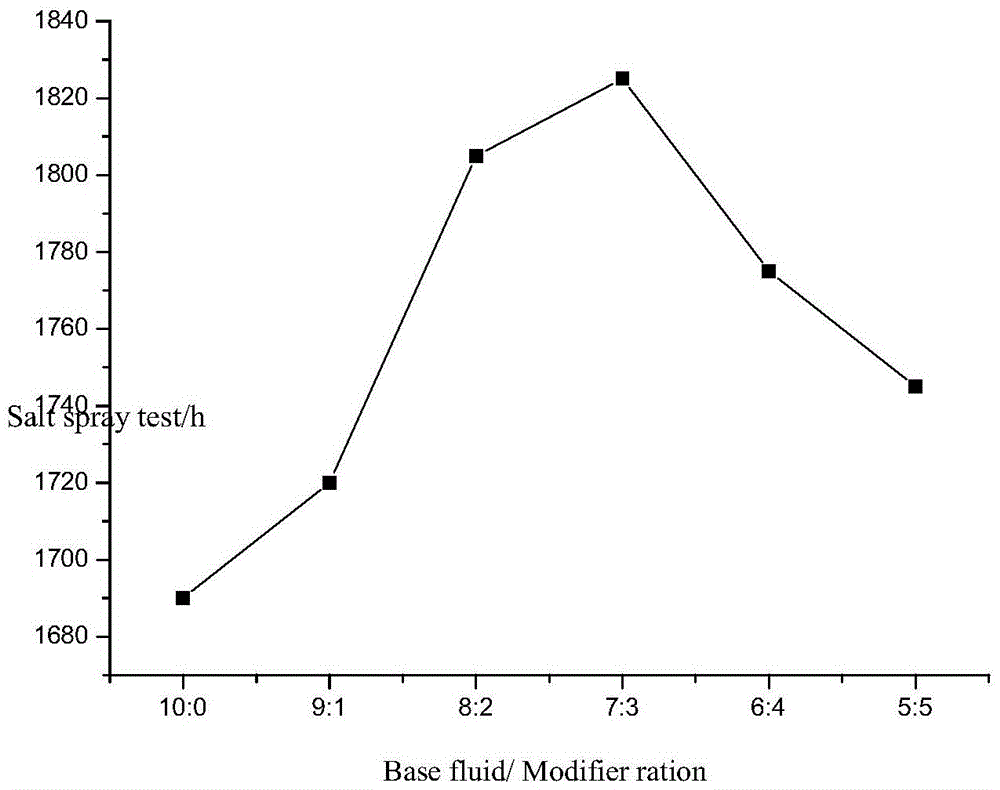

[0043] The salt spray resistance performance of the obtained phosphate coating material refers to the attached figure 1 shown. From figure 1 The effect of the amount of aldehyde-based resin modifier added on the salt spray resistance of the coating can be seen that the salt spray resistance time of the phosphate coating starts to increase with the decrease of the proportion; when the proportion is 7:3, the salt spray resistance The fog time is 1825h; then as the ratio decreases, the salt spray resistance time begins to decrease again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com