Preparation method of anti-aging ethylene-propylene rubber powder-based EVA thermoplastic elastomer sealing element

A thermoplastic elastomer, ethylene propylene rubber powder technology, used in building components, building insulation materials, construction and other directions, can solve the problems of being unsuitable for making high-end products, RPTPE has a strong smell, poor performance stability, etc. The effect of excellent ozone aging performance and reduction of raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

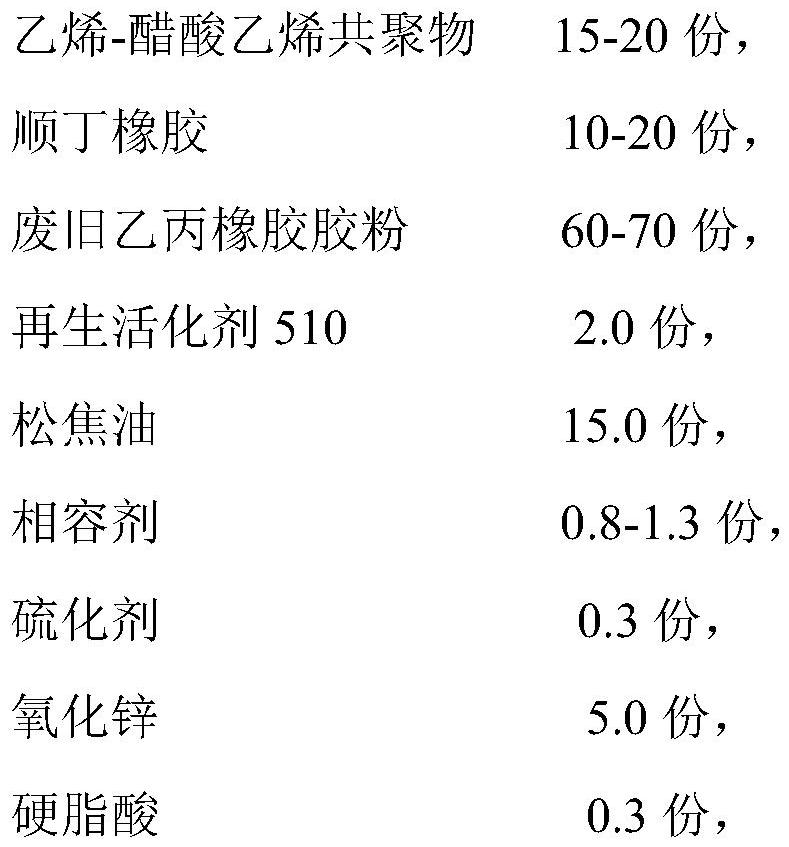

Method used

Image

Examples

Embodiment 1

[0022] Activate 21Kg, 100 mesh and above waste ethylene-propylene rubber powder at 200°C for 30 minutes.

[0023] At room temperature, masticate 4.5Kg butadiene rubber for 5 minutes, and disperse the above-mentioned activated ethylene-propylene rubber fine powder of 100 mesh or above and 4.5Kg transparent EVA particles in a kneader. The butadiene rubber plastic compound is added to the above-mentioned mixture and kneaded evenly to obtain a kneaded plastic.

[0024] Add 0.09Kg, sulfur, 0.33Kg, compatibilizer BIBP, 1.5Kg, zinc oxide, 0.09Kg, stearic acid, 0.09Kg, antioxidant 1010 to the mixed plastic in the twin-screw extruder at 180°C, Disperse evenly, and carry out cross-linking reaction with the help of dynamic cross-linking system and strong mechanical shear stress to obtain ethylene-propylene rubber powder-based thermoplastic elastomer for EVA water pipes, and molded into sheets.

Embodiment 2

[0026] Activate 21Kg of 100 mesh and above waste ethylene-propylene rubber powder at 200°C for 30 minutes.

[0027] At room temperature, 3.0Kg butadiene rubber was masticated for 5 minutes, and the above-mentioned activated ethylene-propylene rubber fine powder of 100 mesh and above and 6.0Kg transparent ethylene-vinyl acetate copolymer EVA particles were uniformly dispersed in a kneader. Add the above-mentioned mixture to the butadiene rubber plastic compound at +5°C and knead evenly to obtain a kneaded plastic.

[0028] Add 0.09Kg of sulfur, 0.33Kg of compatibilizer BIBP, 1.5Kg of zinc oxide, 0.09Kg of stearic acid, 0.09Kg of antioxidant 1010 and other compounding agents into the kneading plastic in a twin-screw extruder at 180°C to disperse evenly. When rubber powder, plastic resin and various compounding agents are reacted and compounded, the dynamic cross-linking system and strong mechanical shear stress are used to carry out cross-linking reaction to obtain ethylene-prop...

Embodiment 3

[0030] Activate 18Kg of 100 mesh and above waste ethylene-propylene rubber powder at 200°C for 30 minutes.

[0031] Masticate 6.0Kg butadiene rubber for 5 minutes at room temperature, disperse the activated ethylene-propylene rubber fine powder of 100 mesh or above and 6.0Kg transparent EVA particles in a kneader, The above-mentioned mixture is added to the butadiene rubber plastic compound and kneaded evenly to obtain a kneaded plastic.

[0032] Add 0.09Kg, sulfur, 0.33Kg, compatibilizer BIBP, 1.5Kg, zinc oxide, 0.09Kg, stearic acid, 0.09Kg, antioxidant 1010 to the mixed plastic in the twin-screw extruder at 180°C, Disperse evenly, and carry out cross-linking reaction with the help of dynamic cross-linking system and strong mechanical shear stress to obtain ethylene-propylene rubber powder-based thermoplastic elastomer for EVA water pipes, and molded into sheets.

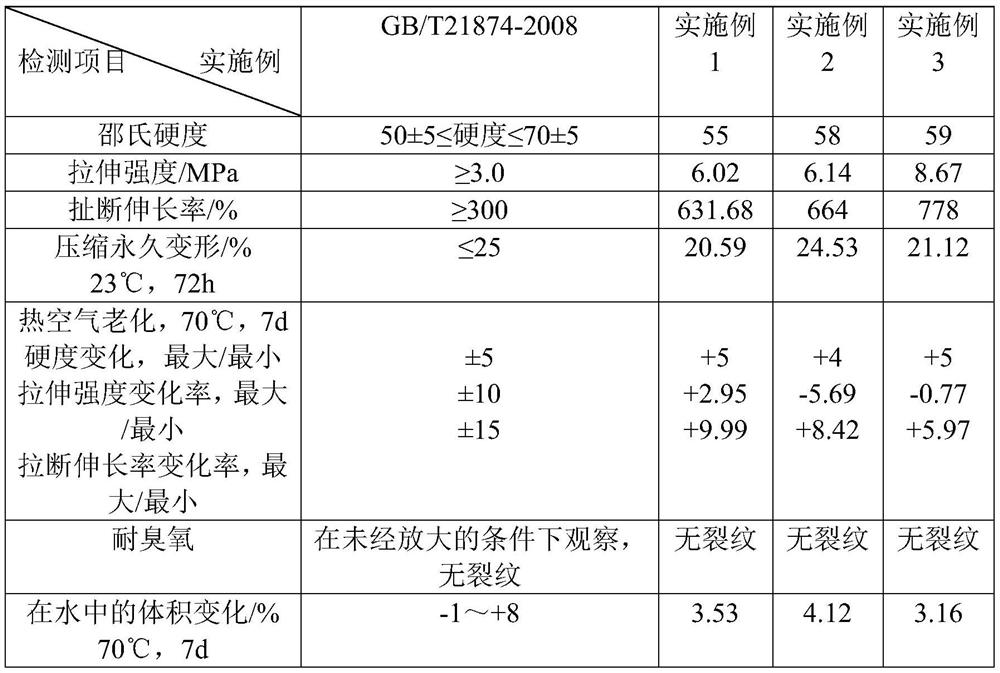

[0033] Perform performance testing according to GB / T21874-2008,

[0034] Table 1 Performance of thermoplastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| elongation change rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com