Control system and control method of compression pump for oxygenerator

A control system and compression pump technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as failure to start normally, start speed mismatch, etc., to achieve improved service life mismatch, rapid response, and precise control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

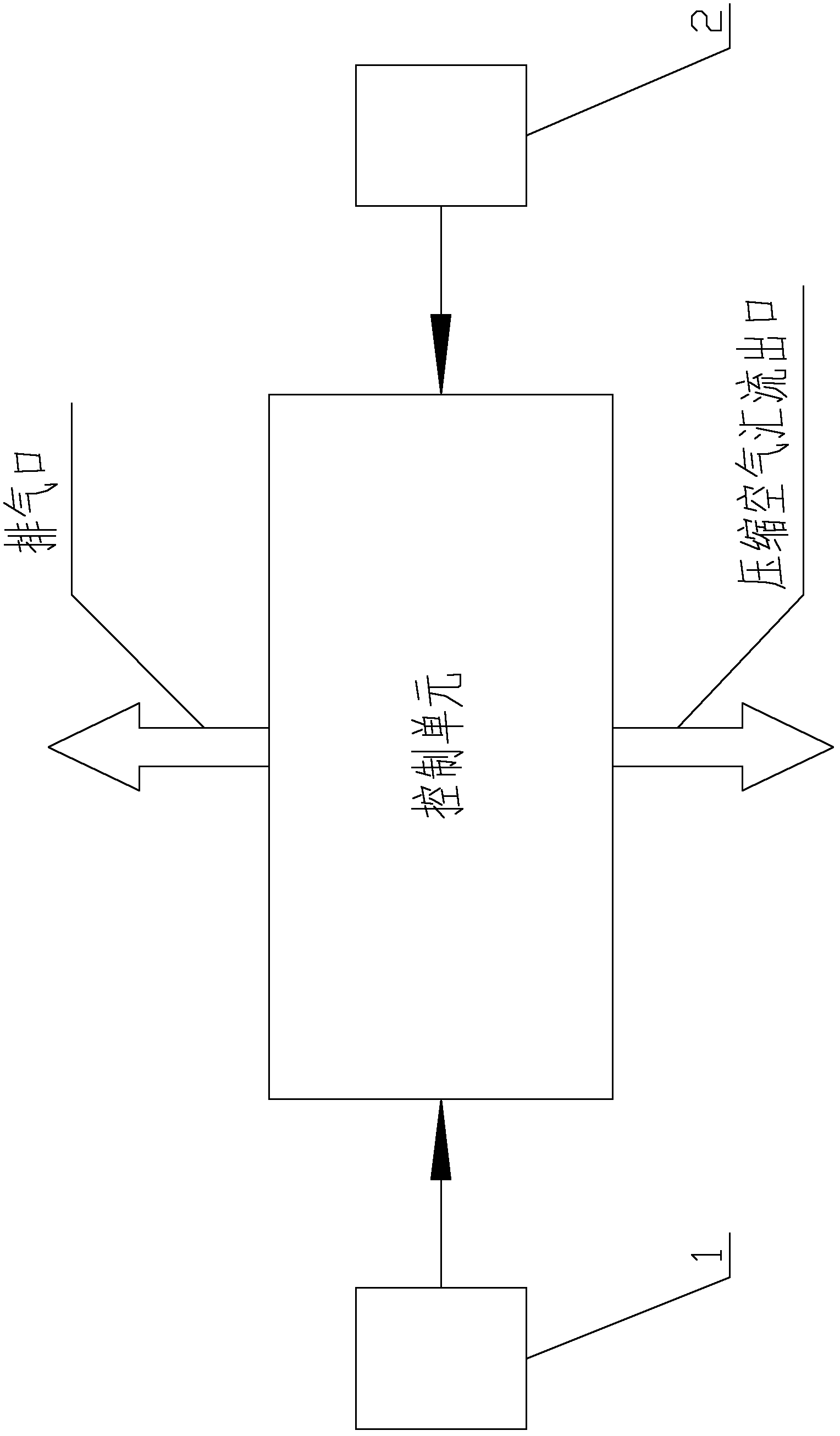

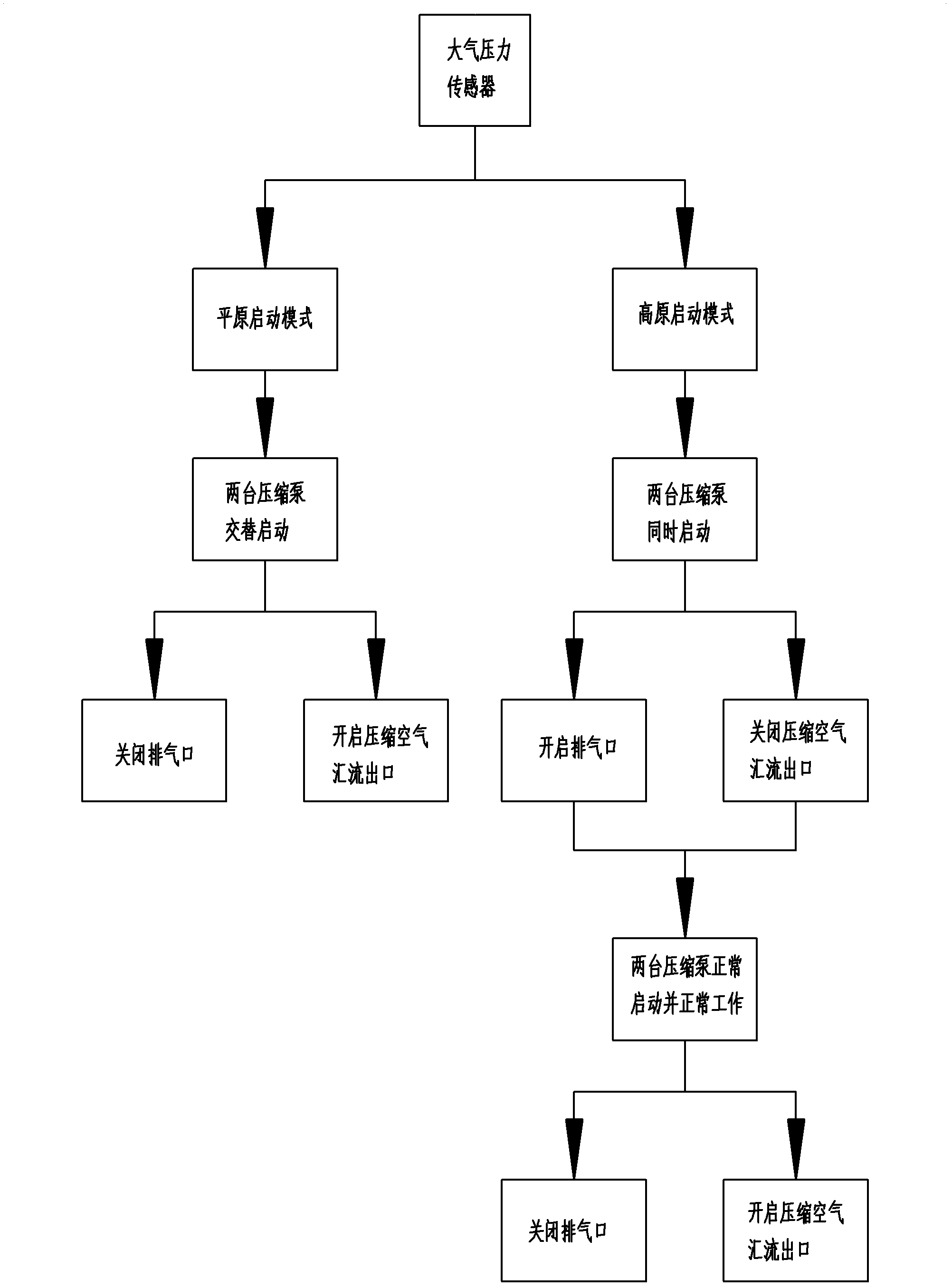

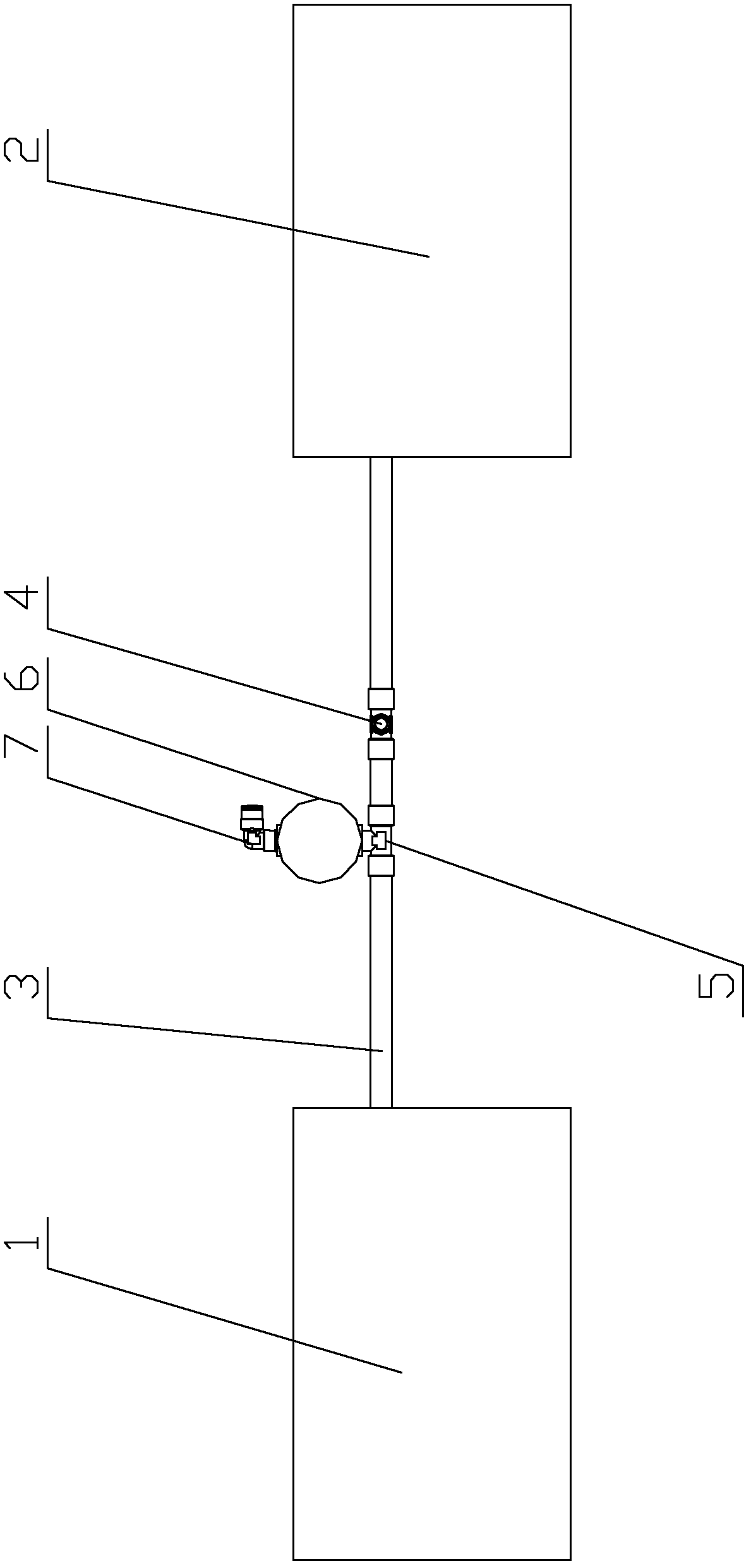

[0039] Such as figure 1 , 2 As shown, in a preferred embodiment of the present invention, the oxygen generator compressor pump control system includes two identical first compressor pumps 1, second compressor pumps 2 and control units, and the first compressor pump A silicone tube 3 is installed between the output end of 1 and the output end of the second compression pump 2, and the first three-way pipe joint 4 is installed on the silicone tube 3, and it is used as a compressed air converging outlet. On the silicone tube 3 on the left side of 4, that is, close to the first compression pump 1, a second three-way pipe joint 5 is installed, and a two-position two-way solenoid valve 6 is installed at its exhaust port, and a two-position two-way solenoid valve 6 is installed. The valve 6 is equipped with a push-in joint 7 that can turn back and is used as an exhaust port.

[0040] At the same time, the barometric pressure sensor is included in the control unit.

[0041] When wor...

Embodiment 2

[0045] Such as figure 1 , 3 As shown, in a preferred embodiment of the present invention, the oxygen generator compressor pump control system includes two identical first compressor pumps 1, second compressor pumps 2 and control units, and the first compressor pump A silicone tube 3 is installed between the output end of 1 and the output end of the second compression pump 2, and the first three-way pipe joint 4 is installed on the silicone tube 3, and it is used as a compressed air converging outlet. On the silicone tube 3 on the right side of 4, that is, near the second compression pump 2, a second three-way pipe joint 5 is installed, and a two-position two-way solenoid valve 6 is installed at its exhaust port, and a two-position two-way solenoid valve The valve 6 is equipped with a push-in joint 7 that can turn back and is used as an exhaust port.

[0046] At the same time, the barometric pressure sensor is included in the control unit.

[0047] When working, after the ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com