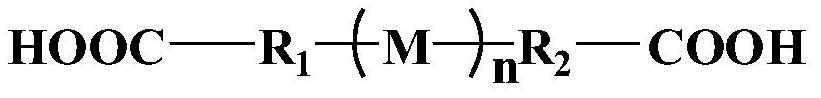

Ozone aging resistant carboxyl-terminated telechelic liquid rubber preparation method

A technology of ozone aging-resistant liquid rubber, which is applied in the field of preparation of ozone-resistant carboxyl-terminated telechelic liquid rubber, which can solve the problems of aging resistance decline, anti-aging agent volatilization and migration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

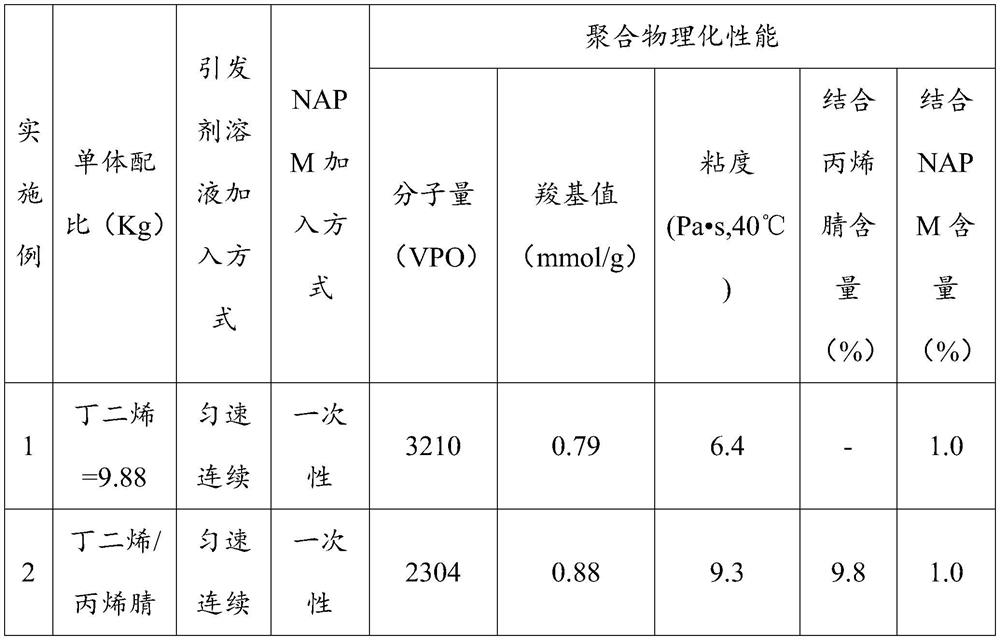

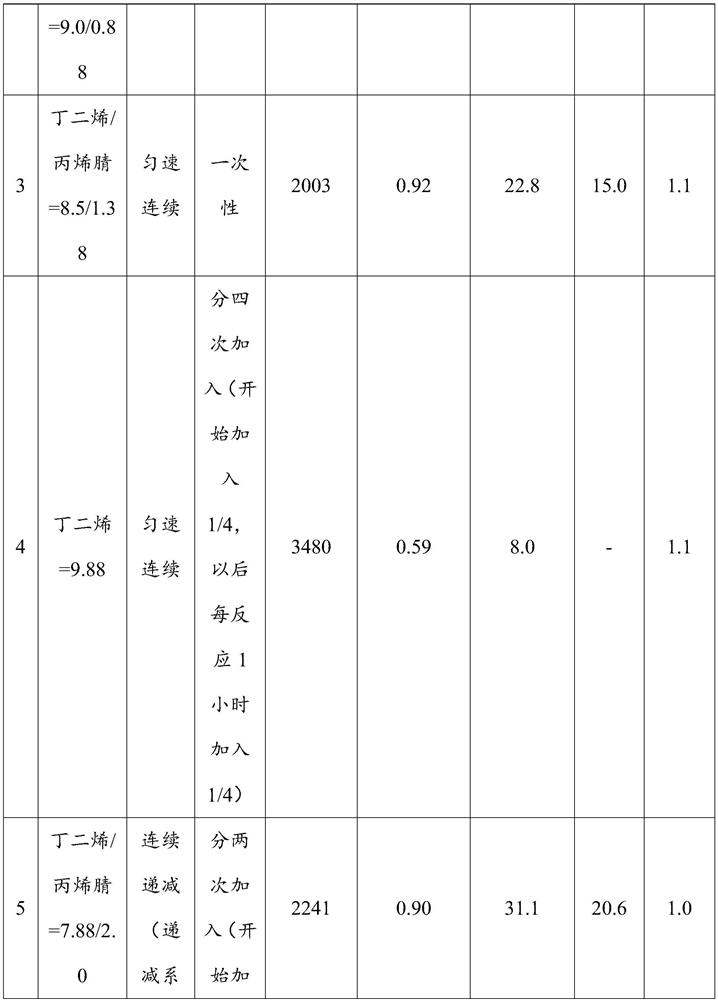

Embodiment 1

[0028] Add glutaric acid peroxide and absolute ethanol into the preparation tank to configure the initiator according to the mass ratio of 1:7, and stir after adding until the glutaric acid peroxide is completely dissolved in absolute ethanol to obtain glutaric acid peroxide without Water ethanol solution (being initiator);

[0029] Add 9.88Kg of butadiene, 0.12Kg of N-(4-anilinophenyl)methacrylamide and 13Kg of absolute ethanol solution of glutaric acid peroxide into a 50L pressure-resistant polymerization kettle, the reaction temperature is 110°C, and the reaction time is 4 Hour. After the polymerization is completed, the polymerization solution is settled, washed and dried to obtain the product. Among them, glutaric acid peroxide absolute ethanol solution is added continuously at a uniform speed, and N-(4-anilinophenyl)methacrylamide is added at one time.

[0030] The absolute ethanol in this embodiment can be replaced by any one or any mixture of two or more of methanol,...

Embodiment 2

[0033] Add glutaric acid peroxide and absolute ethanol into the preparation tank to configure the initiator according to the mass ratio of 1:7, and stir after adding until the glutaric acid peroxide is completely dissolved in absolute ethanol to obtain glutaric acid peroxide without Water ethanol solution (being initiator);

[0034] Add butadiene, acrylonitrile total 9.88Kg (proportion butadiene / acrylonitrile=9.0 / 0.88), N-(4-anilinophenyl) methacrylamide 0.12Kg and Oxyglutaric acid absolute ethanol solution 13Kg, reaction temperature 110°C, reaction time 4 hours. After the polymerization is completed, the polymerization solution is settled, washed and dried to obtain the product. Among them, glutaric acid peroxide absolute ethanol solution is added continuously at a uniform speed, and N-(4-anilinophenyl)methacrylamide is added at one time.

[0035]The absolute ethanol in this embodiment can be replaced by any one or any mixture of two or more of methanol, n-propanol, isoprop...

Embodiment 3

[0038] Add glutaric acid peroxide and absolute ethanol into the preparation tank to configure the initiator according to the mass ratio of 1:7, and stir after adding until the glutaric acid peroxide is completely dissolved in absolute ethanol to obtain glutaric acid peroxide without Water ethanol solution (being initiator);

[0039] Add butadiene, acrylonitrile total 9.88Kg (proportion butadiene / acrylonitrile=8.5 / 1.38), N-(4-anilinophenyl) methacrylamide 0.12Kg and Oxyglutaric acid absolute ethanol solution 13Kg, reaction temperature 110°C, reaction time 4 hours. After the polymerization is completed, the polymerization solution is settled, washed and dried to obtain the product. Among them, glutaric acid peroxide absolute ethanol solution is added continuously at a uniform speed, and N-(4-anilinophenyl)methacrylamide is added at one time.

[0040] The absolute ethanol in this embodiment can be replaced by any one or any mixture of two or more of methanol, n-propanol, isopro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com