A kind of cross-linked hydrogenated nitrile polyurethane

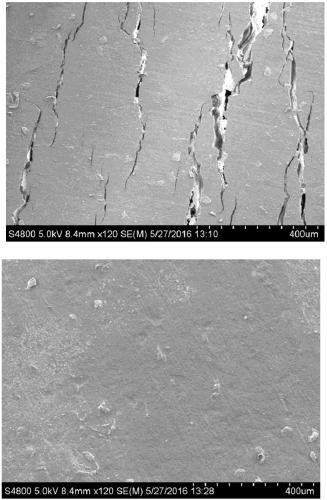

A hydrogenated nitrile and polyurethane technology, which is applied in the field of cross-linked hydrogenated nitrile polyurethane and its preparation, can solve problems such as low mechanical properties, poor ozone aging resistance, and affecting product performance, so as to broaden the application range and overcome Poor aging resistance, overcoming the effect of low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

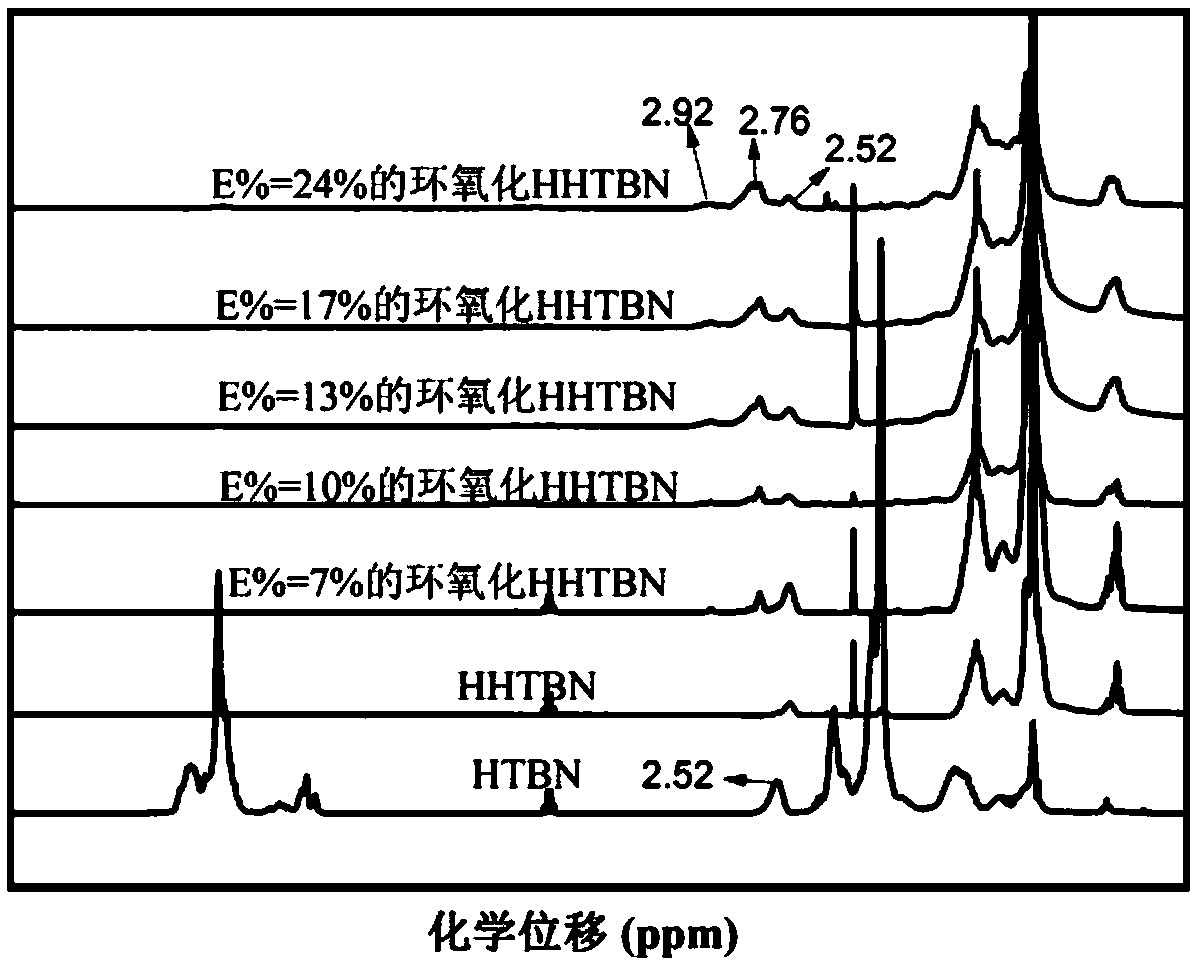

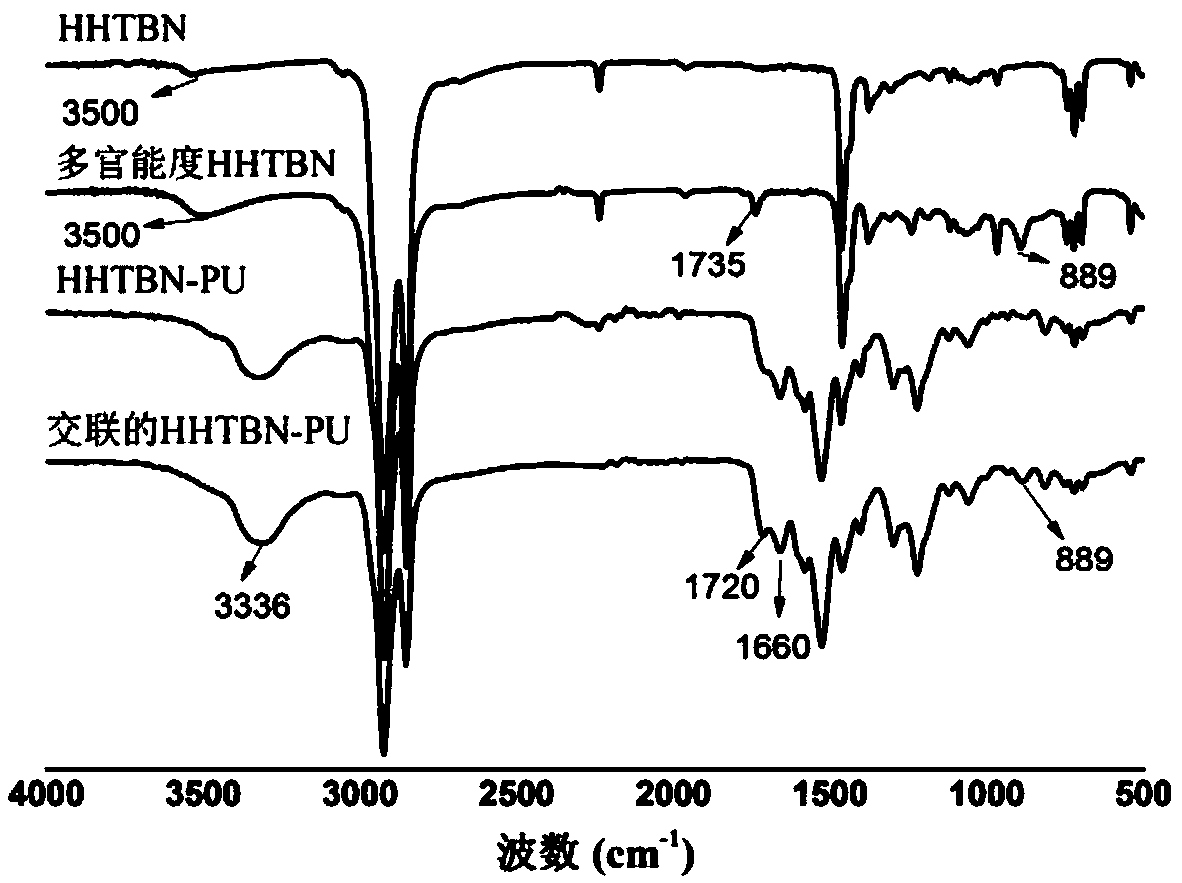

[0035] (1) Get hydroxyl-terminated liquid nitrile rubber (HTBN) and be dissolved in xylene, be mixed with the solution of mass fraction 10wt%; Get 300g above-mentioned solution in the 500ml there-necked bottle, add 29.88g acetic acid, then add dropwise hydrogen peroxide solution ( Aladdin reagent, mass fraction 30%) 84.66g, stirred and reacted at 65°C for 4h. The reacted mixed solution is precipitated, washed, and dried to obtain epoxidized hydroxyl-terminated liquid nitrile rubber (EHTBN), and the epoxy degree E%=7% is calculated by nuclear magnetic detection.

[0036] (2) use xylene as solvent, EHTBN is made into the glue solution that mass concentration is 10%, adds glue solution 250g in autoclave, adds Wilkinson catalyst 0.2g again, ligand triphenylphosphine 0.6g, The temperature was 110° C. and the hydrogen pressure was 4 MPa, and the hydrogenation reaction was carried out for 8 hours. After the reaction, a hydroxyl-terminated liquid hydrogenated nitrile rubber (E-HHTBN) ...

Embodiment 2

[0040]The step (1) epoxidation time is extended to 6h, and other conditions remain unchanged, namely obtain EHTBN of E%=10%; The higher the epoxidation degree of EHTBN will make the product hydroxyl obtained by step (3) ring-opening reaction Value is higher; Therefore, the isocyanate content of step (4) gained prepolymer reduces, and its value is 5.49% after measuring, calculates according to material proportion, needs to add MOCA quality and be 2.62g.

[0041] Other operations are the same as in Example 1.

Embodiment 3

[0043] Prolong step (1) epoxidation time to 8h, other conditions remain unchanged, namely obtain the EHTBN of E%=13%; The epoxidation degree of EHTBN is higher, will make the product hydroxyl that step (3) ring-opening reaction obtains Value is higher; Therefore, the isocyanate content of step (4) gained prepolymer reduces, and its value is 4.89% after measuring, calculates according to material proportion, needs to add MOCA quality and is 2.33g.

[0044] Other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com