Preparation method of anti-aging tire rubber powder-based PP thermoplastic elastomer automobile part

A technology for thermoplastic elastomers and auto parts, applied in the field of material manufacturing, to achieve excellent ozone aging resistance, large market space, and significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

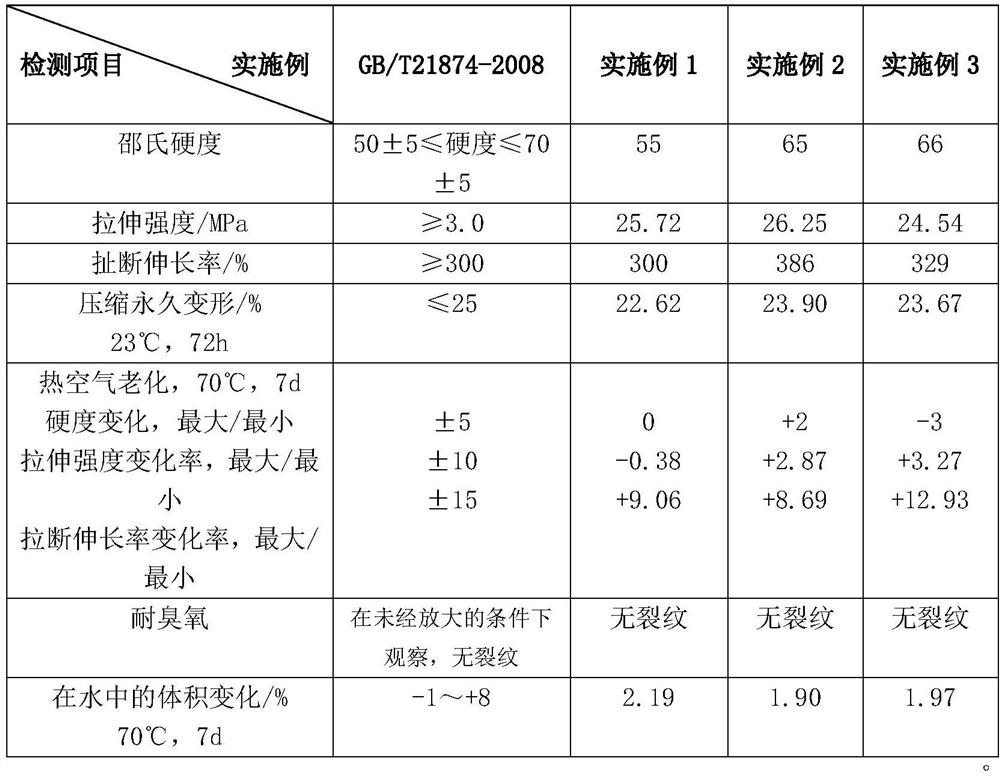

Examples

Embodiment 1

[0020] Various raw materials and their mass parts are: PP, 15 parts; EPDM, 10 parts; BR, 10 parts; 60 mesh and below tire rubber powder, 65 parts; regeneration activator 510, 2.0 parts; pine tar oil, 15.0 parts ; Compatibilizer BIBP, 1.1 parts; Vulcanizing agent S 8 , 0.3 parts; zinc oxide ZnO, 5.0 parts; stearic acid SA, 0.3 parts; antioxidant 1010, 0.3 parts;

[0021] Its preparation method, carry out as follows:

[0022] Step 1) Activate 19.5Kg of 60-mesh tire rubber powder at 200°C×30min; mix and masticate 3.0Kg, EPDM, 3.0Kg, and BR at room temperature for 5 minutes to obtain plasticized rubber, and then make the activated 60-mesh Tire rubber powder and 4.5Kg of powdered PP are uniformly dispersed in a kneader to obtain a compound, and the compound is added to the plasticized rubber at 160+5°C and kneaded evenly to obtain a compounded plastic.

[0023] Add 0.09Kg, sulfur S 8 , 0.33Kg, BIBP, 1.5Kg, zinc oxide ZnO, 0.09Kg, stearic acid SA, 0.09Kg, antioxidant 1010, unifor...

Embodiment 2

[0026] Various raw materials and their mass parts are: PP, 15 parts, EPDM, 15 parts, BR, 10 parts, 60 mesh and below tire rubber powder, 60 parts, regeneration activator 510, 2.0 parts, pine tar oil, 15.0 parts , compatibilizer BIBP, 1.1 parts, HDPE-g-MAH, 8.0 parts, vulcanizing agent S 8 , 0.3 parts, zinc oxide ZnO, 5.0 parts, stearic acid SA, 0.3 parts, antioxidant 1010, 0.3 parts.

[0027] Its preparation method, carry out as follows:

[0028] Step 1) Activate 18.0Kg of 60-mesh tire rubber powder under the condition of 200°C×30min. At room temperature, 4.5Kg, EPDM, 3.0Kg, and BR were masticated for 5 minutes to obtain masticated rubber, and then the 60-mesh tire rubber powder and 4.5Kg powdered PP were uniformly dispersed in a kneader to obtain a mixture. Add the mixture to the plasticized rubber at ℃, and knead evenly to obtain the kneaded plastic.

[0029] Add 0.09Kg, sulfur S 8 , 0.33Kg, BIBP, 2.4Kg, HDPE-g-MAH, 1.5Kg, zinc oxide ZnO, 0.09Kg, stearic acid SA, 0.09Kg,...

Embodiment 3

[0032] Various raw materials and their mass parts are: PP, 15 parts, EPDM, 1515 parts, BR, 10 parts, 60 mesh and below tire rubber powder, 65 parts, regeneration activator 510, 2.0 parts, pine tar oil, 15.0 parts , compatibilizer BIBP, 1.1 parts, PAPI, 0.7 parts, vulcanizing agent S 8 , 0.3 parts, zinc oxide ZnO, 5.0 parts, stearic acid SA, 0.3 parts, antioxidant 1010, 0.3 parts.

[0033] Its preparation method, carry out as follows:

[0034] Step 1) Activate 19.5Kg of 60-mesh tire rubber powder under the condition of 200°C×30min. At room temperature, masticate 4.5Kg EPDM and 3.0Kg BR for 5 minutes to obtain masticated rubber, and then disperse the activated 60-mesh tire rubber powder and 4.5Kg powder PP in a kneader to obtain a mixture. Add the mixture to the plasticized rubber, and knead evenly to obtain the kneaded plastic.

[0035] Add 0.09Kg of sulfur S to the kneading plastic in a twin-screw extruder at 180°C 8 , 0.33Kg BIBP, 0.21Kg PAPI, zinc oxide ZnO, 0.09Kg stear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com