A preparation method of hollow fiber damping material with coupling airbag adjustment

A damping material and hollow technology, applied in fiber processing, textiles and papermaking, conjugated synthetic polymer artificial filaments, etc., can solve the problems of single reflection of external vibration frequency and deformation, single airbag, etc., and achieve excellent mechanical properties. Improved airbag damping value and excellent oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

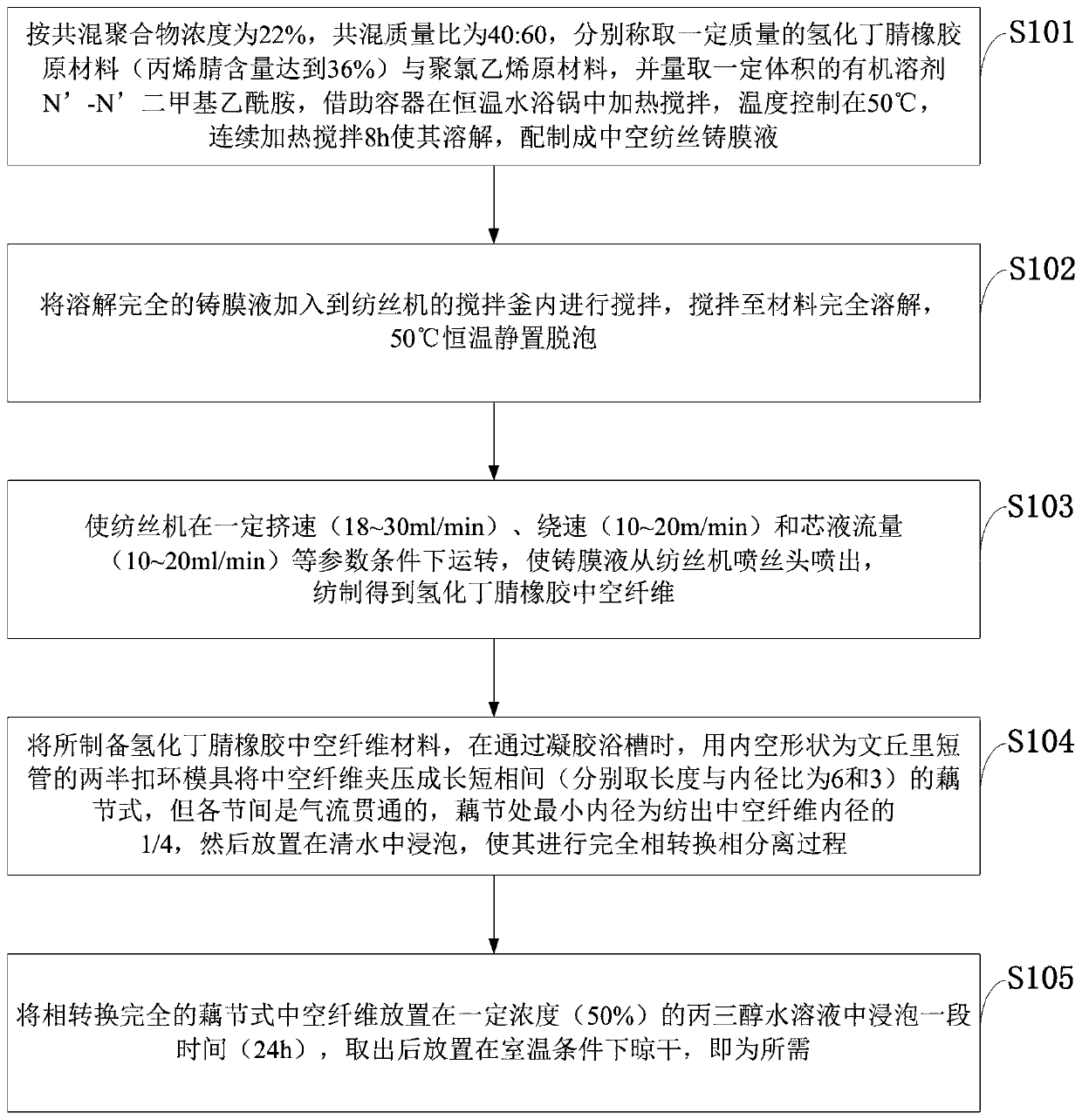

[0023] Such as figure 1 As shown, the preparation method of the hollow fiber damping material with coupling airbag adjustment provided by the embodiment of the present invention includes the following steps:

[0024] S101: According to the concentration of the blended polymer being 22%, the blending mass ratio is 40:60, respectively weigh a certain quality of hydrogenated nitrile butadiene rubber raw materials (acrylonitrile content reaches 36%) and polyvinyl chloride raw materials, and measure a certain amount. The volume of organic solvent N'-N'dimethylacetamide is heated and stirred in a constant temperature water bath with the help of a container, the temperature is controlled at 50°C, and it is continuously heated and stirred for 8 hours to dissolve it, and the hollow spinning casting solution is prepared;

[0025] S102: Add the completely dissolved casting solution into the stirring tank of the spinning machine and stir until the material is completely dissolved, then st...

Embodiment 1

[0031] The preparation method of the hollow fiber damping material provided by the embodiment of the present invention with coupling-type airbag regulation includes the following steps:

[0032] Step 1, according to the concentration of the blended polymer is 22%, the blending mass ratio is 40:60, respectively weigh a certain quality of hydrogenated nitrile butadiene rubber raw material (acrylonitrile content reaches 36%) and polyvinyl chloride raw material, and measure A certain volume of organic solvent N'-N'dimethylacetamide is heated and stirred in a constant temperature water bath with the help of a container, and the temperature is controlled at 50°C. It is continuously heated and stirred for 8 hours to dissolve it, and is prepared into a hollow spinning casting solution;

[0033] Step 2: Add the completely dissolved casting solution into the stirring tank of the spinning machine for stirring, stir until the material is completely dissolved, and stand at a constant temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com