Plastic wood composite floor

A technology of composite flooring and plastic wood, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of high cost of PVC floor paving, cumbersome installation in small areas, and inapplicable geothermal systems, etc., to achieve low paving costs, It has the effect of wear resistance and convenient paving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

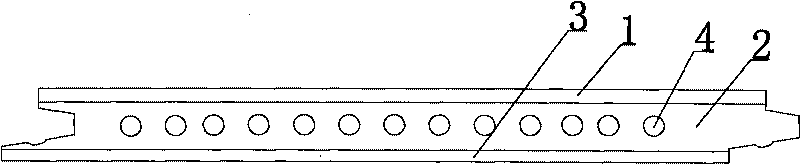

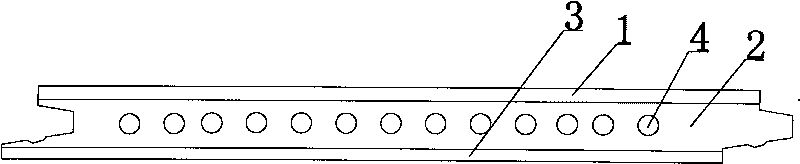

[0014] Such as figure 1 As shown, a plastic-wood composite floor includes a PVC floor surface layer 1 and an environmentally friendly plastic-wood substrate 2, and the PVC floor surface layer 1 and the plastic-wood substrate 2 are bonded together by glue. A locking structure is provided on the plastic-wood base material 2, so that each plastic-wood composite floor can be joined together through the locking structure. A cork bottom layer 3 is arranged under the plastic wood substrate 2, and the plastic wood substrate 2 and the cork bottom layer 3 are bonded together by glue. The viscose is all environmentally friendly waterproof glue imported from Europe. The specifications of the floor can be length 1215mm, width 142mm, thickness 9.2mm, the thickness of the PVC floor surface 1 is 2.0mm, and the thickness of the environmentally friendly plastic wood substrate 2 is 7.2mm

[0015] The PVC floor surface layer 1 is formed by sequentially stacking a PUR layer, a PVC wear-resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com