Positive and negative pressure resistant sealing rubber strip for unit curtain wall

A technology of unit curtain wall and sealing rubber strip, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of insufficient thermal insulation performance, cold bridge, water tightness, poor air tightness, etc., and achieve improved water tightness and good chemical resistance Effects of drug properties and excellent ozone aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

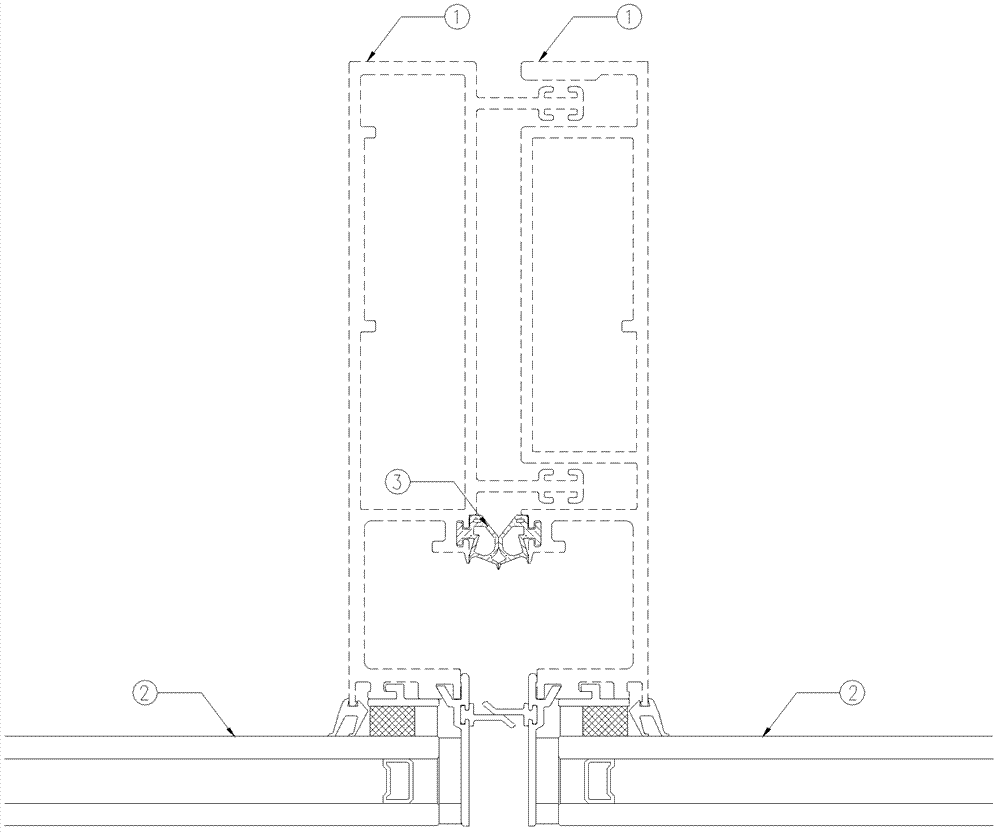

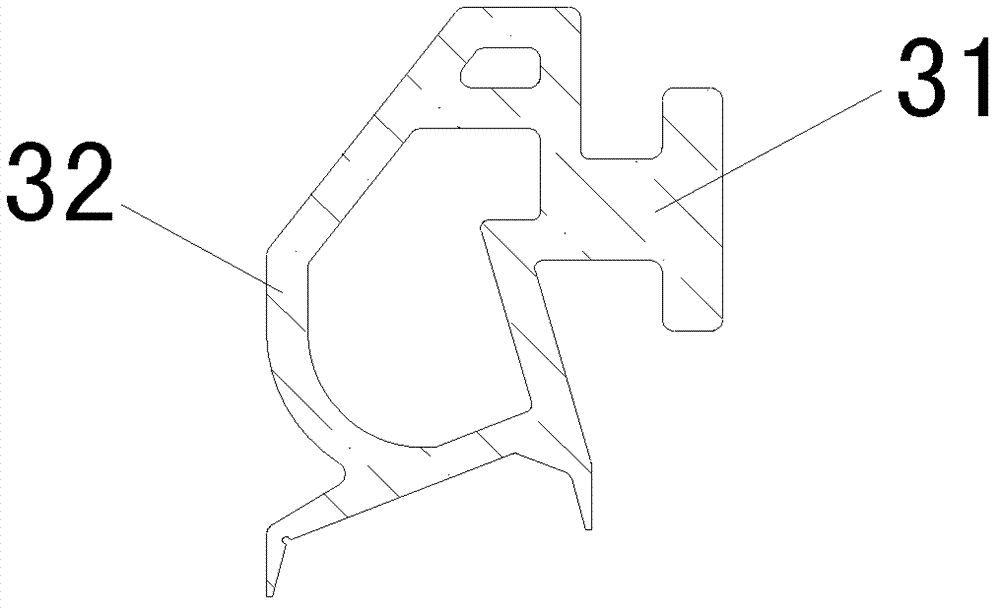

[0012] like figure 1 , figure 2 As shown, a kind of anti-positive and negative wind pressure sealing strips for unit curtain walls, the sealing strips are used on unit curtain walls, said unit curtain walls include unit curtain wall aluminum alloy mullions 1 and tempered glass 2, said The aluminum alloy mullion 1 of the unit curtain wall is fixed on the tempered glass 2, and the aluminum alloy mullion 1 of the unit curtain wall is provided with two waterproof structures, which are respectively an outer waterproof mechanism and an inner waterproof structure, and the sealing strip 3 is installed Inside the inner waterproof structure. The sealing rubber strip 3 includes a T-shaped part 31 and a sealing part 32 embedded in the aluminum alloy mullion of the unit curtain wall, and the sealing parts 32 of two adjacent sealing rubber strips are ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com