Oil and high temperature resistant acrylate rubber tube

An acrylate, high temperature resistant technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor nozzle sealing, air leakage, oil leakage, etc., to overcome hardening and brittleness, meet the Excellent effect of high temperature oil resistance and weathering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0014] The oil-resistant and high-temperature-resistant acrylic hose includes or contains the following components and parts by weight: 100 parts of acrylate rubber, 5 parts of light magnesium oxide, 2 parts of stearic acid, 2 parts of anti-aging agent TR-101, 2 parts of pentaerythritol fat, precipitate 10 parts of white carbon, 45 parts of natural gas semi-reinforced carbon black, quick-pressed furnace black N55020, 20 parts of heavy carbonic acid, 5 parts of TP-95 plasticizer, 0.8 parts of sulfur, 1.1 parts of 1# accelerator, 2# accelerator 1.5 parts, 2.5 parts of 3# accelerator.

[0015] Mixing and processing according to the raw materials and dosage in the listed formula: rubber, raw material weighing→rubber masticating→banbury mixing and feeding→one-stage kneading and unloading→stop cooling→second-stage kneading and vulcanization→vulcanized rubber sheet-cut according to the standard Pattern - for experimental testing.

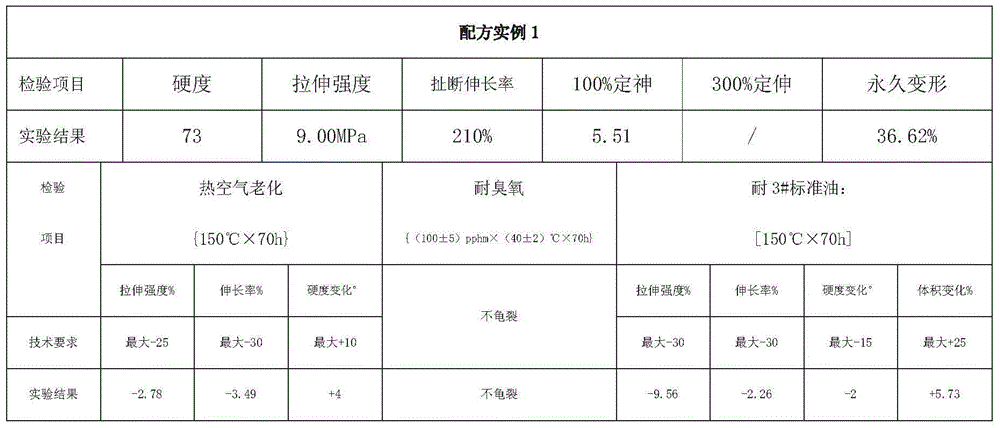

[0016] The acrylic rubber hose prepared according t...

example 2

[0019] The oil-resistant and high-temperature-resistant acrylic hose includes or contains the following components and parts by weight: 100 parts of acrylate rubber, 6 parts of light magnesium oxide, 2 parts of stearic acid, 3 parts of anti-aging agent TR-101, 2 parts of pentaerythritol fat, precipitate 10 parts of white carbon, 55 parts of natural gas semi-reinforced carbon black, 20 parts of quick-pressed furnace black N550, 25 parts of heavy carbonic acid, 8 parts of TP-95 plasticizer, 0.6 parts of sulfur, 1.2 parts of 1# accelerator, 2# accelerator 1.5 parts of agent, 2.5 parts of 3# accelerator.

[0020] Mixing and processing according to the raw materials and dosage in the listed formula: rubber, raw material weighing→rubber masticating→banbury mixing and feeding→one-stage kneading and unloading→stop cooling→second-stage kneading and vulcanization→vulcanized rubber sheet-cut according to the standard Pattern - for experimental testing.

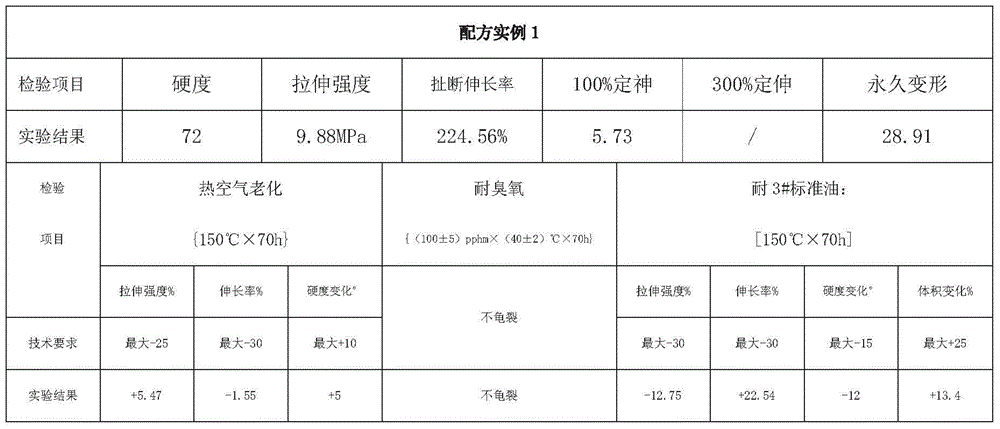

[0021] The acrylic rubber hose p...

example 3

[0024] The oil-resistant and high-temperature-resistant acrylic hose includes or contains the following components and parts by weight: 100 parts of acrylate rubber, 6 parts of light magnesium oxide, 2 parts of stearic acid, 3 parts of anti-aging agent TR-101, 2 parts of pentaerythritol fat, precipitate 10 parts of white carbon, 40 parts of natural gas semi-reinforced carbon black, 15 parts of quick-pressed furnace black N550, 15 parts of heavy carbonic acid, 5 parts of TP-95 plasticizer, 0.5 part of sulfur, 1.3 parts of 1# accelerator, 2# accelerator 2 parts of agent, 2.5 parts of 3# accelerator.

[0025] Mixing and processing according to the raw materials and dosage in the listed formula: rubber, raw material weighing→rubber masticating→banbury mixing and feeding→one-stage kneading and unloading→stop cooling→second-stage kneading and vulcanization→vulcanized rubber sheet-cut according to the standard Pattern - for experimental testing.

[0026] The acrylic rubber hose prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com