A high temperature resistant oil chlorosulfonated polyethylene hose

A chlorosulfonated polyethylene hose, high temperature resistance technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., to achieve the effects of stable composition, improved stability, good physical and mechanical properties and process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

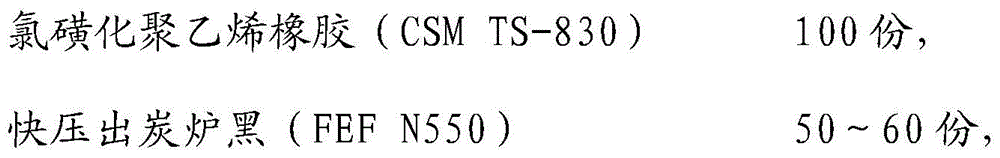

[0015] A high temperature resistant oil chlorosulfonated polyethylene hose, the components and parts by mass are as follows:

[0016]

[0017]

[0018] The CSM rubber hose prepared according to the components and parts by mass provided in Example 1 was applied, and measured:

[0019]

Embodiment 2

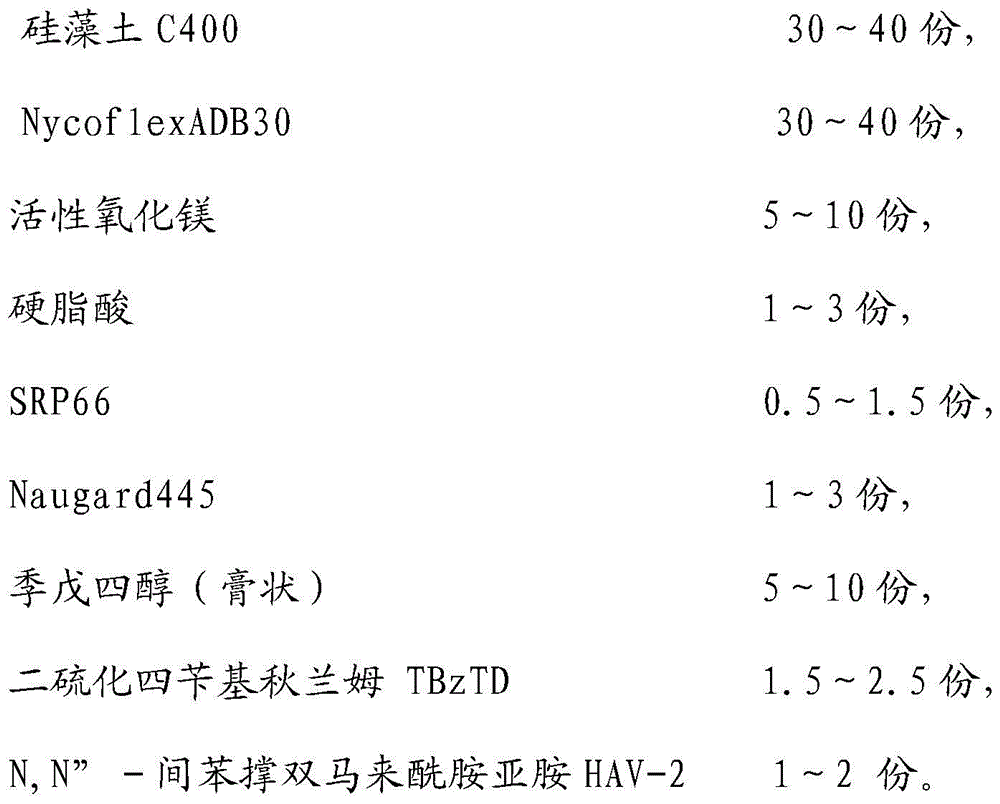

[0021] A high temperature resistant oil chlorosulfonated polyethylene hose, the components and parts by mass are as follows:

[0022]

[0023]

[0024] The CSM rubber hose prepared according to the components and parts by mass provided in Example 2 was applied, and measured:

[0025]

Embodiment 3

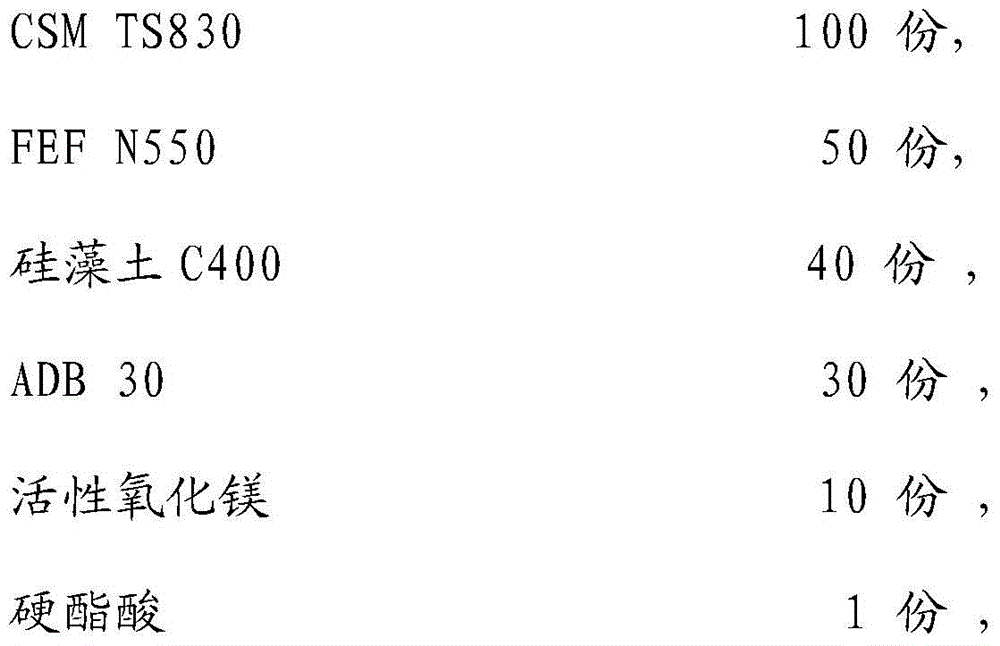

[0027] A high temperature resistant oil chlorosulfonated polyethylene hose, the components and parts by mass are as follows:

[0028]

[0029]

[0030] The CSM rubber hose prepared according to the components and parts by mass provided in Example 3 was applied, and after determination:

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com