Ultraviolet-resistant and weather-resistant nylon material for mudguards of automobiles and method for manufacturing ultraviolet-resistant and weather-resistant nylon material

A technology of anti-ultraviolet and fenders, which is applied in the field of polymer material processing, can solve the problems that the anti-ultraviolet aging and weather resistance cannot meet the needs of the market, and achieve excellent weather resistance, ozone aging resistance and impact resistance, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

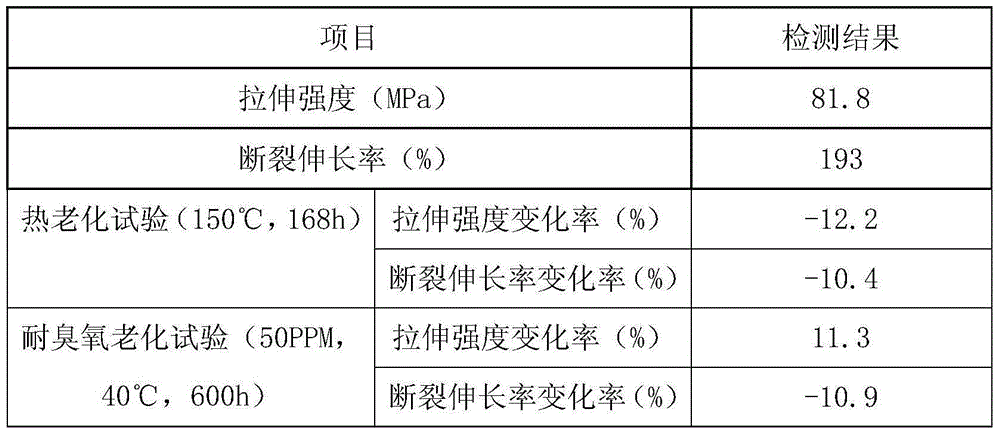

Examples

Embodiment Construction

[0012] An anti-ultraviolet and weather-resistant nylon material for automobile fenders, made of the following raw materials by weight (kg): nylon 6644, polybutylene terephthalate 32, polydiallyl phthalate 26, hydroxyl Ethylhexyl Stearate 8, Flax Fiber 14, Di-Second-Octyl Phthalate 13, Pigment Carbon Black 18, Acrylic Powder 27, Glycidyl Methacrylate 8, Phenyl O-Hydroxybenzoate 5, Golden Red Stone powder 20, ricinoleic acid amide 5, lead fumarate 4, additive 6;

[0013] The preparation method of described auxiliary agent is as follows: a, get the raw material of following weight (kg): superfine ice skating powder 18, cerium isooctanoate 2.5, triisopropylsilyl acrylate 6, hexamethylphosphoric acid triamide 11, 1,3-Propyl sultone 8, polyoxypropylene dipivalate 4.5, nano-titanium nitride 13, yttrium oxide 1.5, aluminum p-tert-butylbenzoate 5, resorcinol monobenzoate 3. Di(2-ethylhexyl) phosphate 7; b. Take superfine ice skating powder, triisopropyl silyl acrylate, and hexamethylp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com