Environmental stress crack-resistant polyethylene sheath material for power wire and preparation method thereof

A technology of environmental stress resistance and polyethylene sheath, applied in the direction of circuits, electrical components, insulating cables, etc., can solve the problems of easy deformation, easy cracking, and limited application range, etc., and achieve the effect of excellent environmental stress crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

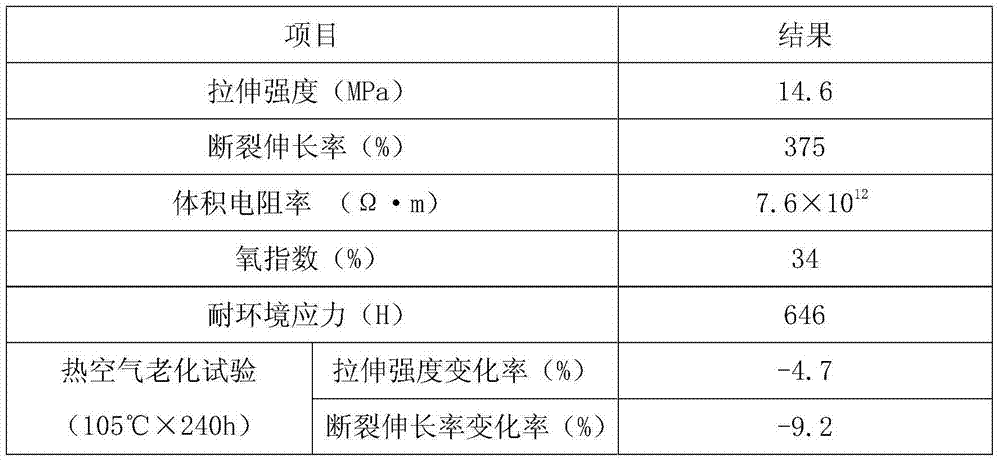

Examples

Embodiment Construction

[0012] A kind of environmental stress cracking resistant polyethylene sheathing material for power lines, made of the following raw materials in weight (kg): linear low density polyethylene 80, polystyrene resin 20, polyparaphenylene terephthalamide 15, Dimethicone 6, lead dibasic phosphite 2, calcium stearate 1, zinc stearate 1, antioxidant 10100.8, antioxidant 1681, ethylene bisstearamide 3, chlorinated paraffin 5, Pine tar 4, magnesium hydroxide 12, zinc borate hydrate 8, ultraviolet absorber UV-3271, aniline methyl triethoxysilane 4, high wear-resistant carbon black 20, quartz powder 12, nano potassium feldspar 8, composite filler 4;

[0013] The preparation method of the composite filler is as follows: a. Take the following raw materials by weight (kg): pyrophyllite 8, diopside 10, protein clay 6, N-2-(aminoethyl)-3-aminopropyltrimethoxy Silane 1.5, calcium lignosulfonate 2, sodium silicate 4, tourmaline slag 5, nano-diamond 4, germanium stone powder 3, sodium stearate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com