New composite film

A composite film, a new type of technology, applied in the direction of synthetic resin layered products, flexible coverings, packaging, etc., can solve the problems that the PE layer is easy to be melted and affects the normal use of packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

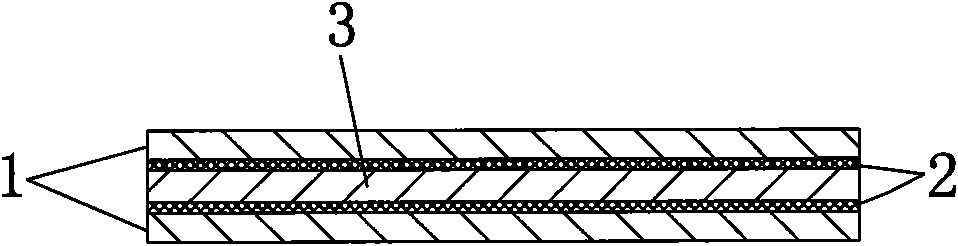

[0027] Embodiment one: if figure 1 As shown, the outer layer 1 adopts a single-layer structure composed of a single-layer film, and the core layer 3 also adopts a single-layer structure, which is the most basic composite film structure.

Embodiment 2

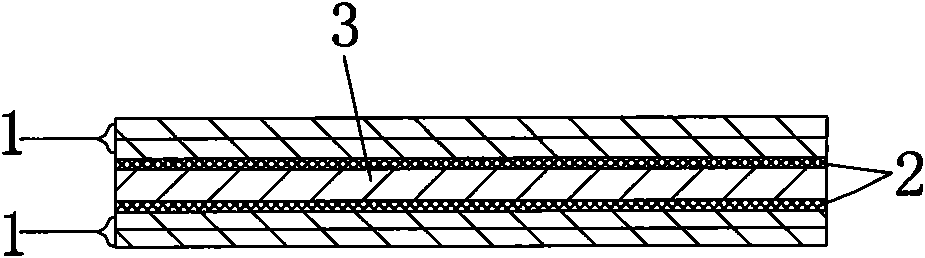

[0028] Embodiment two: if figure 2 As shown, the outer layer 1 adopts a double-layer structure composed of two single-layer films, while the core layer 3 adopts a single-layer structure composed of one single-layer film.

Embodiment 3

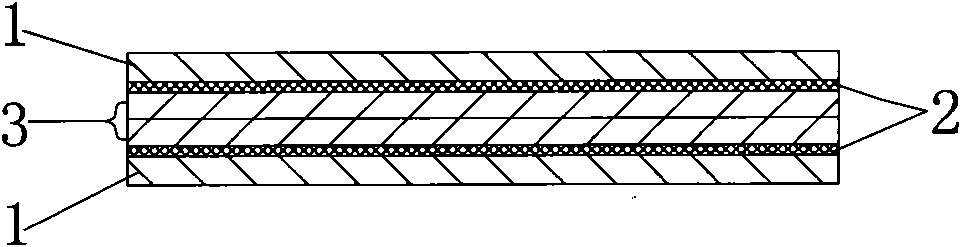

[0029] Embodiment three: as image 3 As shown, the outer layer 1 is a single-layer structure composed of a single-layer film, while the core layer 3 is a double-layer structure composed of two single-layer films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com