Novel high-strength composite material and preparation method thereof

A high-strength composite material and a new type of technology, applied in the field of materials, can solve the problems that the variety, specifications and performance of composite materials cannot meet the development needs, and the investment in composite materials application increases, so as to achieve the effect of enhancing wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

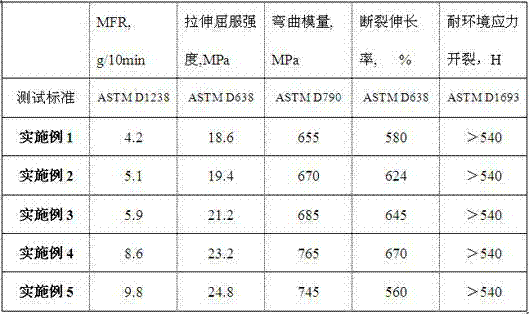

[0027] Add 100 parts of LLDPE with a melt flow rate of about 5g / 10min, 2 parts of HDPE, Japanese Ube PLX-19, and 0.1 part of dicumyl peroxide into the high-speed mixer, mix for 5 minutes, and then add 1 part of PE starch and charcoal Add 1 part of black and 1 part of magnesium hydroxide Mg(OH)2 into a high-speed mixer, mix for 6 minutes, and then extrude and granulate at a temperature of 170-220℃ to obtain a polyethylene composite material. The performance indicators are shown in the table 1.

Embodiment 2

[0029] Add 100 parts of LLDPE with a melt flow rate of about 6g / 10min, 4 parts of HDPE, Ube PLX-19, 0.5 parts of dicumyl peroxide into the high-speed mixer, mix for 6 minutes, and then add 2 parts of PE starch, charcoal Add 2 parts of black and 2 parts of magnesium hydroxide Mg(OH)2 into a high-speed mixer, mix for 6 minutes, and then extrude and granulate at a temperature of 170-220℃ to obtain a polyethylene composite material. The performance indicators are shown in the table 1.

Embodiment 3

[0031] Add 100 parts of LLDPE with a melt flow rate of about 7g / 10min, 6 parts of HDPE, Japanese Ube PLX-19, and 1 part of dicumyl peroxide to the high-speed mixer, mix for 6 minutes, and then add 3 parts of PE starch and carbon Add 3 parts of black and 3 parts of magnesium hydroxide Mg(OH) into a high-speed mixer, mix for 6 minutes, and then extrude and granulate at a temperature of 170-220℃ to obtain a polyethylene composite material. The performance indicators are shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com