Sunscreen composition containing composite solid powder and polymer film-forming agent

A technology of solid powder and composition, which is applied in the field of sunscreen composition and composite solid powder containing composite solid powder and polymer film-forming agent, which can solve problems such as agglomeration, hard touch, and inability to push away smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1 Preparation of Composite Solid Powder

[0081] (1) Prepare a dry physical sunscreen.

[0082] The solid powder of the physical sunscreen to be coated is dried in a desiccator at 105° C. for 4 hours or more.

[0083] (2) Form a mixture with skin feel improving agent

[0084] Put the solid powder of the physical sunscreen prepared in step (1) into a blender, and stir and mix it with the skin feel improving agent in the blender at a high speed, thus obtaining a solid powder composed of a physical sunscreen and a skin feel improving agent .

[0085] (3) Use a surface treatment agent to coat the solid powder

[0086] The surface treatment agent is sprayed onto the composite solid powder obtained in step 2), and then mixed and dispersed for 5-20 minutes, preferably 8-15 minutes, to prepare a composite solid powder.

Embodiment 2

[0087] Example 2 Composite solid powder

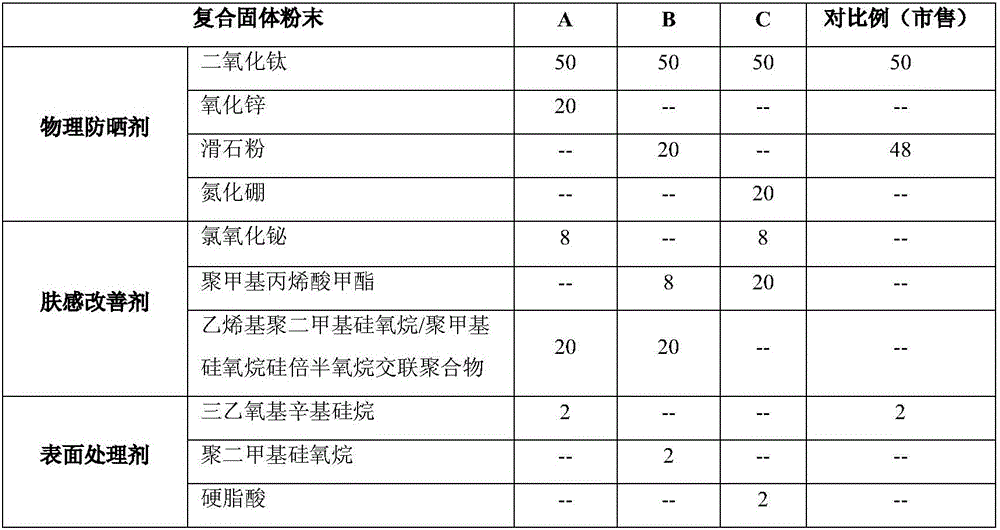

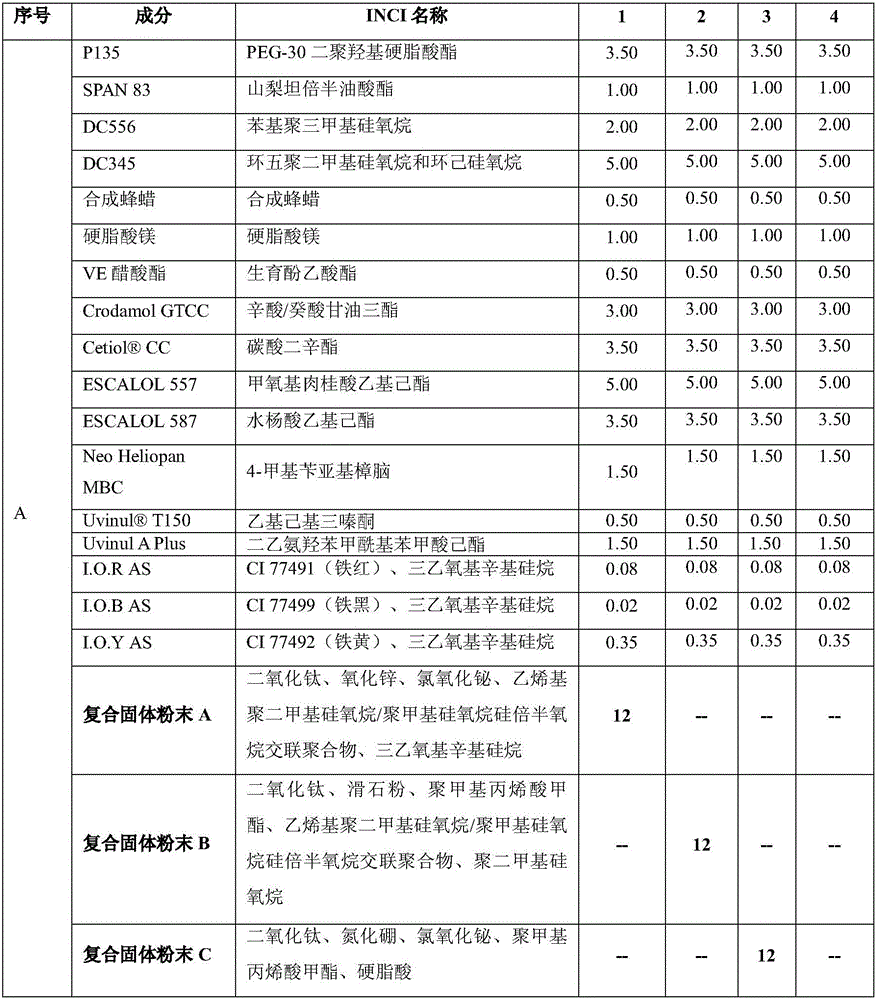

[0088] Table 1 Composite solid powder

[0089]

Embodiment 3

[0090] Embodiment 3 smoothness test

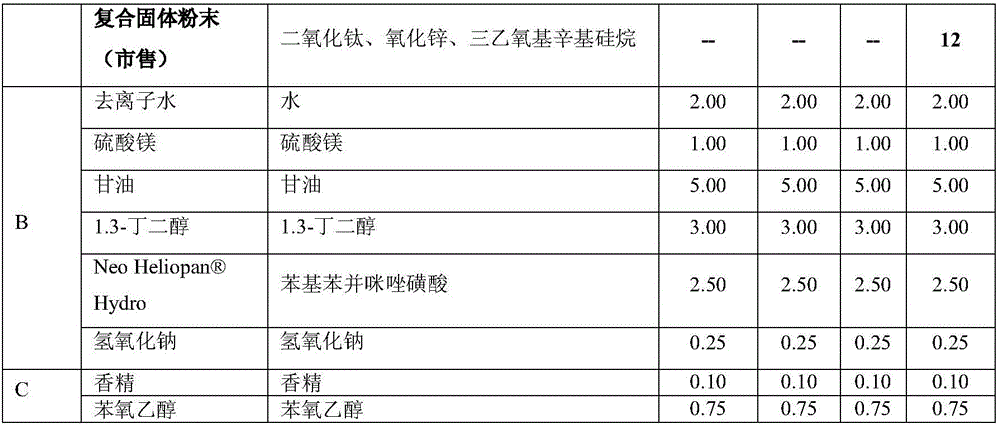

[0091] Experimental method, with the composite solid powder prepared in Example 2, each 0.015g is applied on the artificial leather respectively, and the rheometer is placed on the artificial leather to which the powder has been applied respectively, so as to evaluate the smoothness of each powder ( The solid powder of each combination was measured three times, and the smoothness was averaged). Table 2 shows the evaluation results.

[0092] Table 2 Smoothness experiment

[0093] Composite solid powder smoothness A 98 B 101 C 103 Comparative example (commercially available) 151

[0094]As shown in Table 2 above, the comparative example showed a value higher than 140, which made the skin feel rough, indicating that the commercially available cosmetic composition of triethoxyoctylsilane-coated titanium dioxide powder had a bad touch. However, Composite Solid Powder A, Composite Solid Powder B, Composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com