Pyrolysis carbon black modified cement mortar and preparation method thereof

A technology of cement mortar and carbon black, which is applied in the field of civil engineering, can solve problems such as aging and damage, and achieve the effect of delaying the corrosion of steel bars, improving bonding ability and cohesion, and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

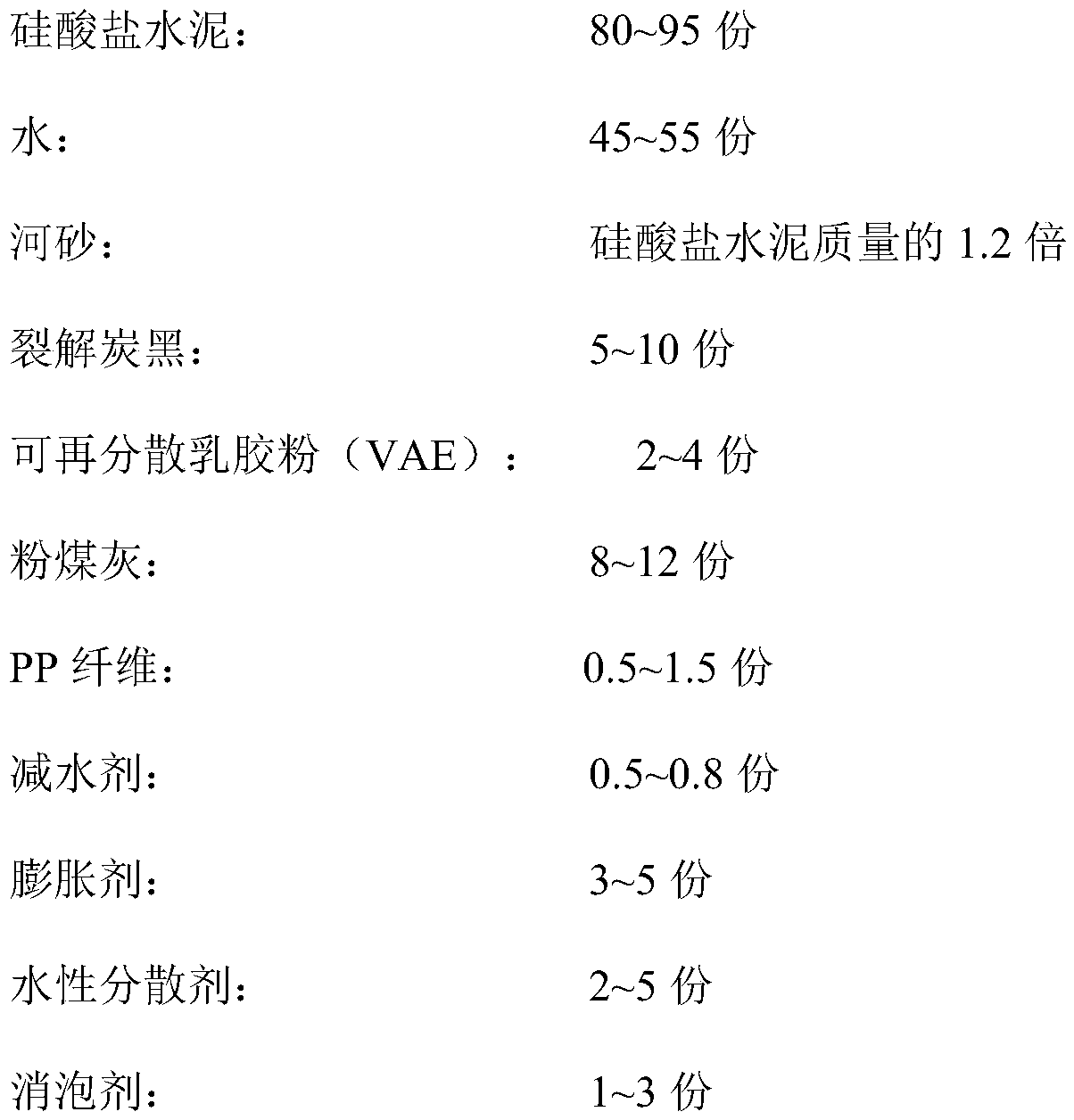

[0025]

[0026] According to the technical scheme, the above-mentioned proportioning is added.

[0027] The pyrolysis carbon black is ground into fine powder by a grinder, the particle size is 3-40um, and the specific surface area is 0.2-6m 2 / g.

[0028] Further, in the above technical solution, the strength grade of the Portland cement is C35 or C40.

[0029] Further, in the above technical solution, the specification of the PP fiber is 3-12 mm.

[0030] Further, in the above technical solution, the specific surface area of the fly ash is 520-760m 2 / kg:.

[0031] Further, in the above technical solution, the water-based dispersant is HPMA.

[0032] Further, in the above technical solution, the water reducer is a polycarboxylate water reducer (powder).

[0033] Further, in the above technical solution, the expansion agent is calcium sulfoaluminate expansion agent.

[0034] Further, in the above technical solution, the defoamer is a special defoamer for cement mort...

Embodiment 2

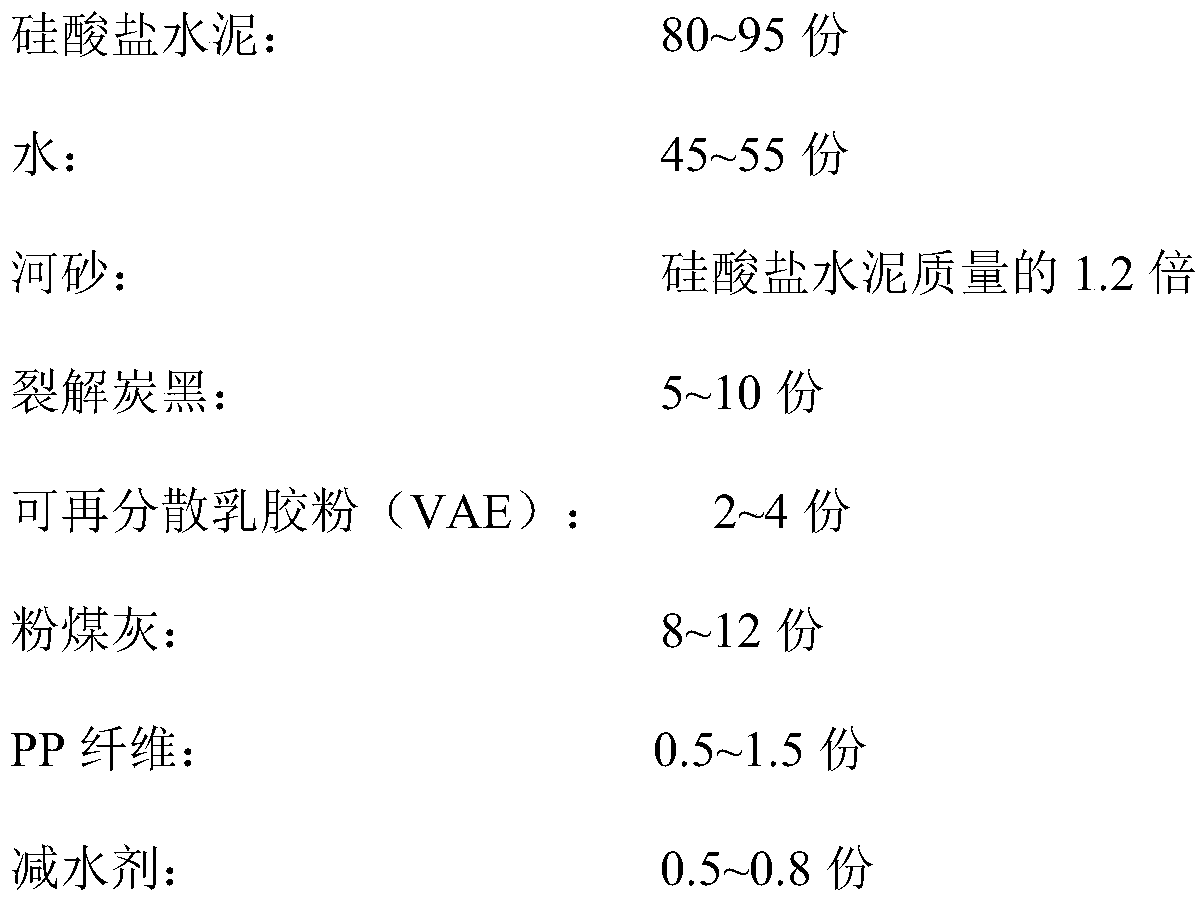

[0036]

[0037] According to the technical scheme, the above-mentioned proportioning is added.

[0038] The pyrolysis carbon black is ground into fine powder by a grinder, the particle size is 3-40um, and the specific surface area is 0.2-6m 2 / g.

[0039] Further, in the above technical solution, the strength grade of the Portland cement is C35 or C40.

[0040] Further, in the above technical solution, the specification of the PP fiber is 3-12 mm.

[0041] Further, in the above technical solution, the specific surface area of the fly ash is 520-760m 2 / kg:.

[0042] Further, in the above technical solution, the water-based dispersant is HPMA.

[0043] Further, in the above technical solution, the water reducer is a polycarboxylate water reducer (powder).

[0044] Further, in the above technical solution, the expansion agent is calcium sulfoaluminate expansion agent.

[0045] Further, in the above technical solution, the defoamer is a special defoamer for cement mort...

Embodiment 3

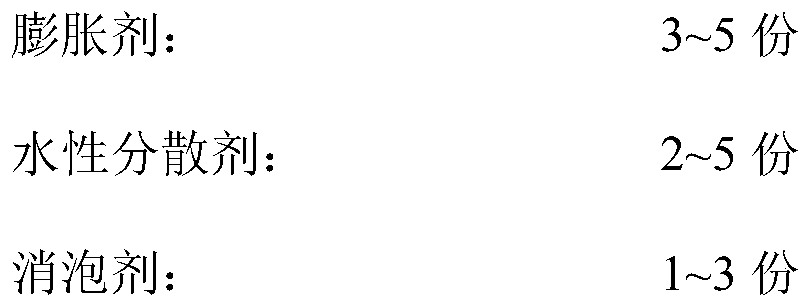

[0047]

[0048] According to the technical scheme, the above-mentioned proportioning is added.

[0049] The pyrolysis carbon black is ground into fine powder by a grinder, the particle size is 3-40um, and the specific surface area is 0.2-6m 2 / g.

[0050] Further, in the above technical solution, the strength grade of the Portland cement is C35 or C40.

[0051] Further, in the above technical solution, the specification of the PP fiber is 3-12mm.

[0052] Further, in the above technical solution, the specific surface area of the fly ash is 520-760m 2 / kg:.

[0053] Further, in the above technical solution, the water-based dispersant is HPMA.

[0054] Further, in the above technical solution, the water reducer is a polycarboxylate water reducer (powder).

[0055] Further, in the above technical solution, the expansion agent is calcium sulfoaluminate expansion agent.

[0056] Further, in the above technical solution, the defoamer is a special defoamer for cement morta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com