Cold-resistant rubber for outdoor cable sheath

A cold-resistant rubber and outdoor cable technology, applied in the rubber field, can solve the problems of short service life of the cable, poor resistance to the external environment, easy cracking of the cable sheath, etc., and achieves the effect of less equipment, low cost and moderate price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

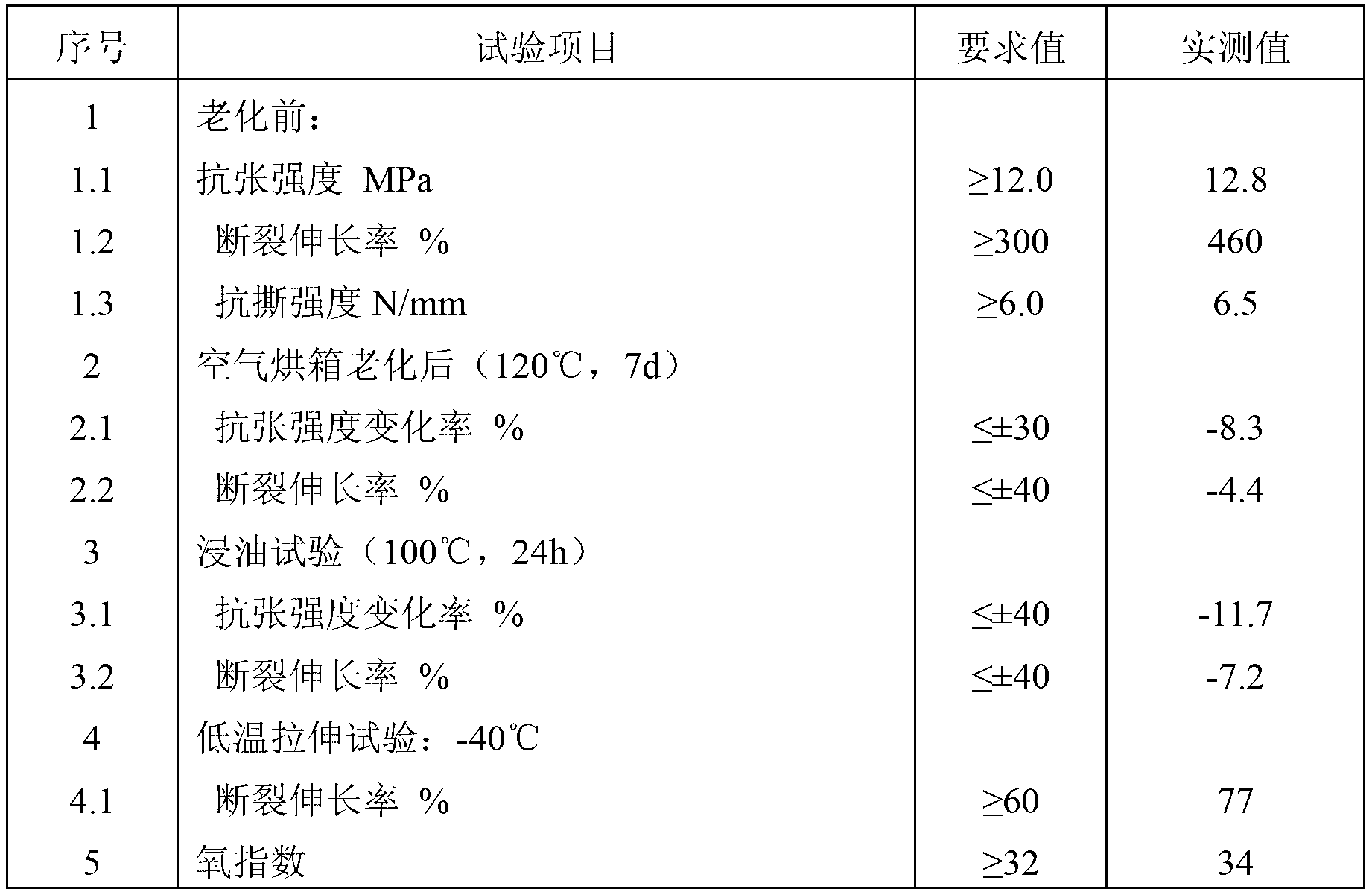

Embodiment 1

[0019] The cold-resistant rubber used for outdoor cable sheaths is as follows by weight: Rubber base material: 90 parts of chlorinated polyethylene base material (Yaxing 6235), 20 parts of imported ethylene-propylene rubber, and vulcanizing agent triallyl isocyanurate 10-20 parts of acid ester (TAIC), 4.5 parts of dicumyl peroxide (DCP), stabilizer: 1.5 parts of tribasic lead sulfate, 2 parts of lead stearate, 40 parts of cold-resistant softener stearic acid, anti-aging Agent trimethyl-1,2 dihydroquinoline polymer (RD) 0.5 parts, flame retardant hydrated metal oxide 30 parts, reinforcing filler reinforcing silica 55 parts and flow dispersant RL 202 parts.

Embodiment 2

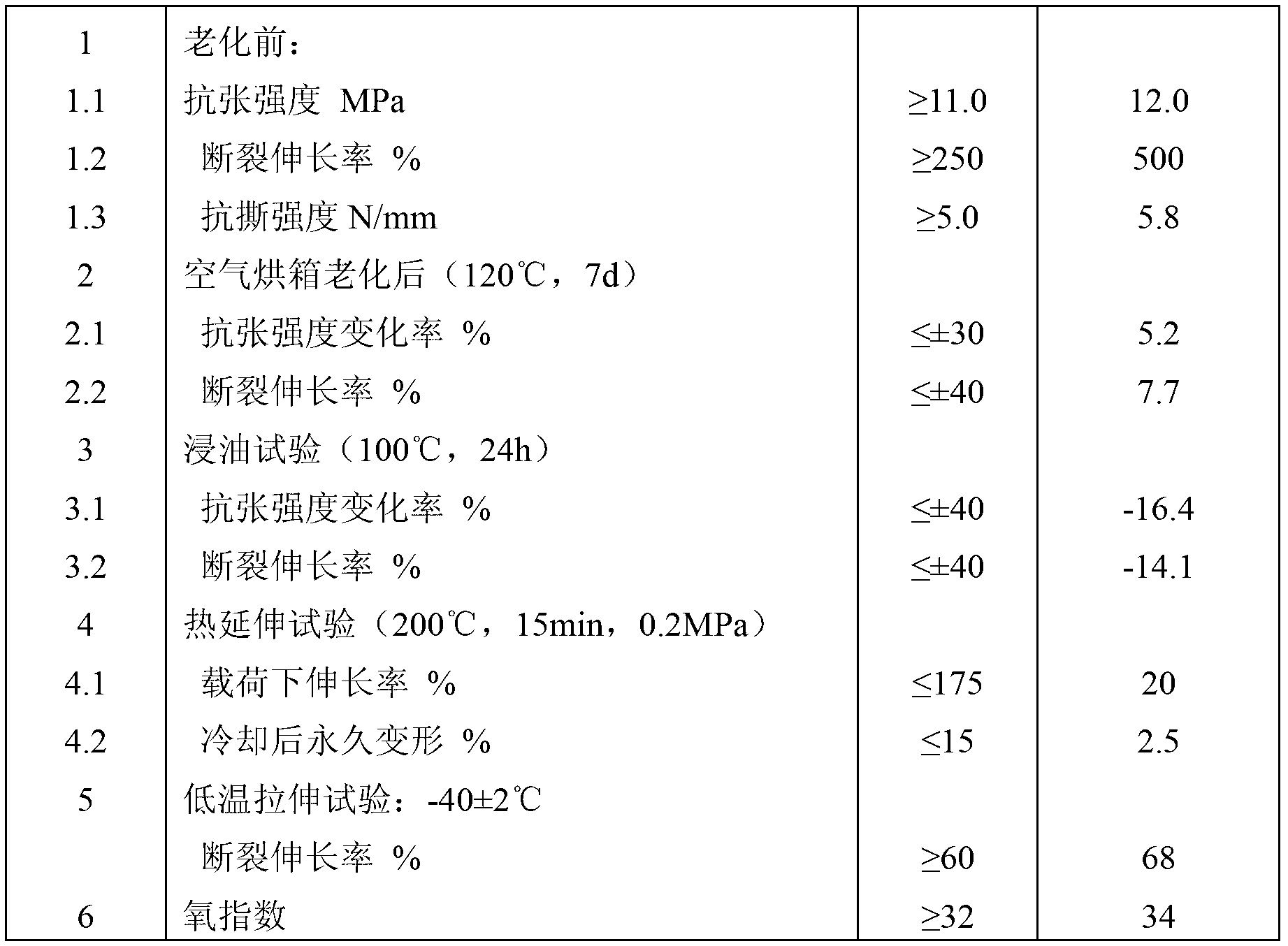

[0021] The cold-resistant rubber used for outdoor cable sheaths is as follows in parts by weight: 50 parts of rubber base material chlorinated polyethylene, 50 parts of ethylene-propylene rubber, 15 parts of vulcanizing agent triallyl isocyanurate, and stabilizer trisalt 4 parts of lead sulfate, 35 parts of cold-resistant softener dioctyl adipate, 0.5 parts of anti-aging agent trimethyl-1,2 dihydroquinoline polymer, 25 parts of flame retardant aluminum hydroxide, reinforcing filler 55 parts of calcium carbonate and 421 parts of flow dispersant WB.

Embodiment 3

[0023] The cold-resistant rubber used for outdoor cable sheaths is as follows by weight: 70 parts of rubber base material triallyl isocyanurate, 50 parts of ethylene-propylene rubber, 10 parts of vulcanizing agent dicumyl peroxide, stabilizer 4 parts of tribasic lead sulfate, 40 parts of cold-resistant softener dioctyl sebacate, 0.5 parts of anti-aging agent RD, 30 parts of flame retardant magnesium hydroxide, 55 parts of reinforcing filler semi-reinforcing carbon black and flow dispersion Agent RL201 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com