Super-long weather-resistant surface photovoltaic platform system and installation method thereof

An ultra-long weather-resistant and weather-resistant technology, applied to floating buildings and other directions, can solve problems such as increasing the difficulty of engineering construction, restricting use, and losing support, achieving high UV aging resistance, reducing usage and cost, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

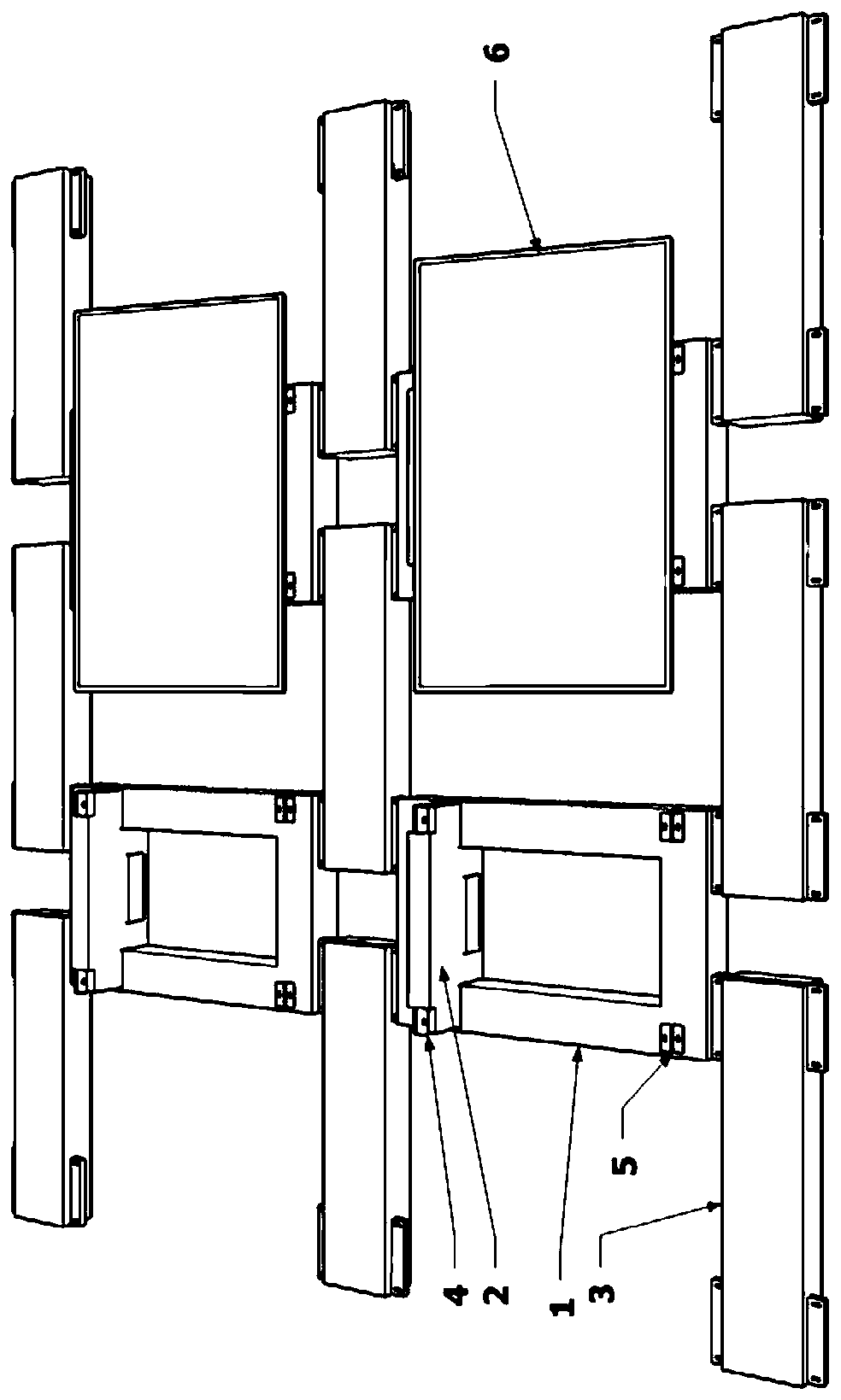

[0056] Such as Figure 1-6 , as shown in 10-12: the entire platform is combined by connecting the floating body 1 and the bracket floating body 2, and connecting the floating body 1 and the aisle floating body 3 to form a floating body floating platform. 4 / 5 is fixedly connected with the photovoltaic module 6, and is continuously connected and expanded along the north-south east-west direction, finally forming a water surface photovoltaic power generation system.

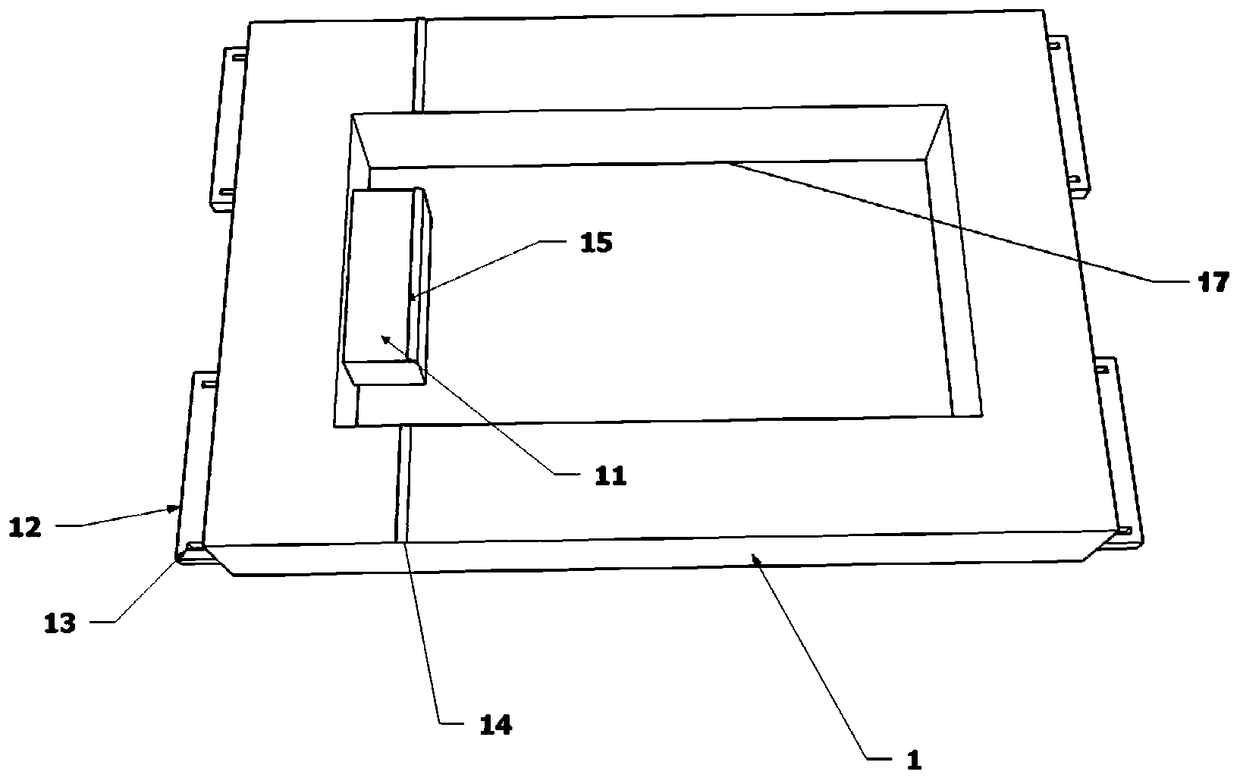

[0057] The connecting floating body 1 has a cuboid structure as a whole, and a rectangular through hole 17 is arranged in the middle of the connecting floating body 1, and the middle part is hollowed out to make the photovoltaic module more hydrophilic. A rectangular inner boss 11 is provided on the south side of the rectangular through hole 17 for combined connection with the support floating body 2 . The inner side of the upper end of the inner boss 11 is provided with a wedge-shaped surface 15, which is used to ...

Embodiment 2

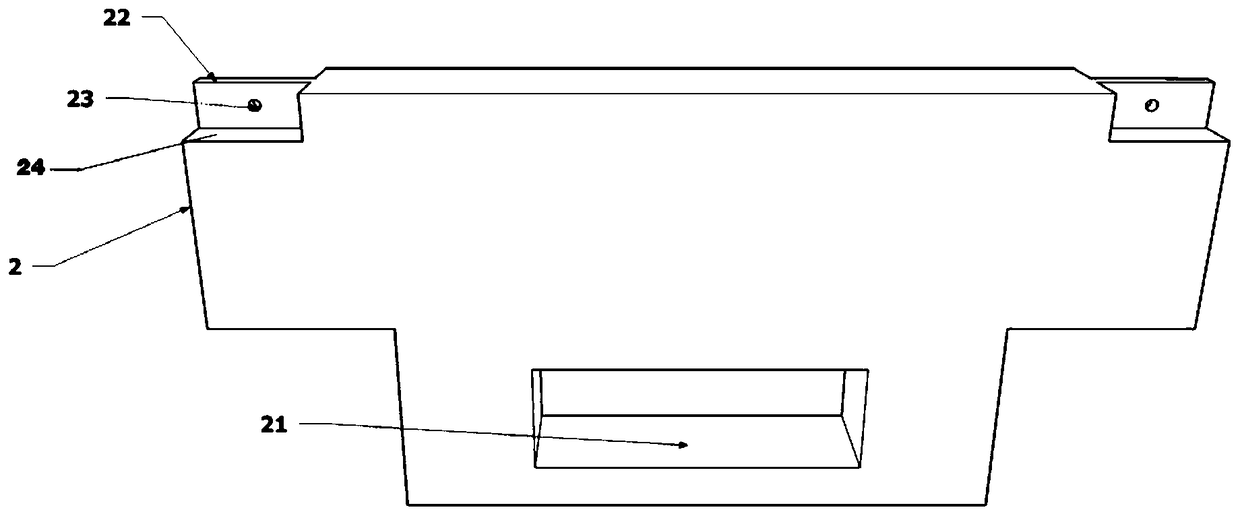

[0076] Such as Figure 7 , Figure 8 , other implementations of embodiment 2 are completely consistent with embodiment 1, only the combination of connecting floating body 1 and bracket floating body 2 is changed.

[0077] The inner boss 11 connecting the floating body 1 is changed into two connecting bolts 16, the length of the connecting bolts 16 is greater than the thickness of the support floating body 2, and it is integrally blow-molded with the connecting floating body 1. Correspondingly, the socket holes reserved on the support floating body 2 21 is changed to two circular bracket mounting holes 25. After the connecting floating body 1 and the bracket floating body 2 are combined, the matching connecting nuts 8 and bolts 16 are fixed, and finally the bracket floating body 2 is completely limited to prevent north-south sliding .

[0078] The specific steps of the assembly method of the ultra-long weather-resistant water surface photovoltaic platform system based on the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com