Patents

Literature

34results about How to "Large particle size range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

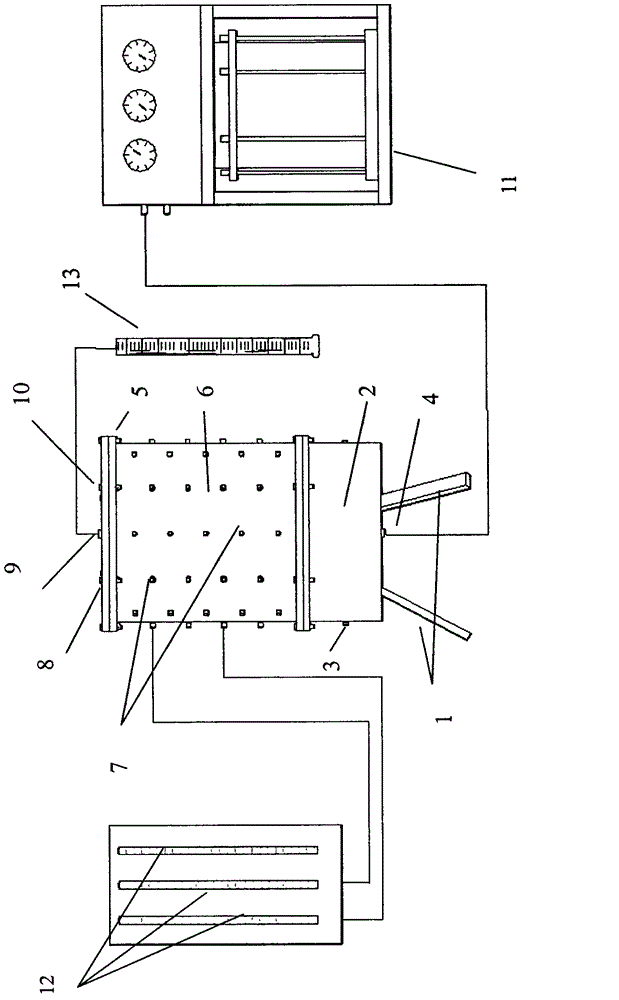

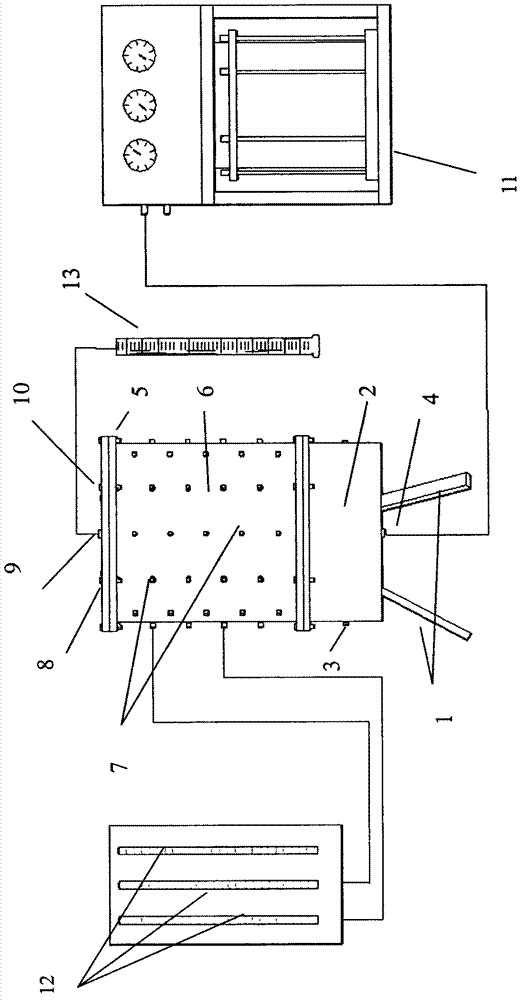

Device and method for determining permeability coefficient of coarse-grained soil with super large grain size

InactiveCN103149143ALarge particle size rangeAvoid damagePermeability/surface area analysisEngineeringHydraulic engineering

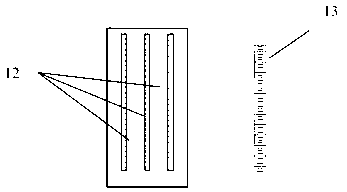

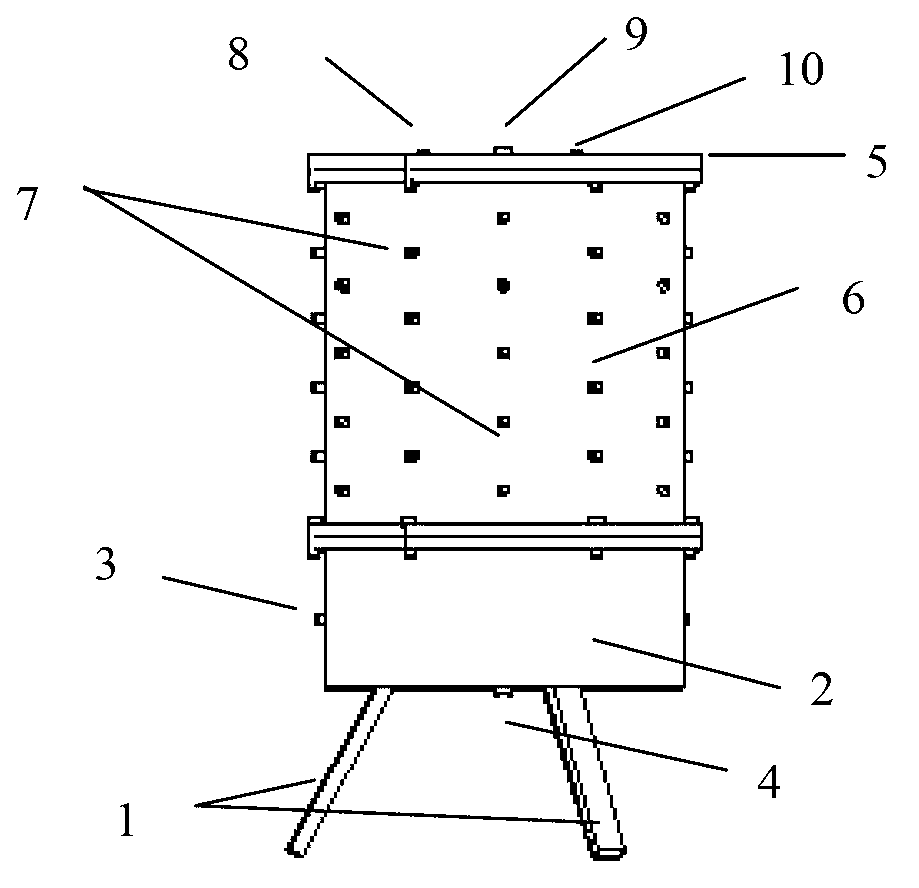

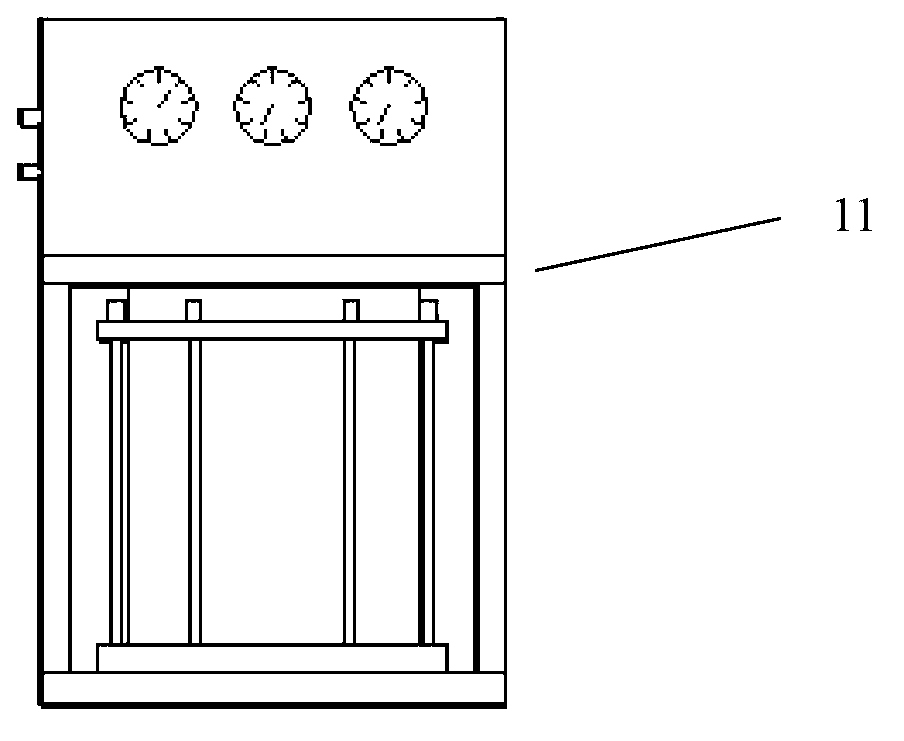

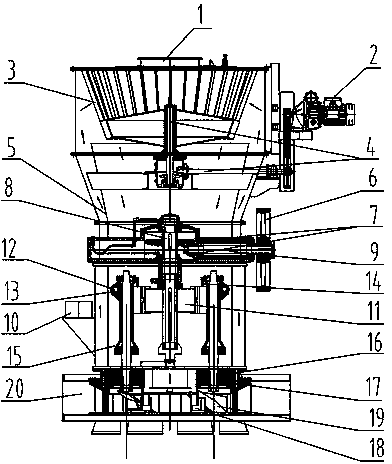

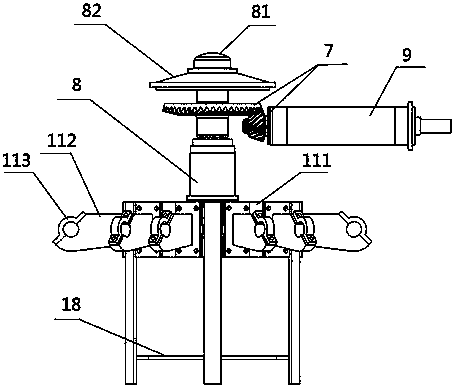

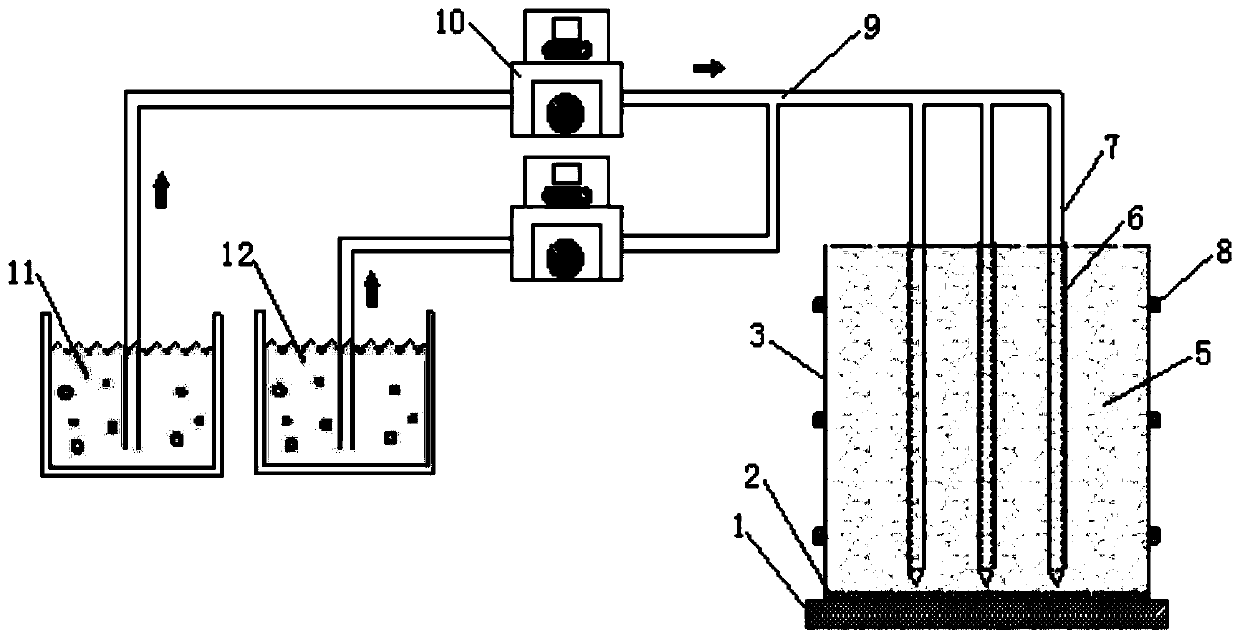

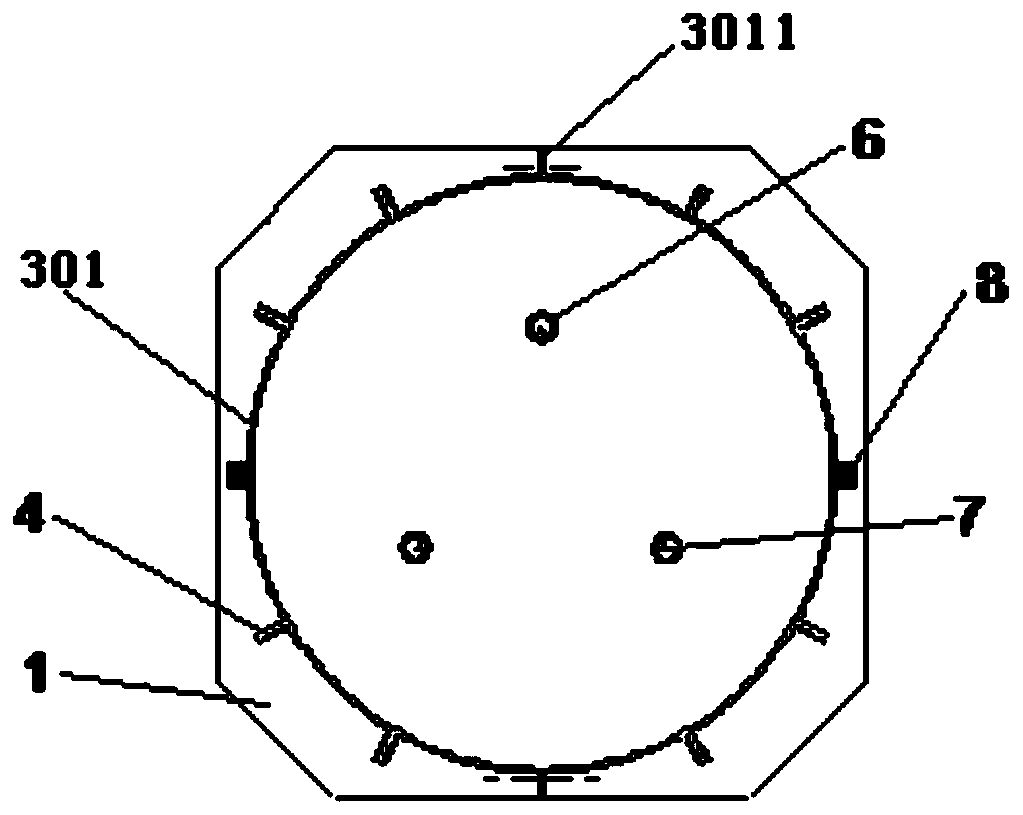

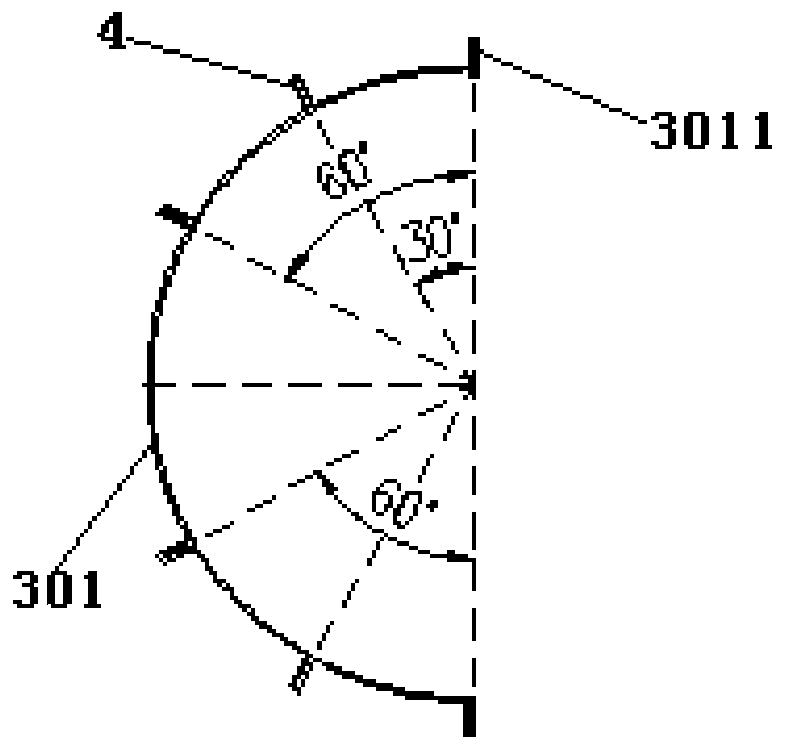

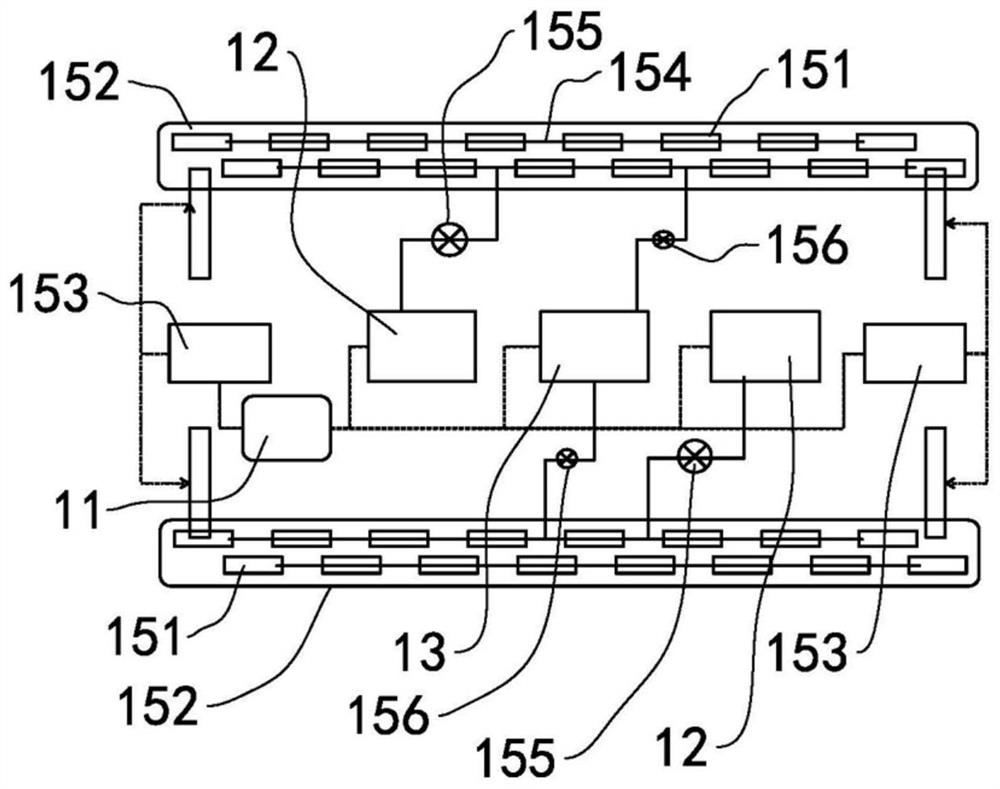

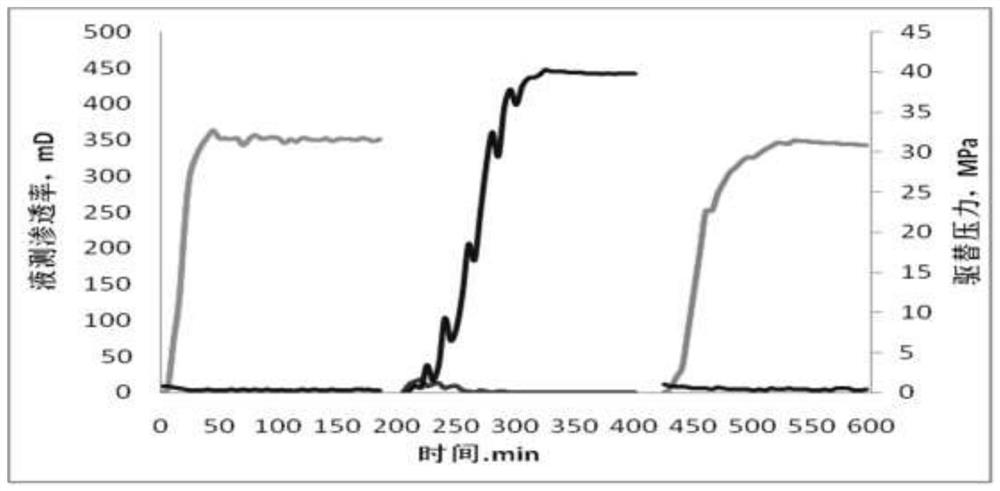

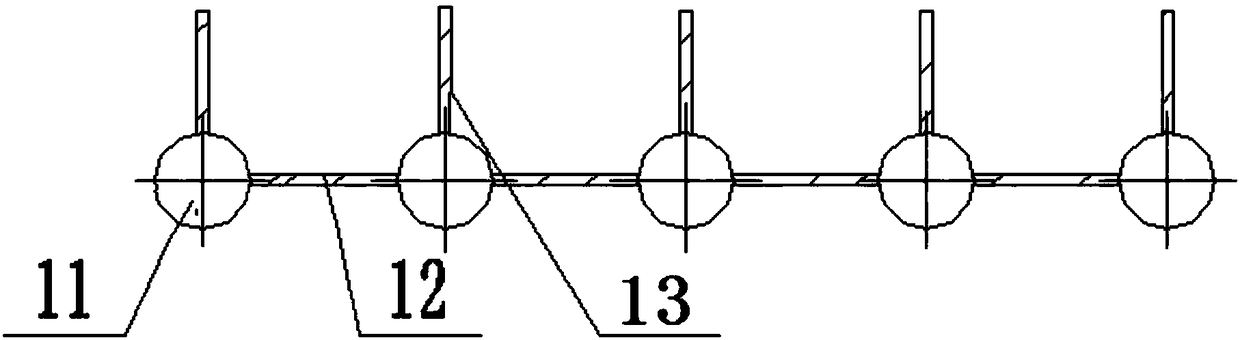

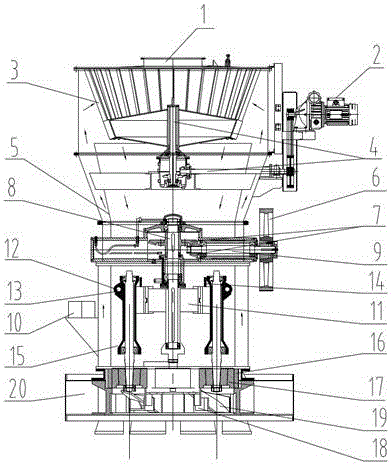

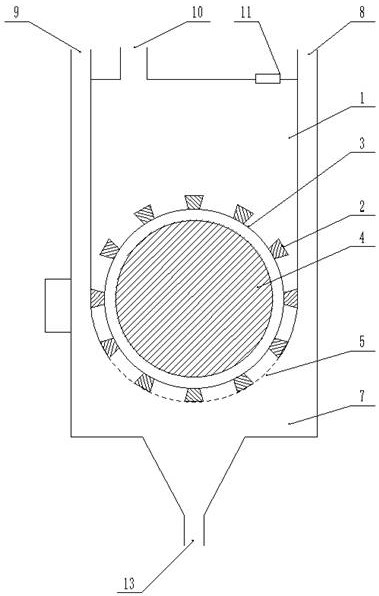

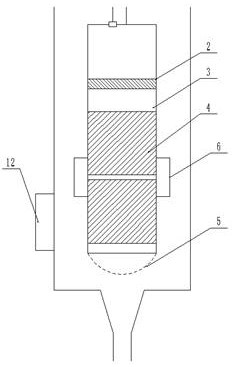

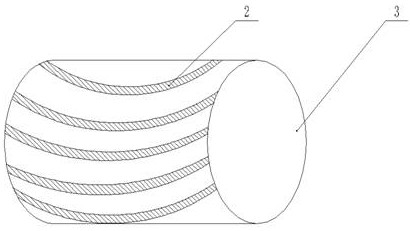

The invention relates to a device and a method for determining parameters of a hydraulic engineering material and particularly relates to a device and a method for determining the permeability characteristic of coarse-grained soil with super large grain size (the d85 is larger than or equal to 60mm and smaller than or equal to100mm), and the IPC (International Patent Classification) codes of the device and the method are respectively E02D1 / 04 and E02D33 / 00. The device comprises a testing drum, an automatic compression system 11 and a pressure determining tube 12, wherein a plurality of pressure determining holes are formed in the wall of the testing drum, the pressure determining holes in the wall of the testing drum can be used as air discharge holes when air is discharged out of soil body from saturation, and the pressure determining holes and air discharge holes in the drum top and the drum bottom jointly accelerate air discharge, so that a sample can be saturated rapidly. Proven by a large number of experiments, the method has the advantages that hot water at the temperature of 25-40 DEG C is used, the sample with super large grain size cab be saturated rapidly and the influences on the chemical and physical stability of the sample are minimized.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

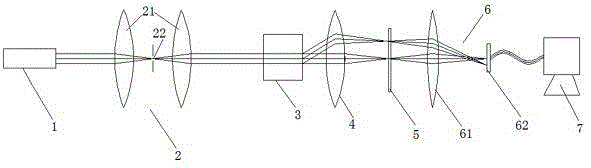

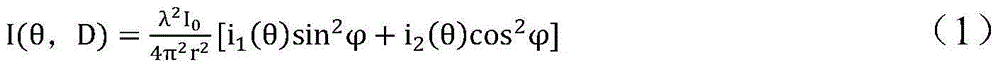

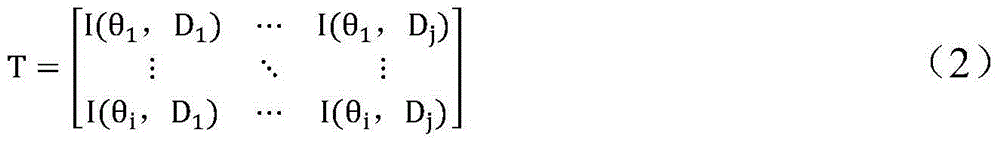

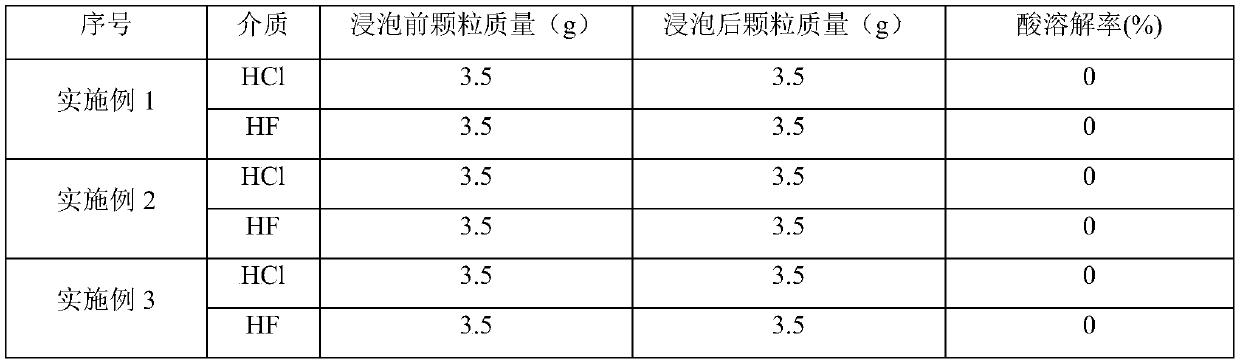

Concentration measuring device and method for dust in large diameter range

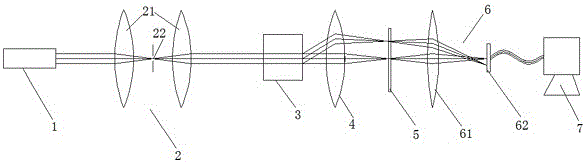

ActiveCN104374677AHigh sensitivityQuick responseParticle suspension analysisComputational physicsLight extinction

The invention discloses a concentration measuring device and method for dust in large diameter range. Aiming at the shortcoming that scattering integration method in the prior art is not applicable when the particle size is smaller than 10 microns, the measuring device uses a multistep neutral density filter to attenuate transmission light and scattered light to a same light intensity level, realizes simultaneous shooting of transmission light and scattered light in a measurement system of a single digital area-array camera, and has the advantages of high sensitivity, fast response and simple and compact optical system. According to the obtained information of scattered light and transmission light, the distribution of particle size can be acquired; with the known particle size distribution, a method combined scattered light with scattering integration can be used to measure dust concentration of micron level, and a method combined transmission light with light extinction can be used to realize the measurement of dust concentration of submicron and nanometer levels. The invention successfully realizes the measurement of dust concentration of micron, submicron and nanometer levels, covers large particle size range, and has great market advantage.

Owner:NANJING INST OF MEASUREMENT & TESTING TECH

Method for measuring filtration coefficient of oversized-grain-diameter coarse-grained soil

InactiveCN103217371ALarge particle size rangeAvoid damagePermeability/surface area analysisSoil scienceOsmotic coefficient

The invention relates to a parameter measuring method of a water conservancy engineering material, and particularly relates to a method for measuring a filtration coefficient of oversized-grain-diameter coarse-grained soil (the grain diameter d85 of which is more than or equal to 60mm and is less than or equal to 100 mm), and the IPC international patent classification is E02D1 / 04 and E02D33 / 00. The method provided by the invention adopts a specialized measuring device which comprises a testing tank, an automatic compression system 11 and a pressure measuring tube 12, wherein the wall of the testing tank is provided with multiple pressure measuring holes, the pressure measuring holes in the tank wall are utilized as vent holes in soil body exhaust saturation and can cooperate with vent holes in the tank top and the tank bottom to accelerate ventilation, and thus a sample rapidly achieves a saturation condition. A large number of tests prove that the measuring method provided by the invention has the advantages that hot water at 25-40 DEG C is utilized to saturate the oversized grain diameter sample rapidly, and the influence to chemical and physical stability of the sample is smallest.

Owner:超飞凡科技(天津)有限公司

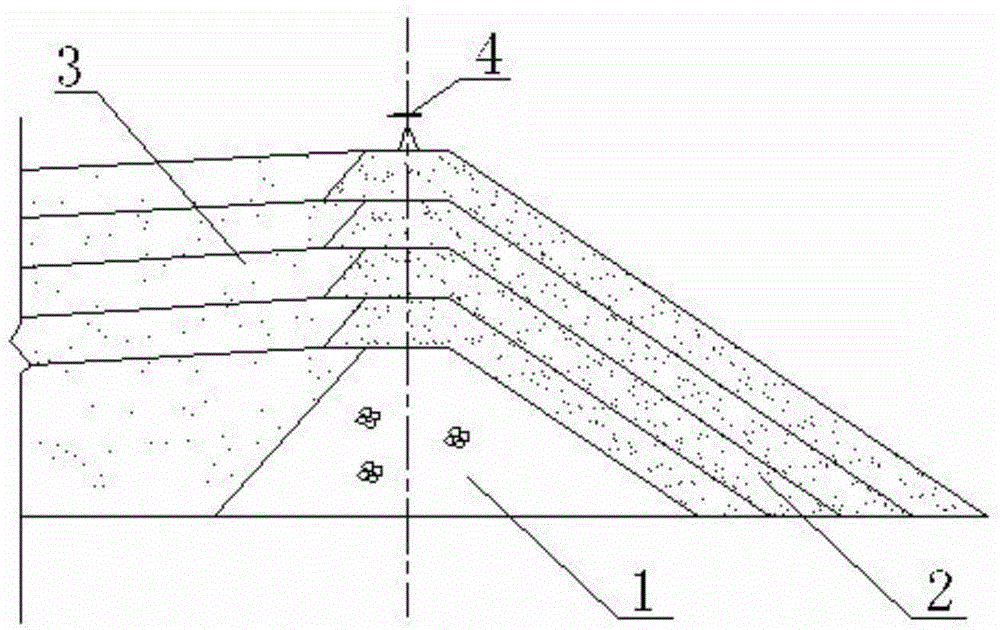

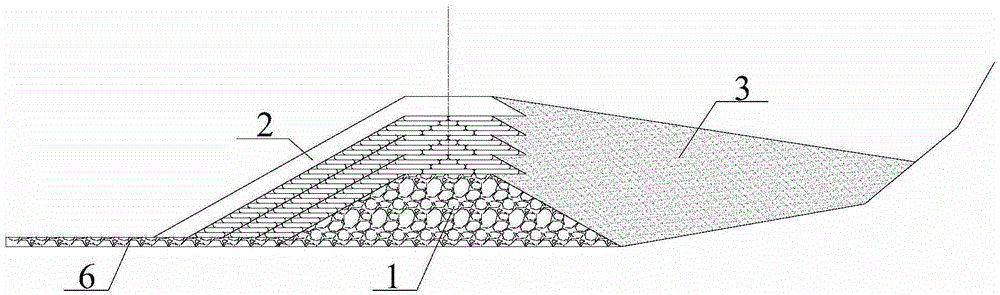

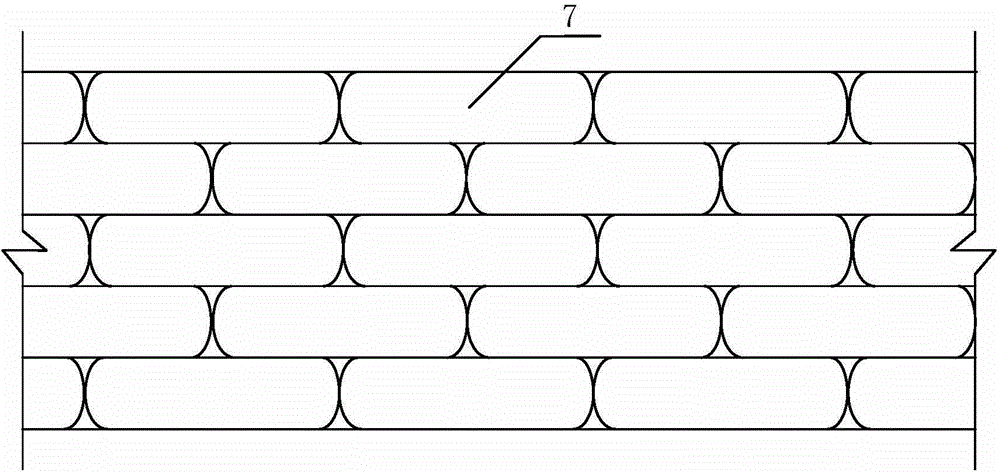

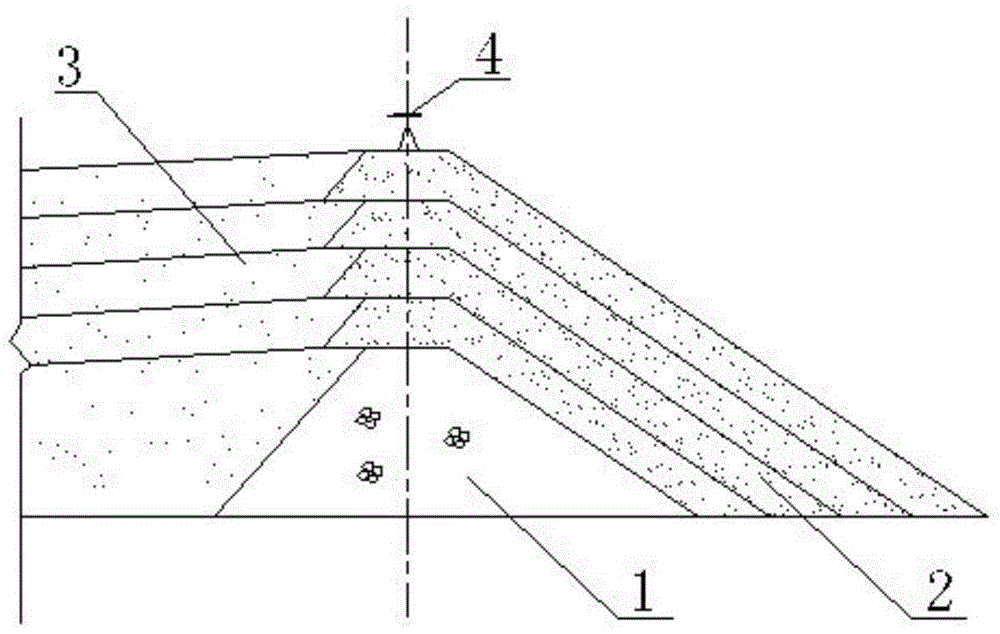

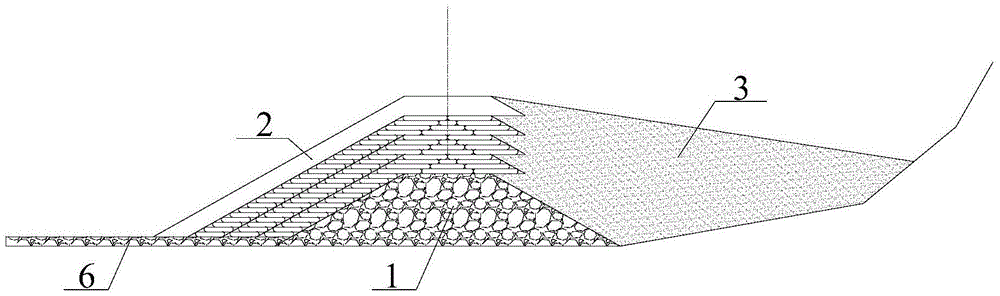

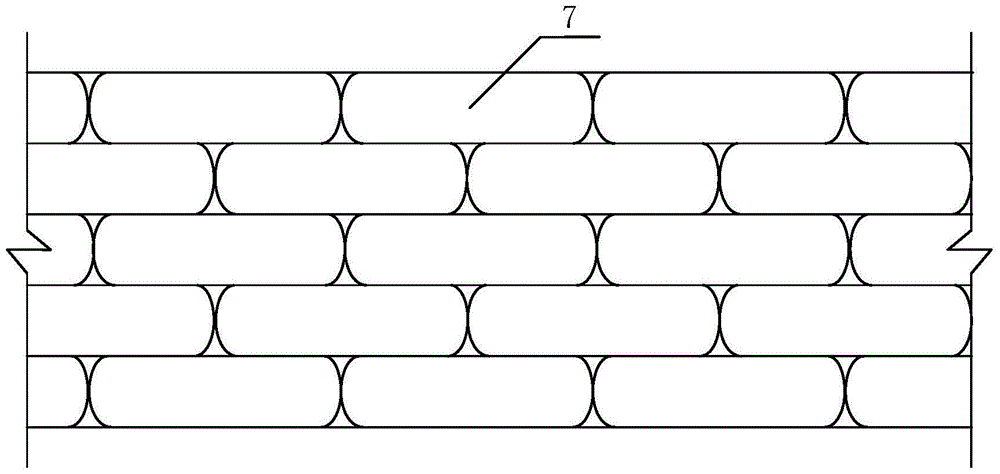

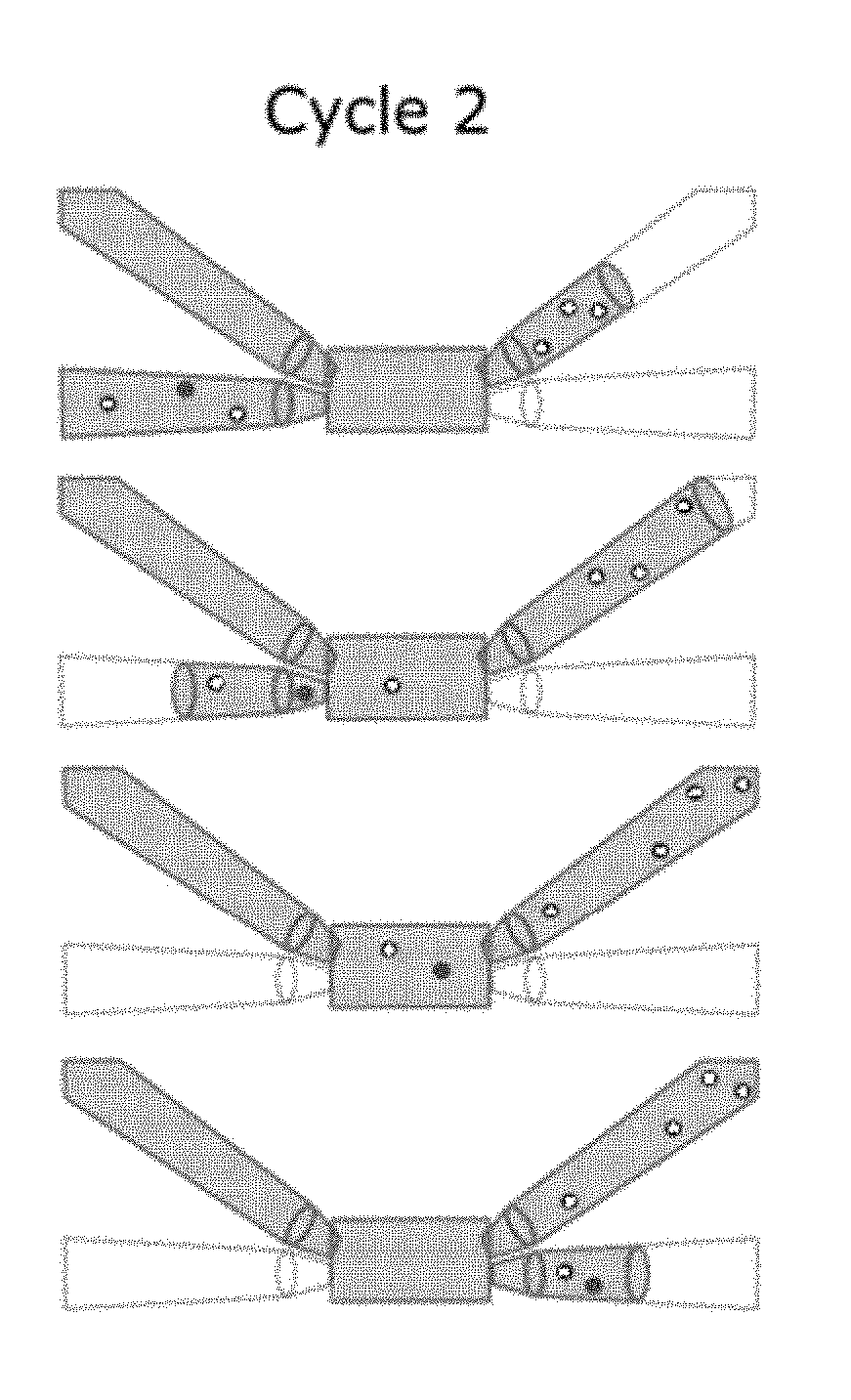

Median type tailing damming method utilizing mold bags

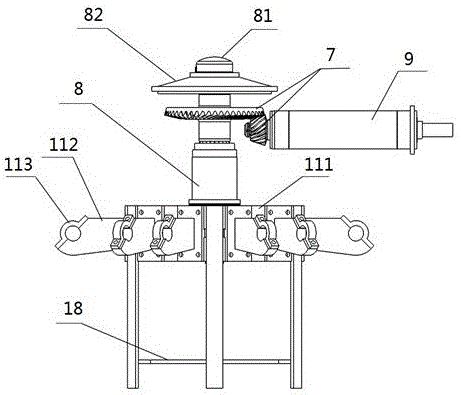

ActiveCN104912087ADrain fastAccelerated consolidationEmbankmentsSoil preservationPrillEnergy consumption

The invention discloses a median type tailing damming method utilizing mold bags. The median type tailing damming method has the advantages that the grouted mold bags 7 are piled up to build a downstream dam body 2, the downstream dam body 2 is kept clean and smooth by the sand consolidation effect of the mold bags 7, and the environmental problems such as dust flying, gullying and coarse sand loss are solved well; tailing pulp with the content of tailing particles, smaller than 0.05mm in size, not larger than 40% (by weight) is taken as mold bag filling pulp for the mold bags 7, so that the particle size range of tailing sand available for damming is widened, sand quantity available for the median type tailing damming method is increased, water drainage of the mold bags 7 can be accelerated, solidification can be speeded up, and grouting efficiency of the mold bags 7 is improved; in addition, the action of gravity is fully utilized for grouting, and the mold bags 7 can be grouted by multiple branch ore drawing pipes 92 at the same time, so that cost and energy consumption are reduced, and damming efficiency is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

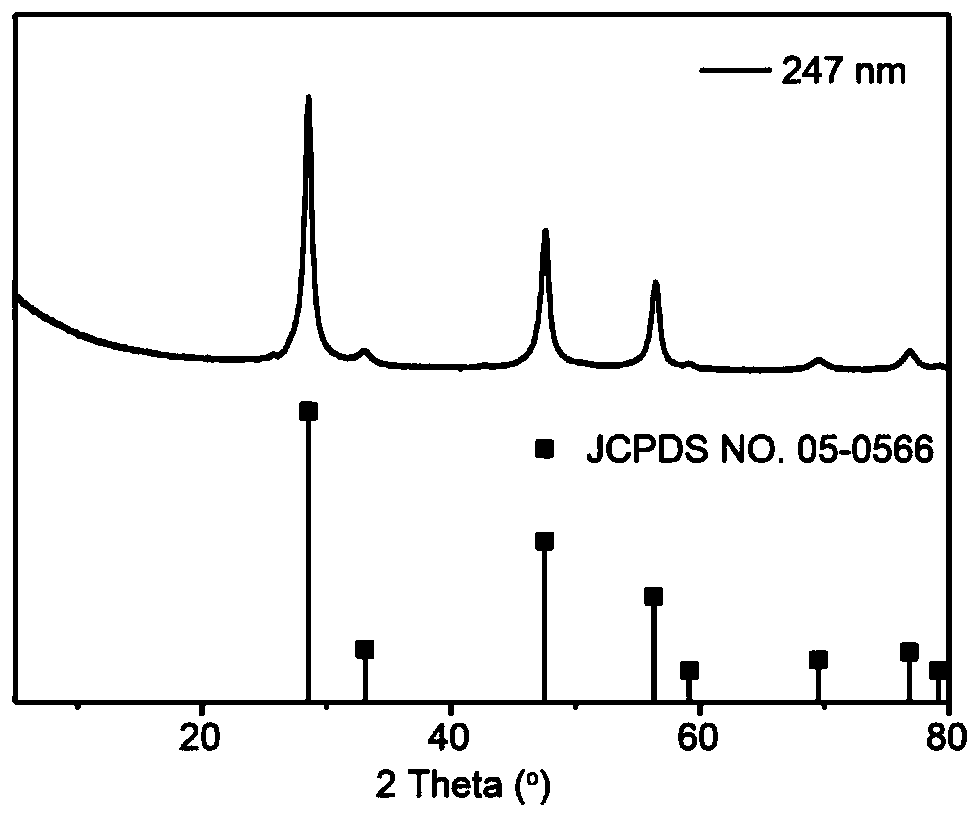

Nano-titanium dioxide automobile topcoat coating

The invention discloses a nano-titanium dioxide automobile topcoat coating. The nano-titanium dioxide automobile topcoat coating is characterized by being prepared from the following raw materials in parts by weight: 55-70 parts of titanium dioxide slurry, 8.5-21.4 parts of nano-titanium dioxide slurry, 6-8 parts of polar resin, 0.2-0.4 part of a flatting agent and 15-20 parts of a dispersing agent, wherein the nano-titanium dioxide slurry comprises the following components in percentage by mass: 88 percent of hydroxy acrylic resin, 7 percent of nano-titanium dioxide, 2 percent of dimethylbenzene, 2.6 percent of butyl alcohol and 0.4 percent of butyl acetate; the particle diameter of the nano-titanium dioxide is 65-130 nanometers; the dispersing agent is the combination of butyl alcohol, butyl acetate and dimethylbenzene. By adopting the coating, the agglomeration, flocculation and dispersion of titanium dioxide are avoided, and stable ultraviolet resistance, high hardness and high compactness are realized.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A Midline Tailings Dam Construction Method Using Die Bags

ActiveCN104912087BDrain fastAccelerated consolidationEmbankmentsSoil preservationSoil scienceTailings dam

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

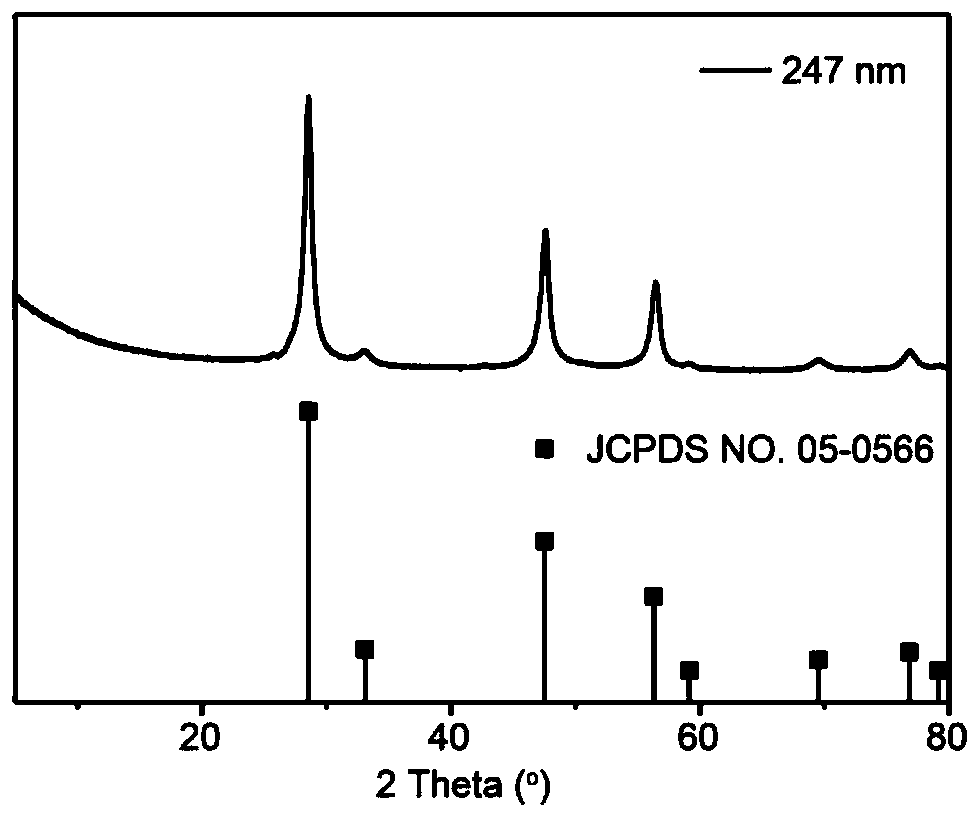

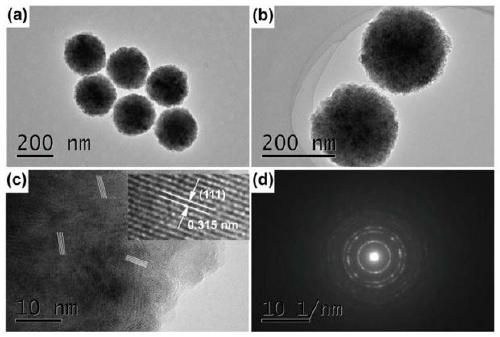

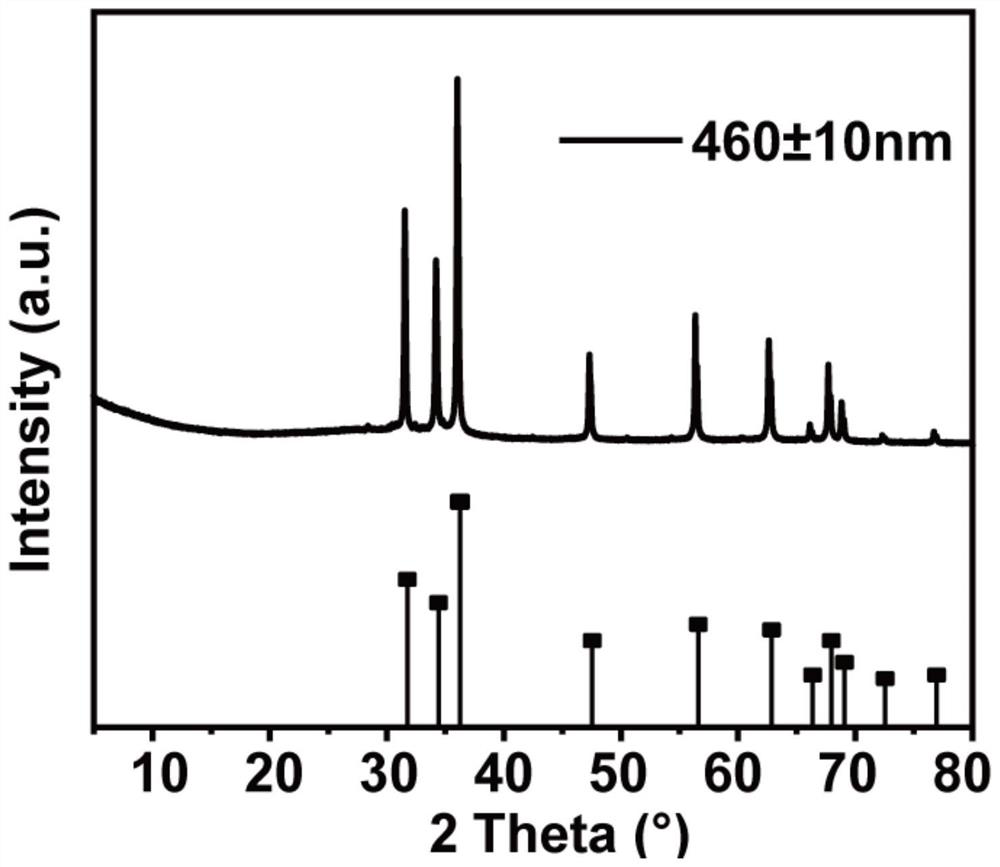

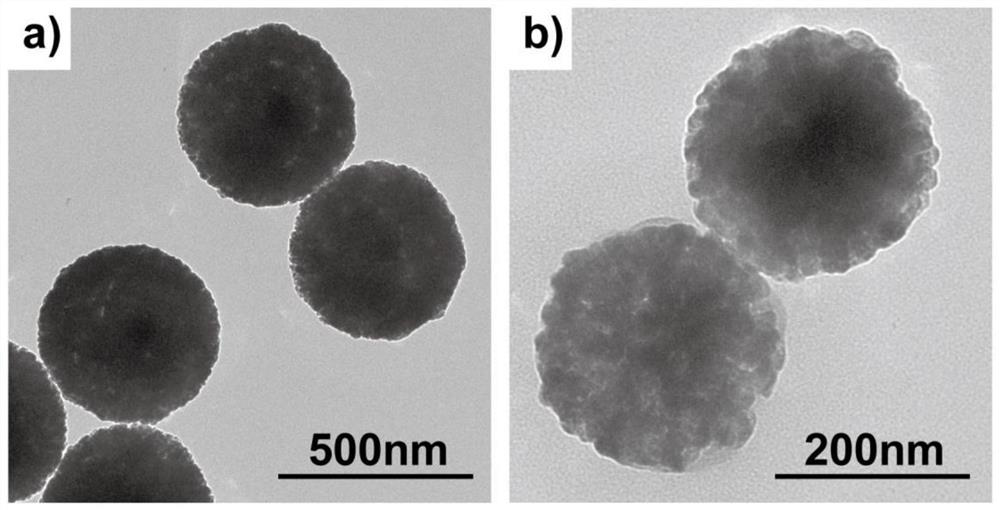

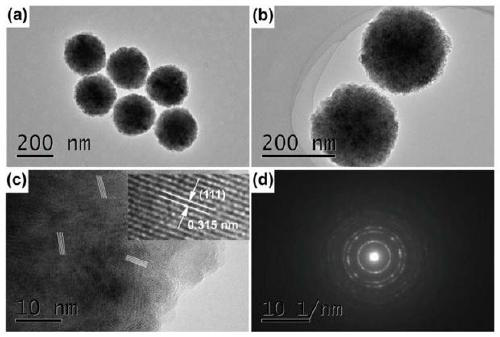

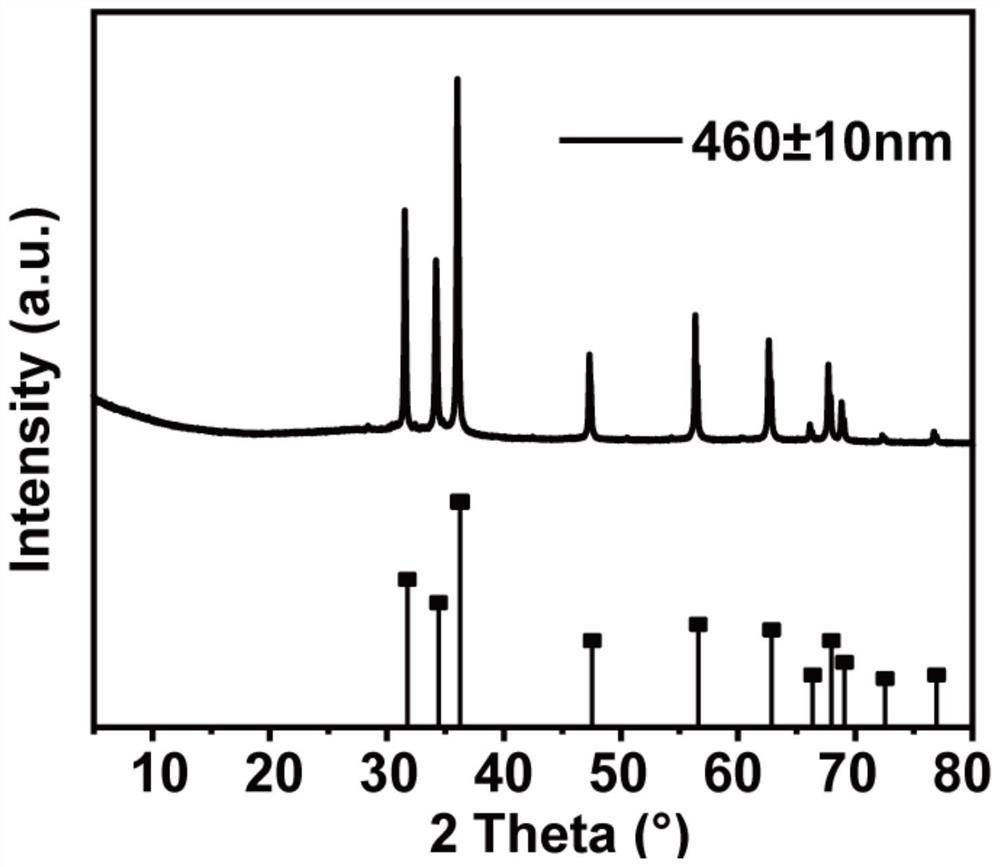

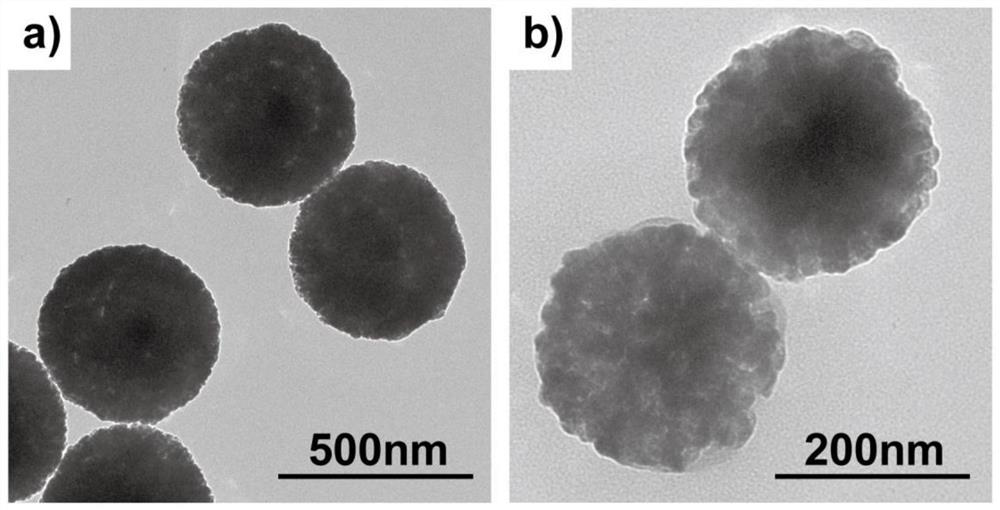

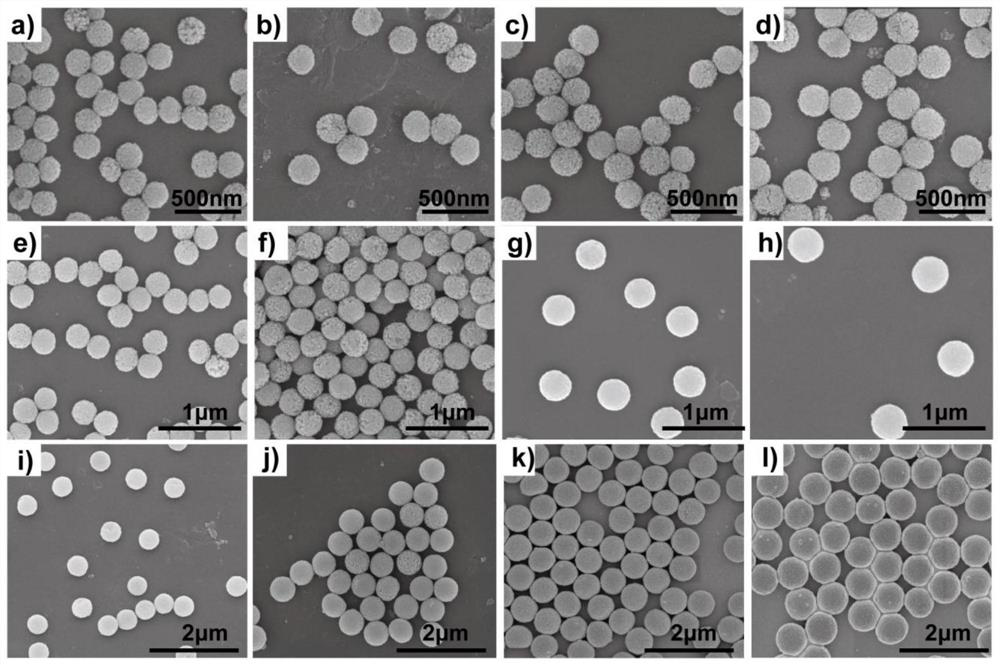

Sulfide highly-uniform microsphere with precisely controllable particle size and preparing method thereof

ActiveCN109942017AUniform particle sizeLarge particle size rangeMaterial nanotechnologyTin compoundsSynthesis methodsMicrosphere

The invention discloses a sulfide highly-uniform microsphere with the precisely controllable particle size and a preparing method thereof. The method includes the primary core growth step and the secondary layer-layer growth step on the basis of the concept of the core-shell-shell structure. In the primary growth step, through stable reaction conditions, the sulfide nanosphere with the stable particle size is obtained; in the subsequent step, the adding moments and amounts of metal salt and a sulfur source are controlled, and then the particle size of the nanospheres can be precisely controlled. According to the synthesis method, the sulfide microsphere with the target particle size can be obtained by precisely designing test steps through the preset target particle size; meanwhile, by means of the method, the controllable particle size range is obviously increased, and the controllable range is 100-1000 nm.

Owner:DALIAN UNIV OF TECH

Energy-saving low-carbon environment-friendly European-type grinding machine

The invention relates to an energy-saving low-carbon environment-friendly European-type grinding machine comprising an analytical machine on the upper part of a host machine, wherein the lower part of the host machine comprises an upper machine body, a middle machine body and a lower machine body; a discharge hole is formed in the top end of the upper part of the main machine; an airflow isolation loop is arranged on the lower part of the host machine; fine powder sending space is formed between the airflow isolation loop and the machine bodies of the lower part of the host machine; a feeding hole is installed in the outer side of the middle machine body; an air inlet is arranged in the lower machine body; a main shaft transmission device is installed in the middle machine body; the main shaft transmission device comprises a host machine belt wheel and a belt wheel transmission shaft; the host machine belt wheel is installed at the outside of the middle machine body; one end of the belt wheel transmission shaft is connected with the host machine belt wheel; the other end of the belt wheel transmission shaft is engaged with the other conical gear of the main shaft; a combined-type grinding roller lifting frame is installed on the main shaft; a cross arm shaft is installed on the combined-type grinding roller lifting frame; the upper end of a long-arm grinding roller shaft assembly is suspended on the cross arm shaft to form a movable fulcrum; a grinding roller capable of performing autogiration is installed at the lower end of the long-arm grinding roller shaft assembly; and a grinding ring with the position corresponding to that of the grinding roller is installed on the lower machine body. The energy-saving low-carbon environment-friendly European-type grinding machine is high in grinding efficiency, convenient to examine and repair and install, and long in service life, and a finished product produced by the energy-saving low-carbon environment-friendly European-type grinding machine is wide in particle size range.

Owner:上海建冶路桥机器设备有限公司

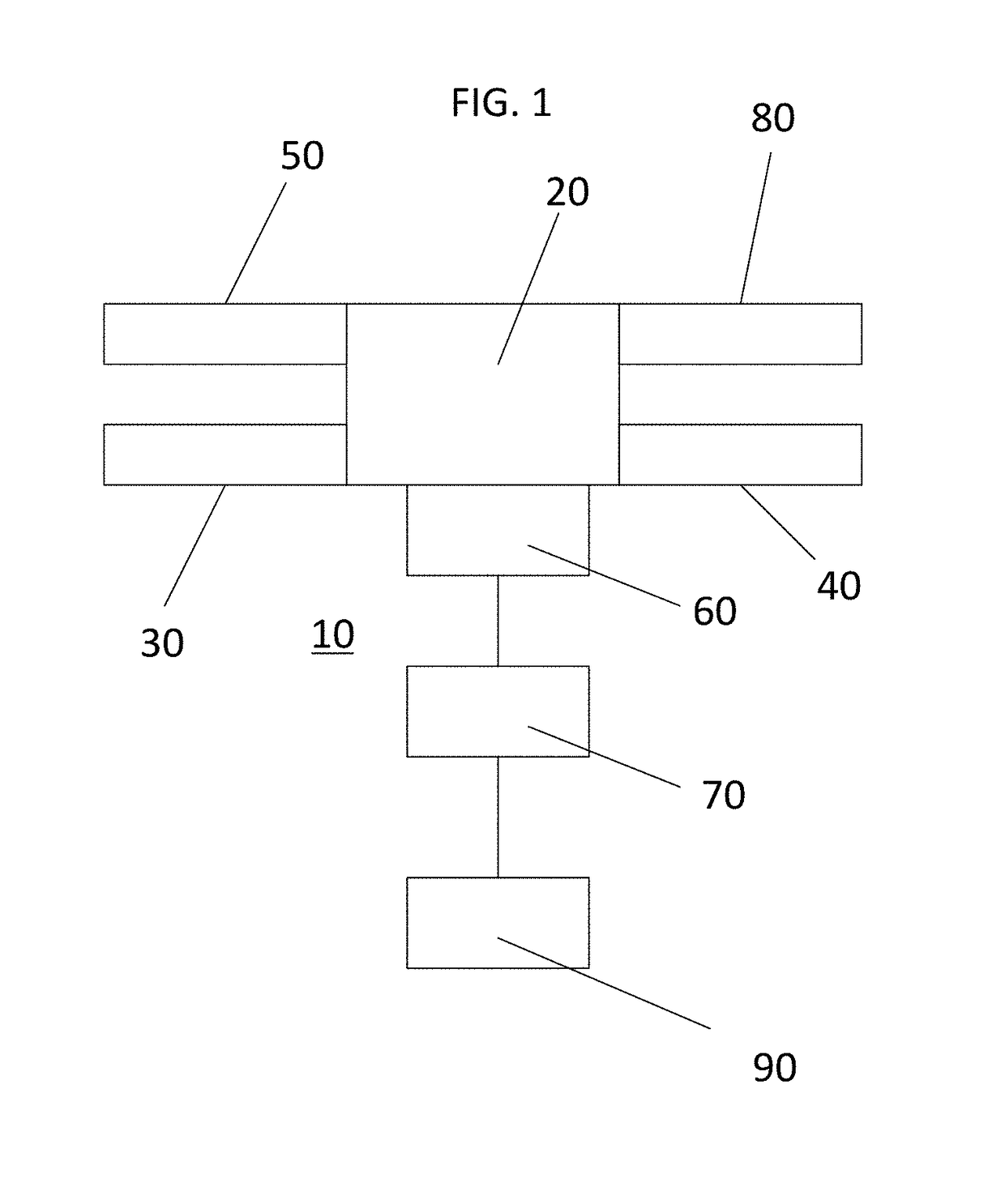

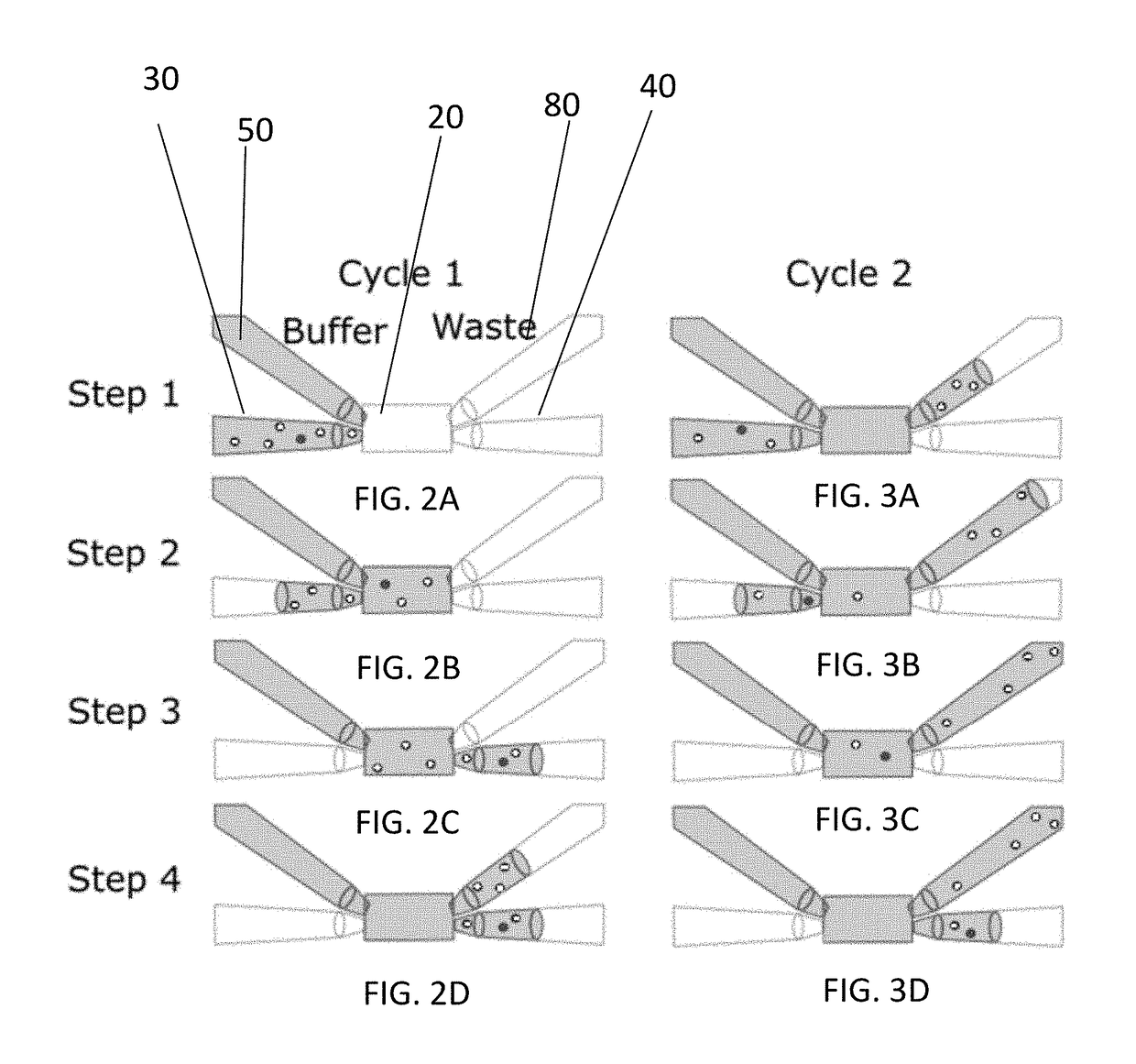

Fluid Sample Enrichment System and Method

ActiveUS20180321128A1Reduce processing timeProcessing speedPreparing sample for investigationLaboratory glasswaresFlow cellHOLDING CHAMBER

An enrichment system for enrichment of a sample comprising one or more microscopic particles of interest in a fluid carrier is disclosed. The enrichment system comprises a flow cell configured to receive a portion of the sample, a plurality of sample holding chambers and a waste, each connected to a flow cell, an imaging sensor configured to obtain an image of the microscopic particles in the fluid carrier in the flow cell and a controller configured to direct passage of the portion of the fluid sample in the flow cell, in dependence on the image obtained by the imaging sensor, to one of the holding chambers or to the waste.

Owner:SEE THROUGH SCI LTD

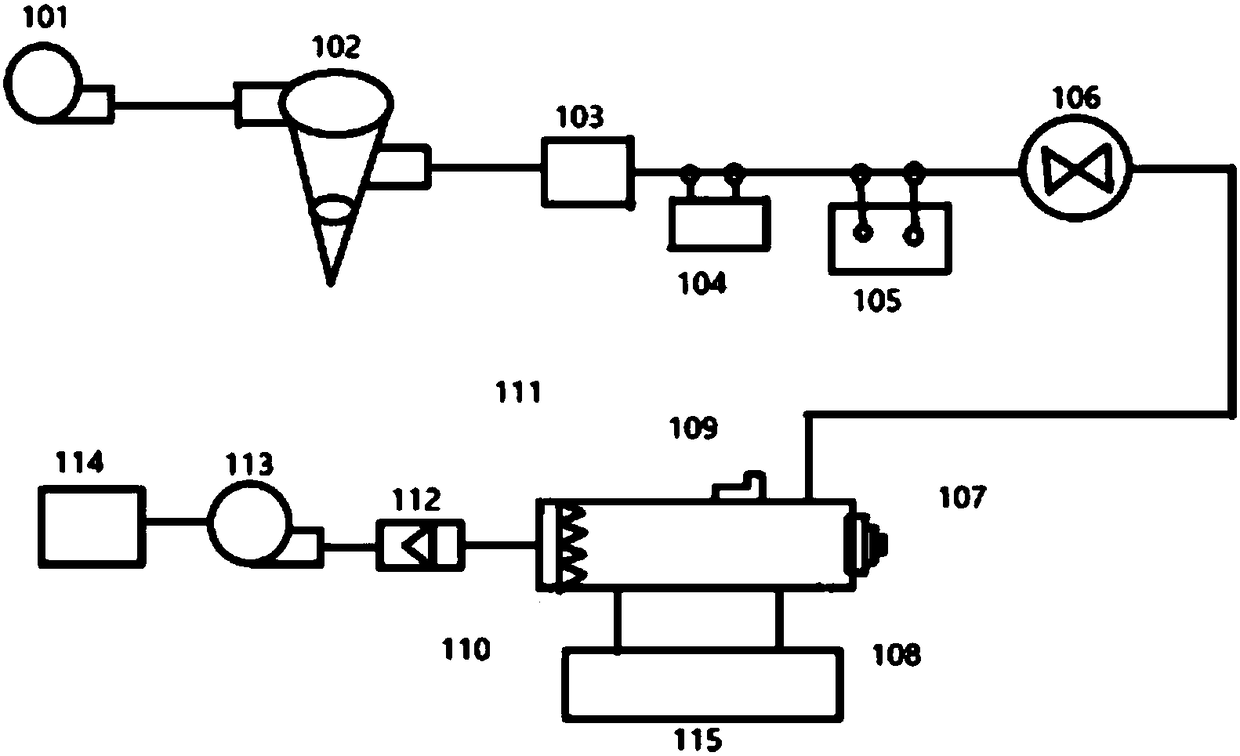

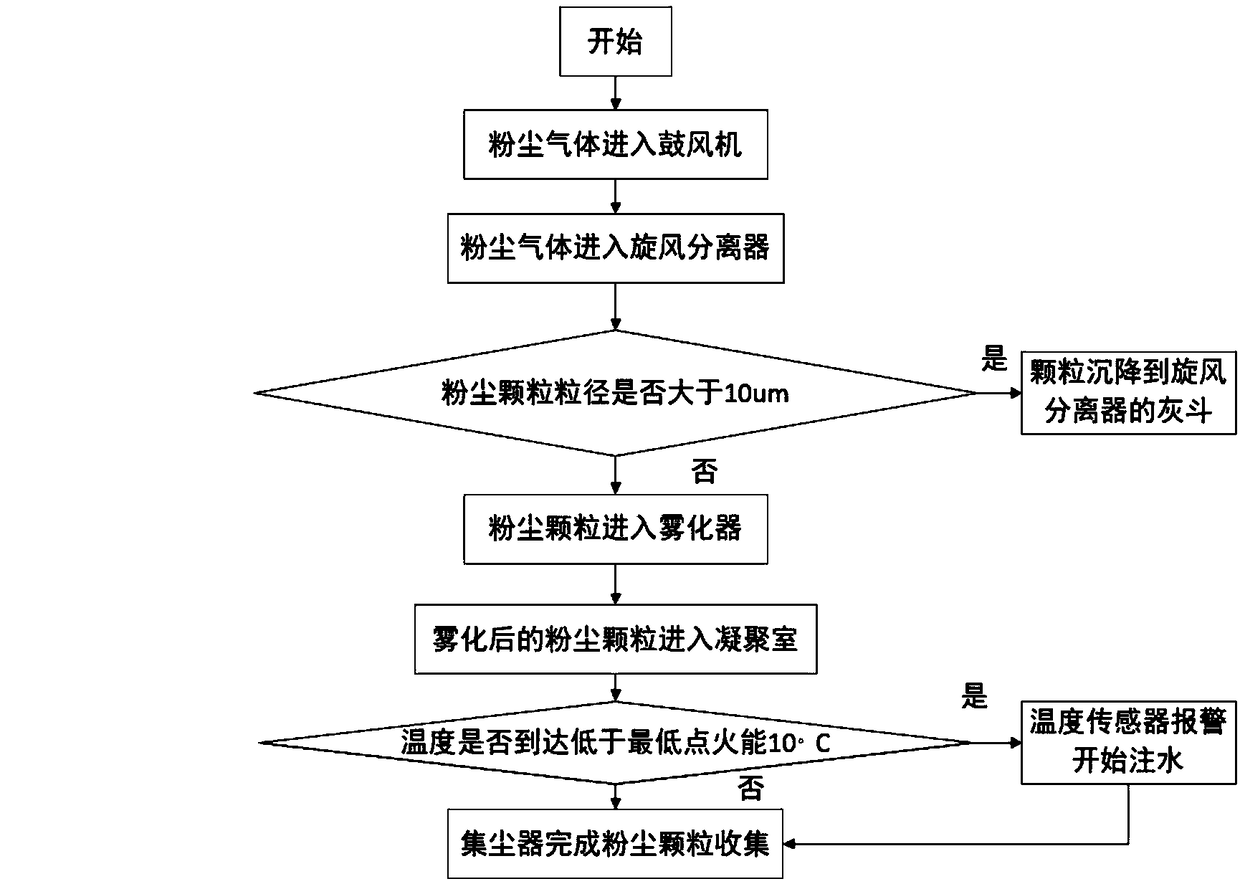

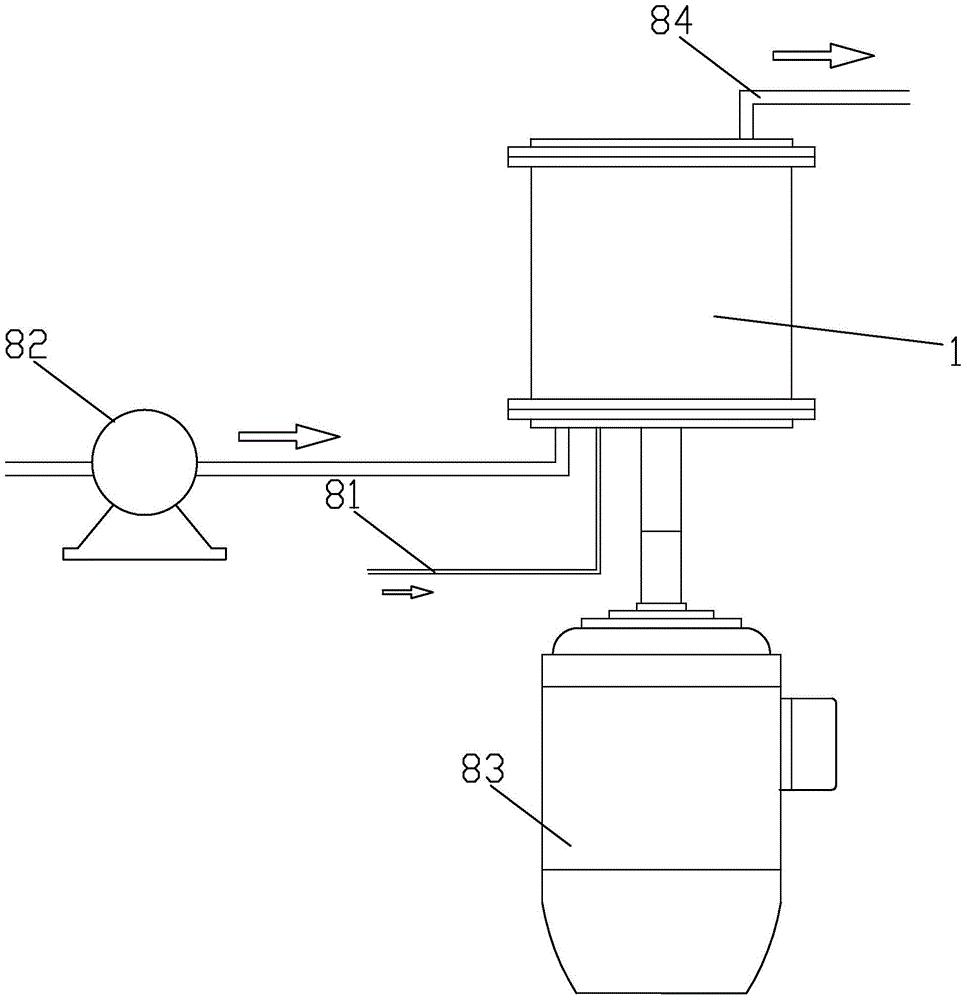

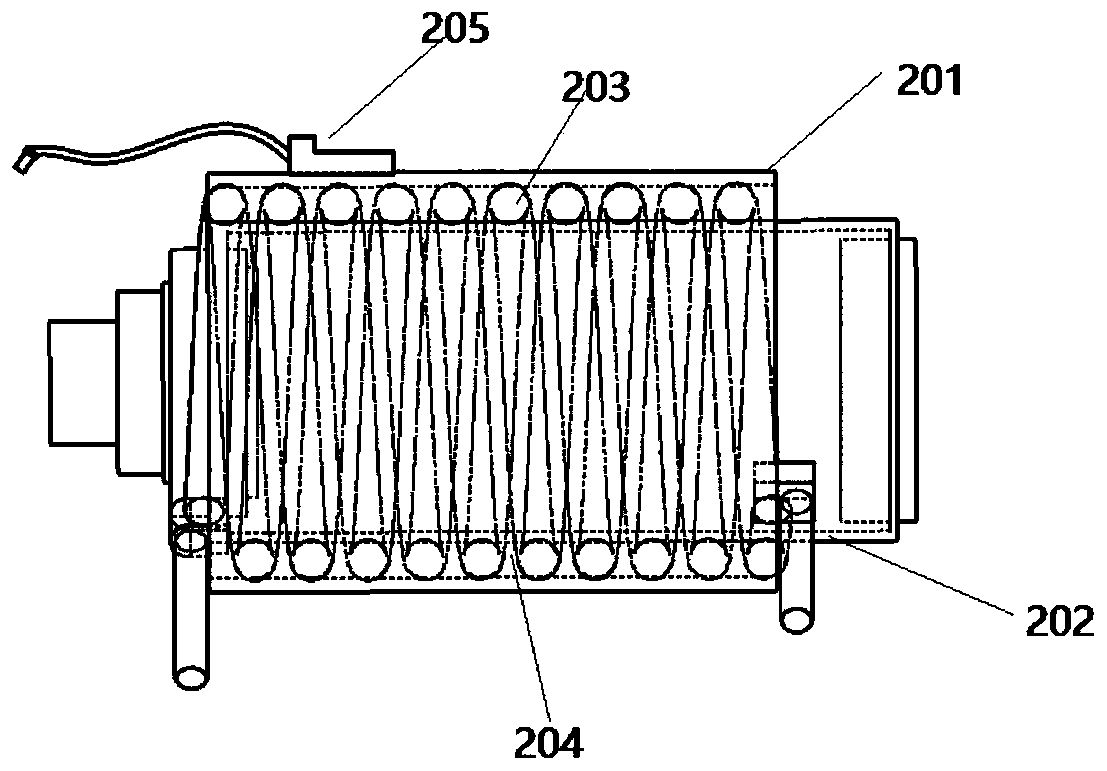

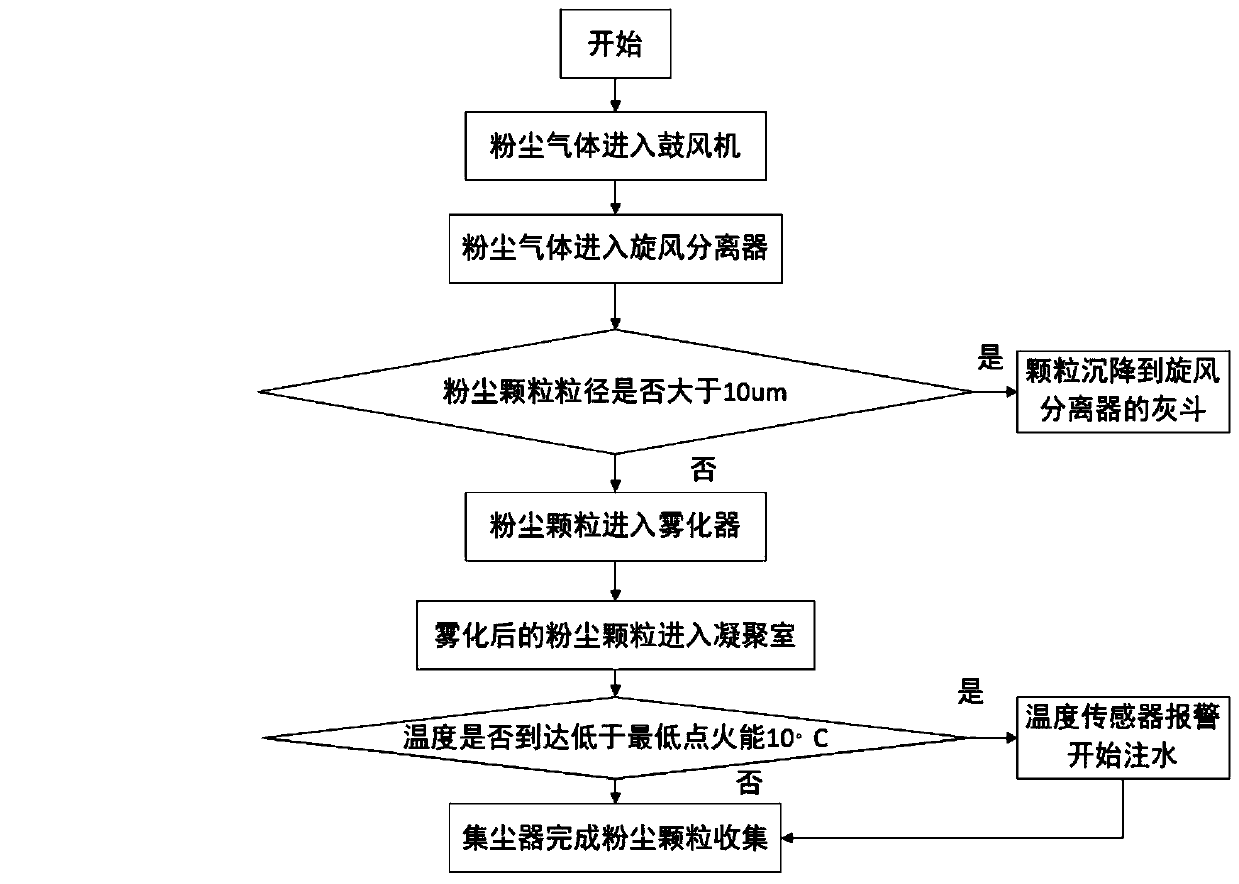

Coal mine dust-removing device based on ultrasonic atomization and condensation

ActiveCN108412534AIncrease cooling areaImprove work efficiencyCombination devicesDust removalAir blowerUltrasonic atomization

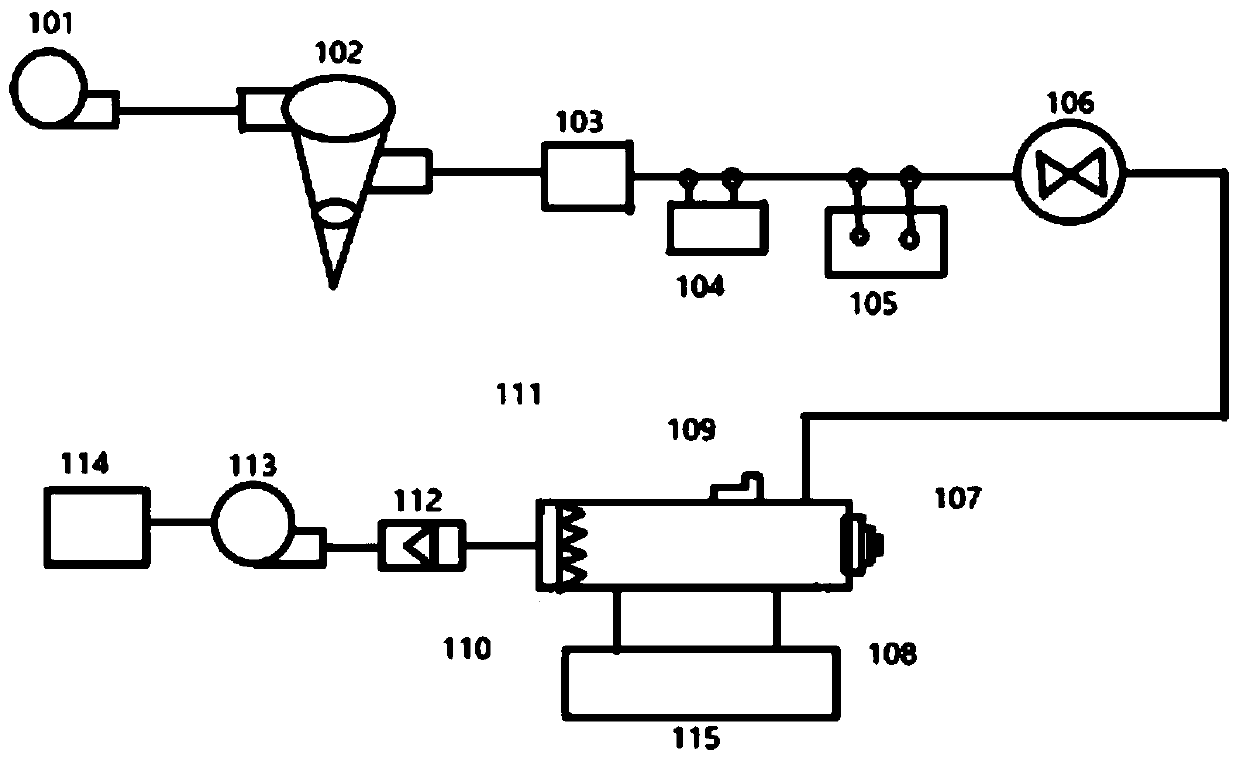

The invention discloses a coal mine dust-removing device based on ultrasonic atomization and condensation. The coal mine dust-removing device comprises a negative pressure pipeline composed of an airblower, a vacuum pump and a connecting pipeline. The negative pressure pipeline is provided with a cyclone separator, an ultrasonic atomizer, a pressure valve and a condensation chamber sequentially.The cyclone separator is connected with the air blower. The vacuum pump is further connected with a dust collector. The condensation chamber is internally provided with an ultrasonic oscillator. A sound absorption sponge is further arranged at an outlet of the condensation chamber. The coal mine dust-removing device is easy to implement and high in efficiency, the content of coal dust in air in acoal mine roadway is effectively decreased, vicious accidents such as coal dust explosion are avoided, and safe conducting of the coal mine roadway exploiting process is ensured.

Owner:丹东长城环境设备有限公司

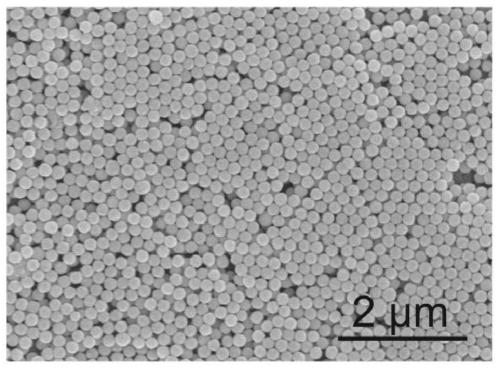

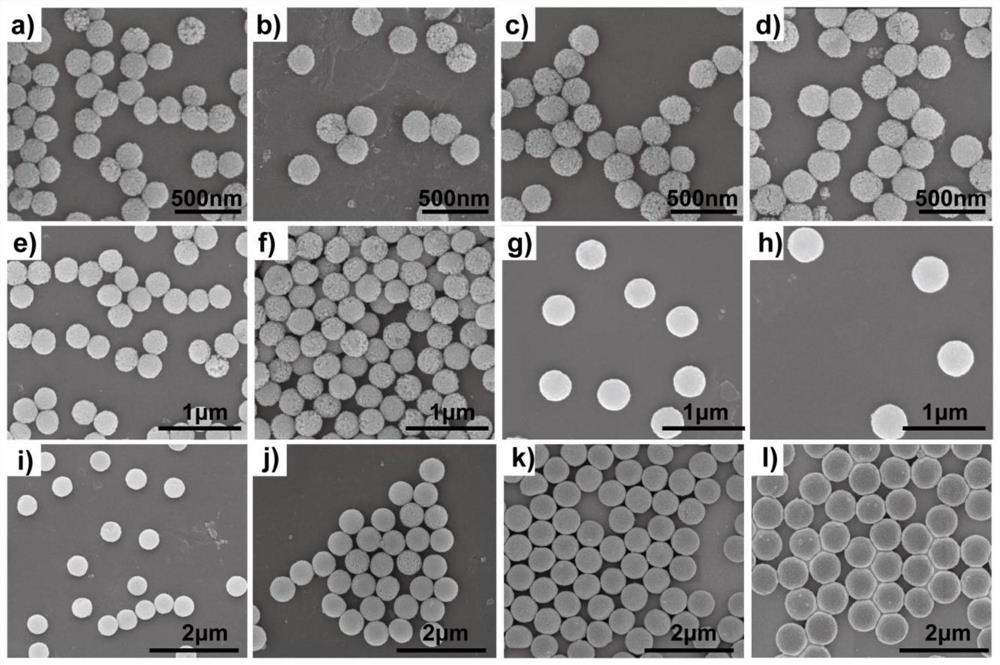

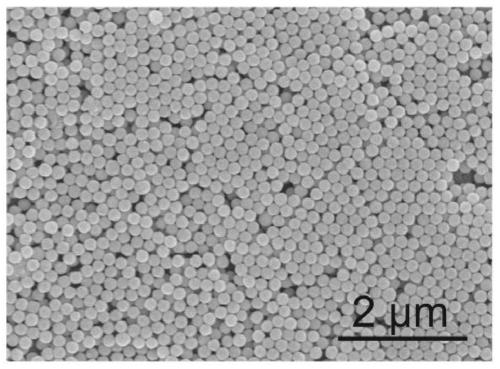

Highly uniform zinc oxide submicrospheres with controllable particle size and preparation method thereof

ActiveCN112777626AUniform particle sizeLarge particle size rangeMaterial nanotechnologyZinc oxides/hydroxidesPhotonic crystalPolyol

The invention discloses highly uniform zinc oxide submicrospheres with controllable particle size and a preparation method thereof, which belong to the field of preparation of photonic crystal materials. According to the method, an alcohol-water system is adopted, so that the temperature and pressure required by synthesis of the zinc oxide microspheres are reduced, and the zinc oxide polycrystalline submicrospheres with good monodispersity are synthesized more cleanly. In the nucleation process, the temperature, the initial rotating speed, the zinc source and the deionized water amount are regulated and controlled, so that the nucleation process is rapidly carried out. In the growth process, mass transfer is further controlled by introducing polyhydric alcohol to control the viscosity of a system, and zinc oxide submicrospheres with stable particle sizes can be obtained through one-step reaction. According to the synthetic method, the zinc oxide submicrospherewith the specific target particle size can be obtained only by changing the amount of the zinc source and the variety and amount of the polyhydric alcohols. The adjustable particle size range of the zinc oxide submicrospheres prepared by the method is obviously enlarged, the adjustable range is 100-800 nm, and the monodispersity of the zinc oxide submicrospheres is good.

Owner:DALIAN UNIV OF TECH

Large direct shear test sample preparation device for microorganism reinforced coarse-grained soil and use method thereof

PendingCN111122280AAvoid disturbanceAvoid destructionPreparing sample for investigationMaterial strength using steady shearing forcesMicroorganismSoil science

The invention discloses a large direct shear test sample preparation device for microorganism reinforced coarse-grained soil and a use method thereof. The large direct shear test sample preparation device comprises a device base, a mold cylinder, sleeves, grouting pipes and bending element sensors. The device base is installed on a direct shear apparatus, and the mold cylinder is installed on thedevice base. A plurality of bending element sensors are arranged on the outer wall of the mold cylinder, and a plurality of drain pipes penetrating the side wall of the mold cylinder are arranged at the lower end of the mold cylinder. A plurality of sleeves are vertically arranged in the mold cylinder, a plurality of through holes are formed in the sleeves, and the space between the sleeves and the mold cylinder is filled with coarse-grained soil. The lower ends of a plurality of grouting pipes are inserted into the corresponding sleeves, the upper ends of the grouting pipes are connected withliquid guide pipes, and the liquid guide pipes are connected with a microbial solution pool and a reaction liquid pool. The device is convenient to assemble and separate, can be used for preparing coarse-grained soil with a large particle size range and has strong operability; the utilization rate of reaction liquid is increased by adopting a method of combining saturated grouting and standing reaction.

Owner:CHONGQING UNIV

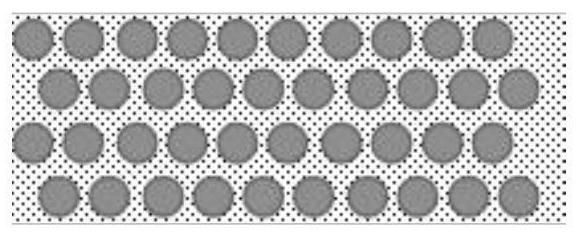

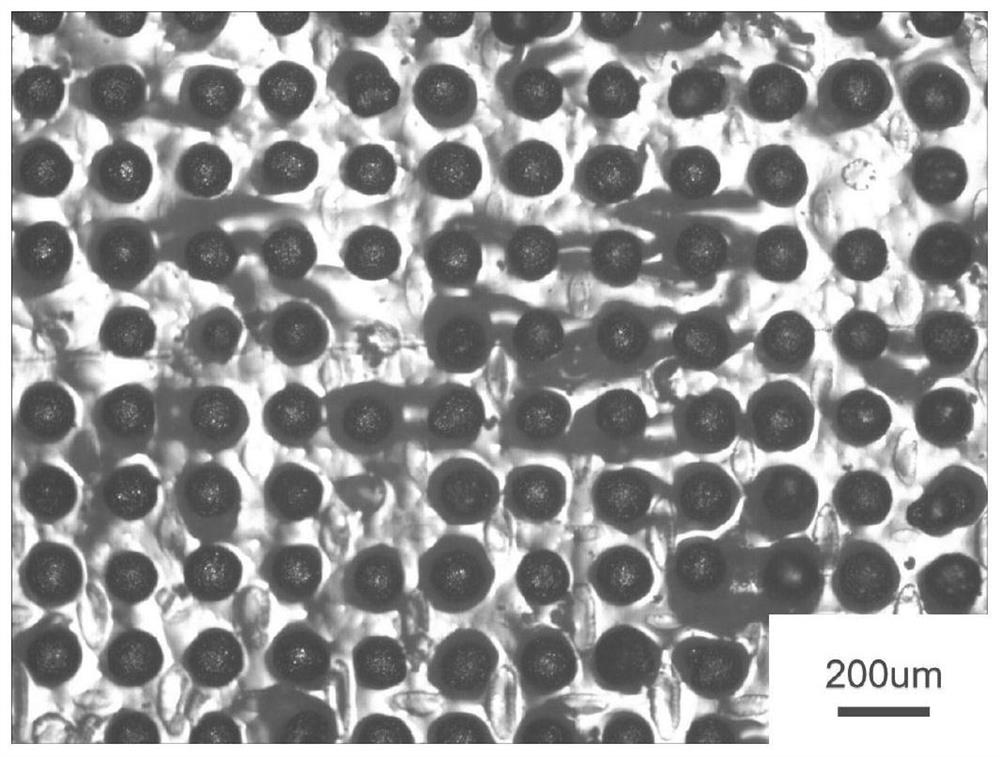

Composite material containing ordered microsphere array and preparation method of composite material

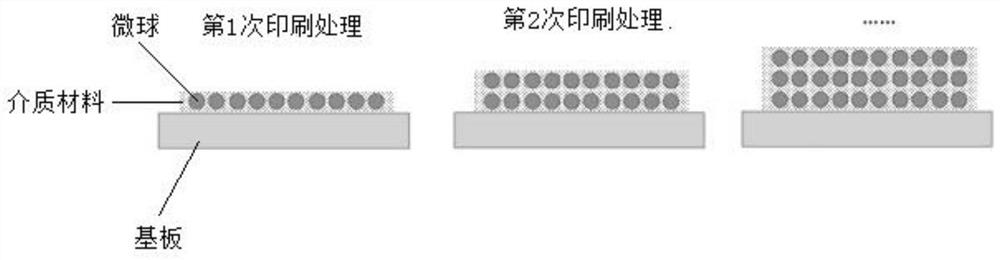

PendingCN111960378AArrangement can be controlledLarge particle size rangeMaterial nanotechnologyDecorative surface effectsScreen printingMicrosphere

The invention provides a composite material containing an ordered microsphere array and a preparation method of the composite material, and belongs to the technical field of functional material preparation. On the basis of a silk-screen printing method, regular silk-screen meshes are filled with microspheres through a scraper blade, and the ordered microsphere array can be obtained after a silk screen is removed. According to the preparation method, regular arrangement of the microspheres is realized by utilizing meshes of the silk screen, the arrangement mode of the microspheres is controllable, the particle size range of the applicable microspheres is large, regular arrangement of larger microspheres can be realized, the operation is simple, the cost is low, the efficiency is high, and the preparation method is suitable for preparation of a large-area two-dimensional microsphere array and a large-volume three-dimensional microsphere array. In the composite material prepared by the method provided by the invention, the array formed by regularly arranging the microspheres can enhance the functionality of the material, and can be applied to the fields of electromagnetic shielding, radiation shielding, catalysis, light filtering and the like.

Owner:SICHUAN UNIV

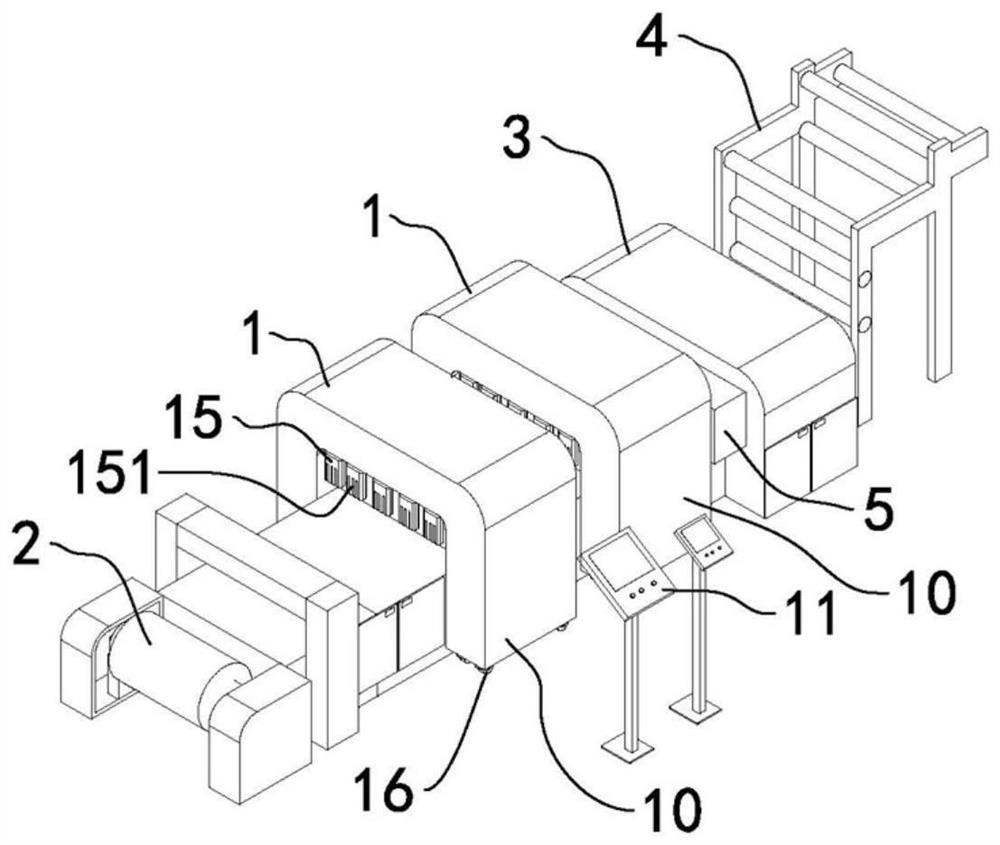

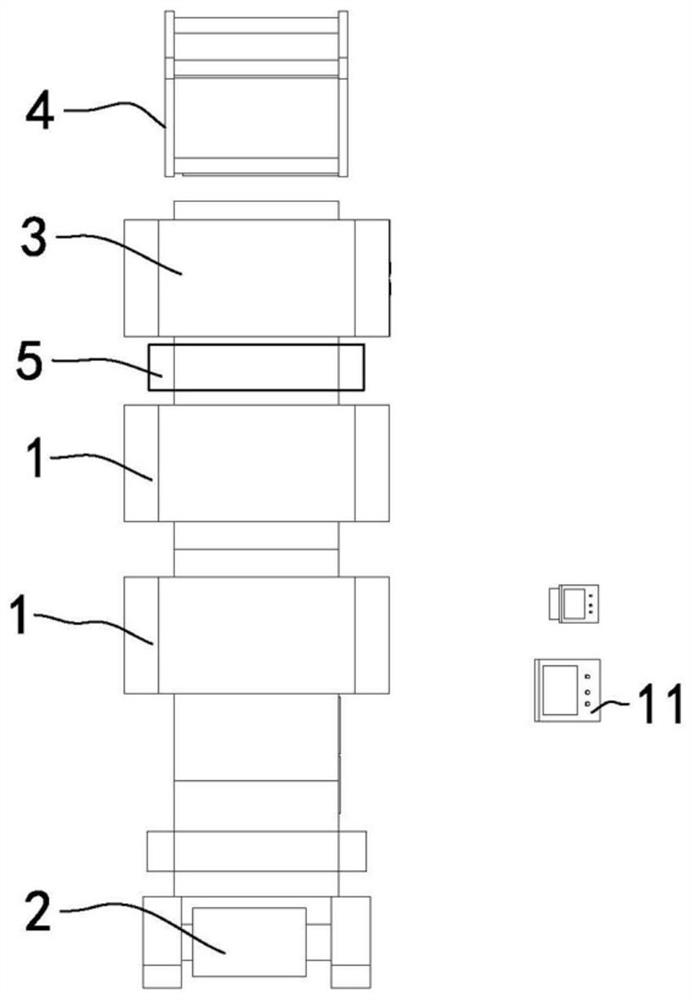

Digital ink jet dyeing machine

PendingCN113103762ADoes not produce dot-like graininessLarge particle size rangeTypewritersDyeing processColor printingEngineering

The invention discloses a digital ink jet dyeing machine. The digital ink jet dyeing machine comprises an unwinding and cloth feeding device, an ink jet device, a drying device and a winding device which are sequentially arranged in the fabric feeding direction, wherein the ink jet device comprises a machine body, a controller, an ink box, a cleaning liquid box, a waste liquid barrel and an ink jet module; the machine body is provided with at least two groups of ink jet modules, at least one ink box, at least one cleaning liquid box and at least one waste liquid barrel; each ink jet module comprises spray heads, a positioning frame and a supporting and moving mechanism; a plurality of spray heads arranged in parallel form spray head groups; and each ink jet module comprises at least one spray head group. According to the scheme, the fixed single-channel spray heads are adopted, and ink of a single color being subjected to color matching is evenly dotted on a textile so as to complete digital pure color printing, so that the most headache point-shaped granular feeling of a conventional digital printing machine is avoided, the color development effect is greatly improved compared with the color development effect of pure color printing of the printing machine, and the digital ink jet dyeing machine has the advantages of quick cleaning.

Owner:浙江环峪科技有限公司

Sewage precipitant and using method thereof

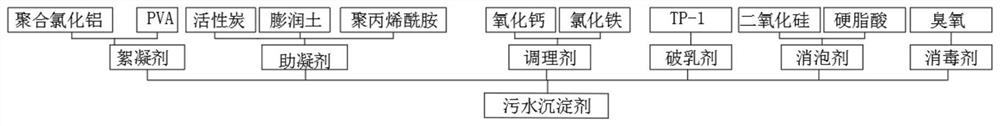

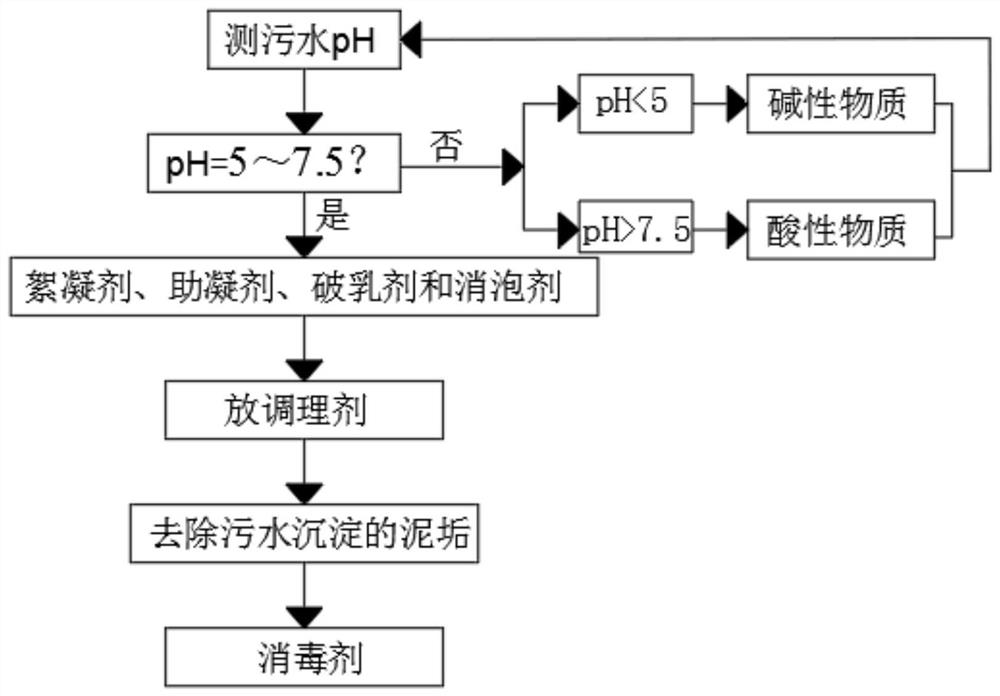

InactiveCN111943335ALarge particle size rangeNot affected by water temperatureFatty/oily/floating substances removal devicesSpecific water treatment objectivesAluminium chlorideDisinfectant

The invention provides a sewage precipitant and a use method thereof. The sewage precipitant comprises a flocculant, a coagulant aid, a conditioner, a demulsifier, a defoamer and a disinfectant, and is characterized in that the flocculant is a mixture of polyaluminum chloride and PVA, the coagulant aid is a mixture of activated carbon, bentonite and polyacrylamide, the conditioner is calcium oxideand ferric chloride, the demulsifier is T-1, the defoamer is a mixture of silicon dioxide powder and stearic acid, the disinfectant is ozone, and the mass ratio of the flocculant to the coagulant aidto the conditioner to the demulsifier to the defoamer is 2: 10: 0.5: 0.1: 0.1. The sewage precipitant is high in precipitation rate, capable of removing heavy metal ions, free of retention of a largeamount of Al<3+> and Fe<3+> after sewage treatment, capable of sterilizing and removing organic matters such as color, smell and the like in water, high in decomposition speed, free of residual substances and free of secondary pollution.

Owner:安徽伊尔思环境科技股份有限公司

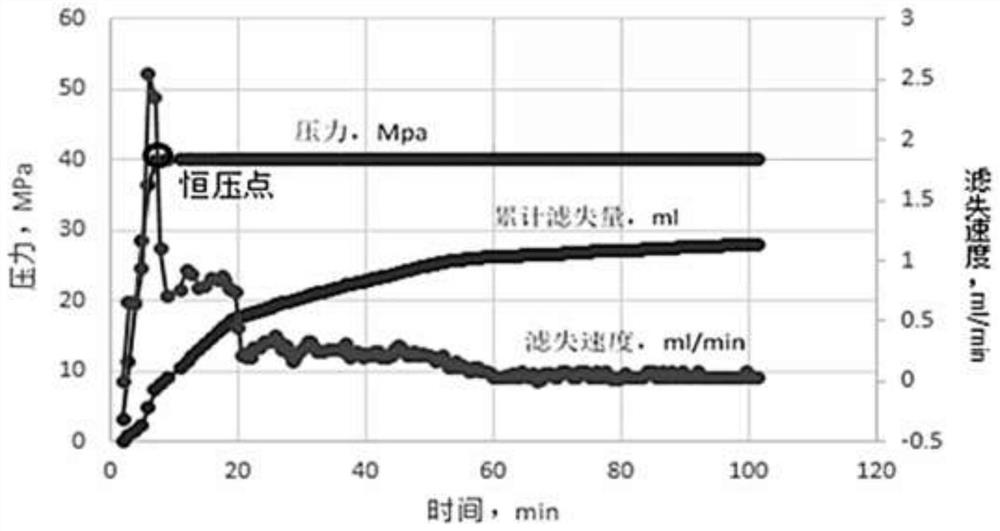

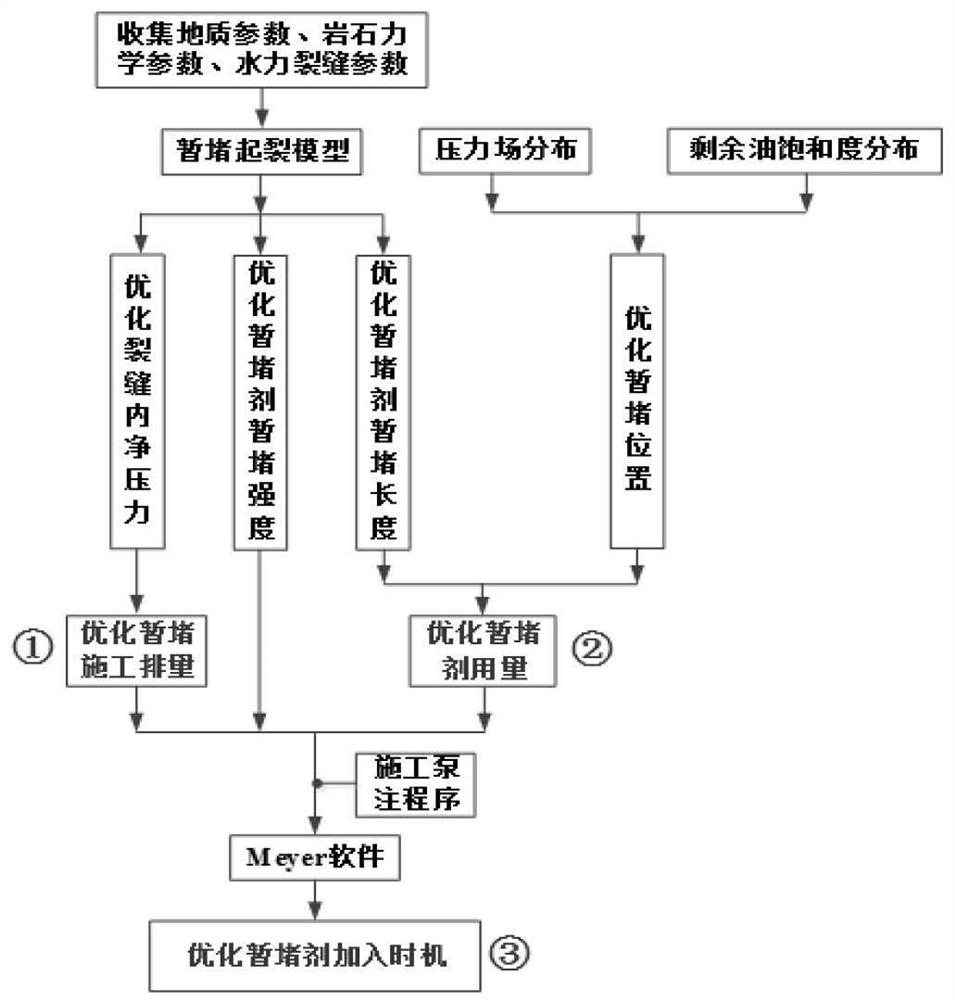

MCF fracturing temporary plugging agent as well as preparation method and application thereof

ActiveCN114369450AOvercoming sticky pumpOvercome cakingDrilling compositionPetroleum resinProcess engineering

The invention provides an MCF fracturing temporary plugging agent and a preparation method and application thereof.The MCF fracturing temporary plugging agent comprises main components and additives, the main components comprise petroleum resin, ozocerite and calcium stearate, the additives comprise thermosetting resin, water-soluble resin and positive electricity gel, and the weight ratio of the additives to the main components is 1: (10-50). The MCF fracturing temporary plugging agent provided by the invention belongs to an oil-soluble resin temporary plugging agent, has the technical advantages of high compression strength, full degradation, adjustable particle size, safety, environmental protection, no danger, small dosage, low cost and the like, and has a wide application prospect.

Owner:延安祁北石油工程技术服务有限公司

Preparation method of ultraviolet cured silica sol modified aqueous urethane acrylate dispersoid

InactiveCN101747487BExpand particle size rangeLarge particle size rangePolyurea/polyurethane coatingsUltravioletSilicon dioxide

A preparation method of ultraviolet cured silica sol modified aqueous urethane acrylate dispersoid belongs to the technical field of ultraviolet cured aqueous paint. The preparation method of the invention comprises: mainly using diisocyanate compounds, polyether polyol, polyhydroxycarboxylic acid and hydroxyl acrylate monomer as main raw materials to prepare a urethane acrylate prepolymer through an acetone process; adding amine compounds and water for salt formation and emulsification, introducing aqueous silicon dioxide sol in the emulsification process to obtain the ultraviolet cured silica sol modified aqueous urethane acrylate dispersoid. The invention introduces the aqueous nanometer-sized silicon dioxide in situ in the synthesis of the aqueous urethane acrylate dispersoid to obtain the silica sol modified aqueous urethane acrylate dispersoid. The introduction of the inorganic nanometer-sized silicon dioxide obviously improves the mechanical property of a light-cured coating. The dispersoid can be widely applied to the surface coating field of woodware, metal and plastic rubber and the like with high scratch resistance and wearing resistance.

Owner:JIANGNAN UNIV

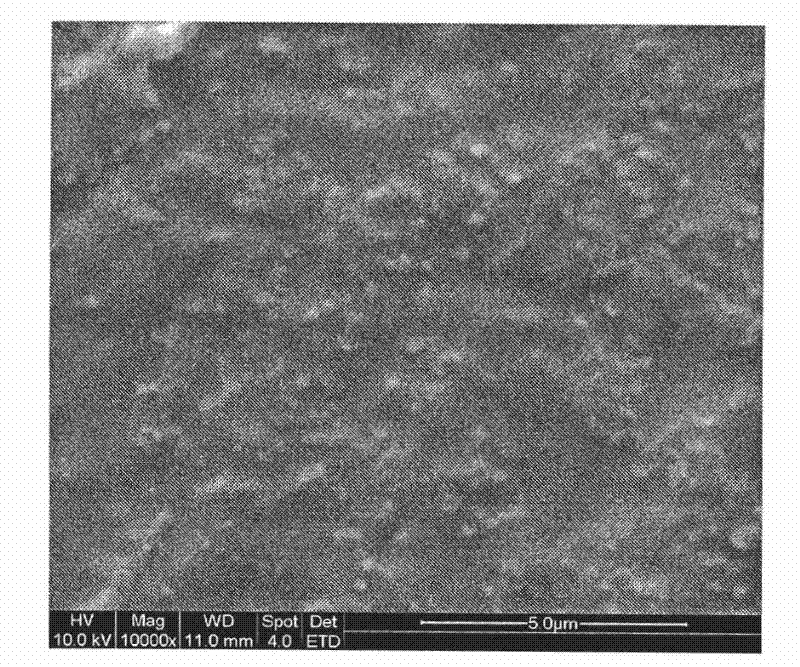

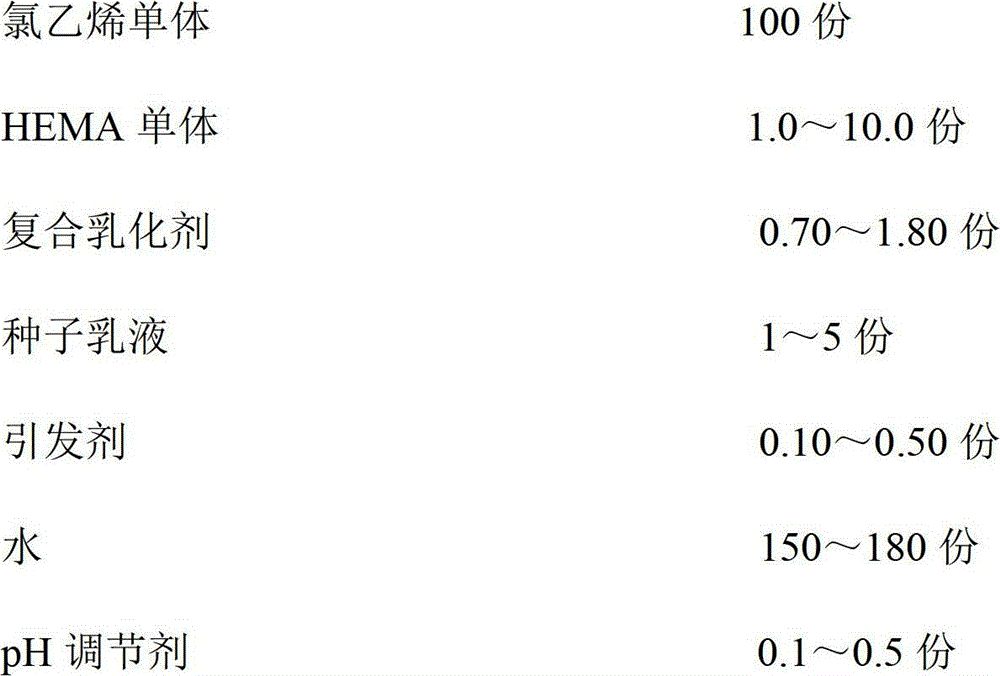

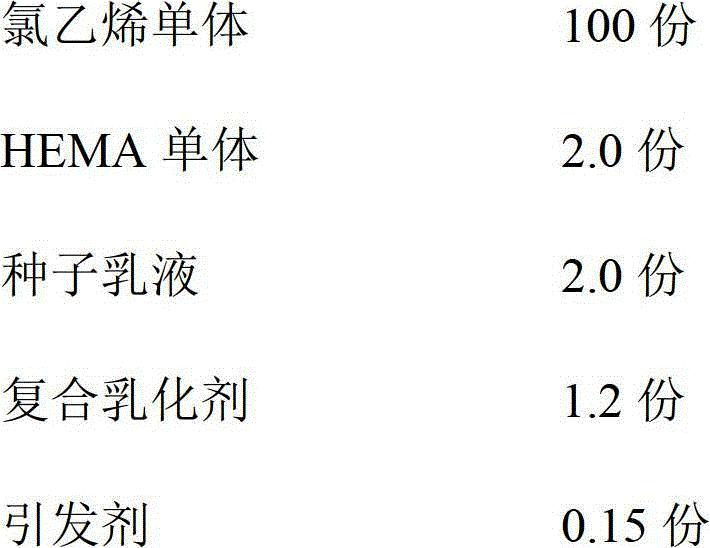

Synthesis method of hydroxylated polyvinyl chloride copolymer resin

ActiveCN102766231BHigh solid contentExpand particle size range(Hydroxyethyl)methacrylatePhenyl Ethers

The invention discloses a synthesis method of hydroxylated polyvinyl chloride copolymer resin. The synthesis method comprises the following steps of: adding hydroxyethyl methacrylate (HEMA) and an initiator II in a mixture of a composite emulsifying agent, an initiator I, water, a pH regulation agent, seed emulsion and a vinyl chloride monomer in a fluid mode, conducting polymerization reaction, and conducting spray drying on prepared emulsion to obtain the hydroxylated polyvinyl chloride copolymer resin, wherein the composite emulsifying agent is composed of an emulsifying agent I and an emulsifying agent II; the emulsifying agent I is sodium dodecyl benzene sulfonate, sodium dodecyl sulfate, sodium lauryl sulfate, nonyl aryl polyether alcohol, ammonium laurate, polyoxyethylene nonyl phenyl ether or polyoxyethylene octylphenol ether; and the emulsifying agent II is tetradecyl alcohol, setanol, stearyl alcohol, dodecanoic acid, tetradecanoic acid, tetradecanoic acid, octadecanoic acid, hexadecane or octodecane. The synthesis method is simple in equipment, solves the problems of low reaction conversion rate, large HEMA homopolymerization rate, low HEMA content in polymer and the like, and is low in cost, saving in energy consumption and less in pollution discharge.

Owner:SHANGHAI CHLOR ALKALI CHEM

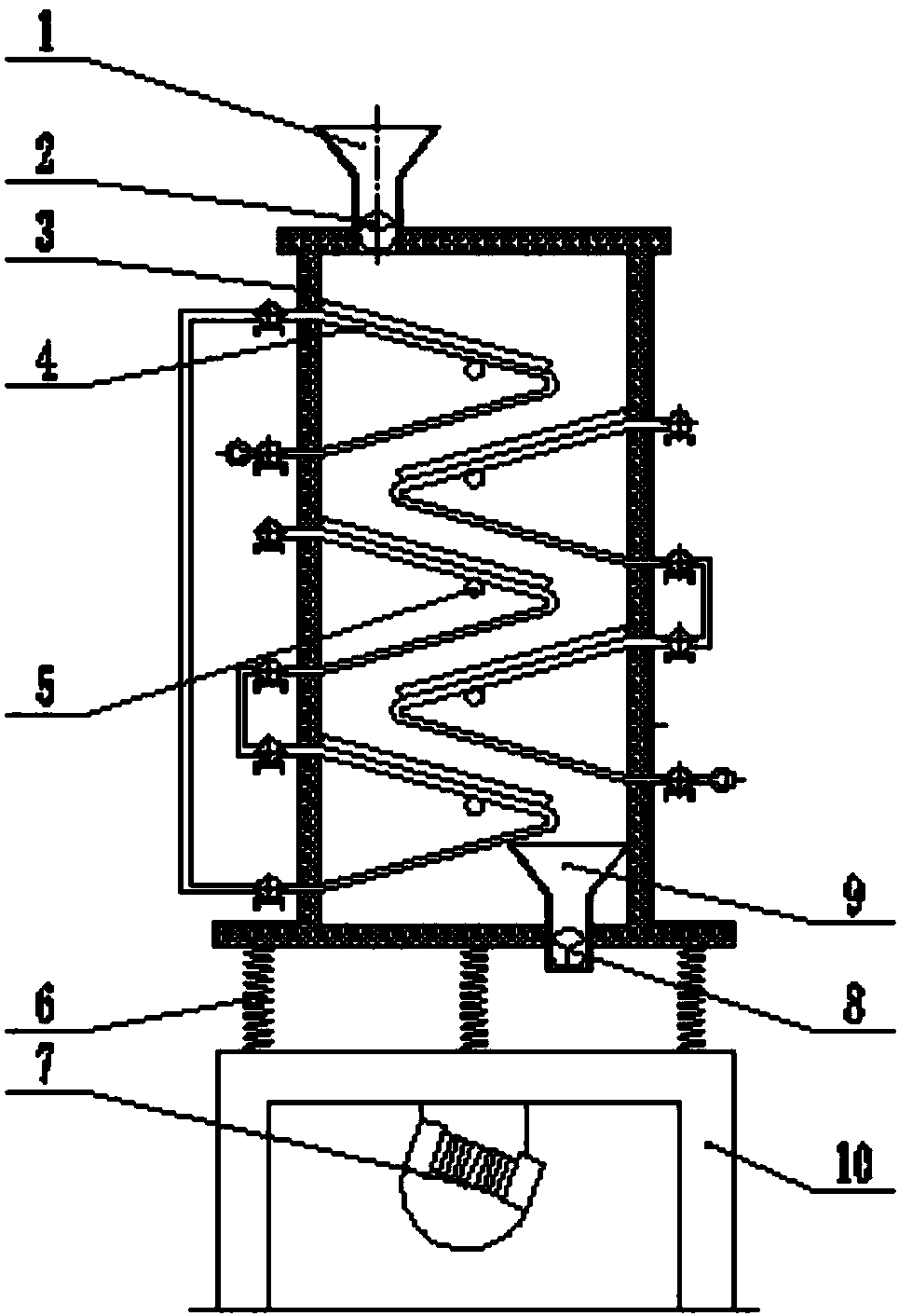

Multilayer acute angle membrane type wall vibration folding high-efficiency particle heat exchanging device

ActiveCN108955322AWide adaptability to shapeLarge particle size rangeHeat exchanger casingsTubular elementsAcute angleElectric machinery

The invention discloses a multilayer acute angle membrane type wall vibration folding high-efficiency particle heat exchanging device. The multilayer acute angle membrane type wall vibration folding high-efficiency particle heat exchanging device comprises a base, a boiler body located above the base and a plurality of acute angle membrane type wall structures. A plurality of vibrating springs arefixedly arranged between the boiler body and the base, and the base is provided with a vibration motor. A feeding port is formed in the boiler body. A feeding hopper communicates with the feeding port. The feeding port is provided with a feeding valve. A discharge port is formed in the lower end of the boiler body and provided with a discharging valve and a discharging hopper. The multilayer acute angle membrane type wall vibration folding high-efficiency particle heat exchanging device is relatively wide in material shape application range and particle size range and also adapts to non-circular particle particles. The materials flow from top to bottom, a working medium in a water pipe flows from bottom to top, good countercurrent is formed between the materials and the working medium, and gradient utilization of waste heat is advantageously achieved. The materials roll down, the gravity of the materials provide part of falling power, and the power consumption is relatively small. Themass transfer in the materials is powerful, and the heat exchanging coefficient of the materials and the inner walls of the boiler body is high.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

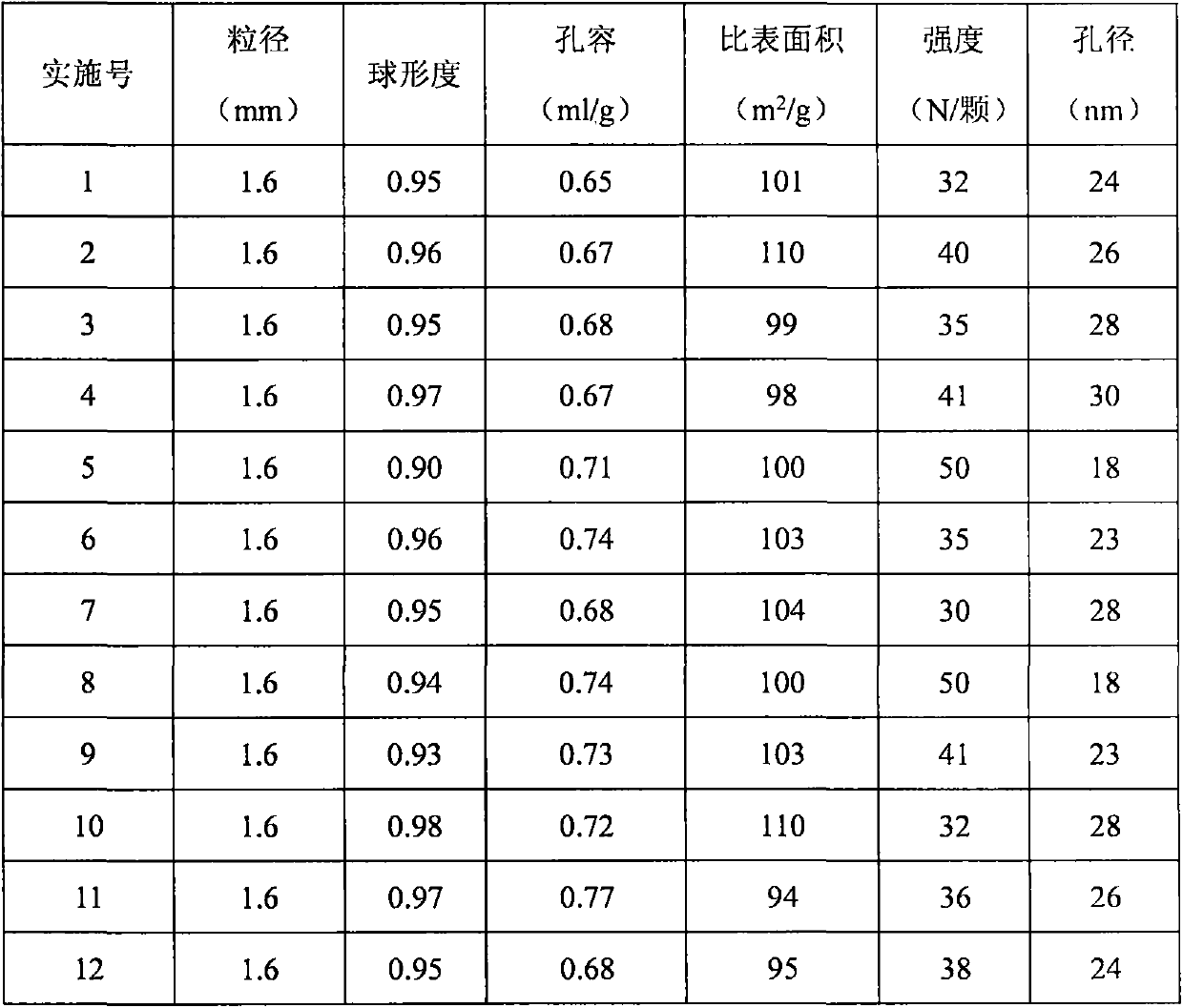

A kind of preparation method of mesoporous θ-alumina spherical carrier

ActiveCN106167270BFast molding speedImprove efficiencyPhysical/chemical process catalystsAluminium oxides/hydroxidesEngineeringUltimate tensile strength

Owner:淄博链科工程材料有限公司

A dust concentration measuring device and method

ActiveCN104374677BHigh sensitivityQuick responseParticle suspension analysisComputational physicsLight extinction

The invention discloses a concentration measuring device and method for dust in large diameter range. Aiming at the shortcoming that scattering integration method in the prior art is not applicable when the particle size is smaller than 10 microns, the measuring device uses a multistep neutral density filter to attenuate transmission light and scattered light to a same light intensity level, realizes simultaneous shooting of transmission light and scattered light in a measurement system of a single digital area-array camera, and has the advantages of high sensitivity, fast response and simple and compact optical system. According to the obtained information of scattered light and transmission light, the distribution of particle size can be acquired; with the known particle size distribution, a method combined scattered light with scattering integration can be used to measure dust concentration of micron level, and a method combined transmission light with light extinction can be used to realize the measurement of dust concentration of submicron and nanometer levels. The invention successfully realizes the measurement of dust concentration of micron, submicron and nanometer levels, covers large particle size range, and has great market advantage.

Owner:NANJING INST OF MEASUREMENT & TESTING TECH

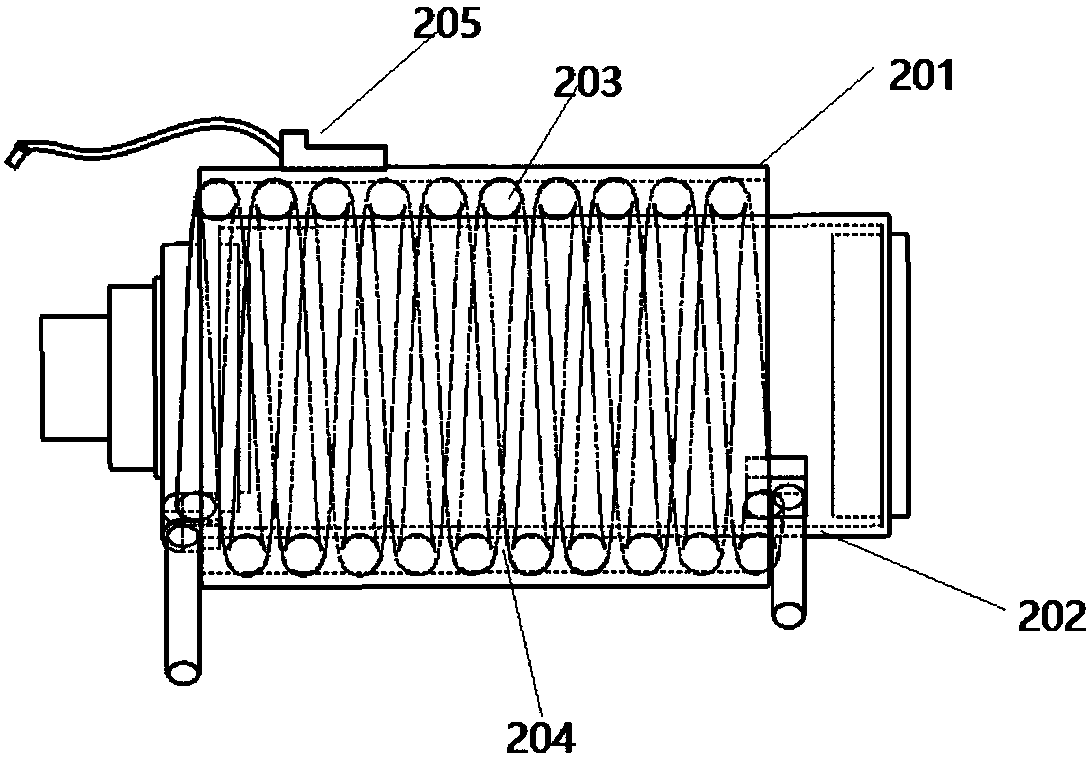

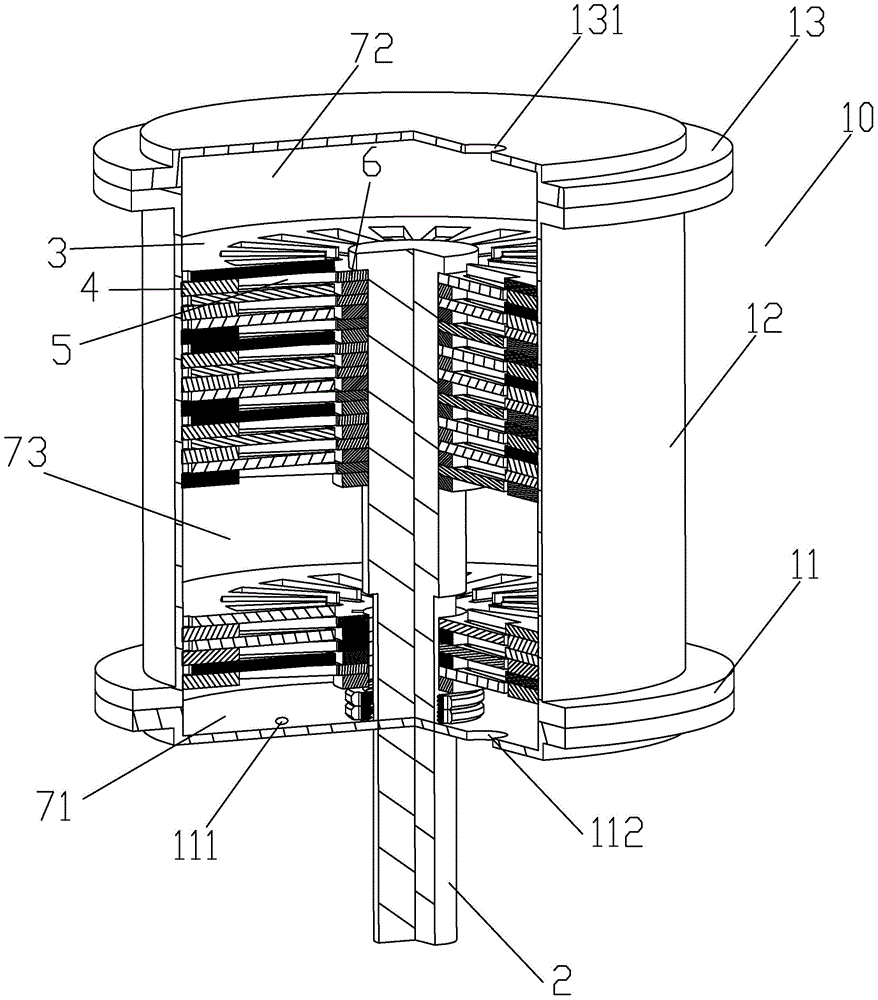

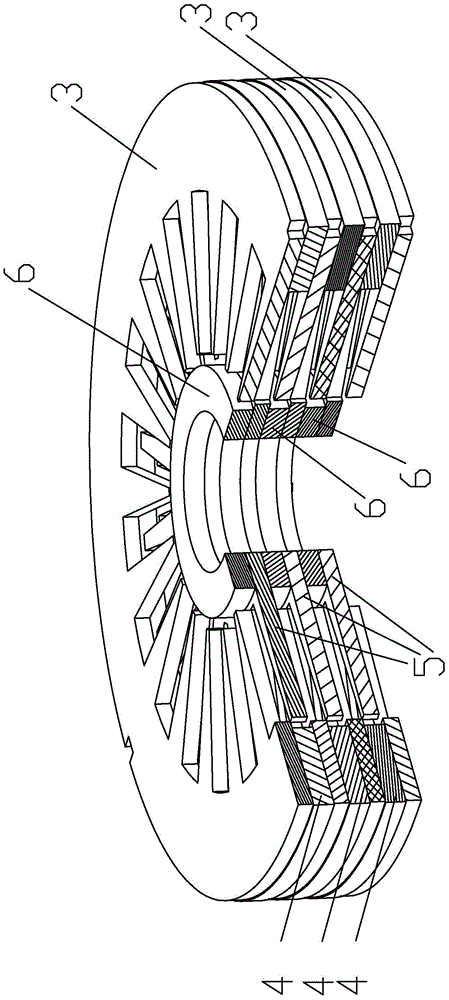

Foaming equipment for preparing foamed ceramic slurry

InactiveCN104667787BUniform particle sizeLarge particle size rangeMixing methodsRotary stirring mixersSlurryPolymer chemistry

The present invention relates to foaming equipment for preparing a foamed ceramic slurry. According to the foaming equipment, the foaming device comprises a fixed part and a rotary part, the outer stirring tooth group comprises outer stirring tooth sheets and outer separation rings, the inner stirring tooth group comprises inner stirring tooth sheets and inner separation rings, the outer stirring tooth sheets and the outer separation rings are fixed on the inner side of the outer housing, the upper cover is provided with a slurry outlet hole, the base is provided with a gas inlet hole and a slurry inlet hole, a shaft penetrates through the center of the base, one end of the shaft extends into the foaming device housing, the inner stirring tooth sheets and the inner separation rings are fixed on the outer side of the shaft, the outer stirring tooth sheets and the inner stirring tooth sheets are alternately arranged up and down, the internal of the foaming device housing is divided into at least three material mixing chambers, the bottom portion forms the primary section material mixing chamber relying on the base, the top portion forms the terminal end material mixing chamber relying on the upper cover, and the middle forms the middle material mixing chamber. The present invention provides the completely-new foaming equipment for preparing the foamed ceramic slurry.

Owner:HEBEI YL BANGDA NEW MATERIALS LTD CO

An energy-saving, low-carbon and environmentally friendly European-style pulverizer

Owner:上海建冶路桥机器设备有限公司

A highly uniform sulfide microsphere with precise and controllable particle size and its preparation method

ActiveCN109942017BUniform particle sizeLarge particle size rangeMaterial nanotechnologyTin compoundsMicrosphereSulfide

A highly uniform sulphide microsphere with precisely controllable particle size and a preparation method therefor. The present method is based on the idea of a core-shell-shell structure, and comprises the two processes of primary "core" growth and secondary "layer-layer" growth. In the first growth step, sulphide nanospheres with stable particle size are obtained by means of stable reaction conditions; in the subsequent steps, the particle size of the nanospheres can be precisely controlled by means of controlling the timing and amount of the addition of the metal and sulphur source. According to said synthesis method, by means of a preset target particle size and precisely designing the experiment steps, sulphide nanospheres of the target particle size can be obtained; in addition, the adjustable particle size range of the present method is significantly increased, the adjustable range being 100 nm-1000 nm.

Owner:DALIAN UNIV OF TECH

Organic profile control agent and preparation method thereof

InactiveCN110467909ACause some damagesShort construction timeDrilling compositionNatural resinShellac

The invention discloses an organic profile control agent. The organic profile control agent comprises 25-50 wt% of profile control agent solid particles, 0.2-0.5 wt% of a surfactant, 0.1-0.2 wt% of adispersing mutual solvent, 1-20 wt% of a water-soluble regulator, and the balance of water. The profile control agent solid particles are a reaction product obtained by heating 60-80 wt% of a naturalresin industrial product and 20-40 wt% of a polyol to 260 DEG C and performing a polymerization reaction for 10 h. The natural resin industrial product is one of rosin, Chinese lacquer, damar resin and shellac. The polyol is one of glycerol, pentaerythritol, diethylene glycol and trimethylolpropane. The organic profile control agent is a light yellow suspension system with a large particle size span, is insoluble in water and acids, and can quickly plug gun perforations and large cracks to effectively prevent a working fluid from entering the formation and selectively plug the target reservoir; and the organic profile control agent also has the advantages of simple preparation process, strong controllability, suitableness for large-scale production, and broad application prospects.

Owner:CHINA NAT OFFSHORE OIL CORP +2

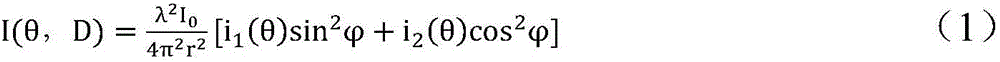

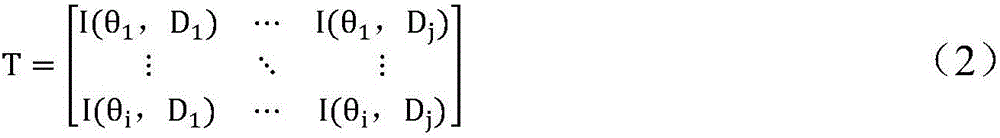

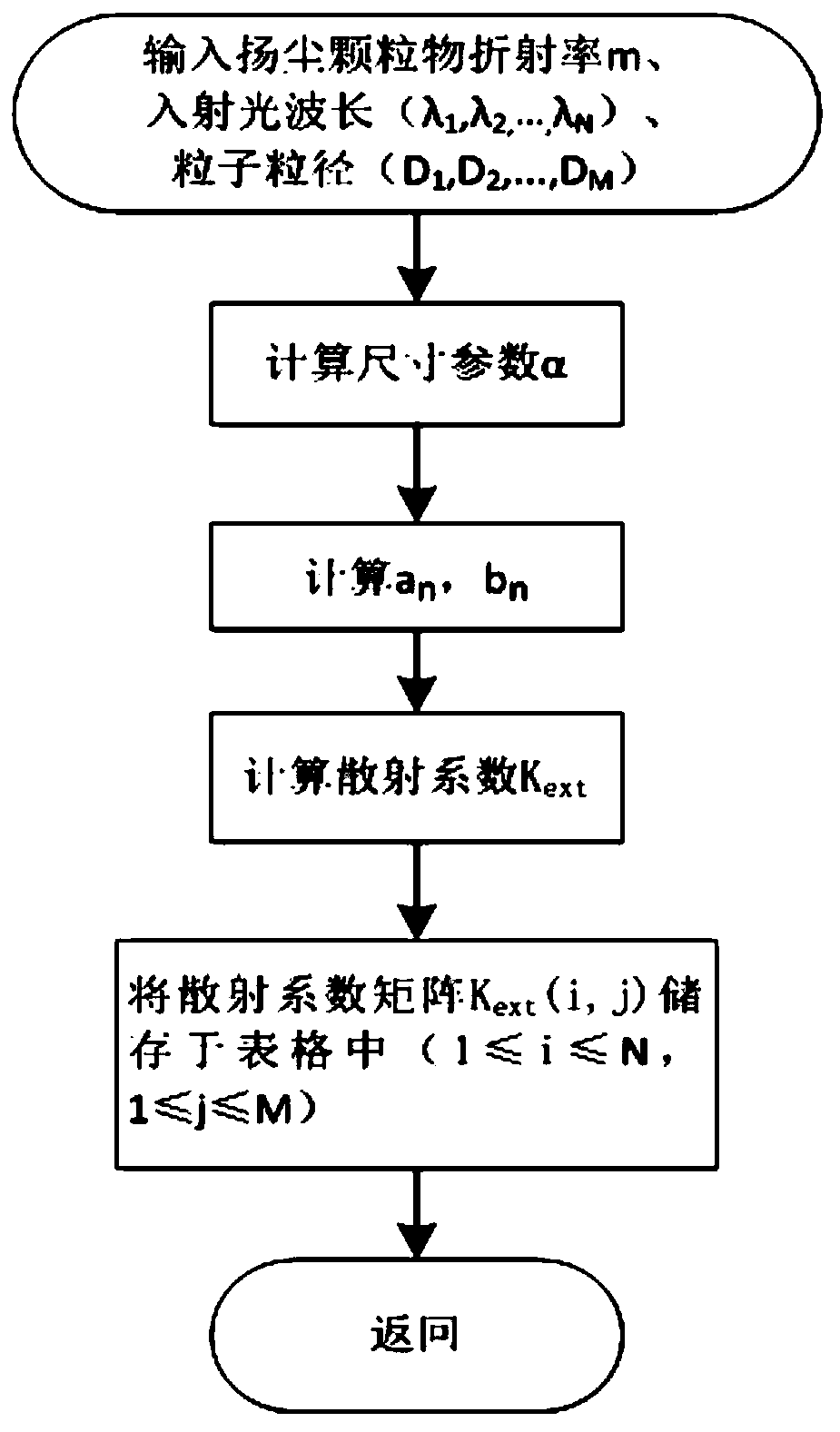

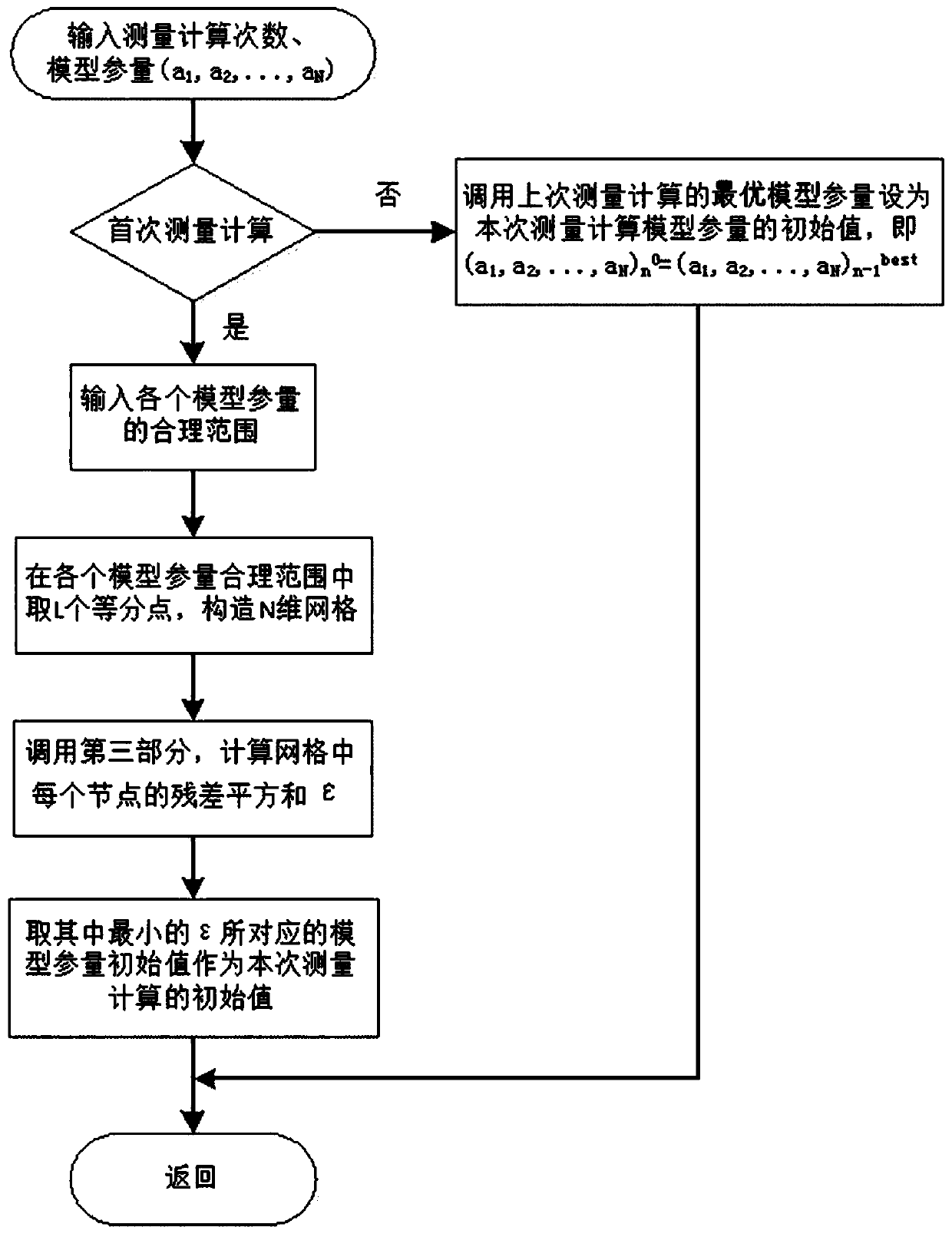

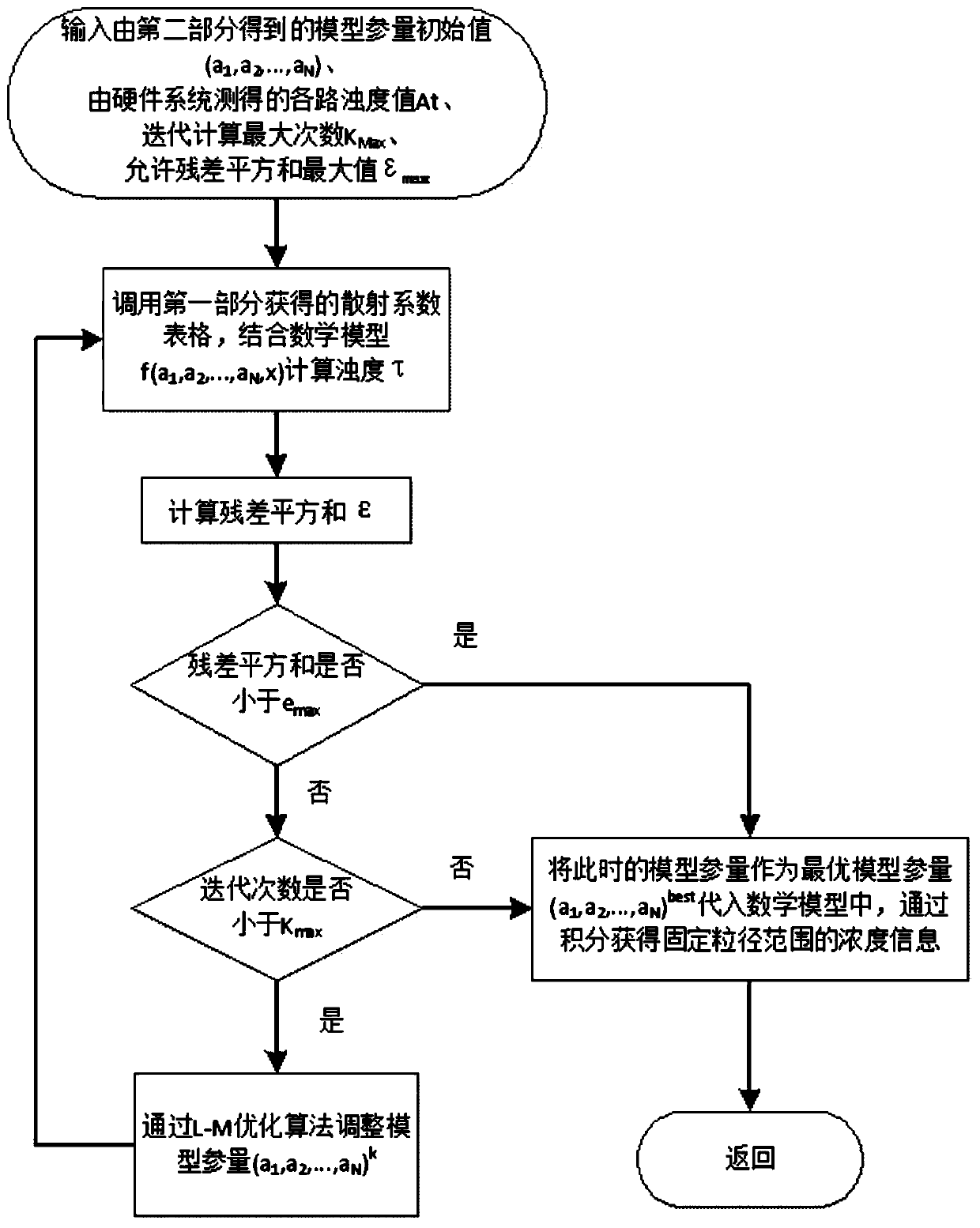

A fast calculation method of mie scattering for on-line monitoring of dust particles

ActiveCN106290094BLarge particle size rangeConcentration changes rapidlyParticle suspension analysisModel parametersDust particles

The invention discloses a rapid calculation method for mie scattering applied to dust particulate matter online monitoring. The method comprises the following steps that a particle scattering system is calculated, and a scattering coefficient table is formed; a particle size distribution mathematic model is built, and a reasonable initial value of a model parameter in an optimization algorithm is selected; particulate matter size distribution is subjected to inversion, and the particulate matter concentration is calculated. The particle theory scattering system is calculated in advance, a table look-up method is adopted for model parameter optimization calculation, repeated loop computation is avoided, and the calculation time is greatly shortened; a grid method is adopted in the algorithm for searching for a reasonable model parameter initial value for performing the first-time optimization algorithm, so that the global minimum value of a target function is accurately obtained; the model parameter initial value not measured at the first time is set as the model optimal parameter calculated the last time, iterations are reduced, and the operating speed is increased; the method has the advantages that the dust particulate matter size application range is large, and concentration change speed is large, and the method is used for a measuring system for performing real-time measurement of the dust particulate matter concentration.

Owner:TIANJIN TONGYANG TECH DEV

A powder feeding mechanism, powder feeder and spraying equipment

ActiveCN114107946BPrecise quantitative deliveryRealize small amount of powder feedingChemical vapor deposition coatingMetallurgyStucco

The invention discloses a powder feeding mechanism, a powder feeding device and spraying equipment. The powder feeding mechanism includes a powder storage cavity (1), and a powder inlet (10) and a heating gas inlet are arranged above the powder storage cavity (1). (11), the powder storage cavity (1) is provided with a stucco, and the stucco includes a rotating body (3) and a brush body (2) fixed on the rotating body (3); Driven by the drive, it rotates along the rotation axis (4); there is a screen (5) under the paint, and the screen (5) is connected to the powder storage cavity (1); the brush body (2) protruding from the paint surface touches the powder storage The inner surface of the cavity (1) is matched with different brush body materials for powders of different particle sizes. The present invention can precisely control the powder feeding rate, realize a small amount of uniform powder feeding, and increase the range of powder feeding particle sizes. There is no requirement for fluidity, and it is suitable for the transportation of various powders.

Owner:BEIHANG UNIV

A coal mine dust removal device based on ultrasonic atomization and coagulation

ActiveCN108412534BMeet the special environmentAvoid harmCombination devicesDust removalCoal dustDust control

The invention discloses a coal mine dust-removing device based on ultrasonic atomization and condensation. The coal mine dust-removing device comprises a negative pressure pipeline composed of an airblower, a vacuum pump and a connecting pipeline. The negative pressure pipeline is provided with a cyclone separator, an ultrasonic atomizer, a pressure valve and a condensation chamber sequentially.The cyclone separator is connected with the air blower. The vacuum pump is further connected with a dust collector. The condensation chamber is internally provided with an ultrasonic oscillator. A sound absorption sponge is further arranged at an outlet of the condensation chamber. The coal mine dust-removing device is easy to implement and high in efficiency, the content of coal dust in air in acoal mine roadway is effectively decreased, vicious accidents such as coal dust explosion are avoided, and safe conducting of the coal mine roadway exploiting process is ensured.

Owner:丹东长城环境设备有限公司

A highly uniform zinc oxide submicron sphere with controllable particle size and its preparation method

ActiveCN112777626BUniform particle sizeLarge particle size rangeMaterial nanotechnologyZinc oxides/hydroxidesPhotonic crystalPolyol

The invention discloses a highly uniform zinc oxide submicron sphere with controllable particle size and a preparation method thereof, belonging to the field of preparation of photonic crystal materials. The method adopts an alcohol-water system, reduces the temperature and pressure required for the synthesis of zinc oxide microspheres, and synthesizes zinc oxide polycrystalline submicron spheres with good monodispersity more cleanly. During the nucleation process, the nucleation process can be carried out rapidly by adjusting the temperature, the initial rotation speed, the zinc source and the amount of deionized water. During the growth process, the mass transfer is further controlled by introducing polyol to control the viscosity of the system, and zinc oxide submicron spheres with stable particle sizes can be obtained in one step. According to the above synthesis method, zinc oxide submicron spheres with a specific target particle size can be obtained only by changing the amount of zinc source and the type and amount of polyol. The adjustable particle size range of zinc oxide submicron spheres prepared by this method is significantly increased, and the controllable range is 100nm-800nm, and the monodispersity of zinc oxide submicron spheres is good.

Owner:DALIAN UNIV OF TECH

Device for determining permeability coefficient of coarse-grained soil with super large grain size

InactiveCN103149143BLarge particle size rangeAvoid damagePermeability/surface area analysisEngineeringHydraulic engineering

The invention relates to a device and a method for determining parameters of a hydraulic engineering material and particularly relates to a device and a method for determining the permeability characteristic of coarse-grained soil with super large grain size (the d85 is larger than or equal to 60mm and smaller than or equal to100mm), and the IPC (International Patent Classification) codes of the device and the method are respectively E02D1 / 04 and E02D33 / 00. The device comprises a testing drum, an automatic compression system 11 and a pressure determining tube 12, wherein a plurality of pressure determining holes are formed in the wall of the testing drum, the pressure determining holes in the wall of the testing drum can be used as air discharge holes when air is discharged out of soil body from saturation, and the pressure determining holes and air discharge holes in the drum top and the drum bottom jointly accelerate air discharge, so that a sample can be saturated rapidly. Proven by a large number of experiments, the method has the advantages that hot water at the temperature of 25-40 DEG C is used, the sample with super large grain size cab be saturated rapidly and the influences on the chemical and physical stability of the sample are minimized.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com