Energy-saving low-carbon environment-friendly European-type grinding machine

A low-carbon, environmentally friendly, pulverizer technology, applied in the field of mining machinery, can solve problems such as being unfavorable to improve product fineness and output, increasing equipment installation difficulty and cost, and unfavorable material separation, extraction and grinding, etc. Extracting and grinding, reducing inconvenient disassembly and maintenance, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

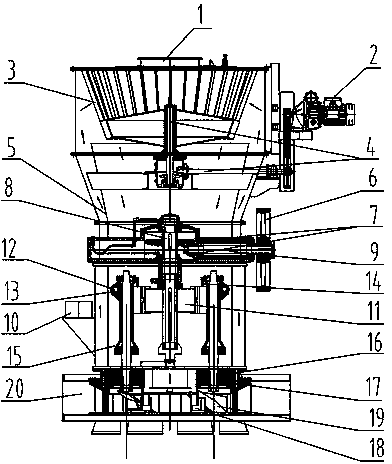

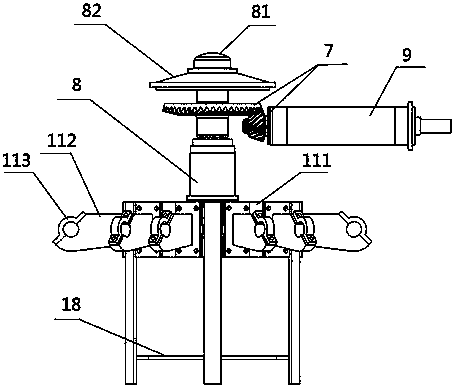

[0031] see Figure 1-4 , which is a structural schematic diagram of a preferred embodiment of an energy-saving, low-carbon, and environmentally friendly European-style pulverizer of the present invention. As shown in the figure: it includes an analysis machine driven by a motor on the upper part of the host, and the lower part of the host is divided into upper body, middle body and lower body from top to bottom; the top of the upper part of the host is equipped with a discharge port 1; the lower part of the host There is an airflow isolation ring 5 inside the body, which forms a fine powder feeding space between the airflow isolation ring 5 and the body at the lower part of the main machine; The position of 200mm-550mm, the powder feeding port of this position adopts the partition type; the outer side of the middle body of the lower part of the main machine is equipped with a feed port 10; the lower body of the lower part of the main machine is provided with an air inlet 20; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com