Median type tailing damming method utilizing mold bags

A mold bag and tailings technology, which is applied in construction, soil protection, filling, etc., can solve problems such as potential safety hazards, coarse-grained tailings, and dust on the dam surface in windy days, so as to reduce costs and energy consumption. The effect of improving dam building efficiency and improving grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

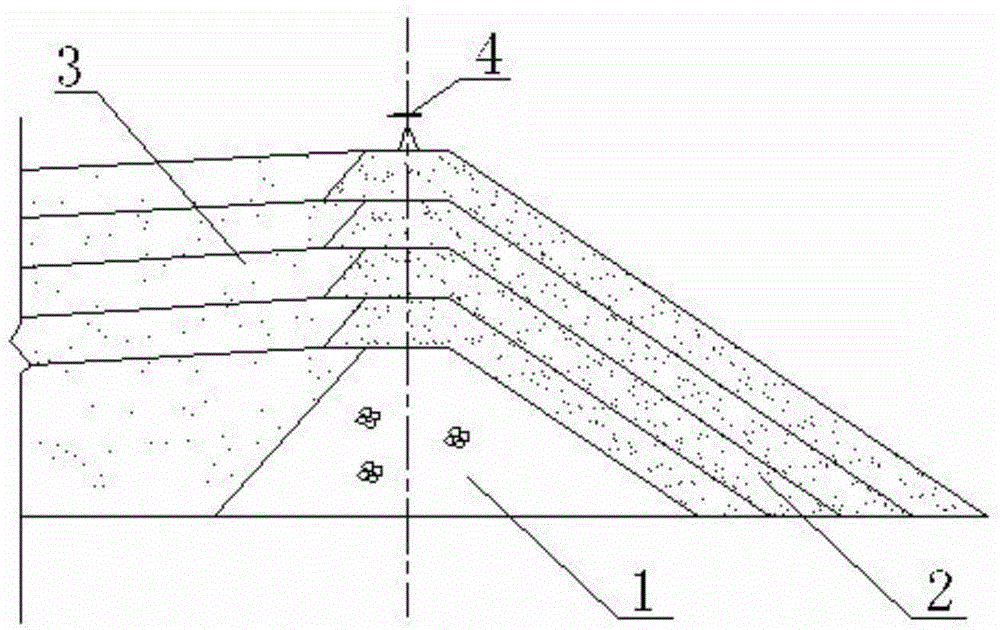

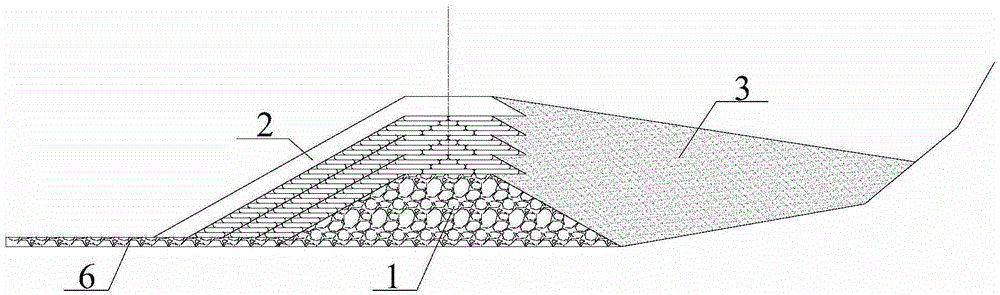

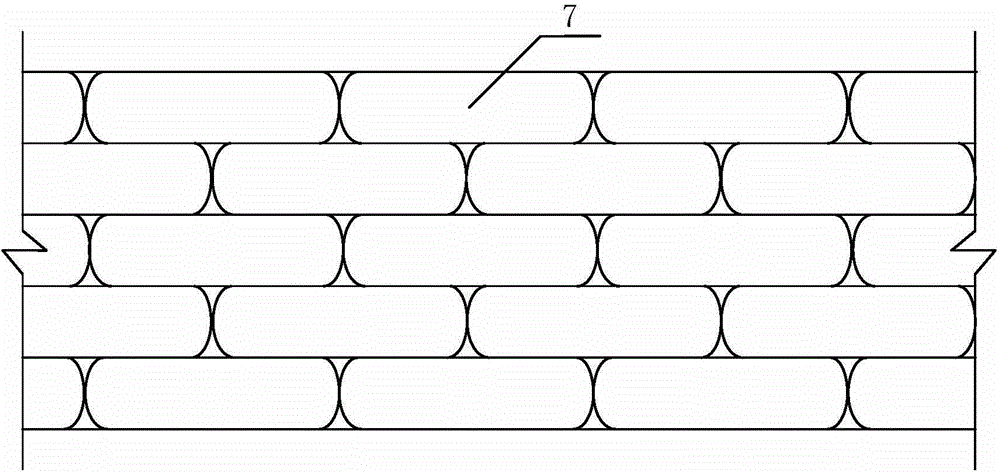

[0036] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, a centerline tailings dam construction method using mold bags can specifically include the following procedures:

[0037](1) Construction process of mold bag grouting system: according to the height and axis position of the current dam body, set up a high-level ore slurry pool 8 at a height of at least 15m higher than the dam crest, and lay an ore-drawing pipeline 9; the top of the ore-drawing pipeline 9 It communicates with the bottom of the high-level slurry pool 8, and the bottom of the ore-drawing pipeline 9 extends downstream of the current dam body.

[0038] Specifically, when there is only the initial dam 1 in the tailings reservoir, the current dam body is the initial dam 1, and when the initial dam 1 already has a heap dam, the current dam body is the current heap dam. The height of the high-level ore slurry pool 8 can be increased along with the height of the dam crest of the current dam body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com