Washing machine without water between barrels and control method

A washing machine and control valve technology, applied in the field of washing machines, can solve the problems of shortened service life, poor reliability, wear and water leakage, etc., and achieve the effects of simple structure, thorough drainage and fast drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

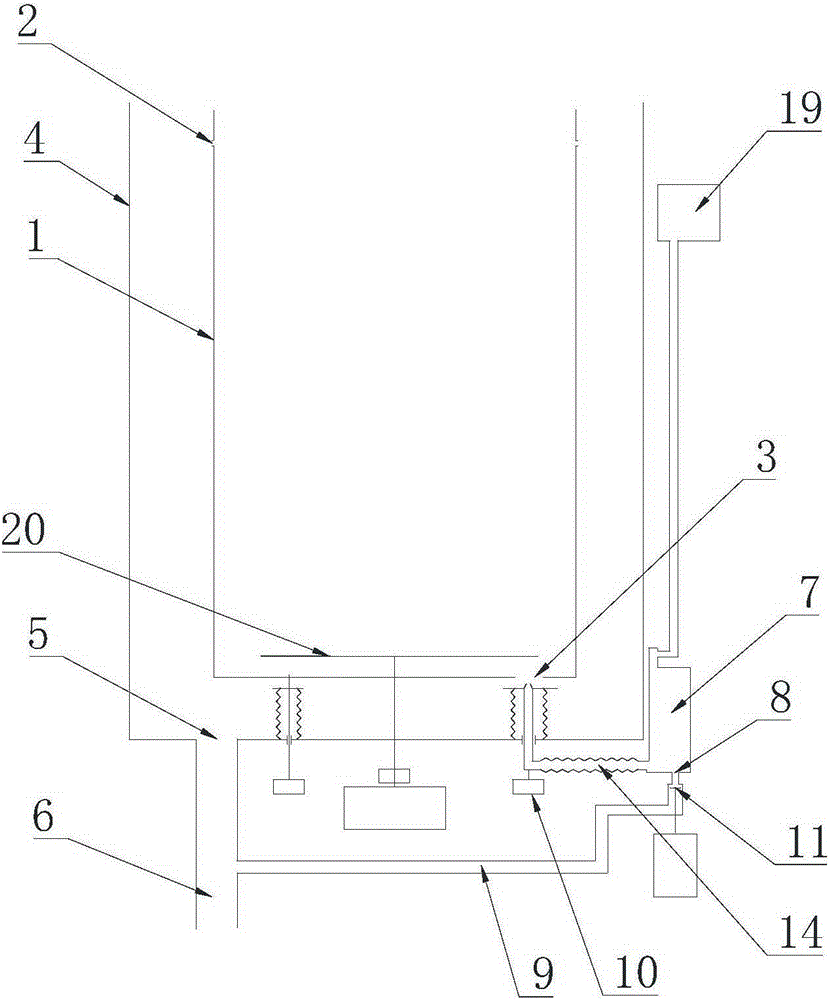

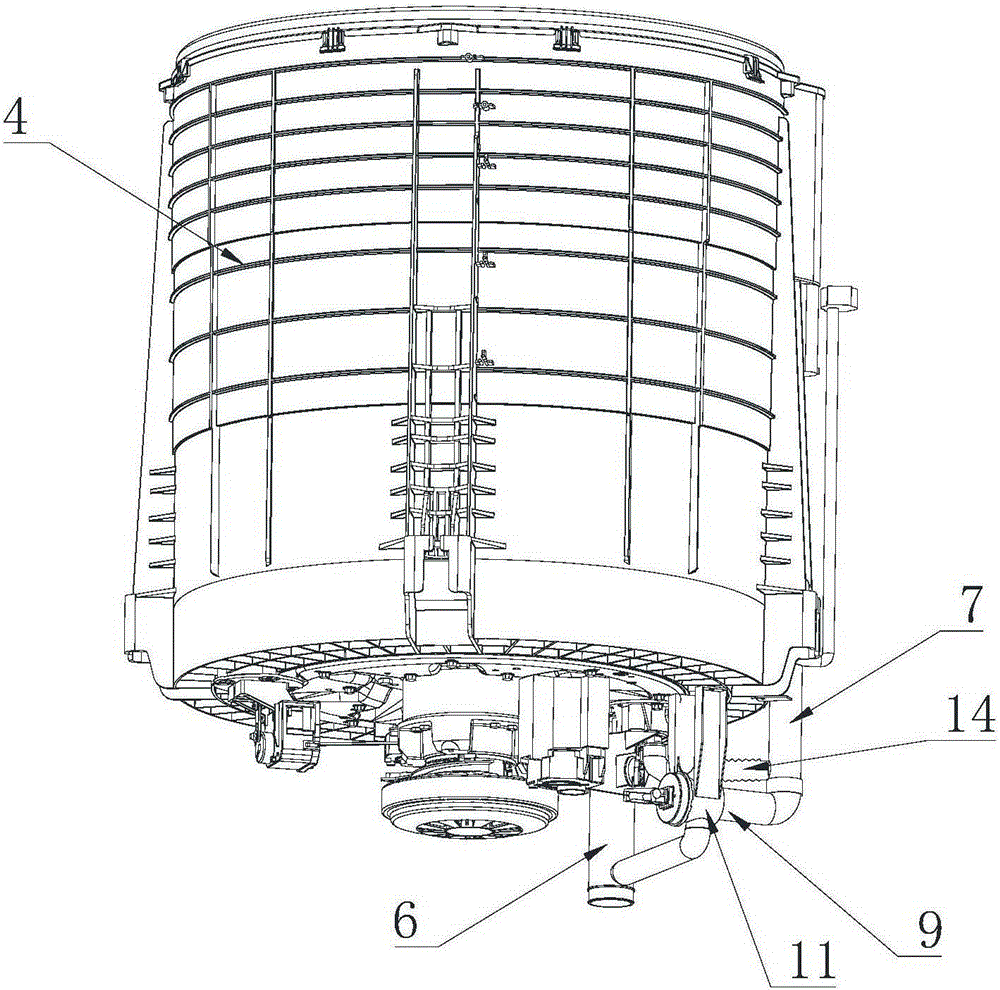

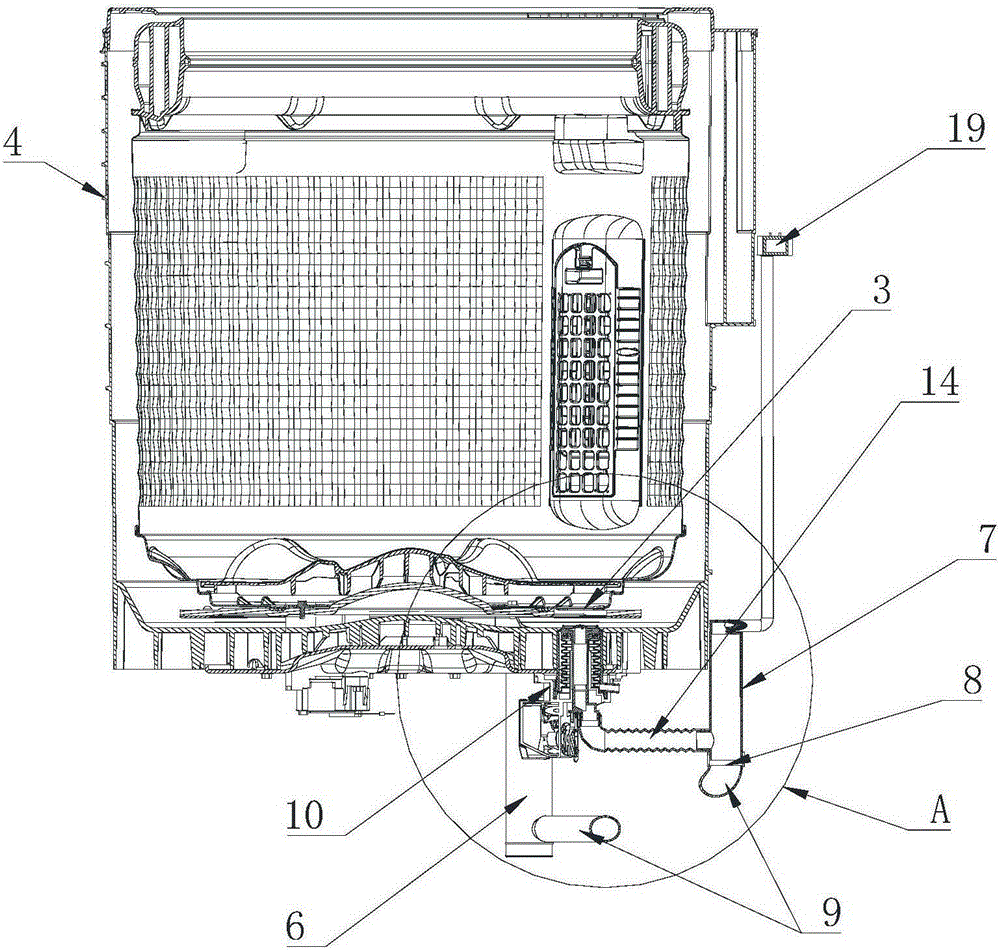

[0034] Such as figure 1 , figure 2 As shown, a water-free washing machine between barrels of the present invention includes an inner barrel 1, an outer barrel 4, and a plurality of water-throwing holes 2 are provided on the upper part of the inner barrel 1 near the upper edge, and at least one inner barrel drain is provided at the bottom of the inner barrel 1. 3. The bottom of the outer barrel 4 is provided with a telescopic drain valve 10 capable of blocking the drain of the inner barrel. The bottom of the outer barrel 4 is provided with an outer barrel drain 5 , and the outer barrel drain 5 is provided with a washing machine drainage pipeline 6 .

[0035] When washing, the inner tub 1 is locked, and the telescopic drain valve 10 blocks the inner tub drain port 3. There is water in the inner tub 1, and there is no water between the inner and outer tubs. Part of the water is discharged from the inner tub 1 through the drain port 3 of the inner tub, and then discharged throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com