Composite material containing ordered microsphere array and preparation method of composite material

A composite material and microsphere array technology, which is applied in the coupling of optical waveguides, metal material coating process, nanotechnology for materials and surface science, etc. It is difficult to control the distance between microspheres and microspheres, and it is difficult to achieve orderly arrangement of microspheres.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

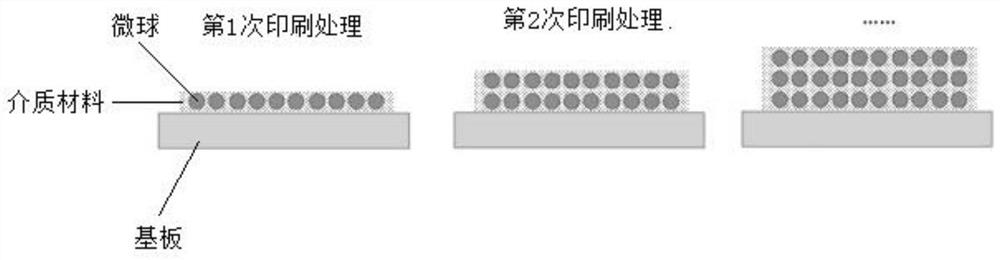

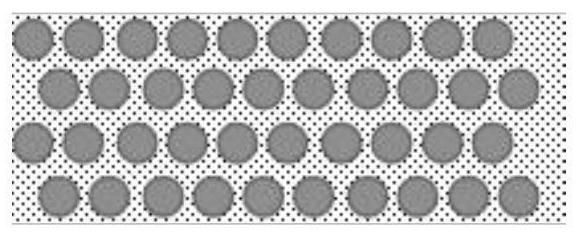

[0024] The invention provides a method for preparing a composite material containing an ordered microsphere array, comprising the following steps:

[0025] providing a mixed slurry comprising microspheres and a binder;

[0026] A screen is provided, the aperture of the mesh on the screen is 0.1-10% larger than the particle diameter of the microspheres, and the arrangement and spacing of the meshes match the ordered microsphere array;

[0027] Spread the screen on the upper surface of the substrate, then pour the mixed slurry on the screen, and use a scraper to scrape the mixed slurry into the mesh of the screen based on the screen printing method, so that The microspheres in the mixed slurry are distributed in an array in the mesh of the screen, and the screen is removed after the surface is dry, which is recorded as one printing process;

[0028] The printing process is repeated n times, and then the substrate is peeled off to obtain a composite material containing an ordere...

Embodiment 1

[0042] SiO with a particle size of 1 μm 2 The microspheres and the silicone resin are uniformly mixed in a volume ratio of 6:4 to obtain a mixed slurry;

[0043] Spread the wire mesh (with a pore size of 1.10 μm, made of stainless steel) on the upper surface of the polycarbonate (PC) plate, pour the mixed slurry onto the wire mesh, and scrape the mixed slurry with a scraper. into the mesh of the screen, so that the microspheres in the mixed slurry are distributed in an array in the mesh of the screen, take off the screen after surface drying, and cut and remove the C plate after it is completely dry to obtain a two-dimensional The composite material of the microsphere array, the distance between the microspheres is 0.2 μm.

[0044] The hydrophobicity of the composite material prepared in this embodiment is tested, and the results show that the contact angle of water droplets is 160°; 2 The microspheres are randomly arranged and the contact angle is only 104°.

Embodiment 2

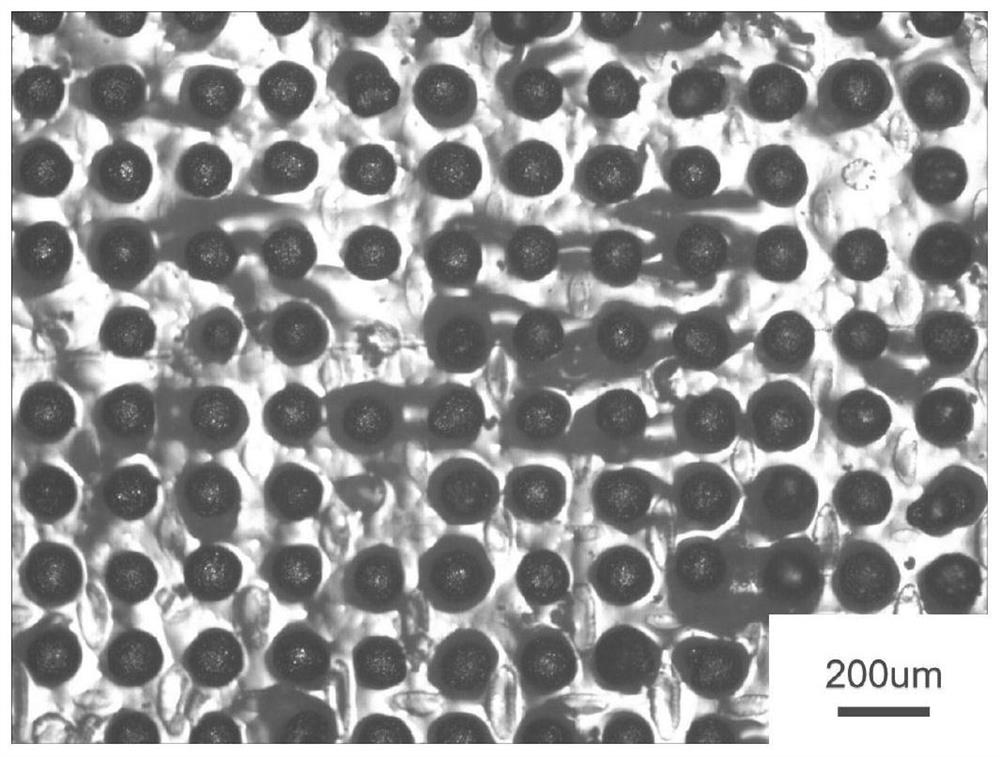

[0046] Fe with a particle size of 100 μm 3 o 4 The microspheres and the epoxy resin are uniformly mixed in a volume ratio of 7:3 to obtain a mixed slurry;

[0047] Spread the wire mesh (with a pore size of 105 μm, made of nylon) on the upper surface of the polyvinyl chloride (PVC) board, pour the mixed slurry onto the wire mesh, and use a scraper to scrape the mixed slurry into the In the holes of the screen, the microspheres in the mixed slurry are distributed in an array in the mesh holes of the screen, the screen is removed after the surface is dry, and the PVC sheet is cut and removed after being completely dry to obtain a two-dimensional microsphere-containing Array of composite materials with a microsphere pitch of 0.1 μm.

[0048] image 3 The microstructure diagram of the composite material (containing PVC sheet) containing two-dimensional microsphere array prepared for this embodiment, by image 3 It can be seen that Fe 3 o 4 The microspheres are evenly distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com