Method for continuous preparation of triangular silver nanoparticles with controllable arrangement

A technology of triangular silver and nanoparticles, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, to achieve the effect of repeatable and stable results, high yield, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

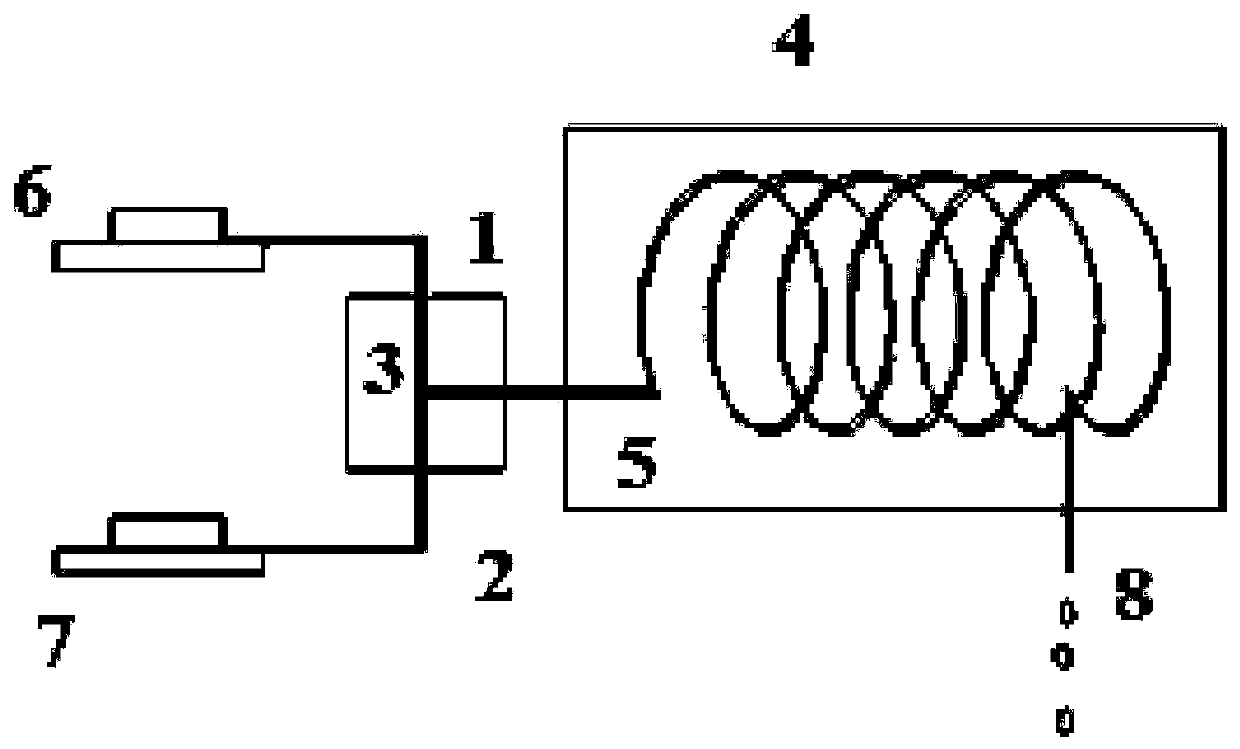

Method used

Image

Examples

Embodiment 1

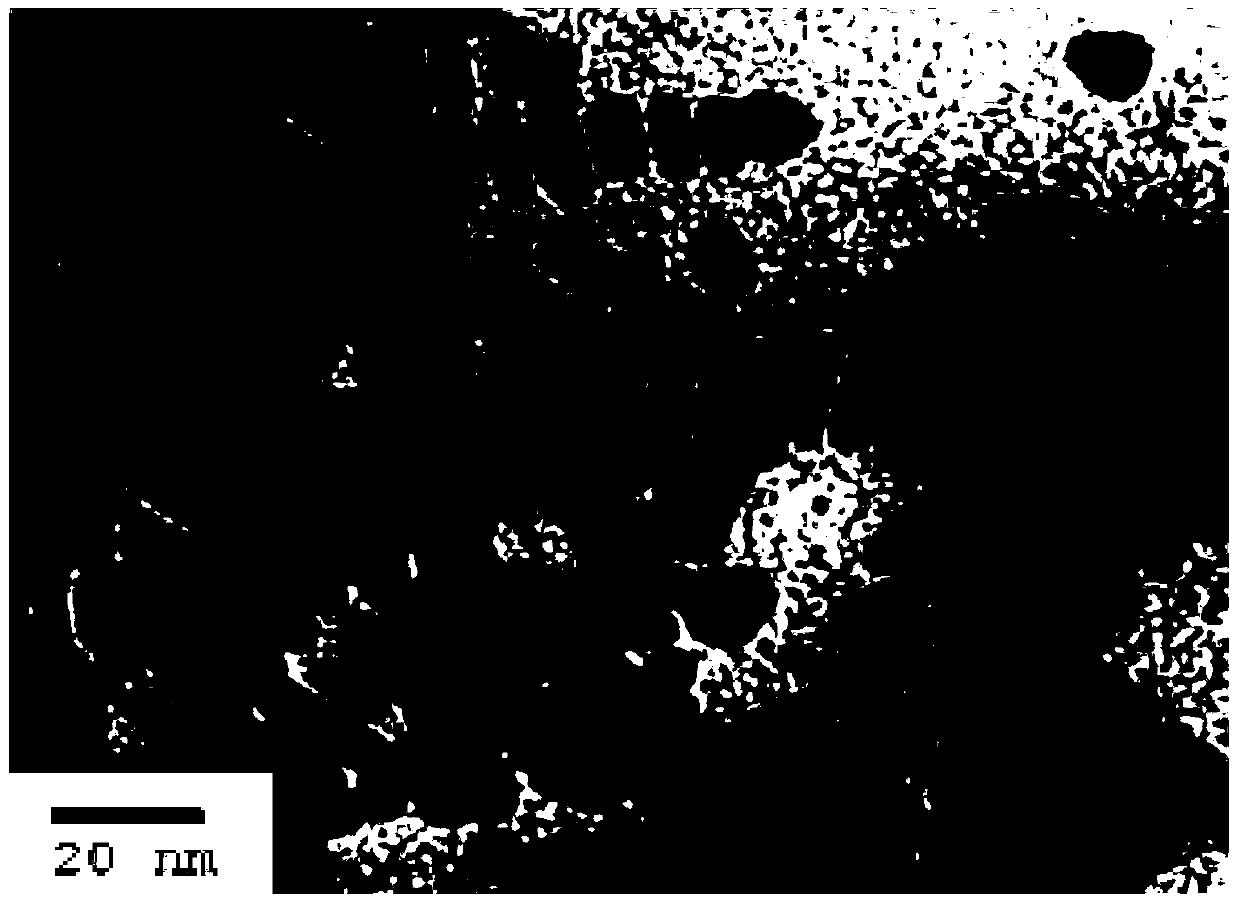

[0036] by AgNO 3 with NaBH 4 In the presence of sodium citrate and sodium lauryl sulfate, by H 2 o 2 The oxide-etching reaction in the microchannel reactor directly prepared the SDS-protected triangular silver nanoparticles.

[0037] Triangular silver nanoparticles arranged vertically are obtained, and the specific operation steps are as follows:

[0038] Specific steps:

[0039] (1) 0.017g AgNO 3 Dissolve in 200mL deionized water to make a 0.0005mol / L solution, add 0.6g SDS and 0.08g sodium citrate to it to keep AgNO 3 The molar ratio with sodium citrate is 0.035:1, stir for 10 minutes to make it fully mixed;

[0040] (2) Add 0.0076g NaBH 4 Dissolve in 200mL ice-deionized water to make a 0.001mol / L solution, bathe in ice for 10min, add 0.8mL of 1mol / L NaOH solution, keep the pH of the solution at about 11.5, and stir evenly;

[0041] (3) Add 30% H to the solution obtained in (1) 2 o 2 Solution 3mL, stir well;

[0042] (4) All the solutions obtained in (2) and (3) a...

Embodiment 2

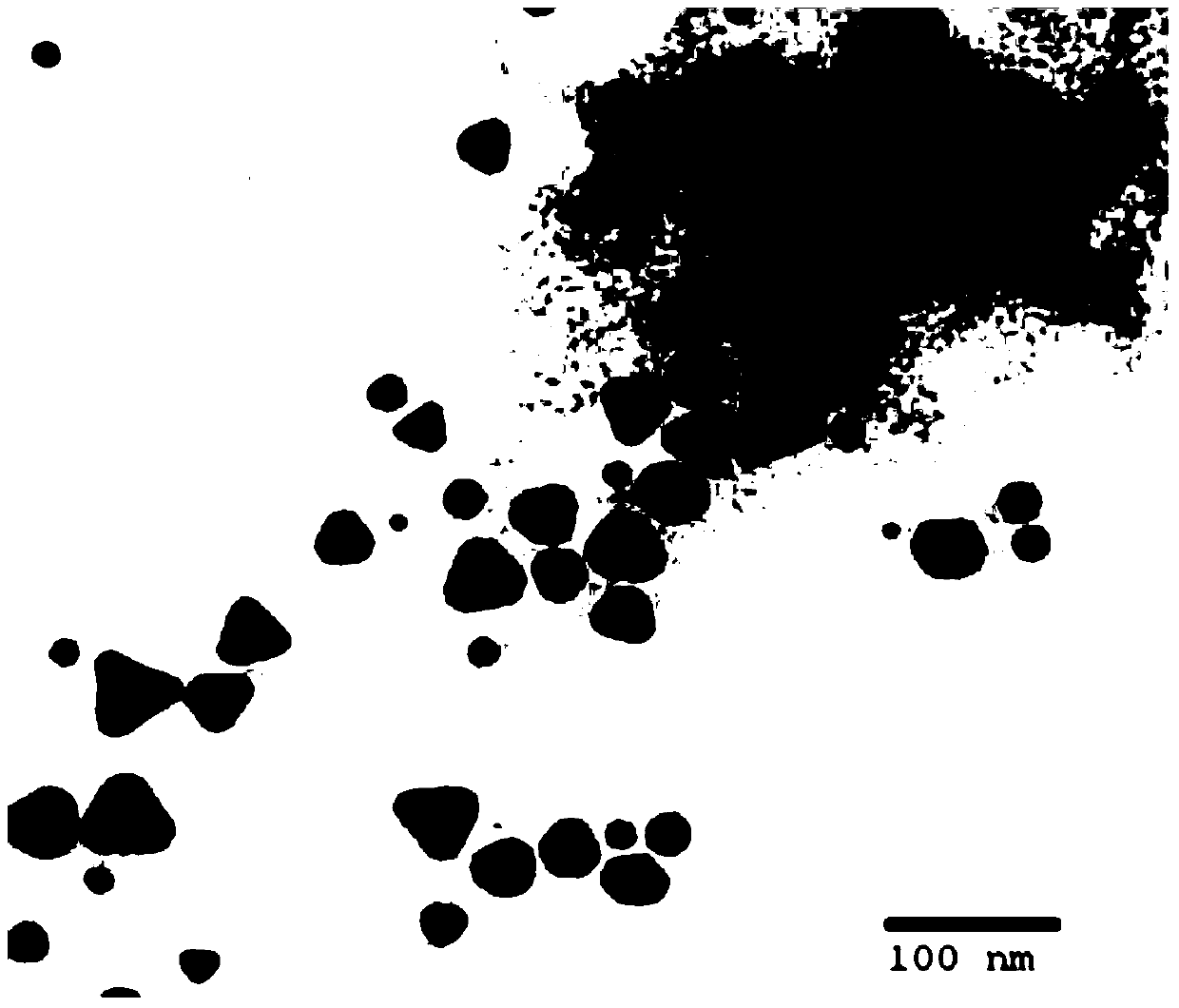

[0044] Triangular silver nanoparticles arranged in tiles are obtained, and the specific operation steps are as follows:

[0045] (1) 0.0272g AgNO 3 Dissolve in 200mL deionized water to make a 0.0008mol / L solution, add 0.6g SDS and 0.8g sodium citrate to it to keep AgNO 3 The molar ratio with sodium citrate is 0.7:1, stir for 10 minutes to make it fully mixed;

[0046] (2) Add 0.0122g NaBH 4 Dissolve in 200mL ice-deionized water to make a 0.0016mol / L solution, bathe in ice for 10min, add 0.8mL of 1mol / L NaOH solution, keep the pH of the solution at about 11.5, and stir evenly;

[0047] (3) Add 30% H to the solution obtained in (1) 2 o 2 Solution 3.4mL, stir well;

[0048] (4) All the solution obtained from (2) and (3) is injected into the microchannel reactor through a syringe pump at a flow rate of 1mL / min. After the solution is mixed, it reacts in the capillary microreactor, keeping the capillary microchannel at 40 ℃ water bath, prepared triangular silver nanoparticles ...

Embodiment 3

[0050] The triangular silver nanoparticles that are arranged vertically in flat tiles are obtained, and the specific operation steps are as follows:

[0051] (1) 0.034g AgNO 3 Dissolve in 200mL deionized water to make a 0.001mol / L solution, add 0.6g SDS and 0.5g sodium citrate to it to keep AgNO 3 The molar ratio with sodium citrate is 0.12:1, stir for 10 minutes to make it fully mixed;

[0052] (2) Add 0.0152g NaBH 4 Dissolve in 200mL ice-deionized water to make a 0.002mol / L solution, bathe in ice for 10min, add 1mol / L NaOH solution to adjust the pH of the solution to about 11.5, and stir evenly;

[0053] (3) Add 30% H to the solution obtained in (1) 2 o 2 Solution 4mL, stir well;

[0054] (4) The solution obtained in (2) and (3) is passed into the microchannel reactor through a syringe pump at a flow rate of 0.8mL / min. After the solution is mixed, it reacts in the capillary microreactor to keep the microchannel reactor and capillary microreactor in a 40°C water bath to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com