A rapid prototyping device and method for abrasives with regular arrangement of abrasives

A molding device and molding method technology, applied in grinding devices, manufacturing tools, grinding/polishing equipment, etc., can solve the problem of low controllability of the performance and life of abrasive tools, poor stability of workpiece grinding quality, and the use of abrasive tools. Unstable performance and other problems, to achieve the effect of shortening the preparation cycle of the abrasive tool, stable molding process, and optimization of the internal structure of the abrasive tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

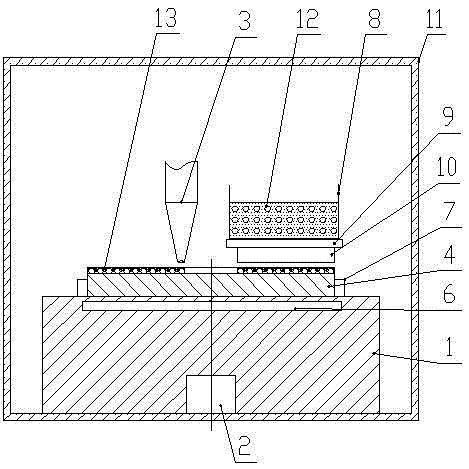

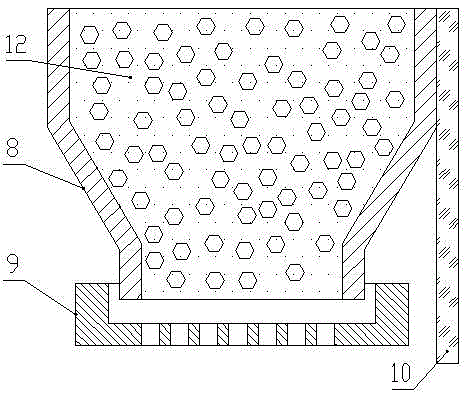

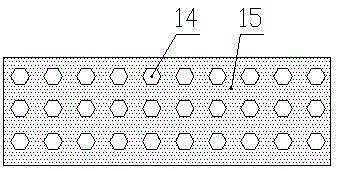

[0041] Such as figure 1 and figure 2 As shown, a rapid prototyping device for abrasives regularly arranged in the present invention comprises a horizontal rotary table 1, a stepping motor 2, a photocuring optical path system 3, an abrasive carrier 4 and a feeding mechanism, and the table 1 and The stepper motor 2 is connected to the transmission, the workbench 1 is equipped with a heating device 6, the abrasive tool carrier 4 is set on the workbench 1 through the positioning mechanism 7 (a kind of fixture, which belongs to the prior art), and the abrasive tool carrier 4 is a disc type structure, the center of the abrasive tool carrier 4 is consistent with the rotation center of the workbench 1, the photocuring optical path system 3 and the feeding mechanism are respectively located above the abrasive tool carrier 4, and the feeding mechanism includes a material bin 8, a vibrating screen 9 and a scraper 10. The upper end of the bin 8 is provided with a material inlet, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com