A controllable method for preparing graphene quantum dots

A technology of graphene quantum dots and ions, which is applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of difficult purification and uncontrollable doping solubility, and achieve controllable arrangement, less waste, and easy preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

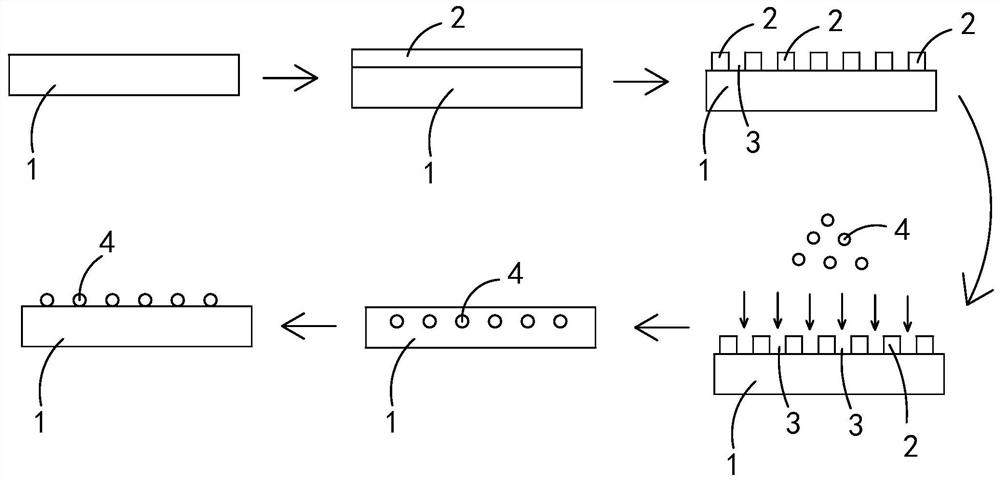

[0030] see figure 1 , what this embodiment provides is a kind of controllable method for preparing graphene quantum dots, comprising the following steps:

[0031] Step ①: preparing a substrate 1, and forming a photoresist 2 on the substrate 1;

[0032] The substrate 1 is a nickel substrate, a semiconductor substrate or a crystal substrate. In this embodiment, a nickel substrate is used to catalyze the growth of graphene quantum dots in the later stage;

[0033] Step ②: Forming the photoresist 2 into the implantation window 3 by photolithography or ion exposure;

[0034] The position, size, quantity and distribution of the injection windows 3 can be adjusted by photolithography or ion exposure. For example, the shape of the injection windows 3 in this embodiment is circular, and all the injection windows 3 are arranged in a rectangular array. The injection window 3 has a diameter of 1 angstrom to 100 nanometers, preferably 10 nm;

[0035] Step ③: Implanting the carbon source...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that in step ③, a dopant source, such as an N dopant source, is also injected at the same time as the carbon source is injected, and the corresponding step ⑤ is extrinsically doped graphene quantum dots . At the same time, there is a year-on-year change between the implantation dose of the N doping source and the carbon source dose in the obtained doped graphene quantum dots, that is, the ratio between the doping element and the carbon source in the doped graphene quantum dots and the implantation process in step ③ The dopant element dose and the carbon source dose ratio are the same, which fully demonstrates that the energy of ion implantation of the dopant element in this embodiment can also ignore the type of substrate and fully enter the interior of the substrate. Leaving the interior of the substrate, it mixes with a carbon source to form doped graphene.

[0044] At the same time, through additional EDS ch...

Embodiment 3

[0046]The difference between this embodiment and embodiment 2 is that in step ③, the carbon source is implanted with N doping source and P doping source at the same time, and the ratio between N, P and C in the obtained doped graphene quantum dots is It is the same as the ratio between N, P and C implantation doses in step ③. Through EDS characterization, it can also show that N, P and C are evenly distributed, which fully shows that the number of doping elements will not affect the doping uniformity. The amount and type of doping in the method of this embodiment have been greatly expanded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com