A preparation method of proximity soft film exposure micro-nano light-trapping structure

A light-trapping structure and proximity technology, applied in the field of solar cells, can solve the problems affecting the accuracy of the imprinting process, the increase in the proportion of hidden cracks in silicon wafers, and the pressure damage of silicon wafers, etc., so as to reduce the accuracy and uniformity , Arrangement controllable, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

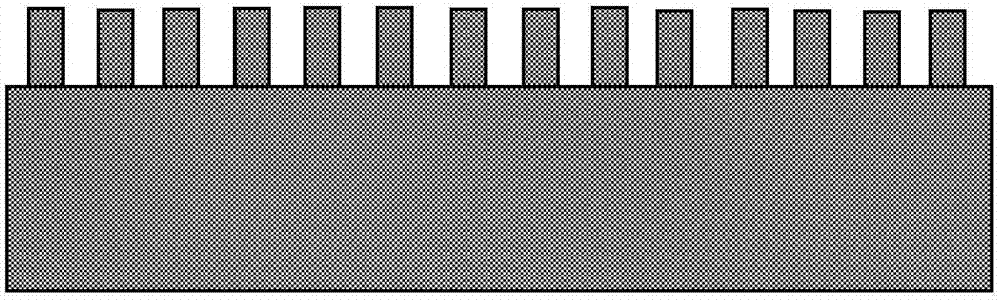

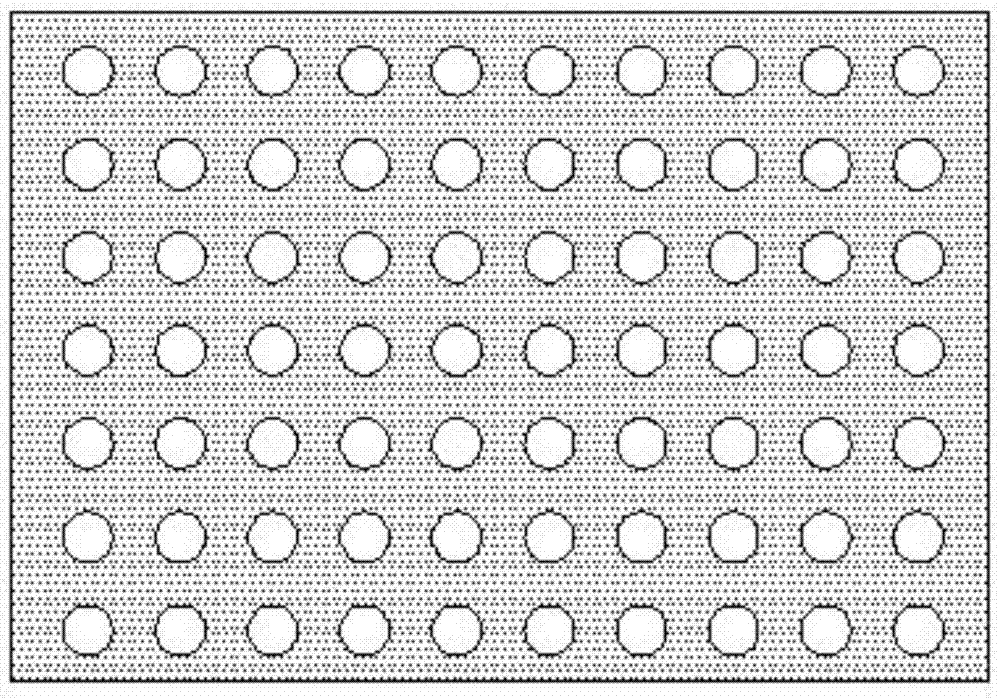

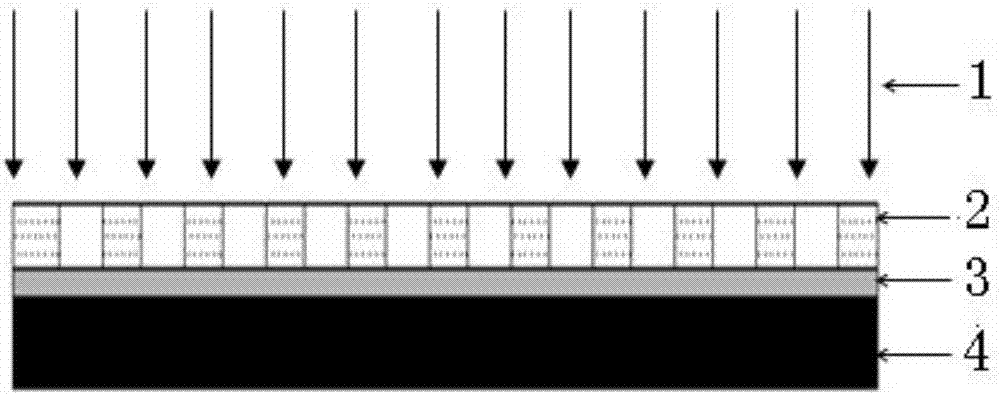

[0045] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a method for preparing a proximity-type soft film exposure micro-nano light trapping structure comprises the following steps:

[0046] 1) Preparation of hard template: The hard template is used as the master of the soft film board, and the material is silicon; the pattern of the hard template is the same as that of the silicon wafer, and the size is 1.2 times that of the silicon wafer. The hard film board is designed by plasma etching technology graphics;

[0047] 2) Convert the hard template graphics to the soft template: the soft template is used as the exposure template, and polydimethylsiloxane (PDMS) is used. The process of making the soft film plate includes:

[0048] (a) firstly, the polydimethylsiloxane is heated to a fluid state, stirred and mixed for 5min;

[0049] (b) cutting the polydimethylsiloxane after stirring on a hard film board placed in the fixture container, the pattern end of the har...

Embodiment 2

[0060] A method for preparing a proximity soft film exposure micro-nano light trapping structure, comprising the following steps:

[0061] 1) Preparation of the hard template: the hard template is the master plate of the soft film board, and the material is gemstone; the pattern of the hard template is the same as that of the silicon wafer, and the size is 1.3 times the size of the silicon wafer. The hard film plate adopts plasma etching technology to obtain the design pattern ;

[0062] 2) Convert the hard template graphics to the soft template, the soft template is used as the exposure template, and the soft template is made of plastic materials, such as polydimethylsiloxane (PDMS) or a mixed material of various components. The process of making the soft film plate includes :

[0063] (a) First heat the plastic material to a fluid state, and stir and mix for 10 minutes;

[0064] (b) Blanking the stirred plastic material on the hard film plate placed in the jig container, t...

Embodiment 3

[0075] A method for preparing a proximity soft film exposure micro-nano light trapping structure, comprising the following steps:

[0076] 1) Preparation of the hard template: the hard template is the master plate of the soft film board, and the material is copper, iron and other metal materials; the pattern of the hard template is the same as that of the silicon wafer, and the size is 1.5 times the size of the silicon wafer. Eclipse technology to get design graphics;

[0077] 2) Convert the hard template graphics to the soft template, the soft template is used as the exposure template, and the soft template is made of plastic materials, such as polydimethylsiloxane (PDMS) or a mixed material of various components. The process of making the soft film plate includes :

[0078] (a) First heat the plastic material to a fluid state, and stir and mix for 20 minutes;

[0079] (b) Blanking the stirred plastic material on the hard film plate placed in the jig container, the pattern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com