Highly uniform zinc oxide submicrospheres with controllable particle size and preparation method thereof

A kind of zinc oxide, submicron technology, applied in the field of highly uniform zinc oxide submicron ball and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

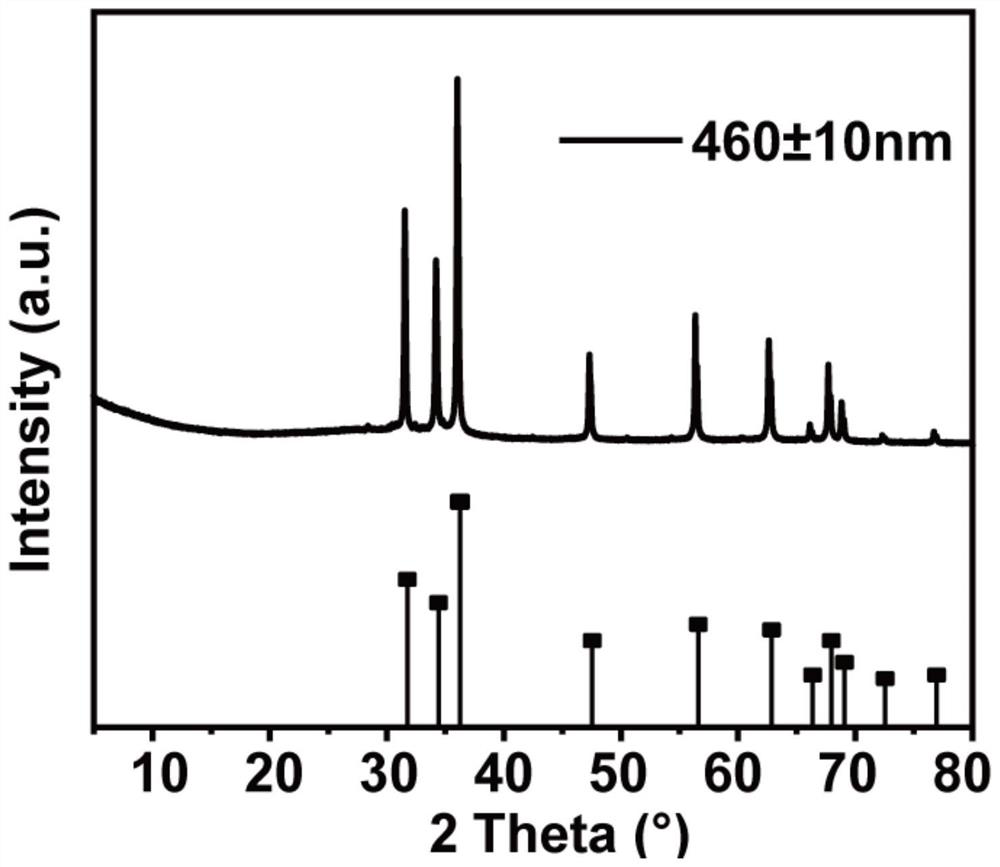

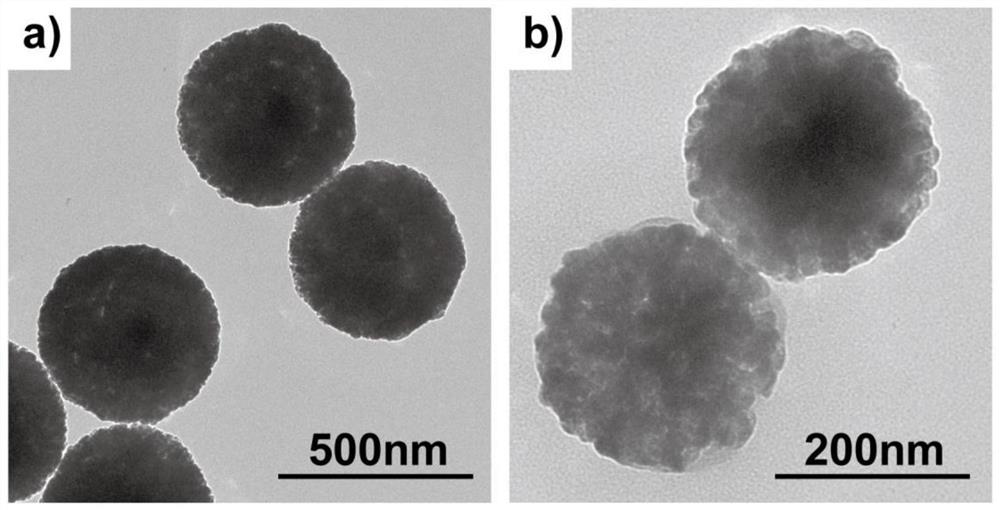

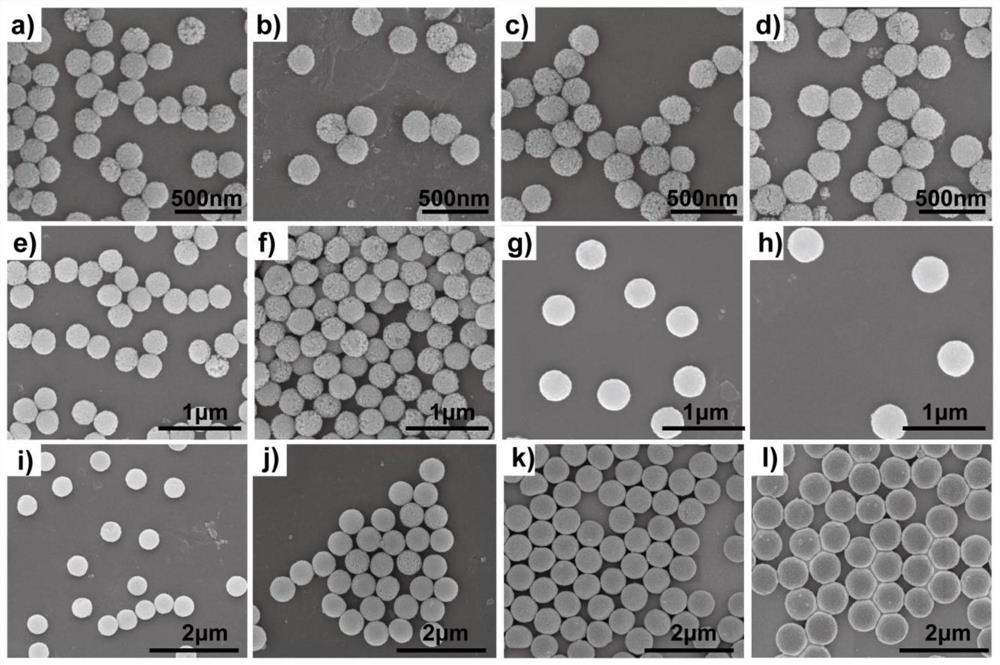

[0028] The monodisperse zinc oxide submicron spheres with a particle size of 460±10nm are prepared by a multi-step growth method of precisely controlling the particle size. The specific preparation method is:

[0029] 1) Weigh 6.00g of polyvinylpyrrolidone with an average molecular weight of 40000, measure 450ml of ethanol, and stir and disperse the polyvinylpyrrolidone in the ethanol solution at room temperature;

[0030] 2) Weigh 1.08g of zinc acetate dihydrate, measure 50ml of ethylene glycol, and disperse the zinc acetate dihydrate in the ethylene glycol solution with ultrasonic stirring at room temperature;

[0031] 3) Mix the solutions obtained in steps 1) and 2), heat to 75°C, and stir for 2-4h;

[0032] 4) Measure 15ml of deionized water, add the deionized water into the solution obtained in step 3) and stir rapidly for 2 minutes;

[0033] 5) Stir and react in an oil bath at 75°C for 1.5h;

[0034] 6) The obtained zinc oxide submicron spheres are washed with ethanol...

Embodiment 2

[0039] The monodisperse zinc oxide submicron spheres with a particle size of 150±10nm are prepared through a multi-step growth method of precisely controlling the particle size. The specific preparation method is:

[0040] 1) Weigh 6.00g of polyvinylpyrrolidone with an average molecular weight of 40000, measure 450ml of ethanol, and stir and disperse the polyvinylpyrrolidone in the ethanol solution at room temperature;

[0041] 2) Weigh 0.54g of zinc acetate dihydrate, measure 50ml of ethylene glycol, and disperse the zinc acetate dihydrate in the ethylene glycol solution with ultrasonic stirring at room temperature;

[0042] 3) Mix the solutions obtained in steps 1) and 2), heat to 75°C, and stir for 2-4h;

[0043] 4) Measure 15ml of deionized water, add the deionized water into the solution obtained in step 3) and stir rapidly for 2 minutes;

[0044] 5) Stir and react in an oil bath at 75°C for 1.5h;

[0045] 6) The obtained zinc oxide submicron spheres are washed with et...

Embodiment 3

[0048] The monodisperse zinc oxide submicron spheres with a particle size of 320±10nm are prepared through a multi-step growth method of precisely controlling the particle size. The specific preparation method is:

[0049] 1) Weigh 6.00g of polyvinylpyrrolidone with an average molecular weight of 40000, measure 450ml of ethanol, and stir and disperse the polyvinylpyrrolidone in the ethanol solution at room temperature;

[0050] 2) Weigh 0.81g of zinc acetate dihydrate, measure 50ml of ethylene glycol, and disperse the zinc acetate dihydrate in the ethylene glycol solution with ultrasonic stirring at room temperature;

[0051] 3) Mix the solutions obtained in steps 1) and 2), heat to 75°C, and stir for 2-4h;

[0052] 4) Measure 15ml of deionized water, add the deionized water into the solution obtained in step 3) and stir rapidly for 2 minutes;

[0053] 5) Stir and react in an oil bath at 75°C for 1.5h;

[0054] 6) The obtained zinc oxide submicron spheres are washed with et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com