Ultrahigh cut-off EVA packaging adhesive film

A kind of encapsulation film, ultra-high technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problems of UV aging resistance and poor yellowing resistance, and achieve UV resistance Improved aging and yellowing resistance, improved UV aging resistance, and improved transparency and UV aging resistance

Inactive Publication Date: 2016-08-24

CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The EVA encapsulation adhesive film in the prior art is poor in UV aging resistance and yellowing resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

[0035] Embodiment 3 is a preferred implementation.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Login to View More

Abstract

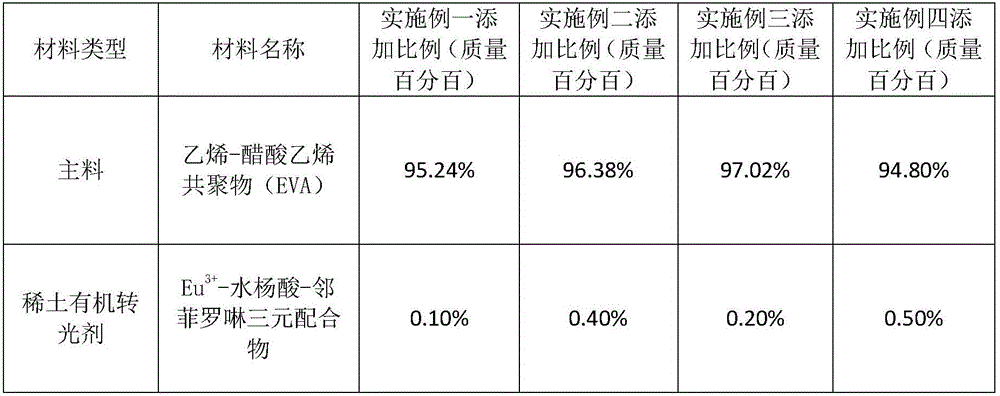

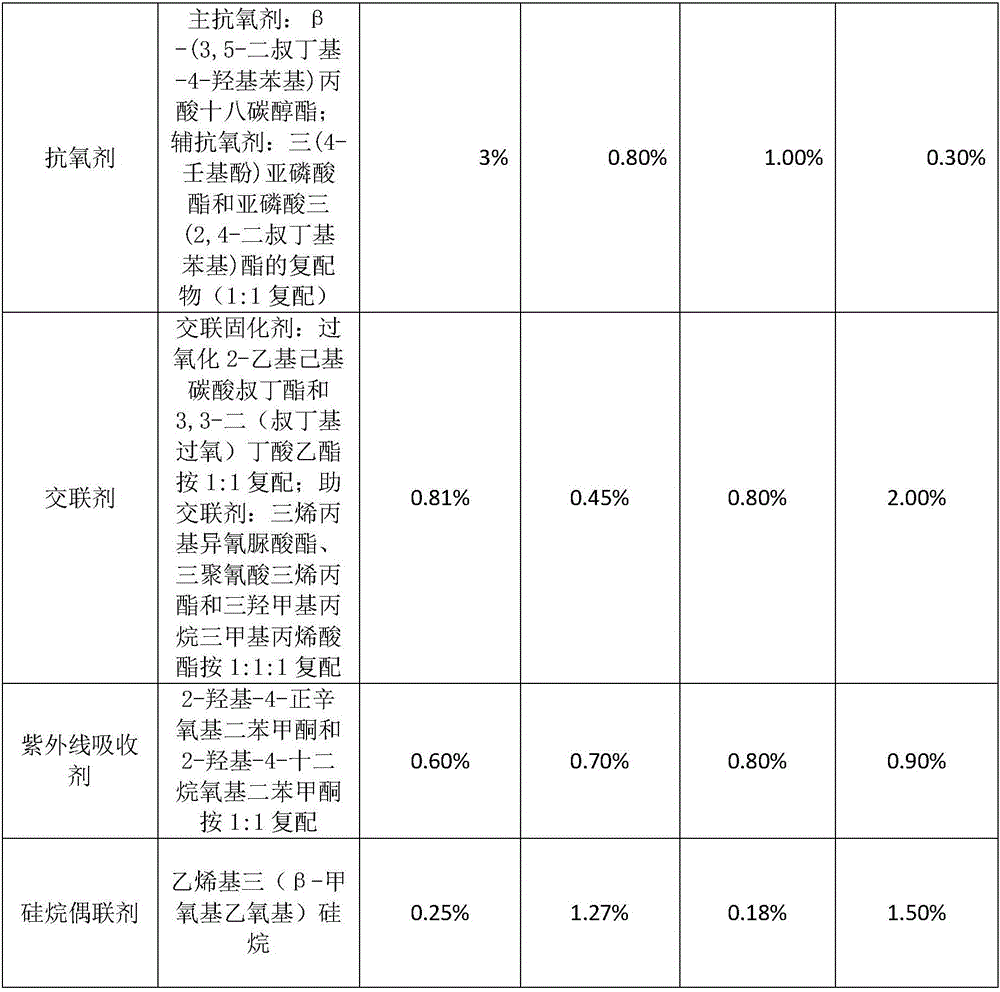

The invention relates to the technical field of packaging adhesive films, in particular to an ultrahigh cut-off EVA packaging adhesive film. The ultrahigh cut-off EVA packaging adhesive film is prepared from the following raw materials in percentage by mass: 94.8%-97.02% of ethylene-vinyl acetate copolymer resin, 0.1%-0.5% of a rare-earth organic light conversion agent, 0.3%-3% of an antioxidant, 0.6%-0.9% of an ultraviolet light absorber, 0.45%-0.2% of a cross-linking agent and 0.18%-1.5% of a silane coupling agent. The transparency and the ultraviolet aging resistance of the EVA adhesive film prepared by a manufacturing method are greatly improved, so that the ultraviolet aging resistance of the adhesive film is improved; the service lifetime of a solar cell assembly is prolonged; and the ultrahigh cut-off EVA packaging adhesive film plays a good protecting role for a backing material of the assembly.

Description

technical field [0001] The invention relates to the technical field of packaging adhesive films, in particular to an ultra-high cut-off EVA packaging adhesive film. Background technique [0002] Battery Encapsulation Adhesive Film (EVA) is a thermosetting adhesive film used to be placed between laminated glass (EVA is the abbreviation of Ethylene Vinyl Vinyl Acetate). Due to the superiority of EVA film in terms of adhesion, durability, and optical properties, it is more and more widely used in current components and various optical products. [0003] The EVA encapsulating adhesive film in the prior art has poor ultraviolet aging resistance and yellowing resistance. Contents of the invention [0004] The technical problem to be solved by the present invention is to overcome the deficiencies in the prior art and provide a super high cut-off EVA encapsulation adhesive film with strong ultraviolet aging resistance and yellowing resistance. [0005] In order to solve the prob...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J7/00C09J123/08C09J131/04C09J11/06

Inventor 张好宾吕松何胡送

Owner CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com