High-shading type double-color TPU (thermoplastic polyurethane) film and production process thereof

A high shading, two-color technology, used in other household appliances, flat products, household appliances, etc., can solve problems such as poor dispersion performance, improve UV aging resistance, reduce impact, and improve shading effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] All the silane coupling agents used to prepare the silane coupling agent modified carbon black are KH550.

[0039] Raw materials for black film:

[0040] TPU masterbatch 100 parts

[0041] 40 parts of silane coupling agent modified carbon black.

[0042] Raw materials for white film

[0043] TPU masterbatch 100 parts

[0044] KH550 modified titanium dioxide 20 parts.

[0045] Production process: Mix the raw materials used for the black film and the raw materials used for the white film in a mixer, and then heat-melt the two mixtures separately, and extrude from the corresponding extrusion port, and then output after being extruded by a casting machine , and finally after cooling, traction, and winding, a two-color TPU film is obtained.

Embodiment 2

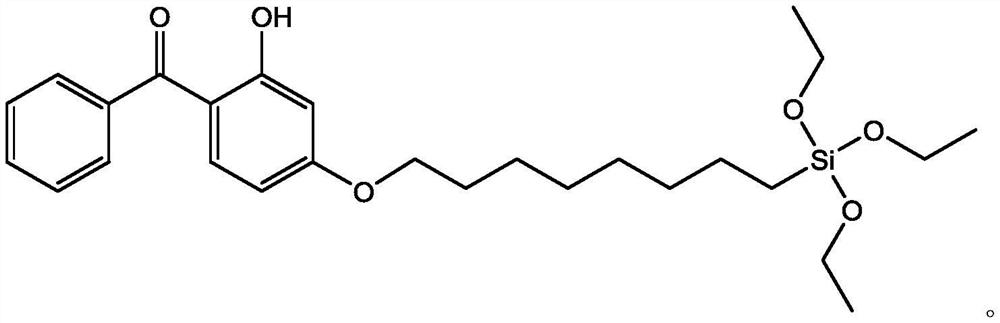

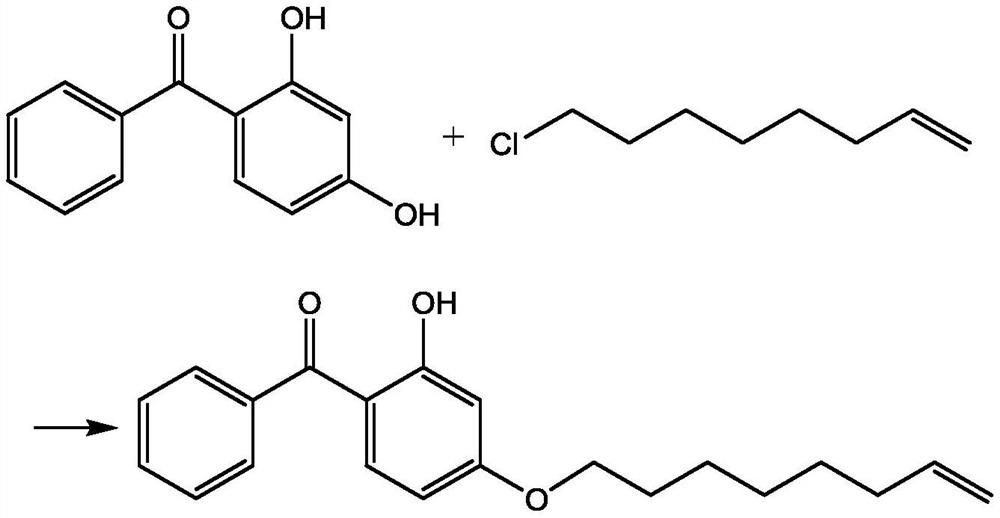

[0047] The silane coupling agent used to prepare the silane coupling agent modified carbon black is a mixture of KH550 and a light-shielding silane coupling agent, wherein the mass percentage of KH550 is 50%, and the mass percentage of the light-shielding silane coupling agent is 50%. %.

[0048] Raw materials for black film:

[0049] TPU masterbatch 100 parts

[0050] 40 parts of silane coupling agent modified carbon black.

[0051] Raw materials for white film

[0052] TPU masterbatch 100 parts

[0053] KH550 modified titanium dioxide 20 parts.

[0054] Production process: Mix the raw materials used for the black film and the raw materials used for the white film in a mixer, and then heat-melt the two mixtures separately, and extrude from the corresponding extrusion port, and then output after being extruded by a casting machine , and finally after cooling, traction, and winding, a two-color TPU film is obtained.

Embodiment 3

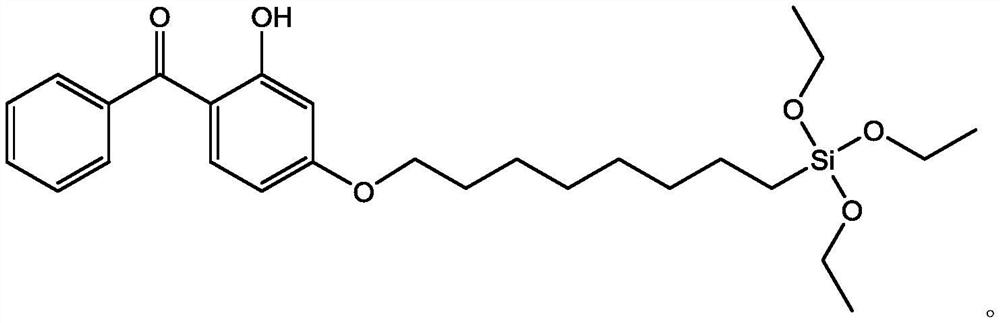

[0056]The silane coupling agent used to prepare the silane coupling agent modified carbon black is a mixture of KH550 and a light-shielding silane coupling agent, wherein the mass percentage of KH550 is 20%, and the mass percentage of the light-shielding silane coupling agent is 80%. %.

[0057] Raw materials for black film:

[0058] TPU masterbatch 100 parts

[0059] 40 parts of silane coupling agent modified carbon black.

[0060] Raw materials for white film

[0061] TPU masterbatch 100 parts

[0062] KH550 modified titanium dioxide 20 parts.

[0063] Production process: Mix the raw materials used for the black film and the raw materials used for the white film in a mixer, and then heat-melt the two mixtures separately, and extrude from the corresponding extrusion port, and then output after being extruded by a casting machine , and finally after cooling, traction, and winding, a two-color TPU film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com