Polycarbonate/polypropylene alloy material and preparation method thereof

A technology for polycarbonate and alloy materials, applied in the field of compatibilization and anti-aging polycarbonate/polypropylene alloy materials and its preparation, can solve the problem of compatibilizers disturbing the regular arrangement of crystallization or crystallite regions, polycarbonate/polypropylene Alloy mechanical strength reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

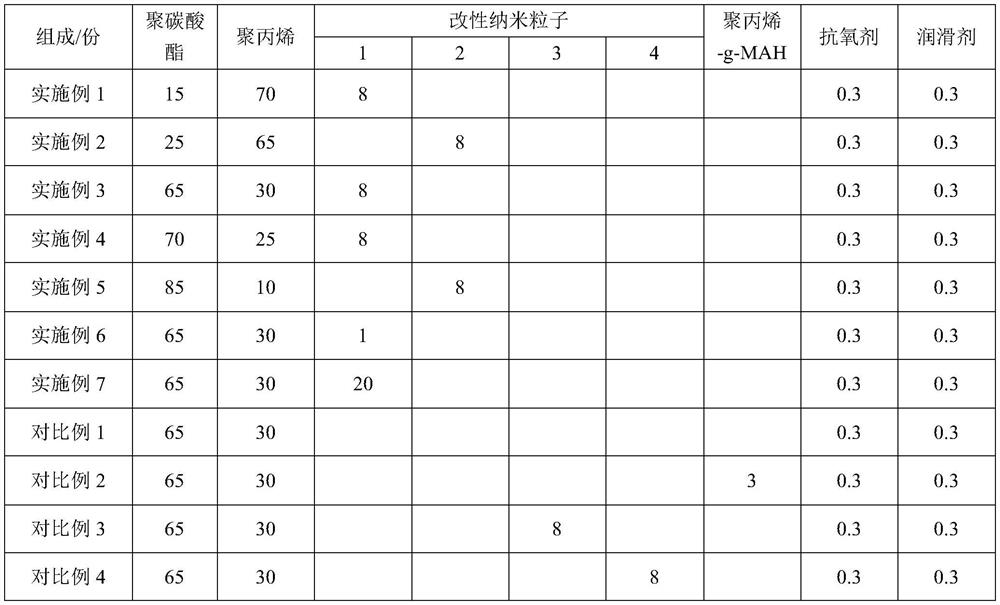

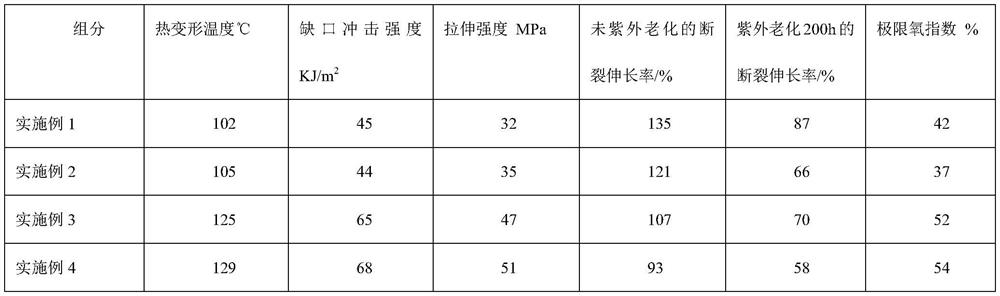

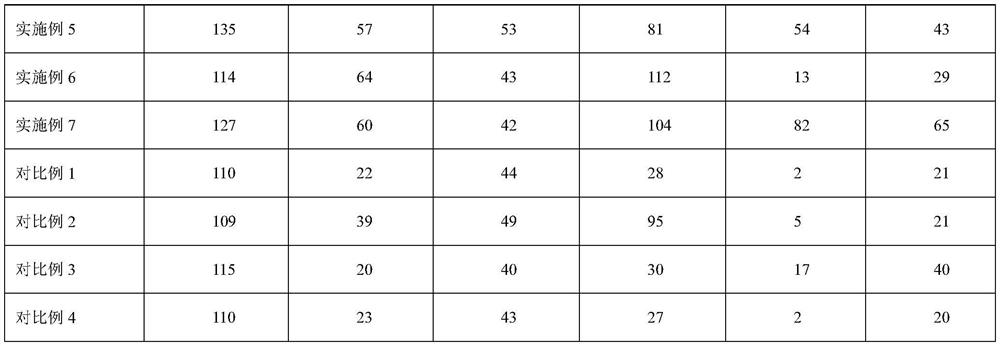

Embodiment 1

[0068] Weigh the raw materials in the following weight ratio: polycarbonate-1:15 parts, polypropylene-1:70 parts, quaternary ammonium salt modified graphene oxide expanded rice particles-1:8 parts, antioxidant 0.3 parts, 0.3 parts of lubricant. Add the material composition into a high-speed mixer and mix it. After mixing, add it to a twin-screw extruder for extrusion and granulation. The processing temperature of the twin-screw extruder is 210°C, the screw speed is 200rpm, and the metering section of the twin-screw extruder pumps The vacuum degree of the vacuum device is -0.7 bar. After the granulation is completed, dry it at 100°C for 4 hours to fully remove the moisture. Then put the pellets into the injection molding machine for injection molding. Control the temperature of the injection mold at 80°C, the temperature of the barrel at 230°C, and the injection speed 50mm / s, injection pressure 60bar, cut out standard splines and templates.

Embodiment 2

[0070] Including the following raw materials in weight ratio: polycarbonate-1:25 parts, polypropylene-1:65 parts, quaternary ammonium salt modified graphene oxide expanded rice particles-2:8 parts, antioxidant 0.3 parts, lubricant 0.3 parts. Put the material composition into a high-speed mixer and mix it. After mixing, add it to a twin-screw extruder for extrusion and granulation. The processing temperature of the twin-screw extruder is 220°C, the screw speed is 200rpm, and the vacuum degree of the vacuum device in the twin-screw metering section is Within -0.7 bar, after granulation is completed, dry at 100°C for 4 hours to fully remove moisture, then put the pellets into the injection molding machine for injection molding, control the temperature of the injection mold at 80°C, the temperature of the barrel at 235°C, and the injection speed at 50mm / s , the injection pressure is 60bar, and the standard splines and templates are obtained by cutting.

Embodiment 3

[0072] Including the following raw materials in weight ratio: polycarbonate-1:65 parts, polypropylene-1:30 parts, quaternary ammonium salt modified graphene oxide expanded rice particles-1:8 parts, antioxidant 0.3 parts, lubricant 0.3 parts. Put the material composition into a high-speed mixer and mix it. After mixing, add it to a twin-screw extruder for extrusion and granulation. The processing temperature of the twin-screw extruder is 240°C, the screw speed is 300rpm, and the vacuum degree of the vacuum device in the twin-screw metering section is Within -0.7 bar, after the granulation is completed, dry it at 100°C for 4 hours to fully remove the water, then put the pellets into the injection molding machine for injection molding, control the temperature of the injection mold at 80°C, the temperature of the barrel at 240°C, and the injection speed at 50mm / s , the injection pressure is 60bar, and the standard splines and templates are obtained by cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com