Scale- and corrosion-inhibiting and antibacterial compounded water treatment agent and preparation method of same

A technology of scale and corrosion inhibition and water treatment agent, which is applied in the chemical industry, can solve the problems of waste of dosing, small amount of fungicide addition, and difficult metering, etc., and achieve good effect and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

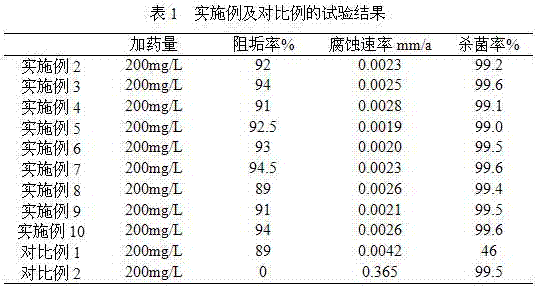

Examples

Embodiment 1

[0018] Scale and corrosion inhibition and sterilization compound water treatment agent, mainly composed of 2-phosphonic acid butane-1, 2, 4-tricarboxylic acid, hydroxyethylidene diphosphonic acid, hydrolyzed polymaleic anhydride, sulfonic acid copolymer, alkylphenol It is prepared from polyoxyethylene ether, quaternary ammonium salt and benzotriazole, and the weight ratio of each raw material is 2-10% of 2-phosphonic acid butane-1, 2, 4-tricarboxylic acid, hydroxyethylidene Diphosphonic acid 2-10%, hydrolyzed polymaleic anhydride 5-15%, sulfonic acid copolymer 3-10%, alkylphenol polyoxyethylene ether 0.1-1%, quaternary ammonium salt 2-10%, benzene three Azole 0.2-1%, the balance is water.

[0019] 2-phosphonobutane-1, 2, 4-tricarboxylic acid (PBTCA), hydroxyethylidene diphosphonic acid (HEDP), hydrolyzed polymaleic anhydride (HPMA), acrylic acid-2-acrylamide-2-methyl Propanesulfonic acid copolymer (AA / AMPS), branched quaternary ammonium salt or polyquaternary ammonium salt, a...

Embodiment 2

[0027] Composite water treatment agent for scale and corrosion inhibition and sterilization, mainly composed of 2-phosphonic acid butane-1, 2, 4-tricarboxylic acid, hydroxyethylidene diphosphonic acid, hydrolyzed polymaleic anhydride, acrylic acid-2-acrylamide-2 -Methylpropanesulfonic acid copolymer, alkylphenol polyoxyethylene ether, branched quaternary ammonium salt and benzotriazole, the weight ratio of each raw material is respectively 2-phosphonic acid butane-1, 2 , 20g of 4-tricarboxylic acid, 20g of hydroxyethylidene diphosphonic acid, 50g of hydrolyzed polymaleic anhydride, 30g of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 1g of alkylphenol polyoxyethylene ether, Branched quaternary ammonium salt 20g, benzotriazole 2g, water 857mL.

[0028] As the preparation method of the above scale and corrosion inhibition and sterilization compound water treatment agent, the specific steps are as follows:

[0029] (1) Pour water into the mixing tank, turn on...

Embodiment 3

[0037] Composite water treatment agent for scale and corrosion inhibition and sterilization, mainly composed of 2-phosphonic acid butane-1, 2, 4-tricarboxylic acid, hydroxyethylidene diphosphonic acid, hydrolyzed polymaleic anhydride, acrylic acid-2-acrylamide-2 -Methylpropanesulfonic acid copolymer, alkylphenol polyoxyethylene ether, branched quaternary ammonium salt and benzotriazole, the weight ratio of each raw material is respectively 2-phosphonic acid butane-1, 2 , 30g of 4-tricarboxylic acid, 30g of hydroxyethylidene diphosphonic acid, 60g of hydrolyzed polymaleic anhydride, 40g of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 2g of alkylphenol polyoxyethylene ether, Branched quaternary ammonium salt 30g, benzotriazole 3g, water 805mL.

[0038] As the preparation method of the above scale and corrosion inhibition and sterilization compound water treatment agent, the specific steps are as follows:

[0039] (1) Pour water into the mixing tank, turn on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com