Emulsion for water-based two-component wood splice adhesive and preparation method of emulsion

A two-component, panel adhesive technology, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., to achieve the effects of reducing hydrophilic groups, improving water resistance, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

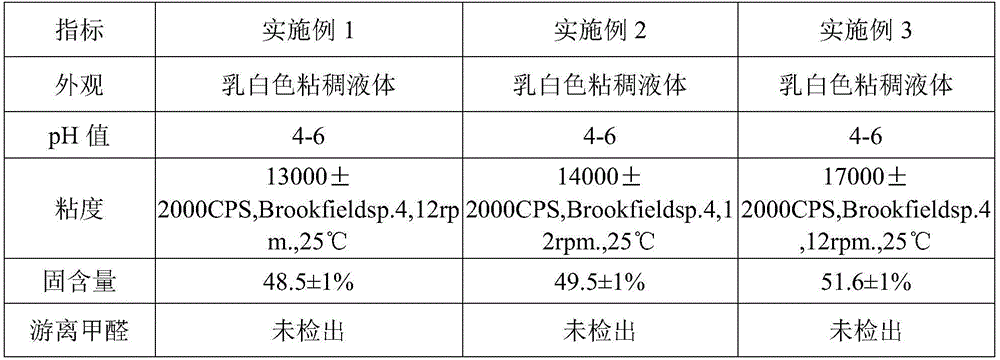

Embodiment 1

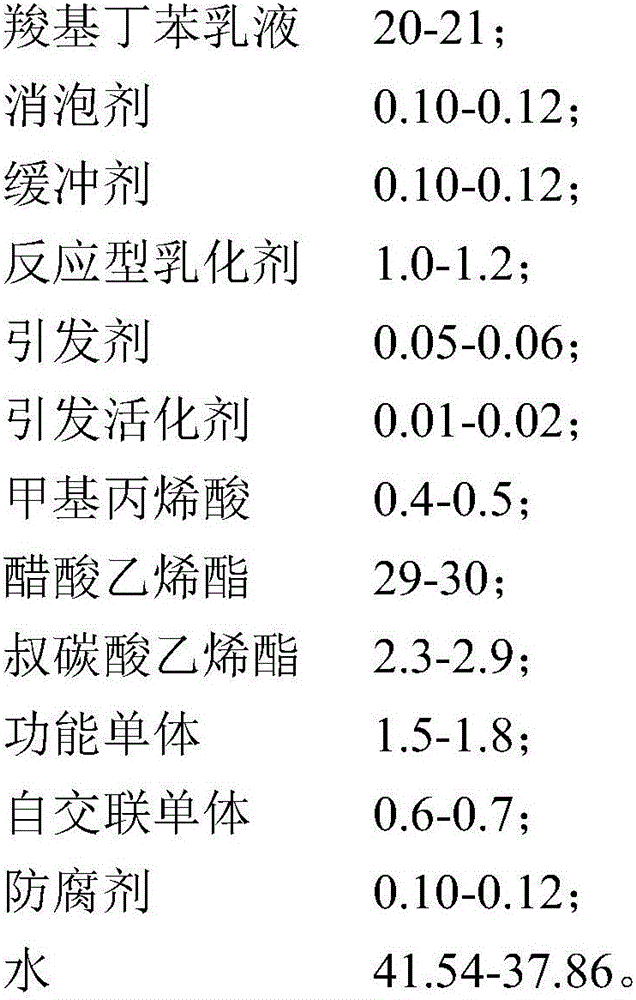

[0019] Recipe: total amount = 1000kg

[0020] PVA1788

25kg

PVA0588

8kg

4kg

Carboxybutylbenzene DL 264PA

200kg

290kg

BYK024

1kg

23kg

Sodium acetate

1kg

4-HBA

15kg

EXG-202

10kg

NMA - 48%

6kg

0.5kg

LEX fungicide

1kg

0.1kg

water

415.4kg

[0021] Production Process:

[0022] A, 0.5kg ammonium persulfate is dissolved in 19.5kg water to obtain 20kg ammonium persulfate solution, 0.1kg sodium thiosulfate is dissolved in 0.9kg water to obtain 1kg sodium thiosulfate solution; 6kg NMA is dispersed in 14kg water to obtain 20kg NMA aqueous solution; 290kg vinyl acetate, 23kg tertiary vinyl carbonate, 15kg4-HBA and 4kg methacrylic acid are added to the monomer tank to mix and stir to make 332kg mixed monomers;

[0023] B, remaining water is ad...

Embodiment 2

[0026] Embodiment two formulas: total amount=1000kg

[0027] PVA1792

30kg

PVA0588

4kg

4kg

Carboxybutylbenzene DL 264PA

205kg

vinyl acetate

295kg

BYK024

1.1kg

26kg

Sodium acetate

1.1kg

4-HBA

17kg

EXG-202

11kg

NMA - 48%

6kg

Ammonium persulfate

0.5kg

LEX fungicide

1.1kg

0.1kg

water

398.1kg

[0028] Production Process:

[0029] A, 0.5kg ammonium persulfate is dissolved in 19.5kg water to obtain 20kg ammonium persulfate solution, 0.1kg sodium thiosulfate is dissolved in 0.9kg water to obtain 1kg sodium thiosulfate solution; 6kg NMA is dispersed in 14kg water to obtain 20kg NMA aqueous solution; 295kg of vinyl acetate, 26kg of tertiary vinyl carbonate, 17kg of 4-HBA and 4kg of methacrylic acid are added to the monomer tank to mix and stir to make 342kg of mixed monome...

Embodiment 3

[0034] Recipe: total amount = 1000kg

[0035] PVA1788

24kg

PVA0588

12kg

5kg

Carboxybutylbenzene DL 392PA

210kg

vinyl acetate

300kg

BYK024

1.2kg

tertiary ethylene carbonate

29kg

1.2kg

4-HBA

18kg

EXG-202

12kg

NMA - 48%

7kg

Ammonium persulfate

0.6kg

LEX fungicide

1.2kg

0.2kg

water

378.6kg

[0036] Production Process:

[0037]a, 0.6kg ammonium persulfate is dissolved in 19.4kg water, obtains 20kg ammonium persulfate solution, 0.2kg sodium thiosulfate is dissolved in 0.8kg water, obtains 1kg sodium thiosulfate solution; 7kgNMA is dispersed in 13kg water, obtains 20kg of NMA aqueous solution; 300kg of vinyl acetate, 29kg of tertiary vinyl carbonate, 18kg of 4-HBA and 5kg of methacrylic acid were added to the monomer tank and mixed evenly to make 352kg of mixed monomer;

[0038] b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com