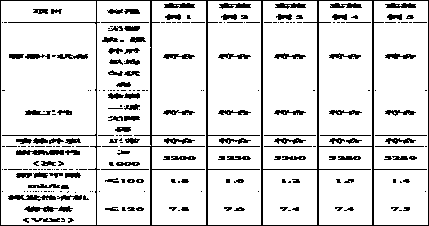

Patents

Literature

46results about How to "Reduce hydrophilic groups" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone modified acrylic ester emulsion and preparation method thereof

The invention discloses a silicone modified acrylic ester emulsion and a preparation method thereof. The emulsion is prepared from the following raw materials in parts by weight: 6.5-9 parts of acrylic ester mixed monomers, 1-3.5 parts of an organosilicone monomer, 0.4-0.6 part of an emulsifier, 0.2-0.3 part of an initiating agent, 0.01-0.03 part of a pH conditioning agent, 28-32 parts of deionized water, wherein the acrylic ester mixed monomers are methyl methacrylate and butyl acrylate with the mass ratio of (5.5-6.5):(3.5-4.5); the organosilicone monomer is gamma- 3-[Tris(trimethylsiloxy)silyl]propyl methacrylate. According to the emulsion, the reactive emulsifier is adopted for polymerization reaction, the prepared emulsion is stable, and the latex film of the emulsion has lower surface energy and better water resistance, and can be used as the main film forming matter of a metal anti-corrosion coating.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

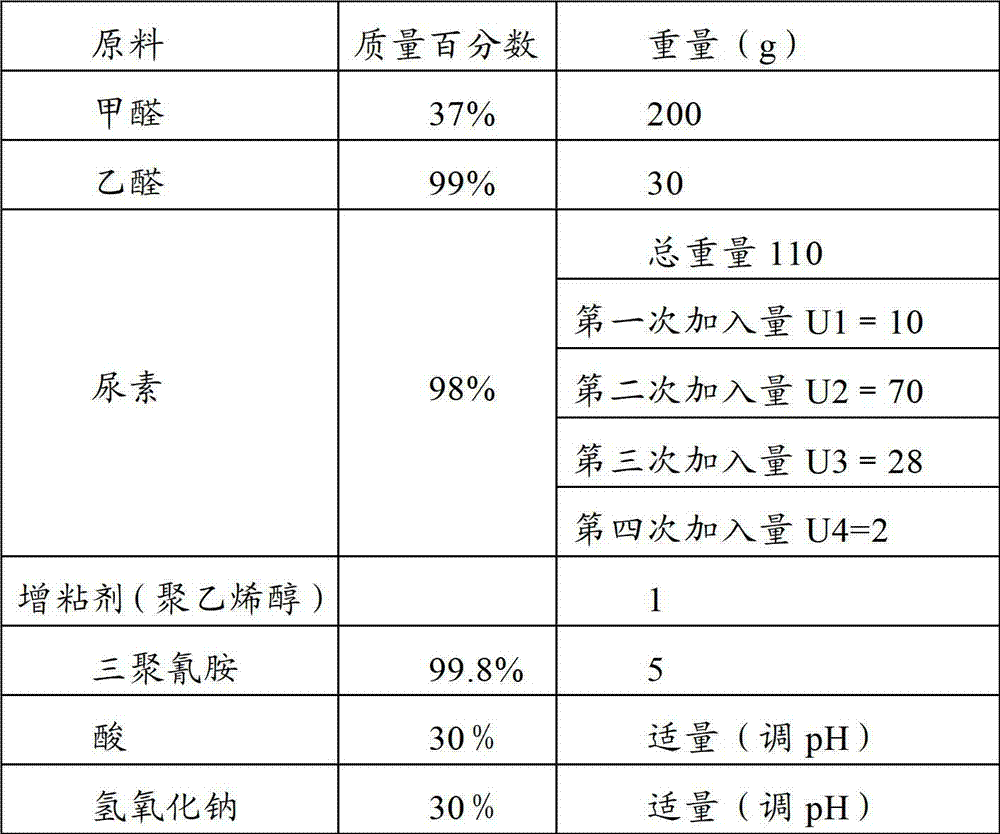

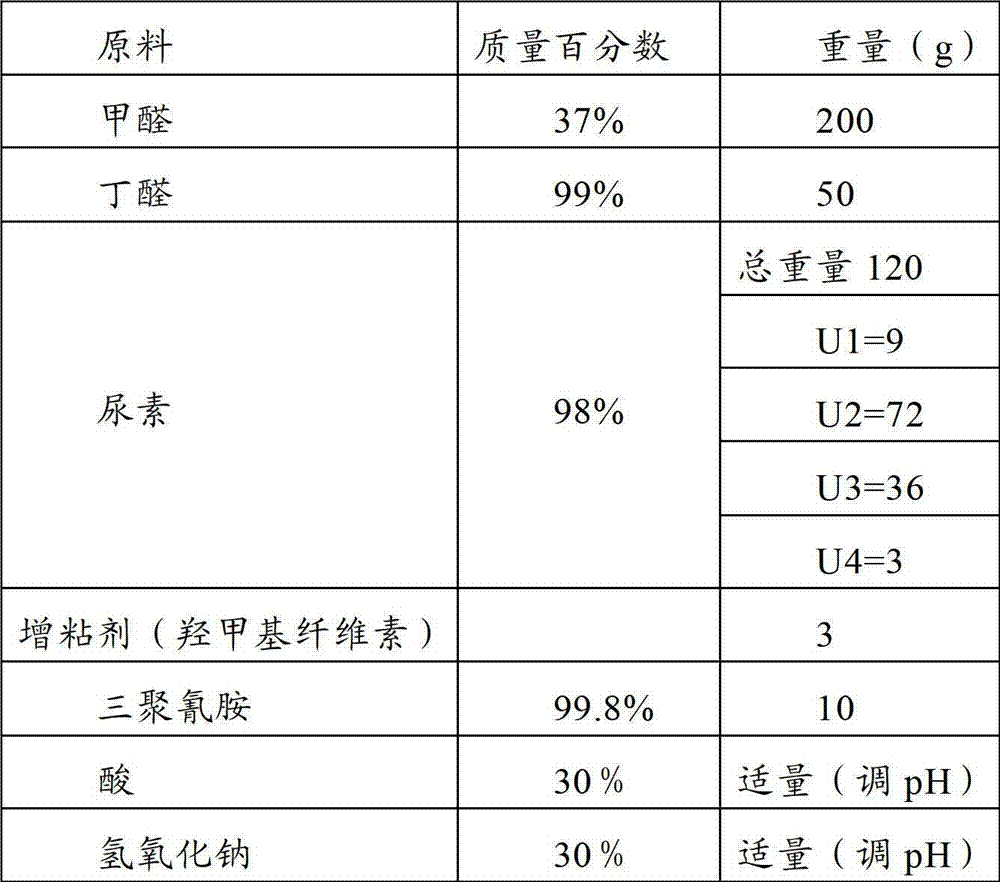

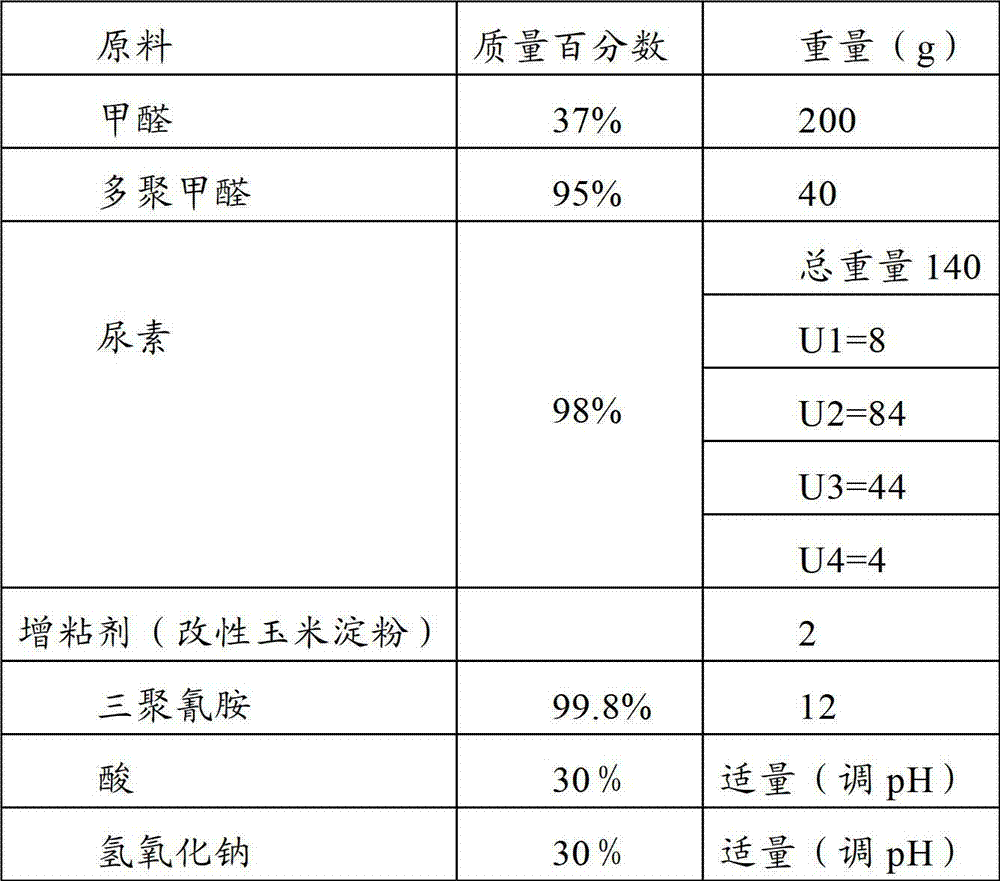

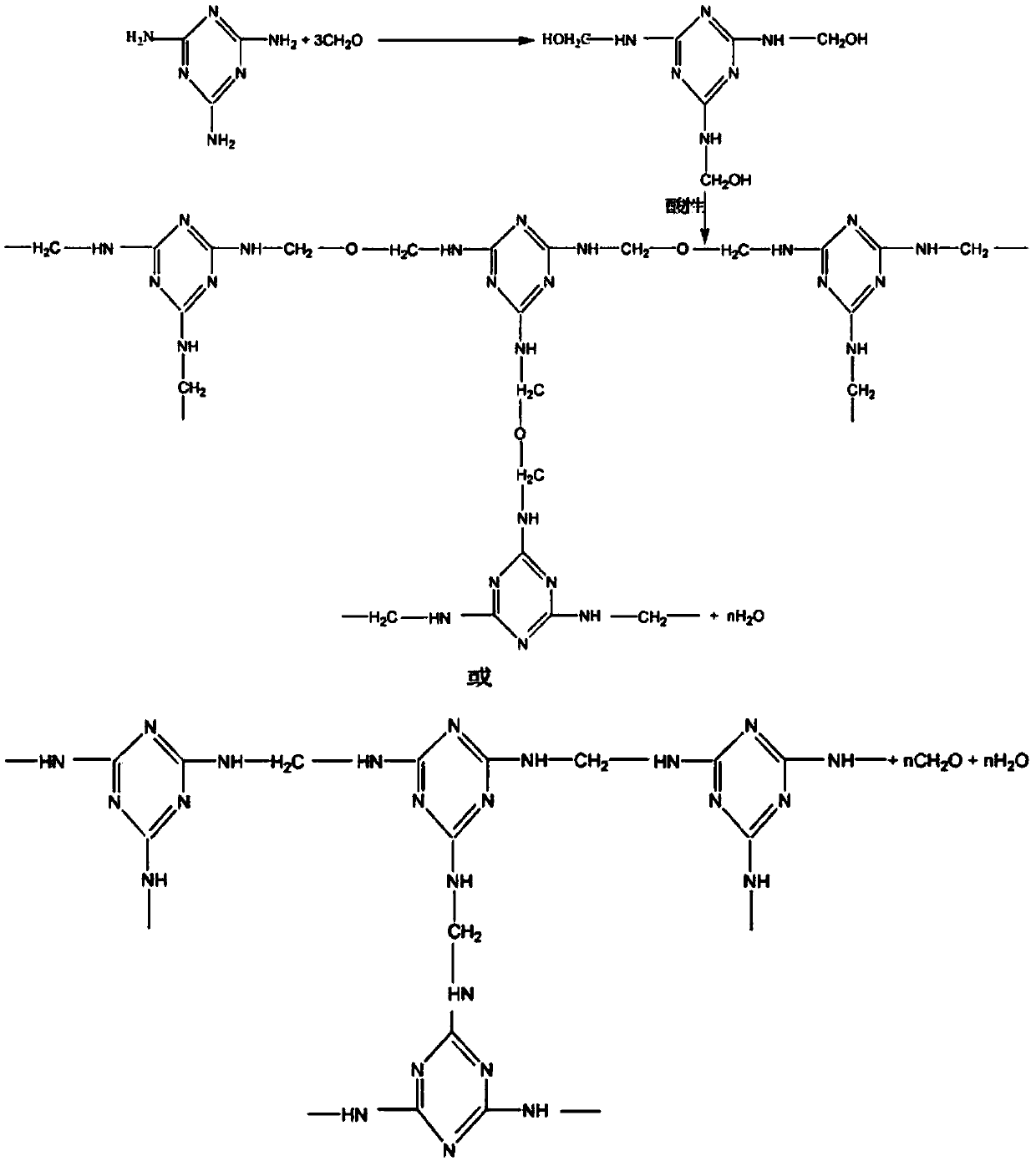

Adhesive for veneering of artificial board and preparation method of adhesive

InactiveCN103031095AReduce penetrationReduce generationMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSolubilityAdhesive

The invention relates to an adhesive for a veneering of an artificial board and a preparation method of the adhesive. The adhesive comprises the components in parts by weight: 200 parts of formaldehyde, 20-50 parts of a modifier, 110-140 parts of urea, 5-15 parts of tripolycyanamide, and 1-10 parts of a tackifier. By addition of appropriate parts of modifier, on the one hand, the high solid content adhesive can be prepared without dehydration, moisture brought to a base material during coating is reduced, permeation of the adhesive is reduced, and glue penetration is reduced. In addition, through addition of the modifier, the molar ratio of formaldehyde and urea in the polycondensation phase in the urea resin synthetic process can be greatly reduced, so that hydrophilic radicals in the resin structure are greatly decreased. Meanwhile, tripolycyanamide in appropriate parts is added to modify, so that the water-solubility of the adhesive is reduced, the hydrophobicity of the adhesive is enhanced, and glue penetration is beneficially reduced. The tackifier in appropriate parts is added to improve the initial adhesion of the adhesive and reduce malposition of a veneer on the base material, so that the product quality is improved.

Owner:EVERFIRST WISEFUND TECH BEIJING

Biochar-based plastic film material and preparation method thereof

The invention discloses a biochar-based plastic film material and a preparation method thereof. The biochar-based plastic film material is prepared by mixing the following raw materials in parts by weight: 20-40 parts of modified biochar, 40-60 parts of polyethylene, 1.5-2 parts of dispersing agent and 1-2.5 parts of coupling agent. According to the invention, the biochar is combined with plastic by a modification technology, to reduce the dosage of the plastic in agriculture and accelerate the decomposition course to plastic products so as to achieve the purpose of protecting the environment.

Owner:国家林业局竹子研究开发中心

Organic silicone modified acrylate emulsion and preparation method thereof

InactiveCN105199040AImproved water resistance and stabilityLow VOC emissionDyeing processIonEmulsion

The invention relates to organic silicone modified acrylate emulsion and a preparation method thereof. The organic silicone modified acrylate emulsion is synthesized through a hard monomer, a soft monomer, a cross-linking monomer, an organic silicone monomer and a reactive emulsification monomer under the action of an initiator at one time; the preparation method comprises the following steps: dissolving the initiator into deionized water; uniformly mixing the hard monomer, the soft monomer, the cross-linking monomer and the organic silicone monomer in a premixing tank; adding an emulsifier and deionized water into a four-mouth flask to be heated to 70-90 DEG C, slowly dropwise adding the uniformly-mixed monomer mixed phase and 90% of an initiator solution for 1-3 h at the temperature of 70-90 DEG C and the rotating speed of 200-400 r / min, carrying out heat preservation for 1-3 h at the temperature of 70-90 DEG C after dropping, meanwhile, dropwise adding 10% of the residual initiator solution, and adding ammonia water for adjusting the PH to 6-8 after cooling to 50 DEG C or below. The migration of the emulsifier in a latex film is avoided through application of the reactive emulsifier and the defects of hot sticking and cold shortness of the pure acrylic resin are overcome through organic silicone modification.

Owner:WUYI UNIV

Production method for fireproof, flame-resistant, medium-density fiber closet plate

InactiveCN109304787AAlleviate the contradiction between supply and demandHigh hardnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberSizing

The invention discloses a production method for a fireproof, flame-resistant, medium-density fiber closet plate. The method comprises the steps of (1) preprocessing of raw materials, (2) screening, (3) steaming and boiling for softening, (4) grinding, (5) sizing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing and (10) edge cutting. In this way,a finished product is obtained. The method disclosed by the invention is characterized in that eucalyptus barks and branches and waste leftover bits and pieces left after panel manufacture are takenas main raw materials, other miscellaneous wood is added and waste is recycled, so wood resources can be utilized fully and effectively; and modified paraffin and flame-resistant urea-formaldehyde resin adhesive are added, so resistance of the product to fire and flame is greatly enhanced. The medium-density fiber cabinet plate is highly resistant to fire, flame and water and low in the content offormaldehyde, so the product is a safe and environment-friendly closet plate.

Owner:广西横州丽冠环保材料有限公司

Method for preparing silk fibroin sodium alginate composite fiber

InactiveCN108193311AIncrease the number ofHigh densityConjugated cellulose/protein artificial filamentsPeptidesFiberHydrolysate

The invention discloses a method for preparing a silk fibroin sodium alginate composite fiber and belongs to the technical field of natural macromolecule composite materials. The method comprises thefollowing steps: firstly, mixing, stirring and dissolving silk fibroin with water, performing dialysis, and performing centrifugal separation so as to obtain a pretreated silk fibroin solution; mixingelastinase and the pretreated silk fibroin solution, adjusting the pH value, and performing constant-temperature stirring enzymolysis so as to obtain enzymatic hydrolysate; mixing phospholipid with the enzymatic hydrolysate, performing ultrasonic dispersion, further adding sodium alginate, plant essential oil and monosaccharide, performing a constant-temperature stirring reaction so as to obtaina reaction liquid, mixing the reaction liquid with Carbomer, performing a constant-temperature stirring reaction so as to obtain a spinning solution, performing vacuum defoaming, spinning, washing with water, and performing traction, coiling and drying, thereby obtaining the silk fibroin sodium alginate composite fiber. The silk fibroin sodium alginate composite fiber prepared by using the methodhas good mechanical properties.

Owner:常州凯奥机电科技有限公司

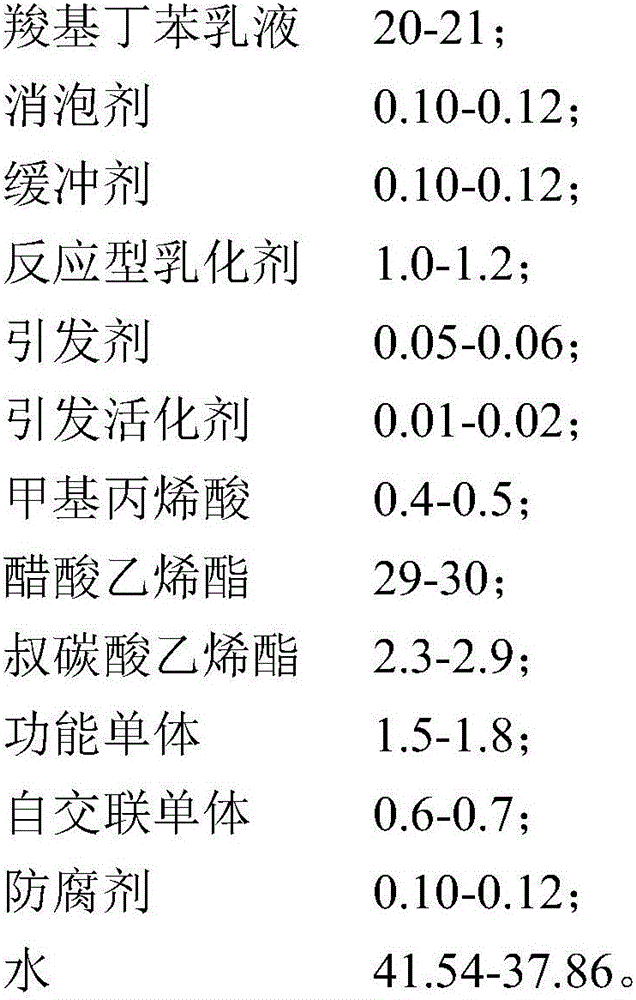

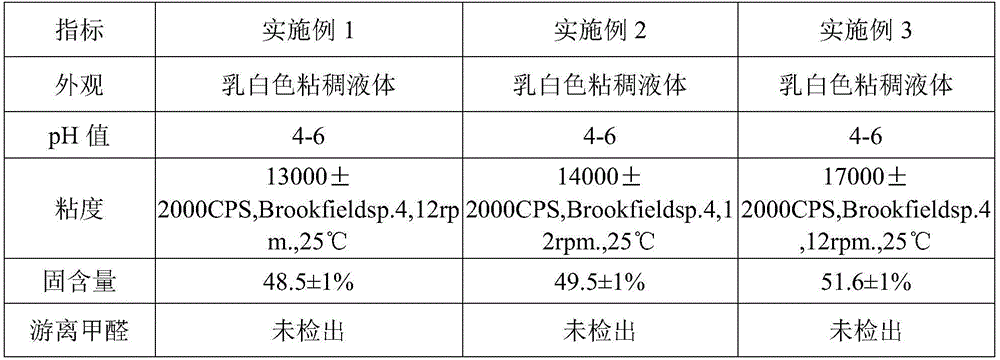

Emulsion for water-based two-component wood splice adhesive and preparation method of emulsion

The invention discloses emulsion which is prepared for a water-based two-component wood splice adhesive by taking carboxylated styrene-butadiene emulsion as a seed. The emulsion is prepared from the styrene-butadiene emulsion, a defoaming agent, a buffering agent, polyvinyl alcohol, a reactive emulsifier, an initiator, methacrylic acid, vinyl acetate, vinyl versatate, a functional monomer, a self-cross linking monomer, a preservative and the like. According to the emulsion for the wood splice adhesive, carboxylated styrene-butadiene is taken as the seed emulsion, flexible chains are introduced into emulsion particles, and therefore the anti-cracking property of the emulsion for the wood splice adhesive is improved; water is taken as a dispersion medium, use is convenient, no pollution is generated to the environment, after compounding is conducted, a polyisocyanate curing agent is added to prepare the two-component wood splice adhesive, and the functional monomer-primary hydroxyl group and the polyisocyanate curing agent in the emulsion achieve bridging, so that the strength and the water resistance are improved.

Owner:顶立新材料科技股份有限公司

Method for preparing waterproof polyvinyl alcohol trademark adhesive

ActiveCN103694930AIncrease viscosityGuaranteed bonding performanceNon-macromolecular adhesive additivesUnsaturated alcohol polymer adhesivesWater bathsPolymer science

The invention discloses a method for preparing a waterproof polyvinyl alcohol trademark adhesive. The method comprises the following steps of: (1) weighing a certain amount of polyvinyl alcohol, dissolving weighed polyvinyl alcohol in water, heating in a water bath, and stirring for swelling to obtain a 8-20% polyvinyl alcohol solution; (2) adjusting the temperature of the polyvinyl alcohol solution obtained from step (1), adding aluminum sulfate, and stirring at constant temperature to obtain the waterproof polyvinyl alcohol trademark adhesive, wherein aluminum sulfate is 12-25% the weight of polyvinyl alcohol. The waterproof polyvinyl alcohol trademark adhesive has strong water resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Production method of special highly-moisture-proof intermediate-density fiber board for office table

InactiveCN109129755ALow costTo achieve the purpose of sizing and water resistanceWood treatment detailsWood veneer joiningFiberThiourea

The invention discloses a production method of a special highly-moisture-proof intermediate-density fiber board for an office table. The method comprises the following steps: (1) preprocessing raw materials; (2) screening; (3) digesting to soften; (4) grinding; (5) applying glue, and drying; (6) pre-pressing; (7) thermally pressing; (8) sawing and sanding; (9) clinging to the surface, and thermally pressing; and (10) cutting the edge to obtain the special board for the office table. According to the method, eucalyptus bark, branches and waste leftovers in board manufacturing are treated as main raw materials; miscellaneous woods such as pine wood, basswood, briar wood, fraxinus mandshurica, beech wood, acer mono wood and lauan wood are added; the wastes are turned into treasures; and the wood resource is fully effectively utilized; hydrogenated rosin and thiourea are added to a moisture-proof urea resin adhering agent, so that the board has the advantages of being environmentally friendly, low in formaldehyde, and outstanding in moisture-proofing performance. The board is outstanding in moisture-proofing performance, high in water resistance, low in formaldehyde content, high in intensity, and high in durability, and is a safe and environmentally-friendly board.

Owner:广西横州丽冠环保材料有限公司

Preparation method of styrene-acrylic emulsion surface sizing agent

InactiveCN104672367AInhibit migrationAvoid desorptionWater-repelling agents additionSulfonateEmulsion

The invention discloses a preparation method of a styrene-acrylic emulsion surface sizing agent. The method is characterized by comprising the following steps: (1) selecting raw materials; (2) preparing a pre-emulsion; (3) preparing a seed emulsion; (4) polymerizing an outer layer; and (5) preparing a sizing liquid. A traditional emulsifier is replaced with a reactive emulsifier acrylamido isopropyl sodium sulfonate in raw material selection; the reactive emulsifier can be bonded to a polymer in a manner of a covalent bond when playing an emulsifying role, so as to become one part of the polymer; emulsifier migration in a film-forming process or desorption of the emulsifier from polymer particles is avoided; hydrophilic groups on the surface of a latex film are greatly reduced; the polymer has relatively good water-resisting property; and the water-resisting property and stability of the styrene-acrylic emulsion surface sizing agent are improved.

Owner:HAO YU ADDITION AGENT

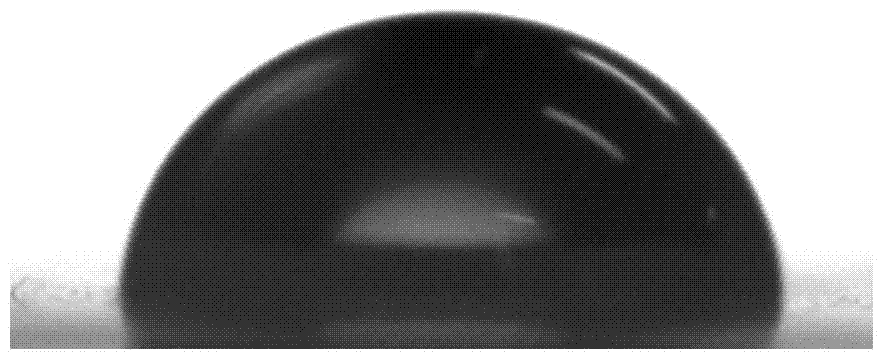

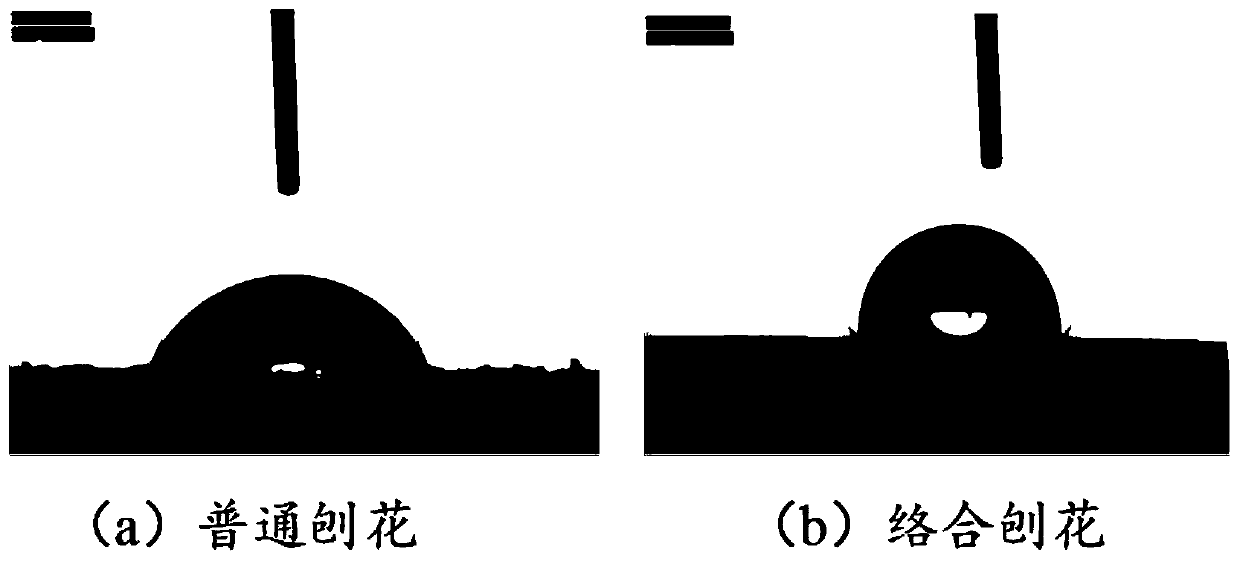

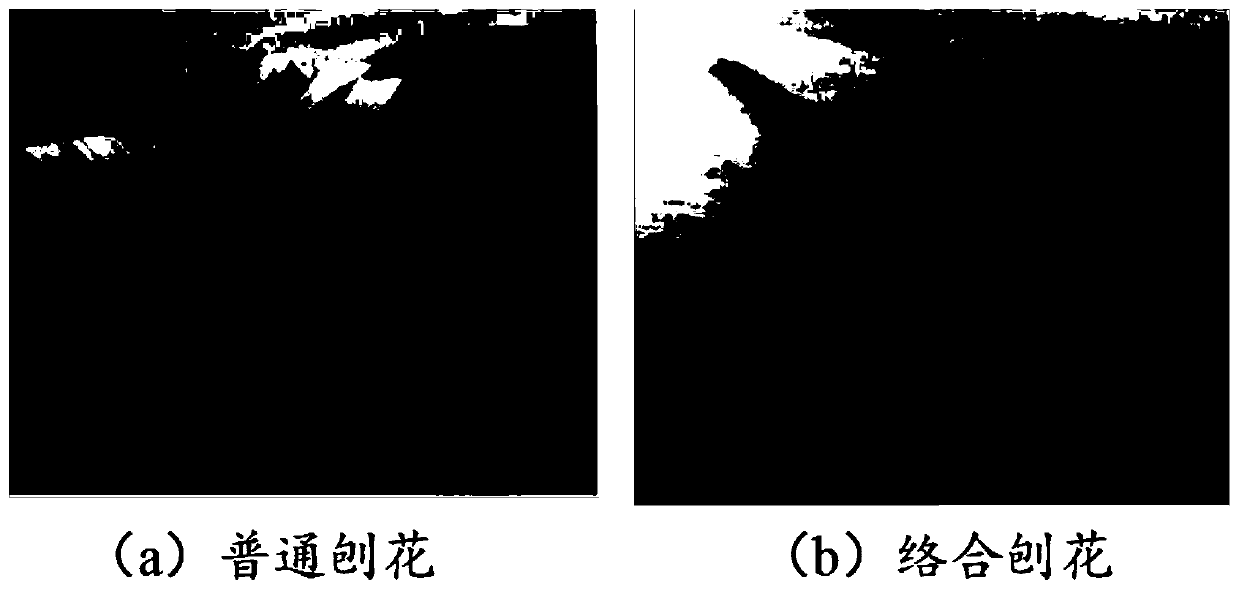

Complexed shavings and complexed shaving board and manufacture methods thereof

ActiveCN110587749AImprove anti-corruptionIncrease mildew resistanceWood treatment detailsPressure impregnationWood shavingsCell cavity

The invention relates to complexed shavings and a complexed shaving board and manufacture methods thereof, and belongs to the technical field of processing of artificial boards. The complexed shavingboard is composed of the complexed shavings and an adhesive, a plant polyphenol metal salt complex is introduced into the complexed shavings, and metal ions are fixed on the surface of the shavings and in cell walls, cell cavities and / or cell gaps, so that not only can the color of the shaving board be changed effectively, but also the waterproof performance, corrosion resistance, mildew resistance and other properties of the shaving board can be increased.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

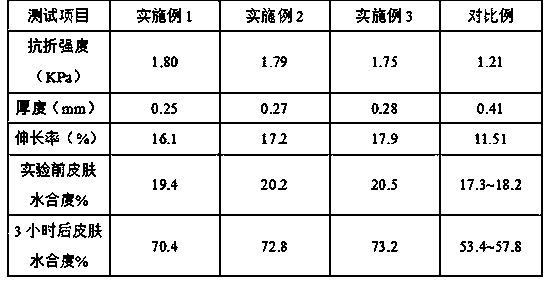

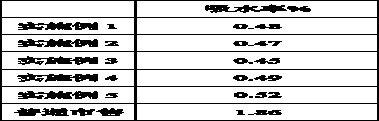

Method for preparing fiber nonwoven fabric for facial masks

InactiveCN108914368AAchieve modificationPromote absorptionConjugated cellulose/protein artificial filamentsNon-woven fabricsPolymer scienceGenipin

The invention belongs to the field of cosmetics, and particularly relates to a method for preparing a fiber nonwoven fabric for facial masks. The method adopts natural silk as a raw material, and obtains preprocessed silk fibroin liquid through degumming and dialysis; the natural Genipin with non-toxic side effects and CaCl2 are used as a crosslinking agent, so that the tensile strength and the breaking strain are improved. Some of the fat-soluble components of the skin can be dissolved, and the absorption of other effective nutrients can be improved. The method utilizes elastase and pepsin tocarry out secondary enzymatic hydrolysis of the preprocessed squid skin liquid, increases the number of free amino groups therein, and allows the protein in the squid skin liquid and the saccharide substances in the system to form a stable crosslinked network system. The method can effectively reduce the problem that the mechanical properties are degraded due to water absorption and swelling whenthe non-woven fabric acts on the mask nutrient solution, and the interaction of the components can avoid the problem of unintentional tearing. The method solves the problem that the fiber nonwoven fabric for facial masks which is commonly used at present is easy to be torn in use.

Owner:高昕文

A kind of biochar-based plastic film material and preparation method thereof

The invention discloses a biochar-based plastic film material and a preparation method thereof. The biochar-based plastic film material is prepared by mixing the following raw materials in parts by weight: 20-40 parts of modified biochar, 40-60 parts of polyethylene, 1.5-2 parts of dispersing agent and 1-2.5 parts of coupling agent. According to the invention, the biochar is combined with plastic by a modification technology, to reduce the dosage of the plastic in agriculture and accelerate the decomposition course to plastic products so as to achieve the purpose of protecting the environment.

Owner:国家林业局竹子研究开发中心

Spraying process for water-resistant white true stone paint

PendingCN110644732AAvoid it happening againImprove aestheticsBuilding constructionsComposite materialMaterial technology

The invention relates to the technical field of outer wall space decoration materials, in particular to a spraying process for water-resistant white true stone paint. The spraying process comprises the following steps: (1) base treatment: cleaning disintegrating slag and dirt on a wall; (2) scratching a filling material; (3) arranging a cutting line; (4) spraying a primer: spraying a colored primer, wherein the color of the primer is consistent to that of a finishing coat and a black primer is sprayed to the cutting line; (5) spraying the finishing coat: after the primer is dried and cured, polishing the surface of the primer, and spraying the finishing coat after dust cleaning; and (6) spraying finish-coat paint: after the finishing coat is dried and cured, polishing the finishing coat, then cleaning dust and spraying the finish-coat paint. After the primer is sprayed, the primer is polished once, a base plane can be smoothened to form an isolating layer, so that ageing of the finishing coat caused by water vapor and alkaline substances in the wall space is avoided. The primer is polished, so that the coarseness of the surface can be improved, and therefore, the finishing coat iscombined with the primer better.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

Preparation method of silicon dioxide nanopore super thermal insulation material

InactiveCN107226710AHydroxyl activeUniform and stable dispersionCeramicwareOXALIC ACID DIHYDRATEThermal insulation

The invention discloses a preparation method of a silicon dioxide nanopore super thermal insulation material, and belongs to the technical field of heat preservation and thermal insulation materials. The preparation method is characterized in that firstly, tetraethyl orthosilicate and tetrabutyl titanate are used as raw materials; an oxalic acid solution and ammonium hydroxide are used as acid-base catalysts; after the raw materials are hydrolyzed in an absolute ethyl alcohol system, then solvent exchange and aging are performed; wet gel containing silicon dioxide and titanium dioxide is obtained; then, the dehydration condensation reaction is performed through heating by using terephthalic acid as a modifying agent and concentrated sulfuric acid as a catalyst; next, drying is performed after water washing, ethanol washing and normal hexane washing are sequentially performed; the silicon dioxide nanopore super thermal insulation material is obtained. The obtained product of the silicon dioxide nanopore super thermal insulation material disclosed by the invention has a good thermal insulation performance, an excellent mechanical performance and hydrophobicity; the use range of the silicon dioxide nanopore super thermal insulation material can be effectively expanded.

Owner:王景硕

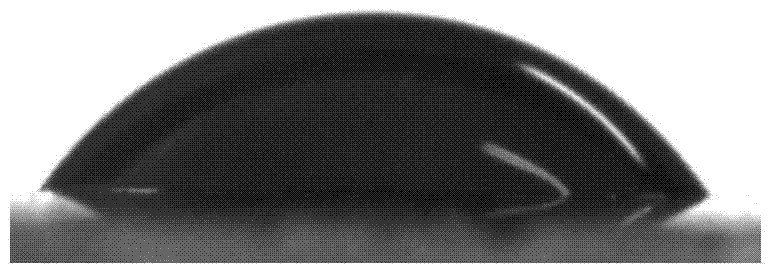

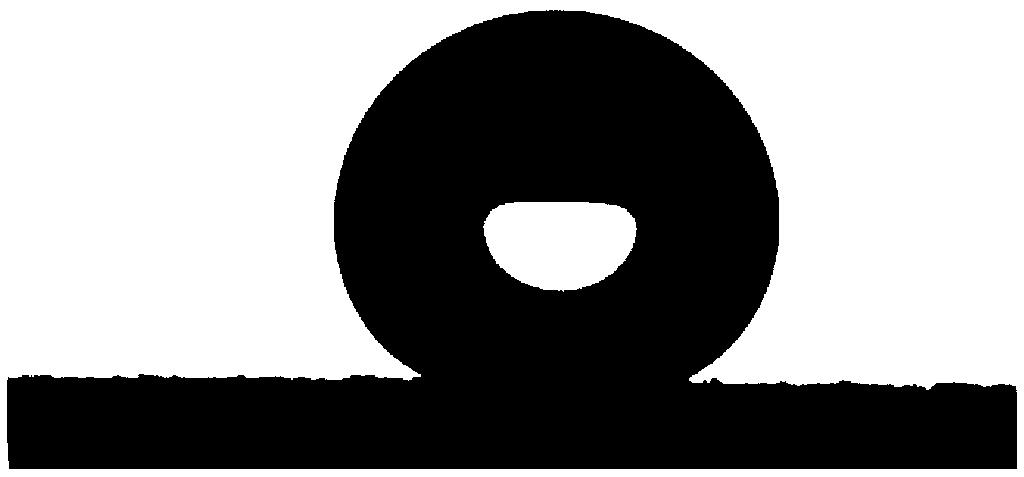

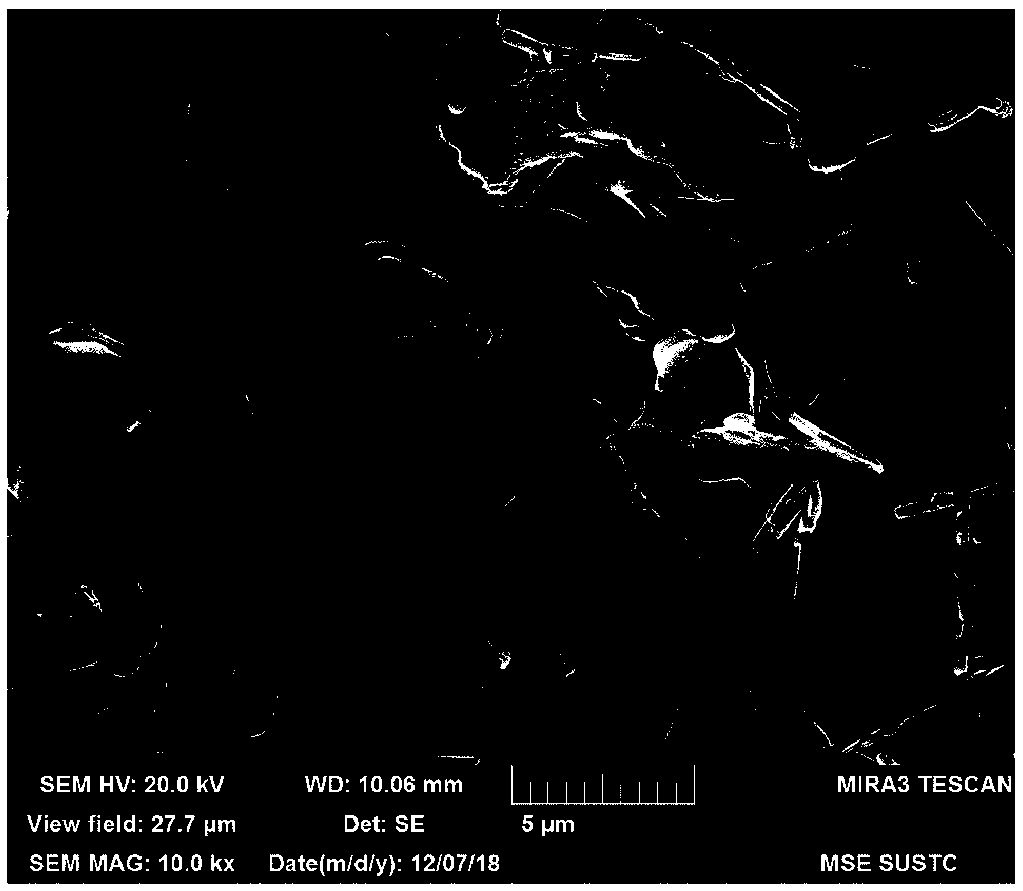

Hydrophobic wood and preparation method thereof

ActiveCN109571674AReduce hydrophilic groupsReduce contact areaWood treatment detailsWood impregnation detailsWaxNano sio2

The invention discloses a preparation method of hydrophobic wood, including the steps of: immersing the dried pretreated wood in a nano SiO2 / polypropylene wax solution for hydrophobic treatment, infiltrating the nano SiO2 / polypropylene wax melt into the wood, then hot pressing, densifying the surface of the wood, and finally removing the SiO2 / polypropylene wax on the surface to obtain hydrophobicwood. The preparation method is simple, convenient in operation, short in preparation period, low in cost and good in environmental protection, surface hardness and mechanical properties of the hydrophobic wood are both improved, and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Environmentally-friendly adhesive

InactiveCN108395853AWide variety of sourcesLow costNon-macromolecular adhesive additivesStarch adhesivesWater bathsCross-link

The invention discloses an environmentally-friendly adhesive, and relates to the technical field of adhesives. The problem of low adhesive strength of starch adhesives is solved. The adhesive is prepared from, by weight, 20-30 parts of starch, 100-150 parts of water, 1-10 parts of 1 mol / L hydrochloric acid, 0.04-0.06 part of 0.1% potassium permanganate, 2-4 parts of sodium hypochlorite, 1-10 partsof a 4% sodium hydroxide solution and 1-2 parts of a cross-linking agent. A preparation method of the environmentally-friendly adhesive comprises the following steps: 1) weighing the starch, adding the starch into the water, performing water bath heating to 50-60 DEG C while stirring, dropwise adding the 1 mol / L hydrochloric acid, and performing uniform stirring; 2) adding the 0.1% potassium permanganate, performing a reaction for 10-15 min, adding the sodium hypochlorite, and performing a reaction for 10-20 min; 3) rising the temperature to 60-70 DEG C, adding the 4% sodium hydroxide solution to adjust the pH value to 12-13.5, and performing a reaction for 45-90 min; and 4) adding the cross-linking agent, performing uniform stirring, adding a pH adjuster to adjust the pH value to 10-12,and performing stirring and reacting for 45-90 min to obtain the environmentally-friendly adhesive. The environmentally-friendly adhesive has the advantages of non-toxicity, environmental protection,low cost, high bonding strength, and meeting of plate production process requirements.

Owner:CHENGDU KECHUANGCHENG TECH

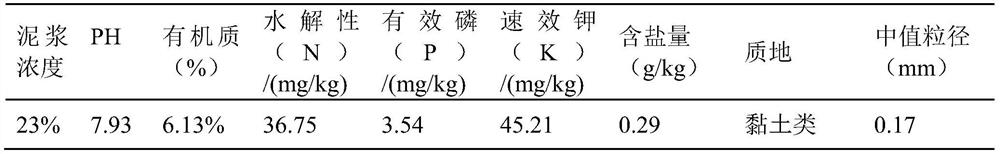

Sludge dehydration curing agent and resource utilization method thereof

PendingCN113371976AGuaranteed dehydration effectImprove structural performanceSludge treatmentSewage/sludge fertilisersFirming agentSlurry

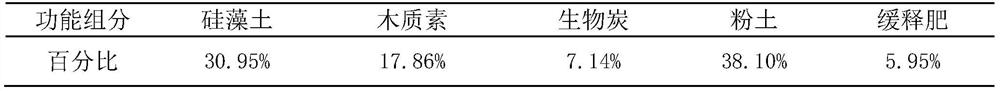

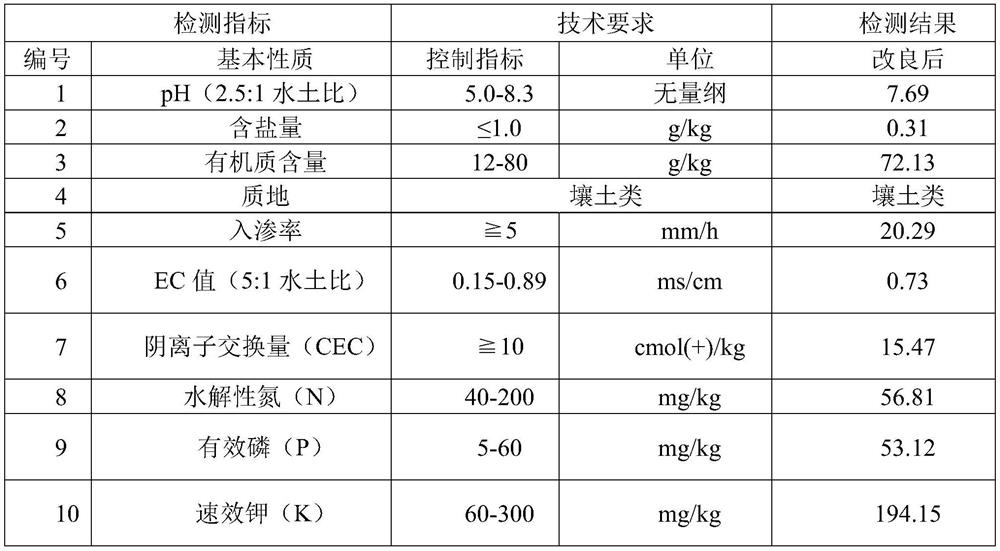

A sludge dehydration curing agent comprises, by mass, 25 to 35 parts of diatomite, 10 to 20 parts of lignin, 5 to 10 parts of charcoal, 30 to 50 parts of silt and 2 to 8 parts of a slow release fertilizer. A resource utilization method of the sludge dehydration curing agent comprises the following steps: fully mixing the raw materials according to the components to obtain the sludge dehydration curing agent; taking a certain mass of sludge to dredge mud; mixing the sludge dehydration curing agent into the sludge dredging slurry, stirring to fully mix the slurry and the curing agent, and standing; dehydrating and drying the sludge obtained after standing; and maintaining the dehydrated sludge, and using the maintained sludge as greening planting soil. Original organic matters and nutritional ingredients in the sludge can be fully utilized, tail water generated in the sludge dewatering process is high in transparency, the PH ranges from 6 to 9, and the SS content is smaller than 10. The sludge dehydration curing agent hasa good application prospect in the field of lakeside sludge treatment.

Owner:SHANGHAI WATERWAY ENG DESIGN & CONSULTING

Bi-component waterborne woodware waterproof coating

InactiveCN108624206AEnhanced interface bindingImprove mechanical propertiesPolyurea/polyurethane coatingsOrganic acidEmulsion

The invention discloses a bi-component waterborne woodware waterproof coating and belongs to the technical field of building materials. A preparation method of the coating includes: putting, by weight, 50-60 parts of waterborne polyurethane emulsion, 2-3 parts of mixed enzyme liquid, 3-5 parts of organic acid, 8-10 parts of bacterial cellulose, 5-6 parts of rare earth, 5-6 parts of defoamer, 5-6 parts of thickener, 8-10 parts of modified sodium alginate liquid, 5-6 parts of coated sodium peroxide and 20-30 parts of water into a 3# beaker, and stirring and mixing at rotating speed of 300-500r / min for 30-50min to obtain a component A; putting, by weight, 10-20 parts of ethyl orthosilicate, 10-20 parts of nano alumina powder, 10-20 parts of sodium fluosilicate and 5-8 parts of animal bone powder into a ball mill, and ball mill mixing for 30-50min to obtain a component B; separately packaging the component A and the component B to obtain the bi-component waterborne woodware waterproof coating. The coating has excellent mechanical performance and waterproof performance.

Owner:潘荣强

Wear-resistant and high-temperature-resistant vehicle wire material and preparation method thereof

PendingCN114213785AReduce hydrophilic groupsGood high temperature resistance and flame retardant effectPolyvinyl chlorideCalcium alginate

The invention discloses a wear-resistant and high-temperature-resistant vehicle wire material and a preparation method thereof, and relates to the technical field of wire materials. When the material for the wear-resistant and high-temperature-resistant vehicle wires is prepared, modified zinc stannate is used as a flame-retardant component and is blended with polyvinyl chloride; the modified zinc stannate is prepared by grafting oxidized sodium alginate and hyperbranched polyurethane with an epoxy group on zinc hydroxystannate, crosslinking the oxidized sodium alginate into calcium alginate, and finally preparing into aerogel; when the hyperbranched polyurethane is prepared, glycidol is introduced, and the hyperbranched polyurethane with an epoxy group is prepared. The wear-resistant and high-temperature-resistant vehicle wire material prepared by the invention not only has flame-retardant and wear-resistant effects, but also is more flexible.

Owner:邵桐

Urea-formaldehyde resin adhesive for artificial boards and preparation method thereof

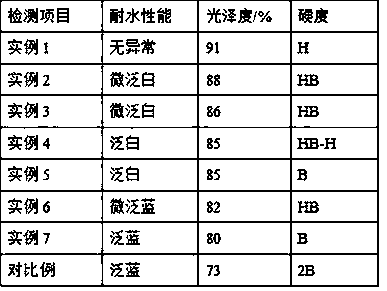

InactiveCN107746696AImprove performanceHigh degree of condensation synthesisAldehyde/ketone condensation polymer adhesivesHeat resistanceMelamine

The invention relates to a urea-formaldehyde resin adhesive for artificial boards and a preparation method thereof. The urea-formaldehyde resin adhesive is prepared from, by weight, 1351-1650 kg of formaldehyde, 900-1500 kg of urea, 131-400 kg of melamine, 10-60 kg of a high-effective water-proofing agent, 3-4 kg of PVA, 29-30 parts of NaOH and 4-5 kg of formic acid. In the formula, the condensation polymerization synthesis degree between hydroxymethyl melamine and hydroxymethyl urea is high under an acidic condition during preparation, so that quantity of hydrophilic groups in the resin is greatly reduced, and heat resistance and water resistance of the hydrophilic group are improved. The urea-formaldehyde resin adhesive has further reinforced non-melting and non-dissolving three-dimensional structure, so that the adhesive is better in performances.

Owner:柳州市林道科技有限公司

Styrene-acrylic emulsion surface sizing agent

InactiveCN104674598AReduce hydrophilic groupsGood water resistanceWater-repelling agents additionPaper coatingEmulsionStyrene

The invention relates to a styrene-acrylic emulsion surface sizing agent. The sizing agent comprises the following components in percent by mass: 20 to 40 percent of fixed styrene, 1 to 3 percent of crylic acid, 2 to 4 percent of a cross-linking monomer, 2 to 3 percent of an emulsifier, 0.5 to 1 percent of an initiator, 1 to 2 percent of a buffer agent, 1 to 2 percent of a neutralizing agent, 2.5 to 10 percent of oxidized starch, and 35 to 70 percent of water. The emulsifier is acrylamide isopropyl sodium sulfonate. The reaction-type emulsifier acrylamide isopropyl sodium sulfonate is adopted to substitute a traditional emulsifier, the reaction-type emulsifier can be bonded into a polymer in a form of a covalent bond to become part of the polymer while playing a role in emulsification, the migration of the emulsifier or the desorption of the emulsifier from polymer particles in film formation can be avoided, hydrophilic groups on the surface of a latex film can be greatly reduced, the polymer is relatively good in water resistance, and the water resistance and stability of the styrene-acrylic emulsion surface sizing agent can be improved.

Owner:HAO YU ADDITION AGENT

Modified urea-formaldehyde resin for producing ecological floors and preparation method for modified urea-formaldehyde resin

The invention discloses modified urea-formaldehyde resin for producing ecological floors and a preparation method for the modified urea-formaldehyde resin. The method comprises the following steps: adding formaldehyde to a reaction kettle; adjusting a liquid pH value in the reaction kettle to 7.5-8.5; adding a first part of urea to the reaction kettle, and raising temperature of the reaction kettle; adding a formic acid solution, and adjusting the pH value to 4.3-5.0; adjusting the pH value to 5.8-6.8, adding a second part of urea, a first part of a reinforcing agent and a first part of a molecular weight modifier, and performing a reaction for 15-45 minutes; adjusting the pH value to 7.0-8.5, adding a second part of a molecular weight modifier, then adding a second part of a reinforcing agent, and performing a reaction until resin is water-clear at the temperature of 13-20 DEG C; adjusting the pH value to 8.5-9.5, starting water cooling, and adding a third part of urea; and continuously performing cooling until the temperature is 40-50 DEG C, and releasing glue to obtain the modified urea-formaldehyde resin. The modified urea-formaldehyde resin provided in the invention has the characteristics of a long storage period, an ultra-low formaldehyde release amount, high bonding strength, boiling water resistance, low costs and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of styrene-acrylic emulsion for water-borne wood paint

PendingCN113736009AIncrease surface areaSlow Ostwald RipeningCoatingsFunctional monomerButyl acrylate

The invention discloses a preparation method of a styrene-acrylic emulsion for water-borne wood paint. The method comprises the following steps: firstly, preparing a styrene-acrylic seed emulsion with uniform particle size distribution through miniemulsion polymerization, and then polymerizing a layer of room-temperature self-crosslinking hard shell. The styrene-acrylic emulsion specifically comprises deionized water, an initiator, a co-stabilizer, an emulsifier, styrene, butyl acrylate, methyl methacrylate, hydroxyethyl acrylate and the like, and a proper amount of bi-crosslinking functional monomer is added to modify the styrene-acrylic emulsion. The obtained product has the characteristics of uniform particle size distribution, high transparency, good grindability, good hardness and good tolerance, and is suitable for single-component or double-component wood lacquer.

Owner:TAIZHOU UNIV +1

High-smoothness papermaking sizing agent

InactiveCN109235127APrevent penetration and diffusionGood waterproof performanceWater-repelling agents additionVegetable material additionSurface energyDouble bond

The invention relates to a high-smoothness papermaking sizing agent and belongs to the field of additives for papermaking. According to the high-smoothness papermaking sizing agent, sodium alginate isactivated firstly and then is treated through a silane coupling agent to improve the surface activity and the performance of polyanions to form hydrogel with a crosslinking network structure, so thatdiffusion and penetration of water liquid are prevented and the hydrogel has good waterproof performance; the silane coupling agent is added so that the surface energy can be reduced, and the surfacestrength and smoothness are further improved; an instable double bond and the like of added oxidized natural rubber can be oxidized into active groups including carboxyl and the like under an oxidization condition of potassium permanganate, so that cells are activated and tissues are regenerated; a reagent B and a plant extracting solution in a composite auxiliary material also can provide needednutrients; the regenerated cells can be filled into a three-dimensional network structure formed by the sizing agent to form a papermaking sizing agent protection layer with a plant cell grade; and the surface strength and smoothness of paper pulp are improved. By adopting the high-smoothness papermaking sizing agent, the problem of a current common papermaking sizing agent that the surface strength and the smoothness are low is solved.

Owner:FOSHAN SENANG BIO TECH CO LTD

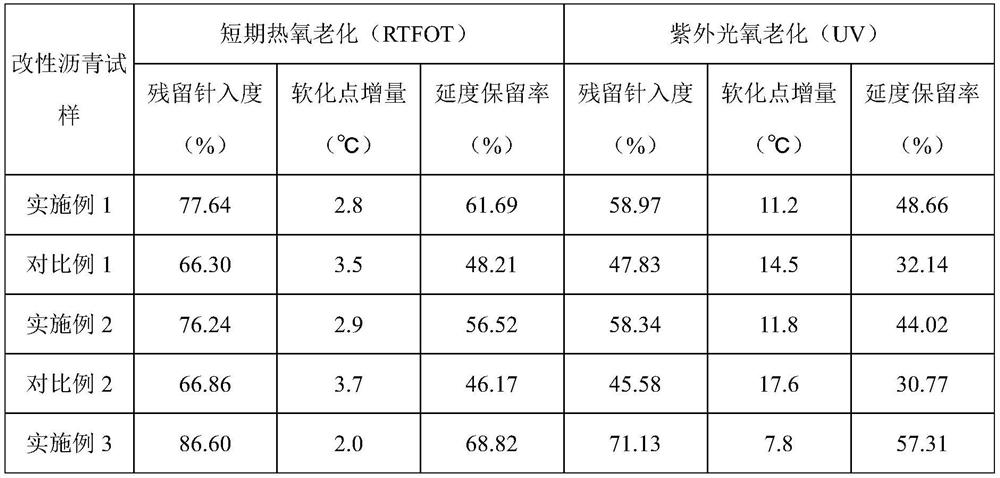

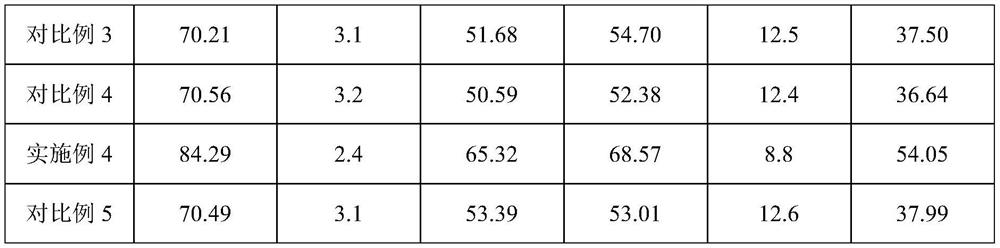

Organic enhanced alkali lignin/SBS (styrene-butadiene-styrene) composite modifier as well as preparation method and application thereof

PendingCN114516995AAchieve organic enhancementGood compatibilitySolid waste managementBuilding insulationsPolymer scienceCyclohexylamines

The invention provides an organic enhanced alkali lignin / SBS (styrene-butadiene-styrene) composite modifier as well as a preparation method and application thereof, and belongs to the technical field of asphalt processing. The organic enhanced alkali lignin / SBS composite modifier is prepared from the following raw materials in percentage by mass: 20%-35% of organic enhanced alkali lignin, 47.2%-67.7% of SBS, 0.3%-0.8% of an accelerant and 12%-17% of a compatilizer, the organic enhanced alkali lignin is obtained by taking diphenylmethane diisocyanate, cyclohexylamine and alkali lignin as raw materials to react in tetrahydrofuran. The organic enhanced alkali lignin / SBS composite modifier is used for preparing the anti-aging SBS asphalt, and the anti-aging SBS asphalt is prepared from the following raw materials in percentage by mass: 81.90%-91.98% of asphalt, 8.00%-18.00% of the organic enhanced alkali lignin / SBS composite modifier and 0.05%-0.10% of a stabilizer. The anti-aging SBS asphalt has excellent thermo-oxidative aging resistance and ultraviolet aging resistance.

Owner:HUBEI ENG UNIV

High-strength bamboo-plastic composite material for container bottom plate

The invention discloses a high-strength bamboo-plastic composite material for a container bottom plate, and relates to the technical field of artificial boards. The invention discloses a high-strength bamboo-plastic composite material for a container bottom plate. The high-strength bamboo-plastic composite material is prepared from the following raw materials: modified bamboo powder, polyethylene resin, recycled plastic, polyvinyl butyral, a compatilizer, a coupling agent, a lubricant and an anti-aging agent, the preparation method of the modified bamboo powder comprises the following steps: adding sodium alginate into a reaction kettle containing a 10wt% NaOH solution, uniformly mixing at a high temperature, then adding bamboo powder, stirring at 80-85 DEG C for 1 hour, then adjusting the pH value to 5-6 by using dilute acid, adding polyoxyethylene alkylamine and hydrogen-containing silicone oil, and stirring at 50 DEG C for 2 hours, thereby obtaining the modified bamboo powder. The high-strength bamboo-plastic composite material for the container bottom plate provided by the invention has excellent impact resistance and toughness, also has excellent waterproofness, flame retardance, corrosion resistance and aging resistance, improves the utilization rate of bamboo wood, has relatively long service life, reduces the production cost and reduces environmental pollution.

Owner:益阳桃花江竹业发展有限公司

Production method of high-moisture-proof and medium-density fiber wardrobe special plate

InactiveCN109318334AImprove molecular structureShorten speedWood working apparatusHot pressingMoisture

The invention discloses a production method of a high-moisture-proof and medium-density fiber wardrobe special plate. The production method comprises the following steps of (1) raw materials pretreating, (2) screening, (3) cooking and softening, (4) grinding, (5) gluing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing, (10), edge sealing, and afinished wardrobe special plate is obtained. According to the production method, barks and branches of eucalyptus and waste leftover materials left in the plate manufacturing process are taken as mainraw materials, then pine wood, basswood, birch wood, weeping willow wood, zelkova wood, aceraceae wood, willow wood and the like are added, the waste is changed into wealth, and the wood resources can be fully and effectively utilized; the produced medium-density fiber wardrobe special plate has the advantages of being good in moisture-proof performance, good in water resistance, low in formaldehyde content, high in strength and good in toughness, and the wardrobe special plate is safe, environment-friendly, attractive, wear-resistant and practical.

Owner:广西横州丽冠环保材料有限公司

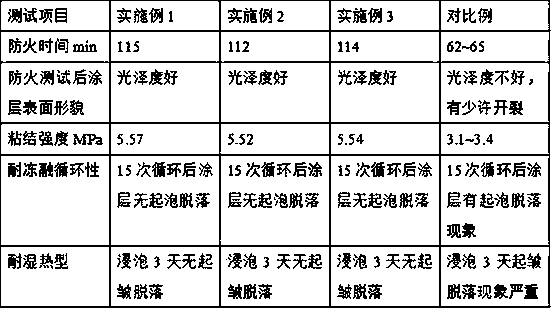

Preparation method of fireproof paint

InactiveCN108948960AReduce aggressionGood compatibilityFireproof paintsPolyurea/polyurethane coatingsHigh humidityPolyethylene glycol

The invention discloses a preparation method of fireproof paint, and belongs to the field of paint. According to the method, a coating material is synthesized by 4,4'-diphenylmethane diisocyanate, sorbitol, polyethylene glycol 4000 and the like and is used to coat ammonium polyphosphate to form a flame retardant active substance of a core-shell structure. The ammonium polyphosphate has a large molecular polarity, is prone to being attacked by water molecules, and is prone to migrating to the surface of the material in high temperature and high humidity environment, resulting in a decrease in flame retardant effect. After the coating, the aggressiveness of the ammonium polyphosphate by the water molecules is slowed down, and so the ammonium polyphosphate can maintain the flame retardant activity in the high temperature and high humidity environment. The preparation method of the fireproof paint solves the problems of poor durability, weatherability and bonding strength of conventional fireproof paint.

Owner:吕莉

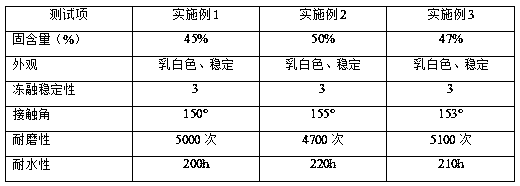

A kind of organosilicon modified acrylic acid micronano emulsion and preparation method thereof

The invention discloses a silicone-modified acrylic micro-nano emulsion and a preparation method thereof. Unsaturated acrylic monomers, silsesquioxanes containing carbon-carbon double bonds, cross-linking monomers and hydrophobic monomers are used as polymerization raw materials. Add nano-SiO2 particles and organic nano-zinc hydroxide as hydrophobic fillers, use 2-acrylamide amino-2-methylpropanesulfonic acid and maleic acid polyoxyethylene ether monoester carboxylate as emulsifier system, through The method of emulsion polymerization prepares a polymer emulsion with good stability, high and low temperature resistance, abrasion resistance, superhydrophobic performance and good mechanical properties, which can be widely used in coatings, adhesives, waterproofing agents and other fields. Good development prospects.

Owner:HUIZHOU CITY HUIYANG DISTRICT JIATAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com