Urea-formaldehyde resin adhesive for artificial boards and preparation method thereof

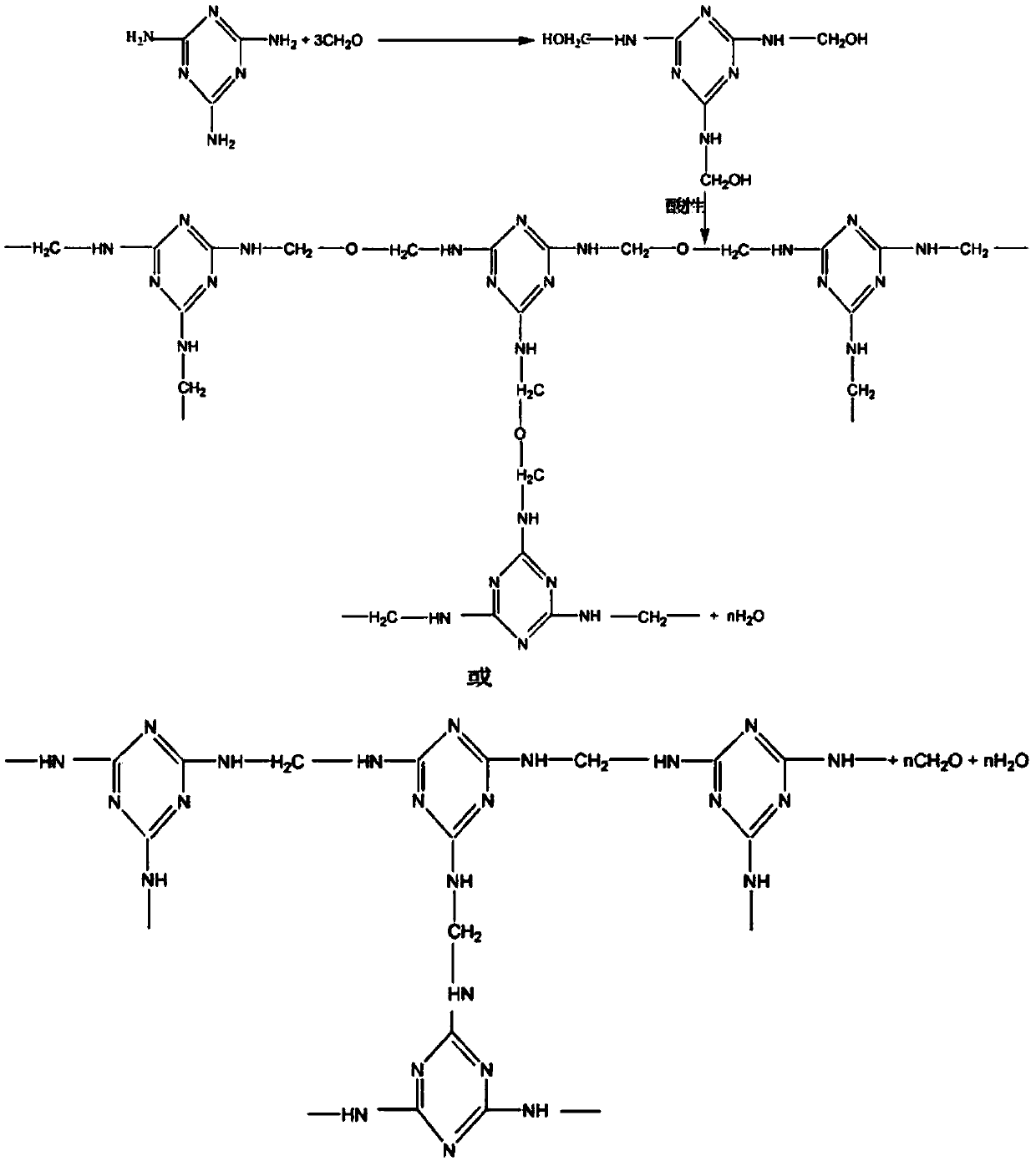

A urea-formaldehyde resin and preparation process technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc. Problems such as the content of hydrophilic groups in the resin, to achieve better performance, improve heat resistance and water resistance, and reduce the effect of hydrophilic groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation process of urea-formaldehyde resin waterproof and boiling-resistant adhesive for wood-based panels, comprising the following steps:

[0019] (1) Weigh the following components respectively: formaldehyde: 1450kg, urea: 1145kg, melamine 131-400kg, high-efficiency waterproofing agent: 35kg, PVA: 3.5kg, sodium hydroxide: 29-30kg and formic acid: 4.5kg, And the weighed urea is divided into four parts to be fed: the first part of urea is 700kg, the second part of urea is 175kg, the third part of urea is 150kg, the fourth part of urea is 120kg, and the formic acid is adjusted into 20% formic acid aqueous solution.

[0020] (2) Add formaldehyde and the first portion of urea to the reaction kettle, open the steam valve to raise the temperature to 40-70°C, add 40-100kg of melamine, then add 3-6kg of sodium hydroxide to adjust the pH value to 7.5-9.0, add After PVA heats up to 85-95°C, close the steam valve and keep warm for 30-70 minutes. In the early stage, urea a...

Embodiment 2

[0030] Weigh each component by weight as follows:

[0031] Formaldehyde: 1351kg, urea: 900kg, melamine 131-400kg, high-efficiency waterproofing agent: 10kg, PVA: 3kg, sodium hydroxide: 29-30kg and formic acid: 4kg, and divide the weighed urea into four parts, the first part of urea For 600kg, the second part of urea 100kg, the third part of urea 100kg, the fourth part of urea 100kg; all the other steps can make the wood-based panel urea-formaldehyde resin adhesive of the present invention equally according to the same process of embodiment one.

Embodiment 3

[0033] Weigh each component by weight as follows:

[0034] Formaldehyde: 1650kg, urea: 1500kg, melamine 131-400kg, high-efficiency waterproofing agent: 60kg, PVA: 4kg, sodium hydroxide: 29-30kg and formic acid 5kg, and the urea weighed is divided into four parts, of which the first urea is 900kg, the second part of urea 250kg, the third part of urea 200kg, the fourth part of urea 150kg; all the other steps can make the wood-based panel urea-formaldehyde resin adhesive of the present invention equally according to the same process of embodiment one.

[0035] Through the ratio of the above components (formaldehyde: 1351-1650kg, urea: 900-1500kg, melamine 131-400kg, high-efficiency waterproofing agent: 10-60kg, PVA: 3-4kg, sodium hydroxide: 29-30kg and formic acid 4 -5kg), the quality indicators of the wood-based panel urea-formaldehyde resin waterproof and boiling-resistant adhesive prepared by the adhesive are as follows:

[0036] Water solubility: 0.61

[0037] Curing time (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curing time | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com