Bi-component waterborne woodware waterproof coating

A two-component, water-based technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient mechanical properties, limited water resistance, poor gloss, etc., and achieve improved mechanical properties, water resistance and gloss. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

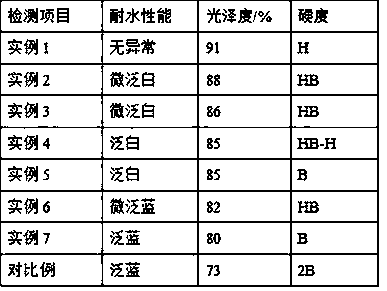

Examples

example 1

[0022] In parts by weight, 2 parts of cellulase, 2 parts of pectinase, 2 parts of laccase, 5 parts of glycerin, and 20 parts of deionized water are placed in a single-necked flask, and the single-necked flask is placed in a digital speed measuring constant temperature magnetic In a stirrer, under the conditions of temperature 35°C and rotation speed 200r / min, stir and mix at constant temperature for 50min to obtain a mixed enzyme solution; put sodium alginate and water in a No. 1 beaker with a mass ratio of 1:100, and use a glass rod to After stirring and mixing for 30 minutes, after standing for swelling for 4 hours, heat, stir and mix for 2 hours at a temperature of 95°C and a rotation speed of 500r / min, and then add sodium alginate twice the mass of sodium alginate with a mass concentration of 200mg / L to the No. 1 beaker. Sodium periodate solution, at a temperature of 95°C and a speed of 500r / min, stir and mix at a constant temperature for 60 minutes to obtain a modified sod...

example 2

[0024]In parts by weight, 2 parts of cellulase, 2 parts of pectinase, 2 parts of laccase, 5 parts of glycerin, and 20 parts of deionized water are placed in a single-necked flask, and the single-necked flask is placed in a digital speed measuring constant temperature magnetic In a stirrer, under the conditions of temperature 35°C and rotation speed 200r / min, stir and mix at constant temperature for 50min to obtain a mixed enzyme solution; put sodium alginate and water in a No. 1 beaker with a mass ratio of 1:100, and use a glass rod to After stirring and mixing for 30 minutes, let it stand for swelling for 4 hours, heat and stir and mix for 2 hours at a temperature of 95°C and a speed of 500 r / min, then add sodium alginate twice the mass of sodium alginate with a mass concentration of 200 mg / L to No. 1 beaker Sodium periodate solution, at a temperature of 95°C and a speed of 500r / min, stir and mix at a constant temperature for 60 minutes to obtain a modified sodium alginate sol...

example 3

[0026] In parts by weight, 2 parts of cellulase, 2 parts of pectinase, 2 parts of laccase, 5 parts of glycerin, and 20 parts of deionized water are placed in a single-necked flask, and the single-necked flask is placed in a digital speed measuring constant temperature magnetic In a stirrer, at a temperature of 35°C and a rotation speed of 200r / min, stir and mix at a constant temperature for 50 minutes to obtain a mixed enzyme solution; put the paraffin in a crucible and heat it to completely melt at a temperature of 60°C to obtain a melted For paraffin wax, put sodium peroxide and molten paraffin in a No. 2 beaker at a mass ratio of 1:10, stir and mix with a glass rod for 10 minutes to obtain a mixed slurry, and then place the mixed slurry in a freezer pulverizer to freeze and pulverize to obtain coating Sodium peroxide; by weight, with 60 parts of water-based polyurethane emulsion, 3 parts of mixed enzyme liquid, 5 parts of organic acid, 10 parts of bacterial cellulose, 6 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com