Hydrophobic wood and preparation method thereof

A wood and hydrophobic technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of poor environmental protection, high cost, complicated process, etc., and achieve the effect of improving surface hardness and mechanical properties, short preparation cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of hydrophobic wood of the present embodiment, comprises the following steps:

[0029] (1) Wood pretreatment: Sand the surface of poplar wood with 180-mesh wood sandpaper, remove the surface dust with high-pressure air and dry it for later use; the wood used in this example is fast-growing poplar wood, with a size of 70 mm×50 mm×22 mm (diameter x chord x length).

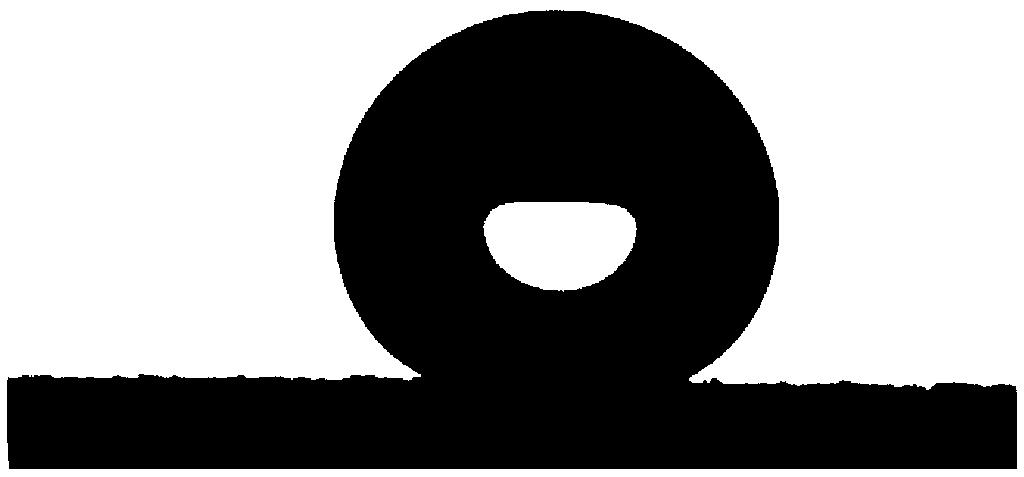

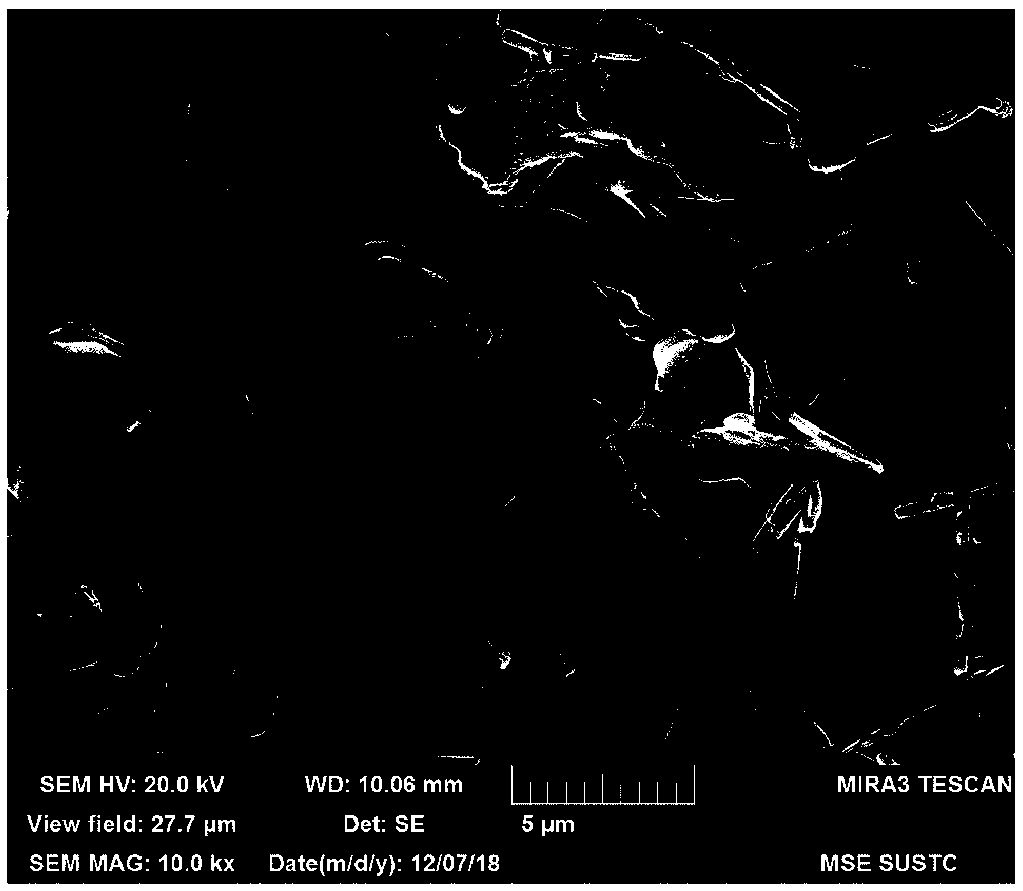

[0030] (2) Hydrophobic material preparation: nano-SiO with a mass fraction of 1% 2 The powder is mixed with polypropylene wax powder, heated to 130 °C to melt the polypropylene wax, and stirred at a speed of 180 r / min to make the nano-SiO 2 The powder is evenly dispersed in polypropylene wax to obtain nano-SiO 2 / polypropylene wax melt; In the present embodiment, nano-SiO 2 The particle size of the powder is 350 nm.

[0031] (3) Hydrophobic treatment: soak the pretreated poplar in nano-SiO 2 / Polypropylene wax melt, at a temperature of 140 ℃ for hydrophobic treatment, so tha...

Embodiment 2

[0037] A kind of preparation method of hydrophobic wood of the present embodiment, comprises the following steps:

[0038] (1) Wood pretreatment: Sand the surface of poplar wood with 180-mesh wood sandpaper, remove the surface dust with high-pressure air and dry it for later use; the wood used in this example is fast-growing poplar wood, with a size of 70 mm×50 mm×22 mm (diameter x chord x length).

[0039] (2) Hydrophobic material preparation: nano-SiO with a mass fraction of 1% 2 The powder is mixed with polypropylene wax powder, heated to 130 °C to melt the polypropylene wax, and stirred at a speed of 180 r / min to make the nano-SiO 2 The powder is evenly dispersed in polypropylene wax to obtain nano-SiO 2 / polypropylene wax melt; In the present embodiment, nano-SiO 2 The particle size of the powder is 300 nm.

[0040] (3) Hydrophobic treatment: soak the pretreated poplar in nano-SiO 2 / Polypropylene wax melt, carry out hydrophobic treatment at 135 ℃ to make nano-SiO ...

Embodiment 3

[0045] A kind of preparation method of hydrophobic wood of the present embodiment, comprises the following steps:

[0046] (1) Wood pretreatment: Sand the poplar wood surface with 180-mesh wood sandpaper, remove surface dust with high-pressure air and dry it for later use; the wood used in this example is fast-growing poplar wood, with a size of 70 mm×50 mm×22 mm (diameter x chord x length).

[0047] (2) Hydrophobic material preparation: nano-SiO with a mass fraction of 2% 2 The powder is mixed with polypropylene wax powder, heated to 130 °C to melt the polypropylene wax, and stirred at a speed of 180 r / min to make the nano-SiO 2 The powder is evenly dispersed in polypropylene wax to obtain SiO 2 / polypropylene wax melt; In the present embodiment, nano-SiO 2 The particle size of the powder is 200 nm.

[0048] (3) Hydrophobic treatment: soak the pretreated poplar in nano-SiO 2 / Polypropylene wax melt, at a temperature of 140 ℃ for hydrophobic treatment, so that nano-SiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com